Electronic device cover glass blank, method for manufacturing same, electronic device cover glass, and method for manufacturing same

A technology for cover glass and electronic equipment, which is applied in glass pressing, manufacturing tools, glass production, etc., and can solve problems such as affecting manufacturing costs and increasing trauma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

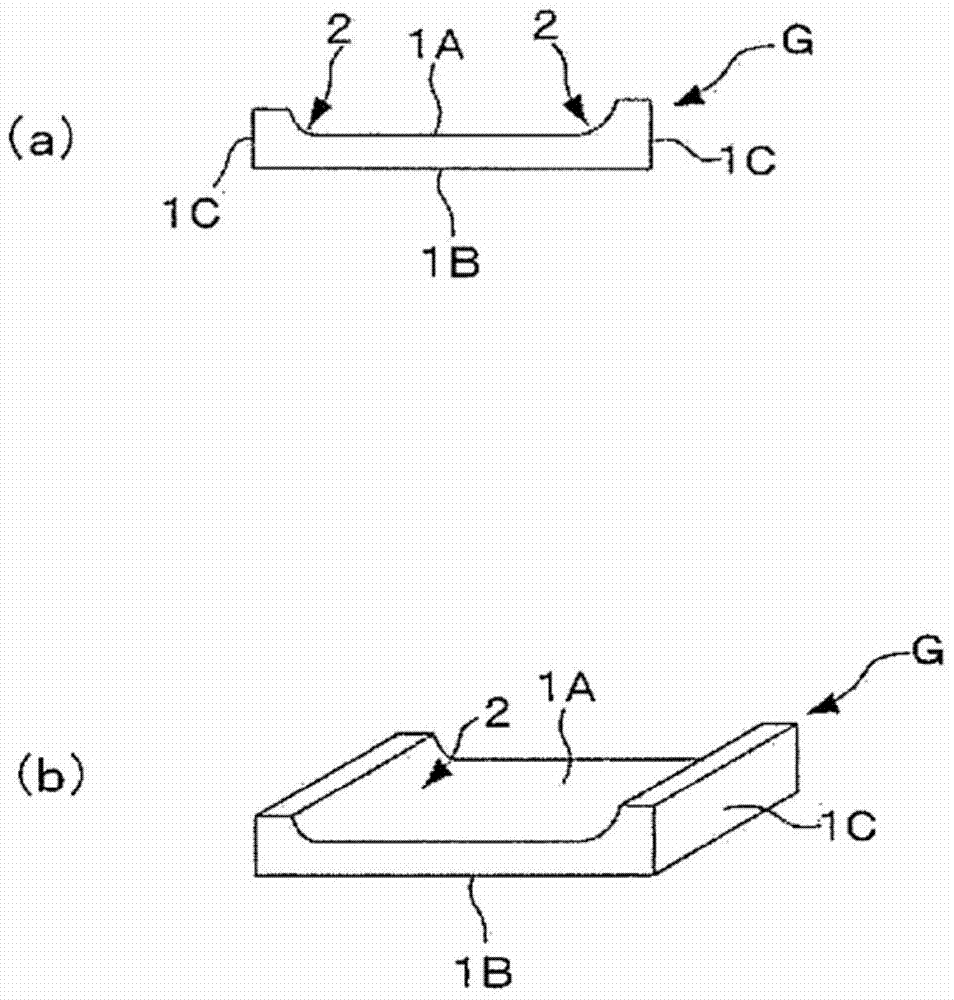

[0219] The cover glass blank for electronic devices according to this embodiment has a pair of opposing main surfaces, an end surface existing between the pair of main surfaces, and at least one of the main surfaces of the pair of main surfaces and the above-mentioned The cover-glass blank for electronic devices of the interposed surface between the end surfaces is characterized in that both the pair of main surfaces and the interposed surface are press-molded surfaces formed by direct punching.

[0220] Figure 8 It is a figure which shows one Embodiment of the cover-glass blank for electronic devices used as the base material of the cover glass for electronic devices which concerns on this embodiment, (a) is an overall perspective view, and (b) is a side cross-sectional view.

[0221] Such as Figure 8 As shown, the cover-glass blank G for electronic devices which concerns on one Embodiment of this invention has a pair of opposing main surfaces 1A, 1B, the end surface 1D wh...

no. 3 approach

[0268] The cover glass for electronic devices which concerns on this embodiment is attached to the display screen of a mobile phone as a cover glass for portable devices, for example.

[0269] Figure 18 It is an overall perspective view showing an example of a portable device, and shows a case of a mobile phone 100 mainly operated on a touch panel as an example of a portable device. This mobile phone 100 includes a case portion 101 and a display screen 102 on the upper surface side, and a cover glass is provided on the display screen 102 .

[0270] Figure 19 (a)-(d) is a plan view which shows the example of the external shape of the cover glass for portable devices which is a cover glass for electronic devices which concerns on this embodiment, respectively.

[0271] Should Figure 19 (a) to (d) all represent examples in which the outer shape of the cover glass is rectangular, Figure 19 (a) shows an example of a simple rectangular cover glass 200A, Figure 19 (b), Fi...

Embodiment 1

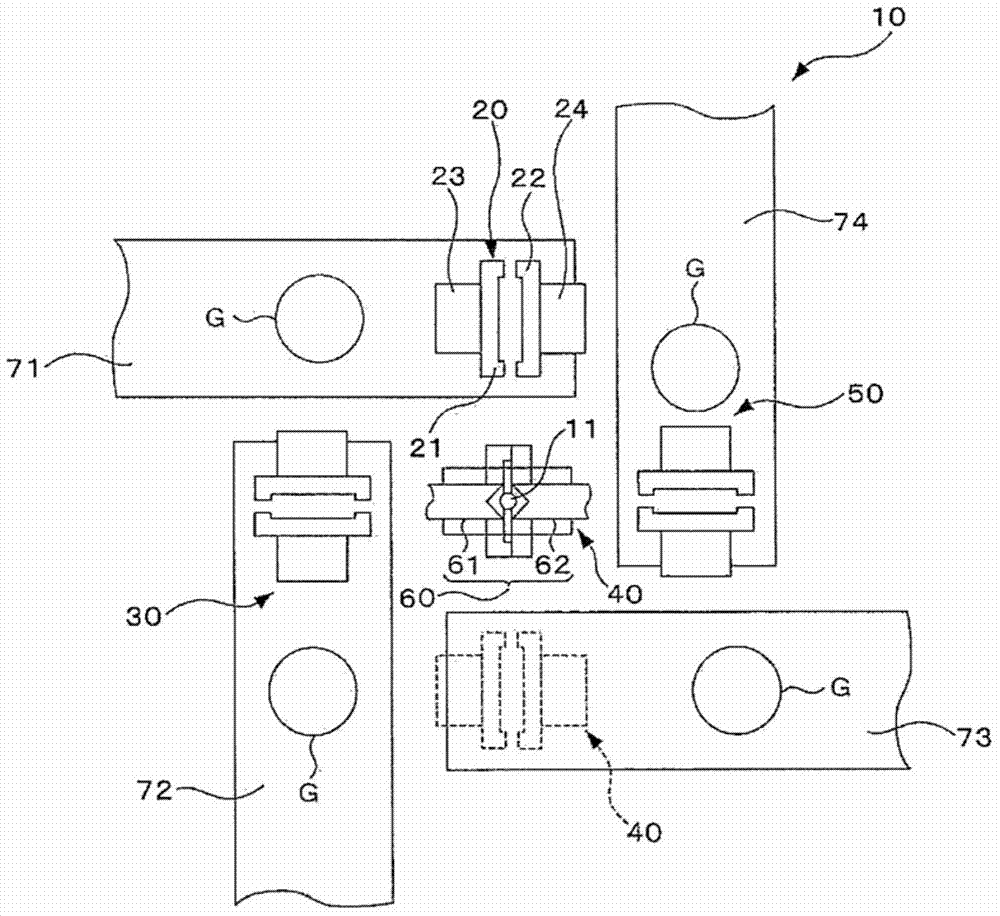

[0332] In this example, the cover glass blank of this example is produced through the following press molding process, and then the glass base material is formed from the cover glass blank, and the glass base material is chemically strengthened to manufacture a portable device The glass base material used for the cover glass.

[0333] [Press forming process]

[0334] As a glass composition, prepare to contain SiO 2 : 62.5 to 64.5% by weight, Al 2 o 3 : 13 to 15% by weight, Li 2 O: 5 to 7% by weight, Na 2 O: 9.5 to 11.5% by weight, ZrO 2 : 5 to 7% by weight of molten glass material, by using the above image 3 , Figure 4 method of the device, made with the above-mentioned figure 1 The three-dimensional shape of the cover glass blank is shown.

[0335] Wherein, the temperature of the molten glass material flowing out from the molten glass outlet is 1300°C, and the viscosity is 10 3 Adjustment is performed in a manner below dPa·s. In addition, the surface roughness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com