Truss type hydraulic entire steel platform climbing formwork

A technology of climbing formwork and integral steel, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the difficulty of placing the climbing formwork, the unbalanced allocation of labor and resources, and the core The problem of large single-layer area of the cylinder is solved, and the effect of convenient and quick assembly, high bearing capacity and good synchronization is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

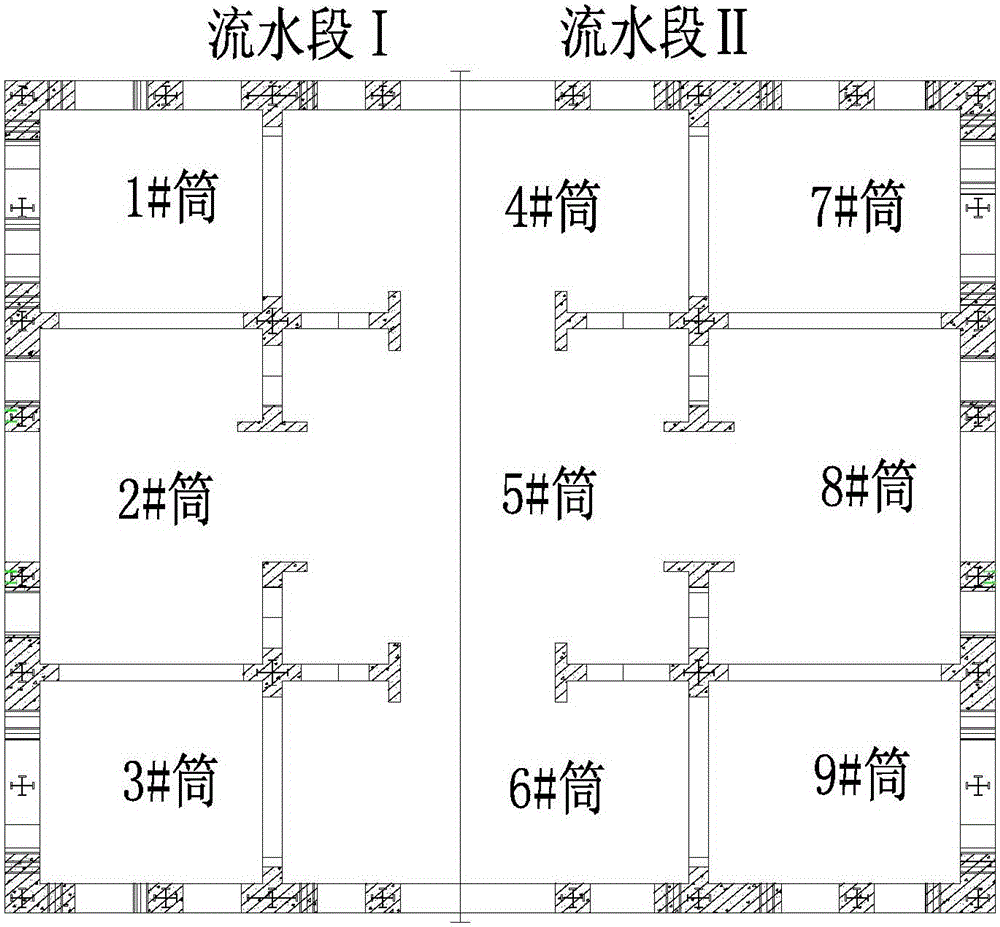

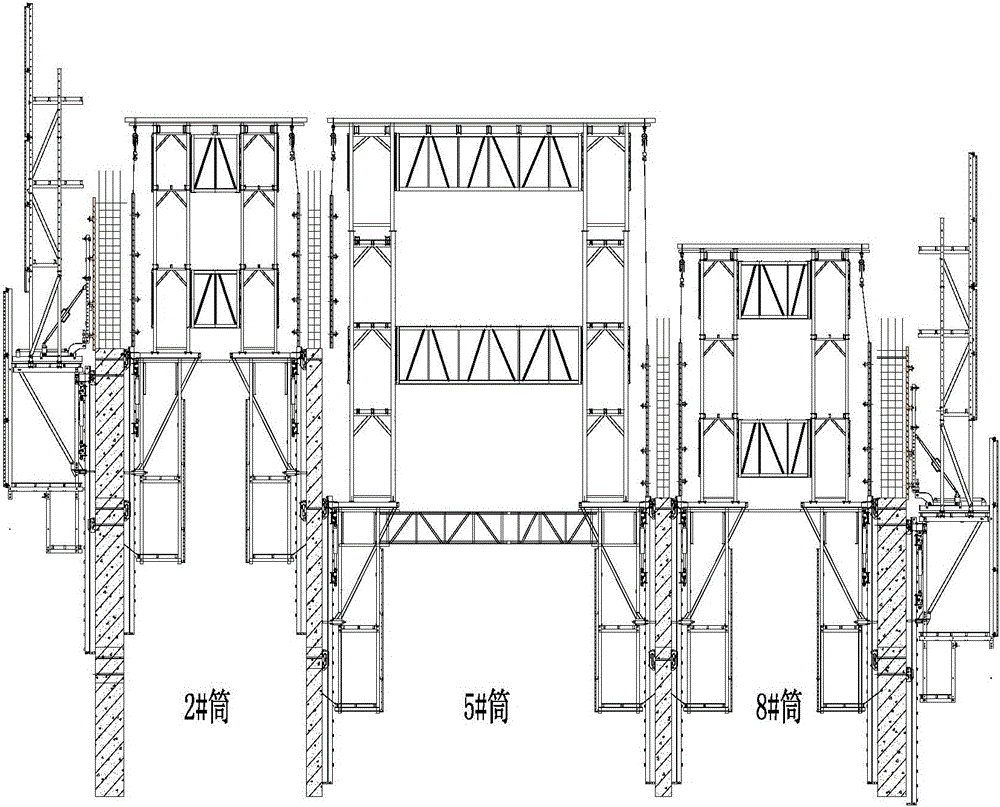

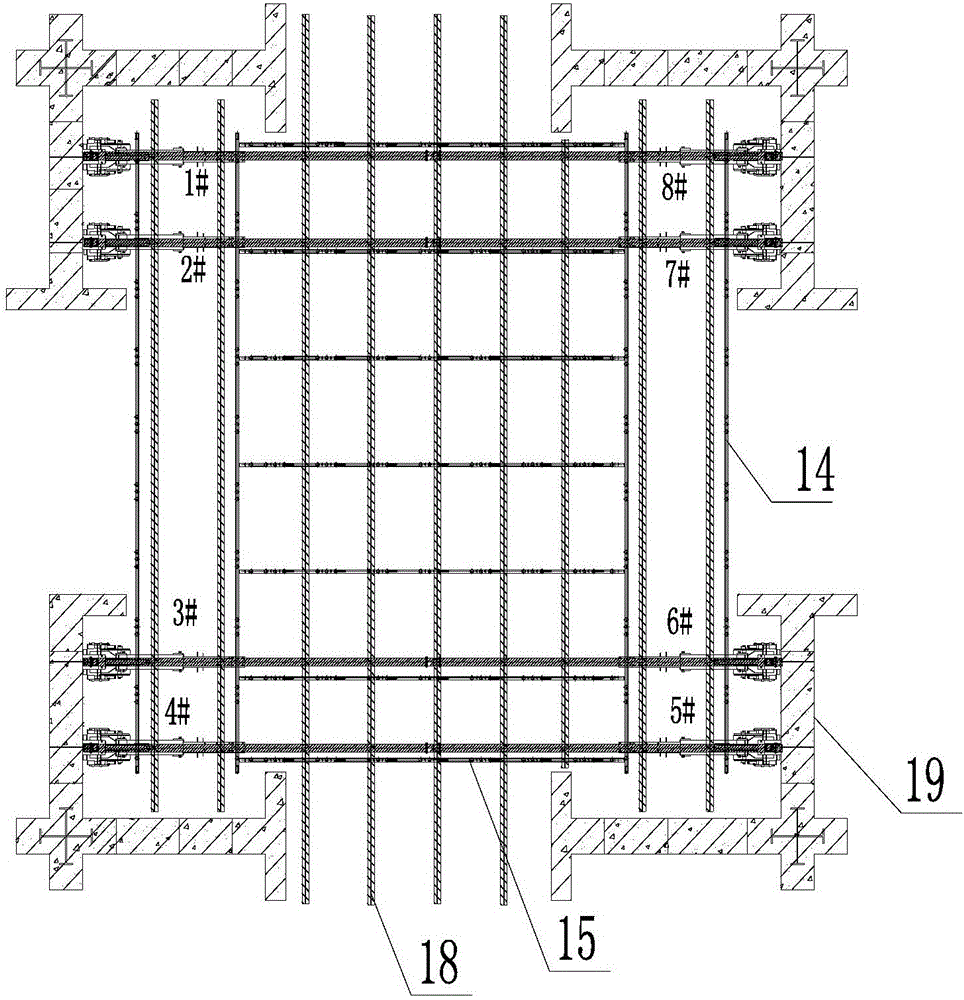

[0036] Such as Figure 1-9 As shown, the embodiment of the present invention is a truss-type hydraulic integral steel platform climbing formwork, including a vertical main frame 1, a wall attachment device 3, a guide rail 2, an anti-fall climber 10, a horizontal mold pushing mechanism 8, and a formwork 11;

[0037] The wall attachment device 3 is fixedly connected with the wall embedded parts, the vertical main frame 1 is suspende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com