Whole process optimization method for hydraulic climbing formwork scaffold construction of super high-rise building

A hydraulic climbing formwork and optimization method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as rationality and safety cannot be predicted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

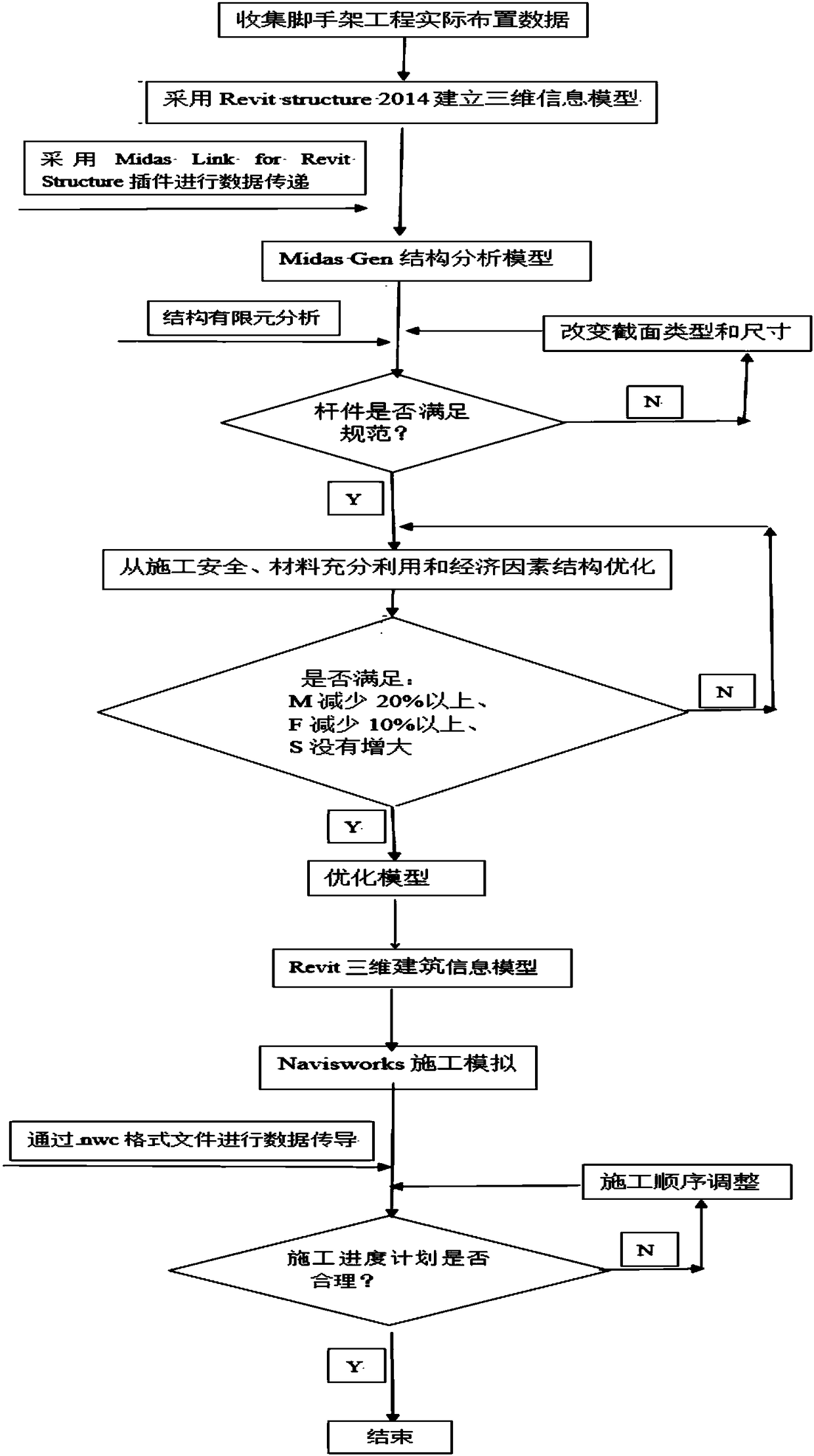

[0031] Embodiment 1: The whole process optimization method of the super high-rise hydraulic climbing formwork scaffolding construction of this embodiment is carried out according to the following steps:

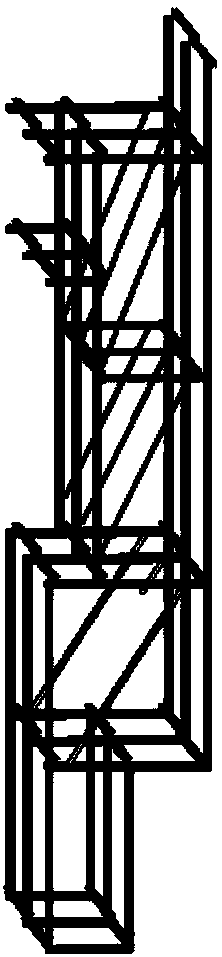

[0032]Step 1: Collect the layout form of the hydraulic climbing formwork scaffolding construction plan in super high-rise projects, the section information of the rods and the main structure information of the super high-rise project; the layout form includes the span, height and width of each floor of the scaffold body; the rods include the upper platform Vertical pole, upper platform crossbar, upper platform diagonal brace, tripod beam, tripod pole, tripod diagonal brace, hanging platform pole, hanging platform crossbar, main platform main beam, other platform crossbeams, section information includes section type and model ;Main structure information includes story height, number of floors, beam, slab and column information, and layout of each floor;

[0033] Step 2: Using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com