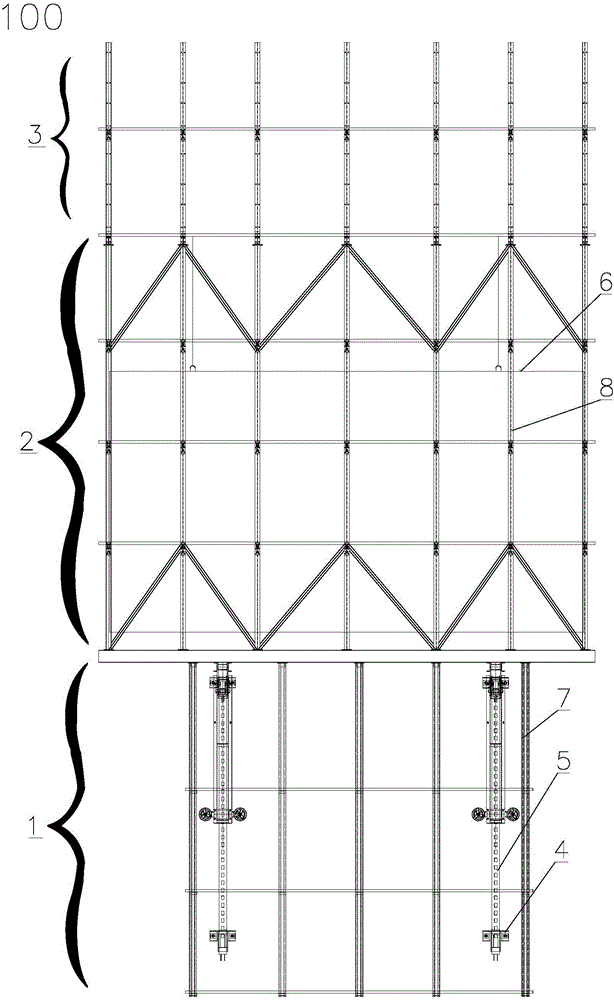

Full-automatic hydraulic climbing formwork system and using method thereof

A climbing formwork, fully automatic technology, applied in the direction of formwork/formwork/work frame, on-site preparation of building components, construction, etc., to reduce the workload of preparation and operation, improve safety performance, and reduce the occurrence of safety accidents. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

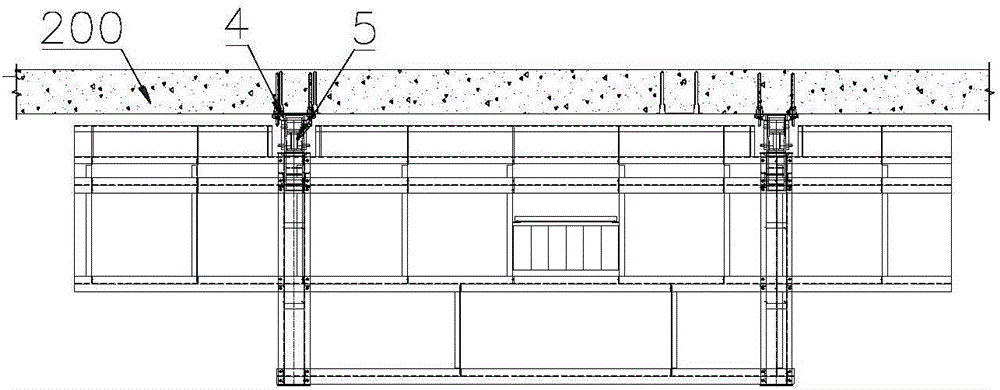

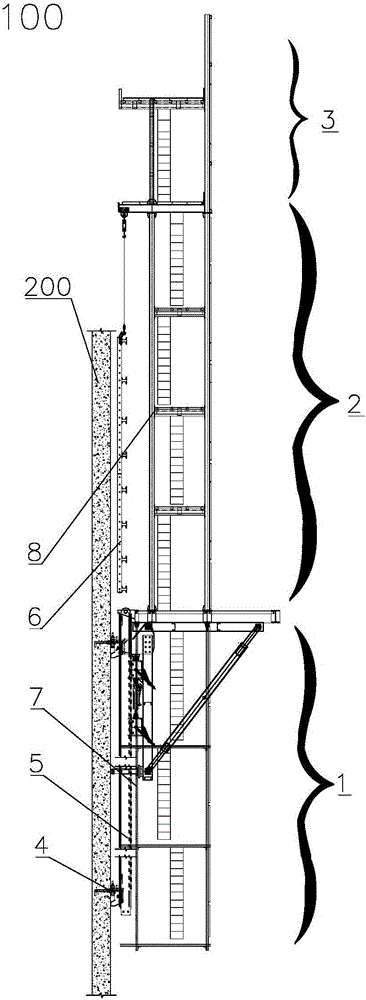

[0059] refer to Figure 11 The difference between this embodiment and Embodiment 1 is that the fully automatic hydraulic climbing formwork system 100 in another embodiment of the present invention includes three sets of wall-attached device groups and three rails 5, and the three sets of wall-attached device groups are fixed on the same section of core tube concrete On the same side of 200, three rails 5 are respectively suspended on the corresponding wall-attached devices 4; 100 to stack some construction materials or equipment. Due to the limited load capacity of the two-position fully automatic hydraulic climbing formwork system 100, it can only climb with a small frame and no stacking; the three-position fully automatic hydraulic climbing formwork system The system 100 has a larger bearing capacity, and can drive a larger frame body and a small amount of heap load to climb, meeting the climbing needs of some special high-rise buildings with a large bearing capacity and a s...

Embodiment 3

[0061] refer to Figure 12 The difference between this embodiment and Embodiment 1 is that the fully automatic hydraulic climbing formwork system 100 in another embodiment of the present invention includes four sets of wall-attaching device groups and four rails 5, and two of the four sets of wall-attaching device groups are respectively fixed on The four rails 5 are respectively suspended on the corresponding wall attachment devices 4 on the two inner sides of the core tube concrete 200 of the two sections opposite to each other; Compartment, because the space of the cubicle is relatively small, especially the size in the width direction is very small, so it does not have the conditions to install the fully automatic hydraulic climbing formwork system 100 on its four sides; Two wall-attached device groups are respectively installed on the opposite concrete wall, and the equipment frame 1, the template frame 2 and the reinforcement frame 3 together form a steel frame structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com