Climbing formwork and method for erection of a concrete structure

A technology of concrete structure and climbing formwork, which is applied in the direction of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve the problem that the laser collimator cannot be arranged on the ground. On and determine the absolute template position, can not be achieved and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

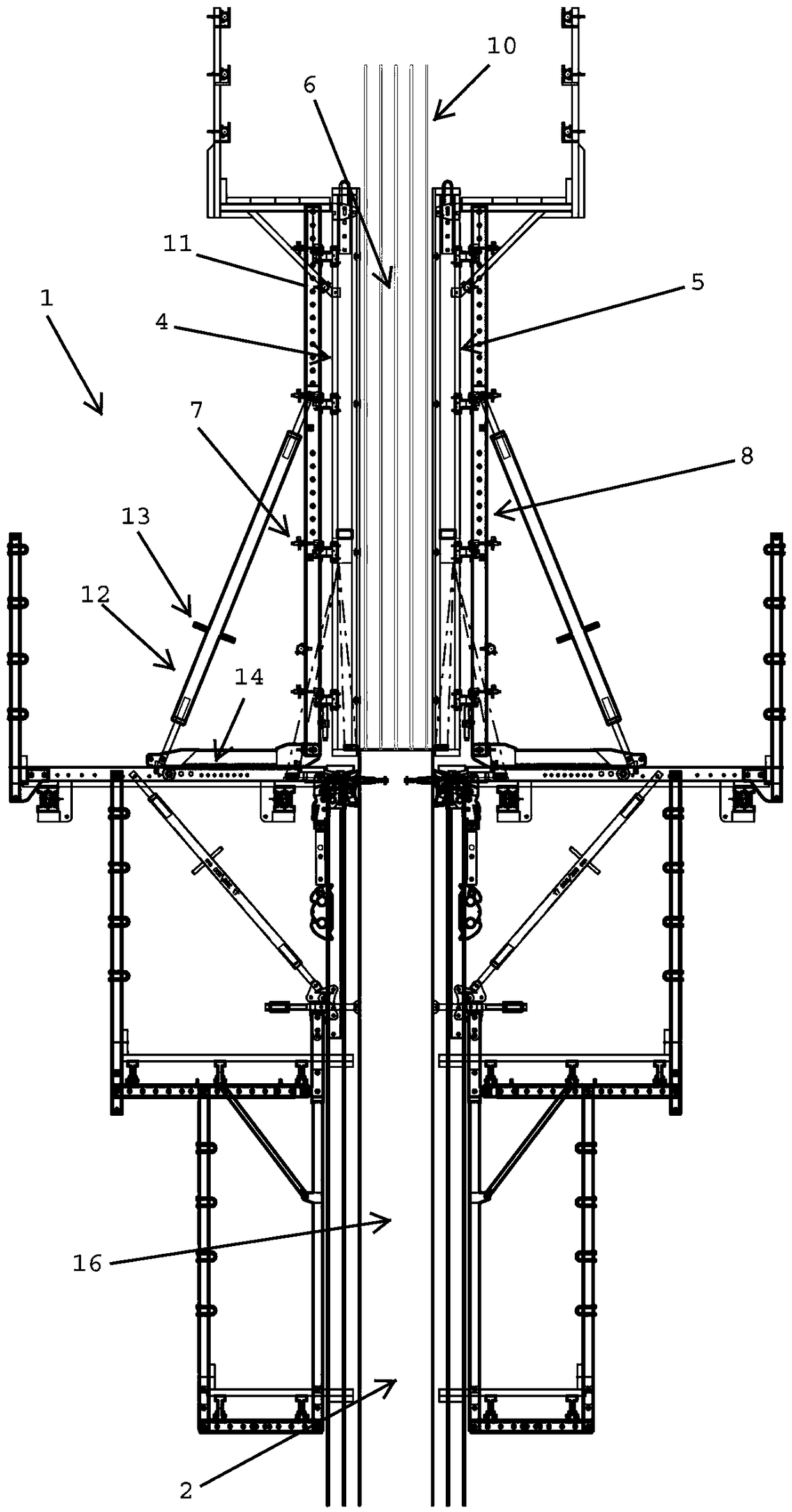

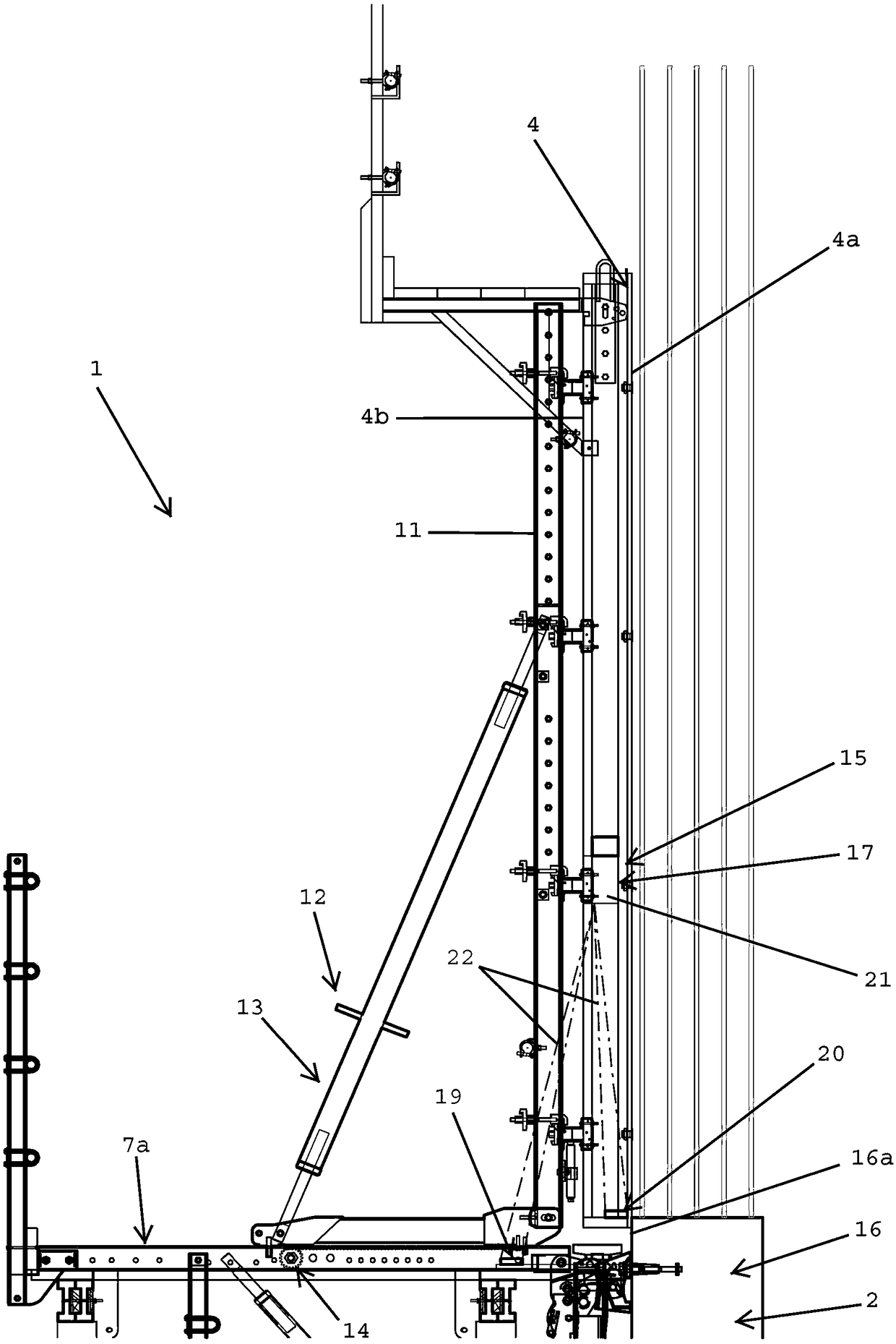

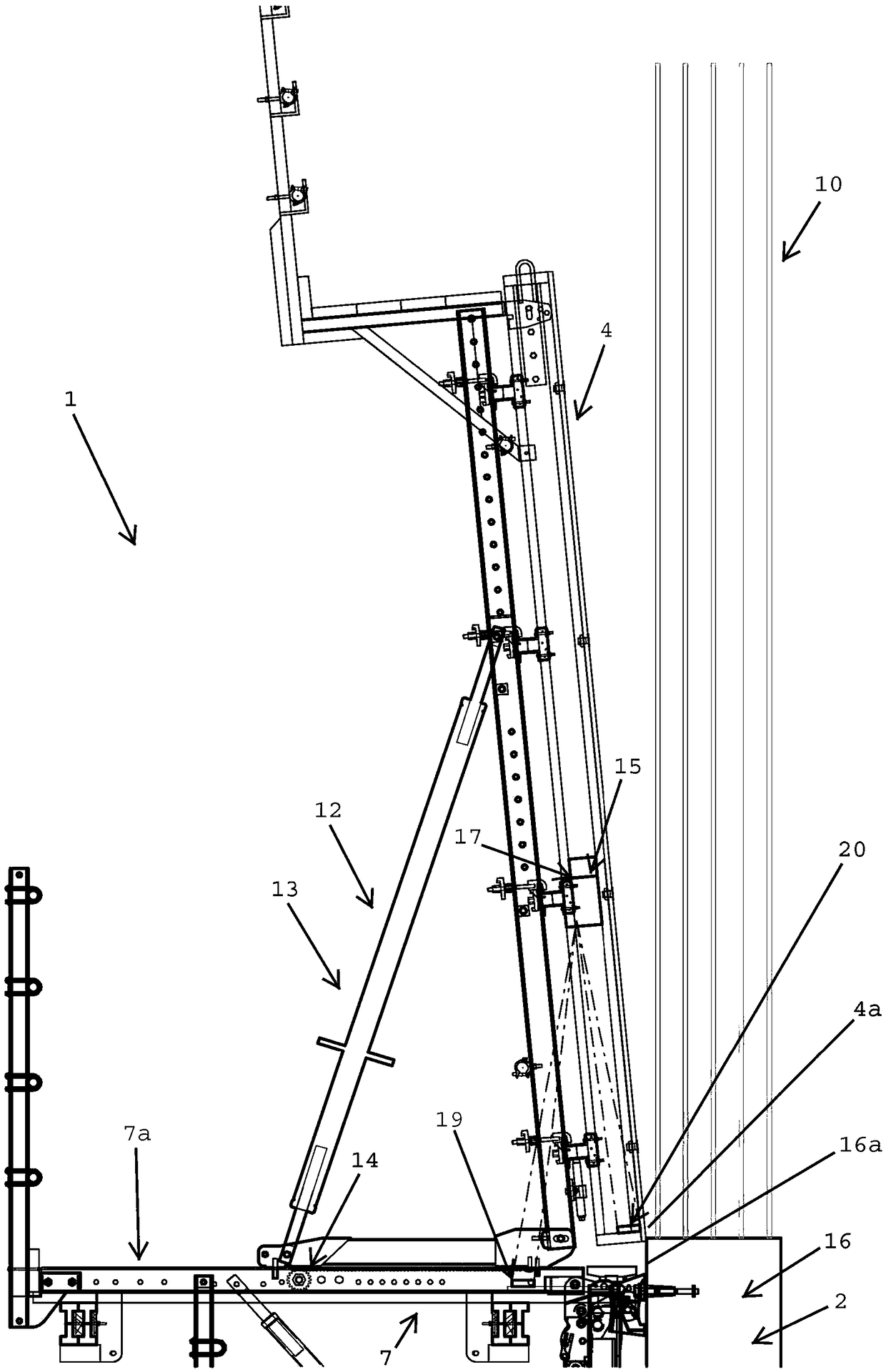

[0083] figure 1 A climbing formwork 1 for progressive erection of a concrete structure 2, such as a skyscraper, is shown. The concrete structure 2 is erected by a plurality of casting steps in which a corresponding number of casting sections 3 are formed, each of which corresponds to a floor of the concrete structure 2 . To this end, the climbing formwork 1 comprises a first formwork element 4 and a second formwork element 5 . Each of the first formwork element 4 and the second formwork element 5 comprises a formwork panel. In the casting position, the first formwork element 4 and the second formwork element 5 define a cavity or space 6 therebetween for receiving concrete for forming the uppermost casting section. In detail, the outer surface 4a of the first formwork element 4 faces the cavity 6, while the inner surface 4b of the first formwork element 4 faces away from the cavity 6 to receive the concrete. Usually, the reinforcement 10 is arranged in the cavity 6 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com