Building cornice double-water-drip-line formwork and construction method thereof

A construction method and building technology, applied in building structure, formwork/formwork/working frame, construction, etc., can solve problems such as difficult, cumbersome procedures, and easy to fall, and achieve the effect of simple procedures and easy-to-master techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

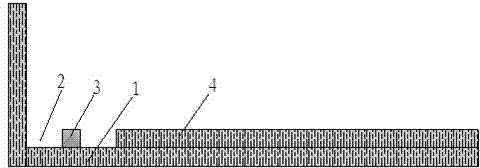

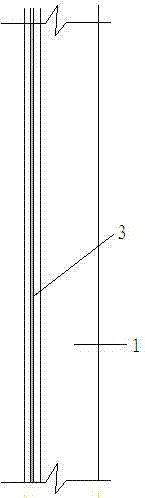

[0036] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes building eave formwork, and it is characterized in that: the edge of bottom mold 1 of described eave formwork is provided with groove 2, and the central position of groove 2 is provided with aluminum alloy bar 3; The width of described groove 2 is 5cm, the thickness of the groove 2 is not less than 10mm, and the width of the aluminum alloy strip 3 is 10mm.

[0037] The present invention is to manufacture the double drip line while constructing the concrete structure of the building body. Take the lintel of a window as an example to illustrate:

[0038] (1) First prepare the formwork according to the design size of the lintel.

[0039] (2) After the lintel formwork is prepared, select the bottom mold, and add a layer of plywood 4 on top of the bottom mold. The length of the plywood 4 is the same as that of the bottom mold 1, and the width is 5cm narrower than the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com