Construction method of cable-stayed bridge pylon

A construction method and tower column technology, applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of high total project cost, unsynchronized construction, long construction period, etc., to shorten the construction period, save cost, and speed up construction progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

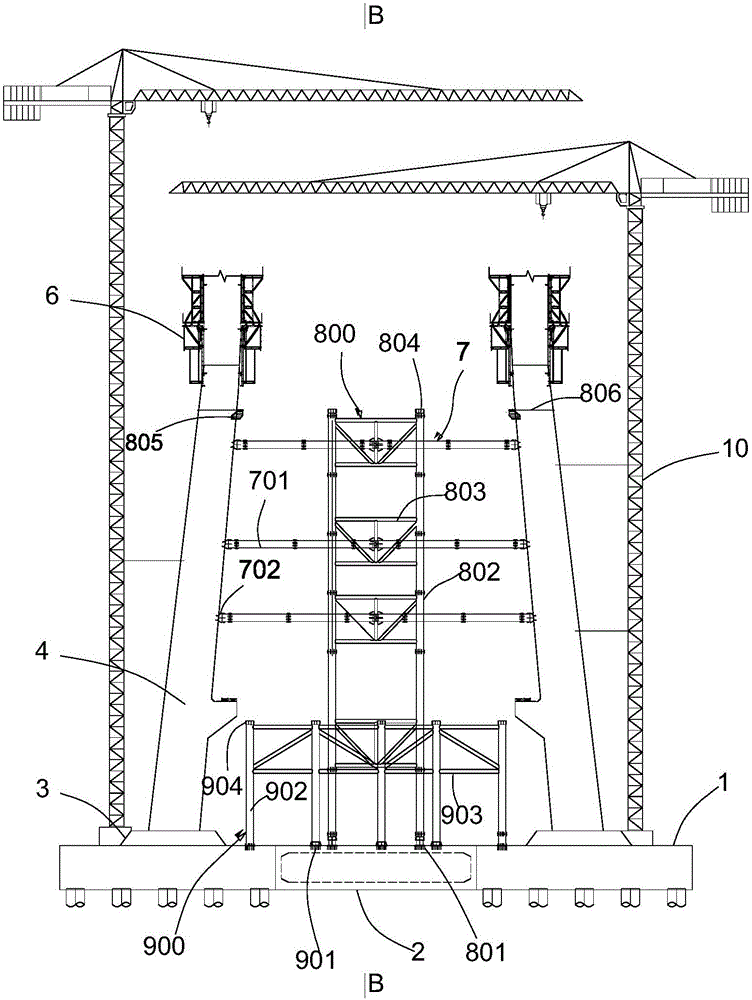

[0051] see Figure 1 to Figure 12 Shown, the embodiment of the present invention provides a kind of construction method of cable-stayed bridge cable tower, concrete steps are as follows:

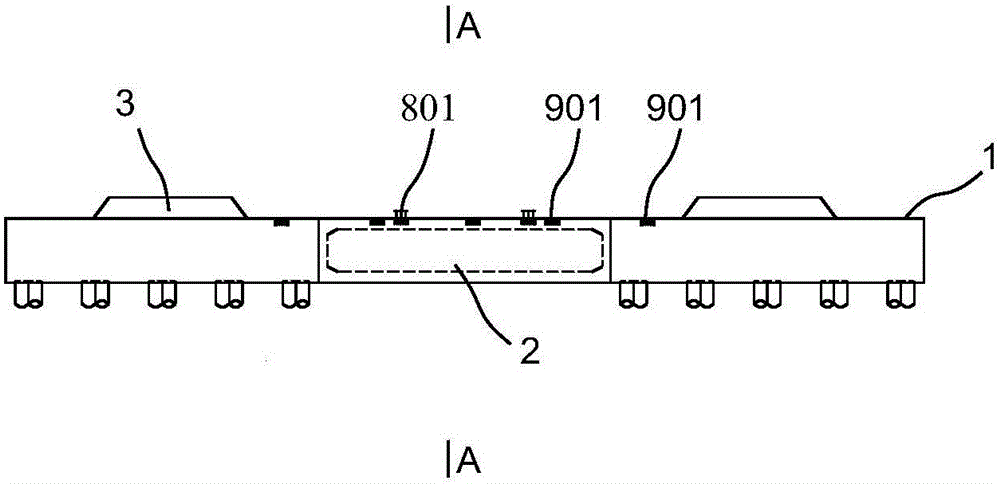

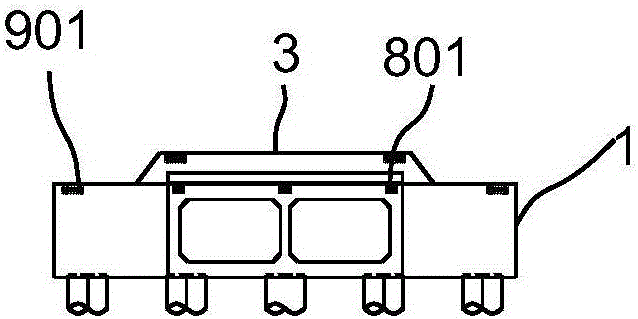

[0052] Step 1, construct cap 1, tie beam 2 and tower base 3, and set the embedded part 901 of the main beam pier top section bracket on the upper end faces of cap 1, tie beam 2 and tower base 3, The upper end surface of 2 is provided with an upper beam bracket embedded part 801;

[0053] Step 2, the lower tower column 4 and the upper tower column 5 carry out the climbing formwork construction along the height direction, and at the same time use the tower crane 10 to simultaneously install the upper beam support 800, the main beam pier top segment support 900 and the cross brace 7;

[0054] Among them, the upper beam support 800 includes the upper beam stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com