Patents

Literature

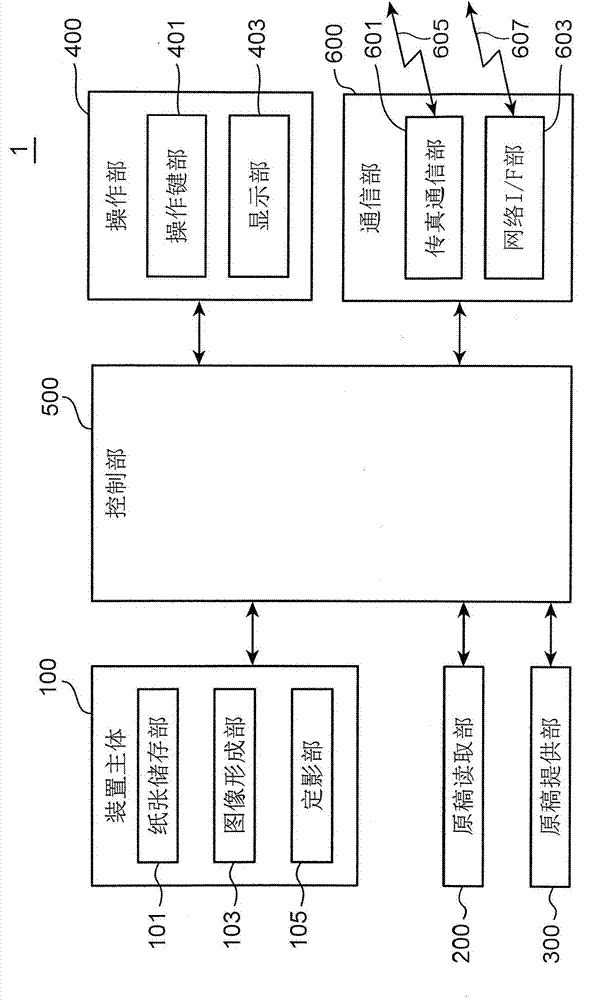

51results about How to "Reduce the number of manufacturing processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

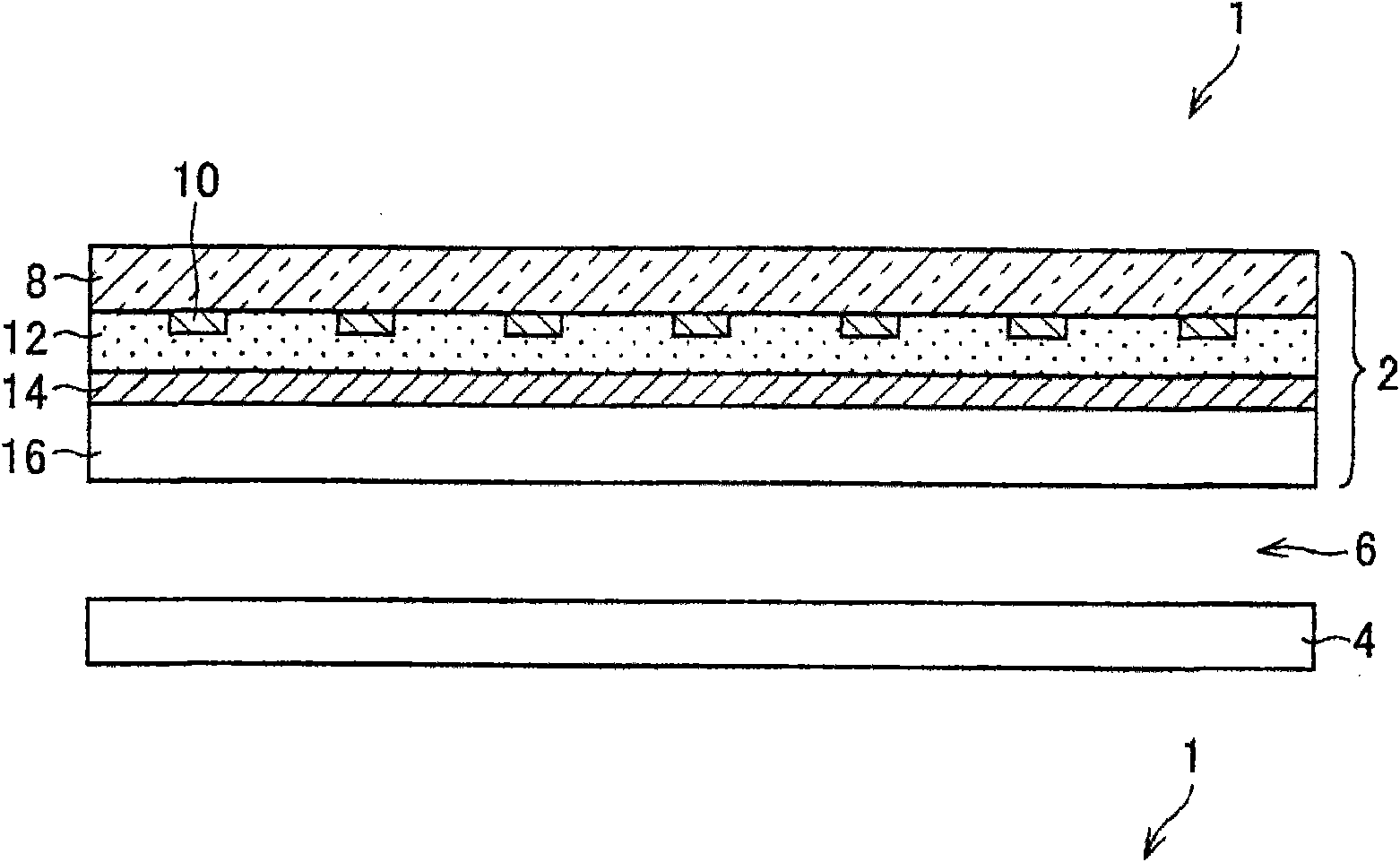

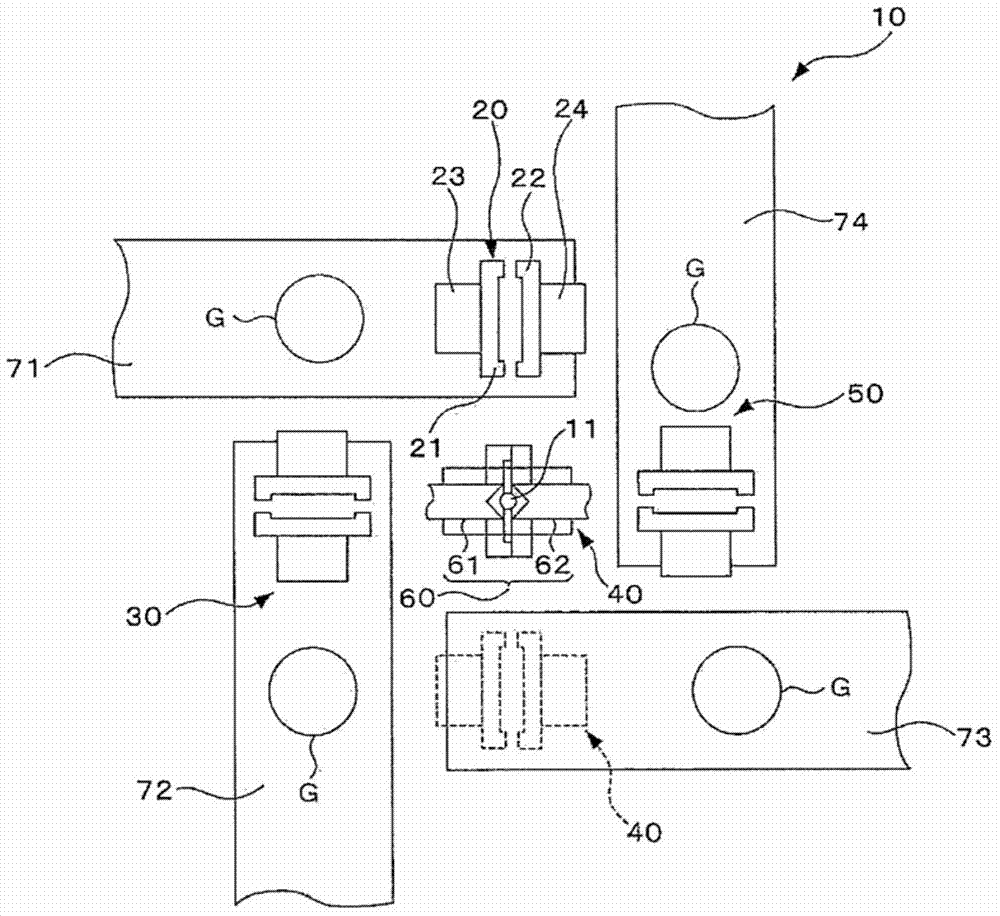

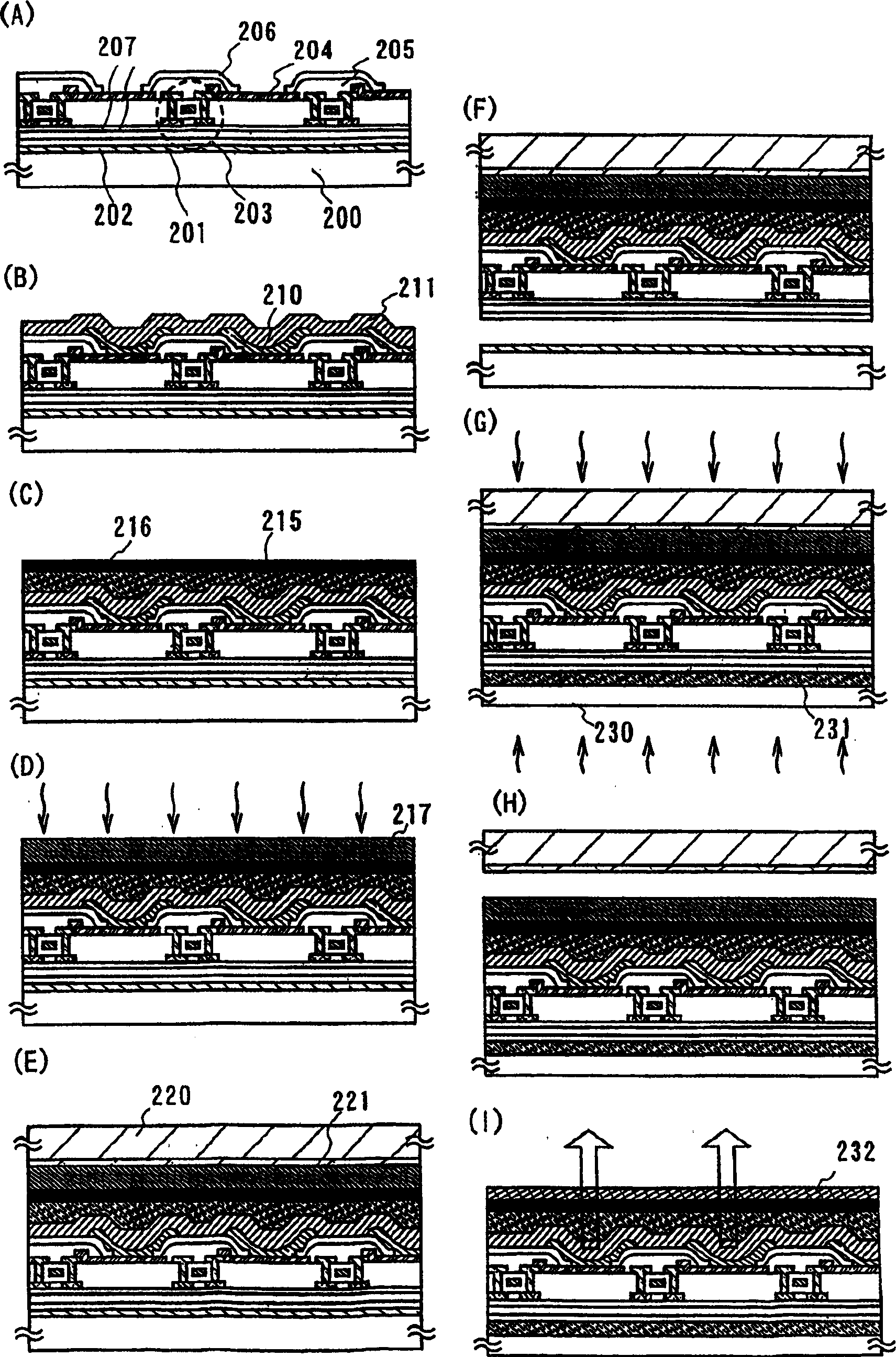

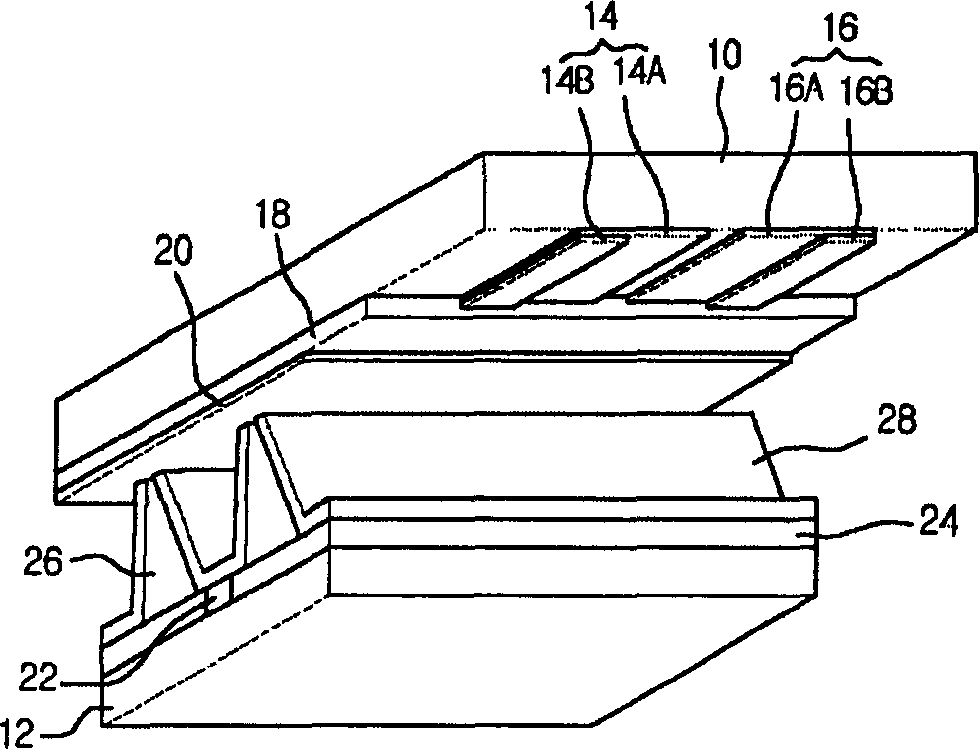

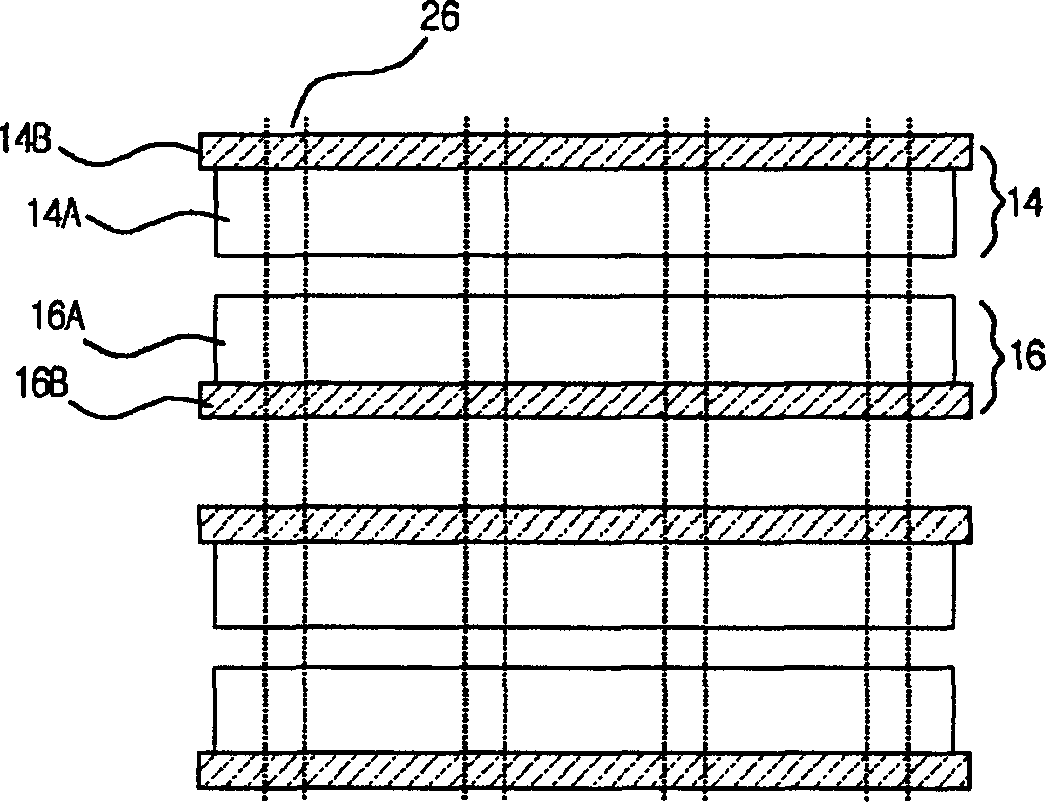

Display panel substrate, display panel, display device and method for manufacturing display panel substrate

InactiveCN101558370AReduce the number of manufacturing processesReduce manufacturing costNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

A display panel substrate is provided with at least an insulating substrate; a first conductive wiring formed on the insulating substrate; a piezoelectric material film formed on the first conductive wiring; a second conductive wiring intersecting with the first conductive wiring; and protecting films for protecting the first conductive wiring, the second conductive wiring and the piezoelectric material film, respectively. The insulating film is formed at least in a region in an effective display region on the insulating substrate, and the piezoelectric film is formed at least on an intersecting point of the first conductive wiring and the second conductive wiring. Thus, the display panel substrate capable of integrating a touch panel function without increasing the sizes of the display panel is provided.

Owner:SHARP KK

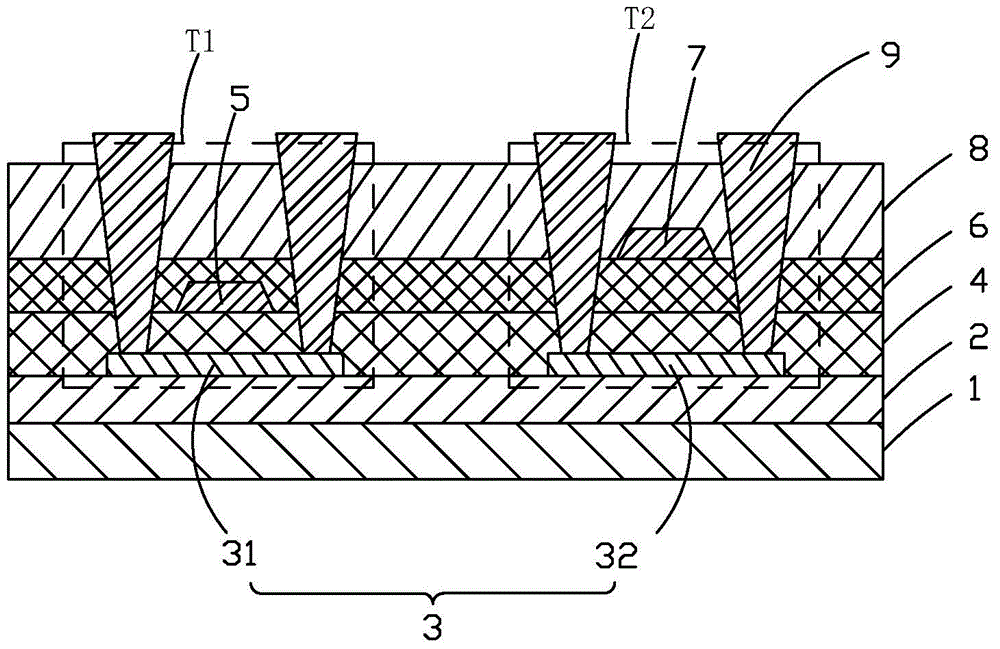

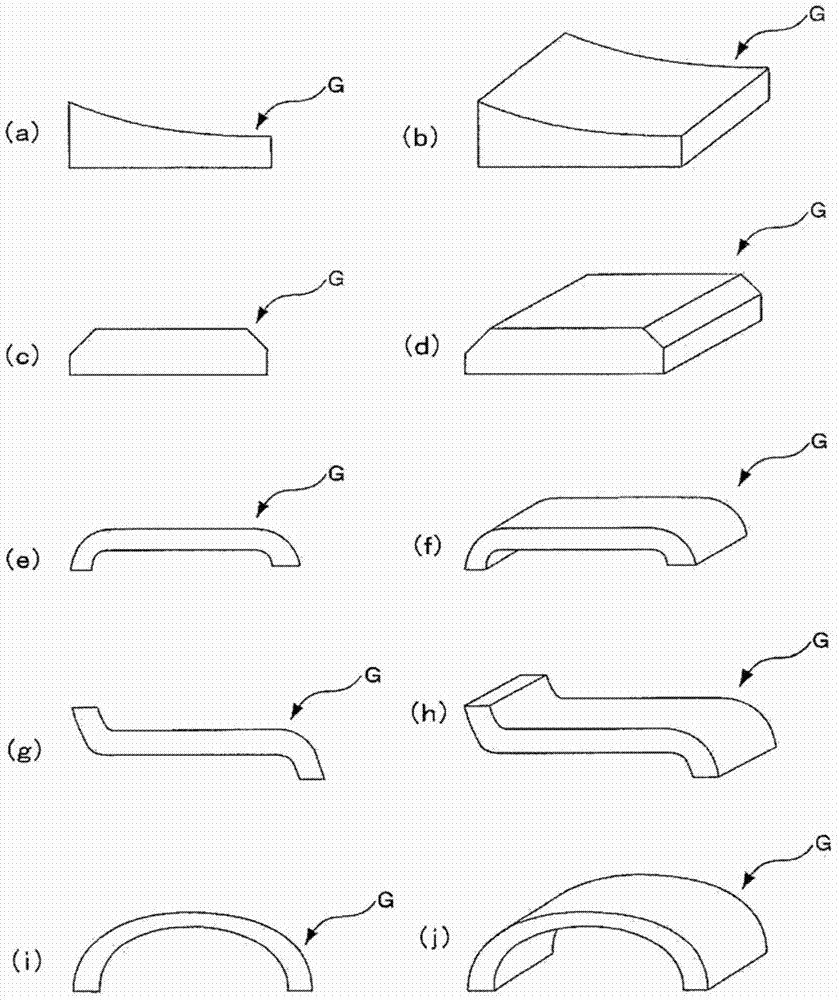

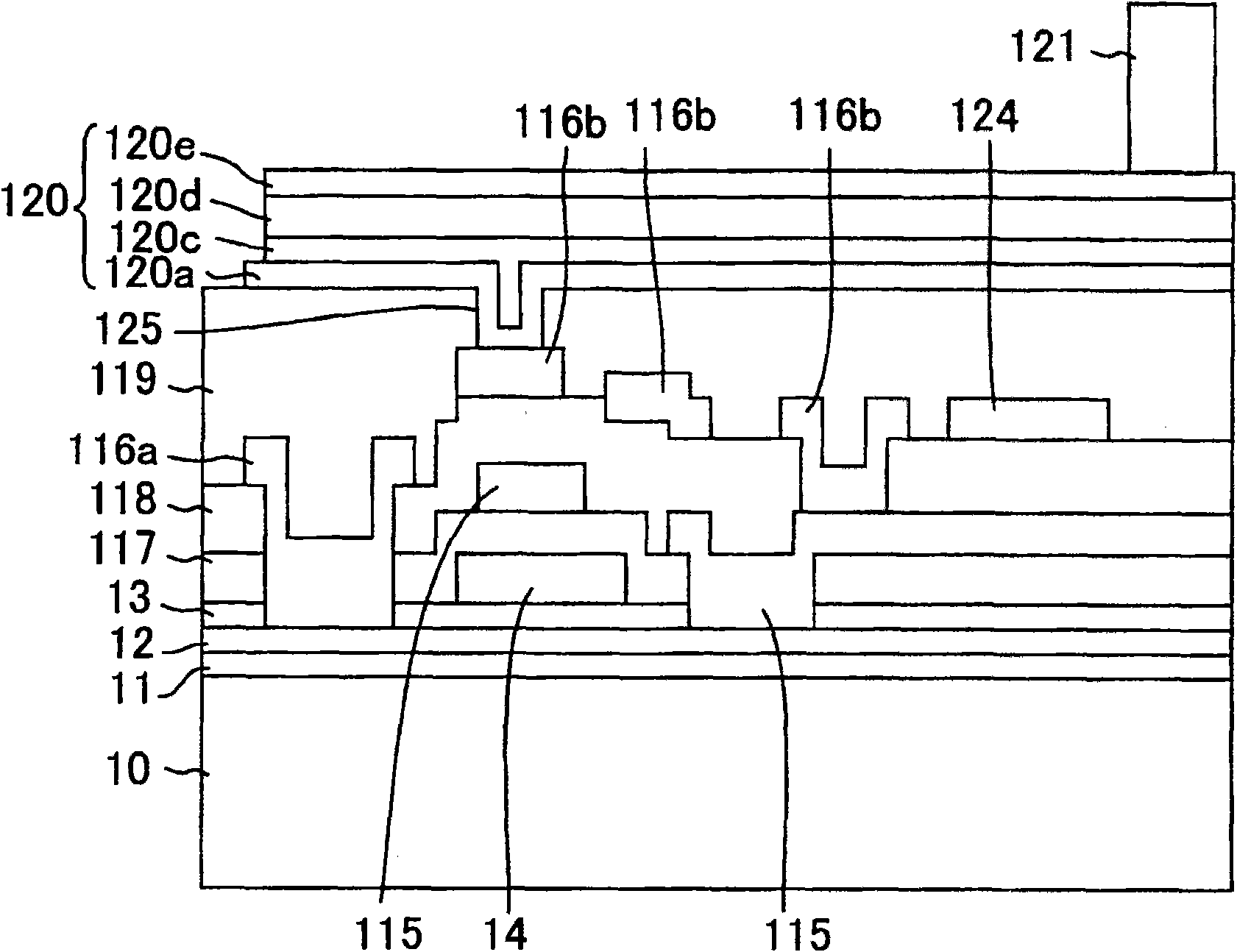

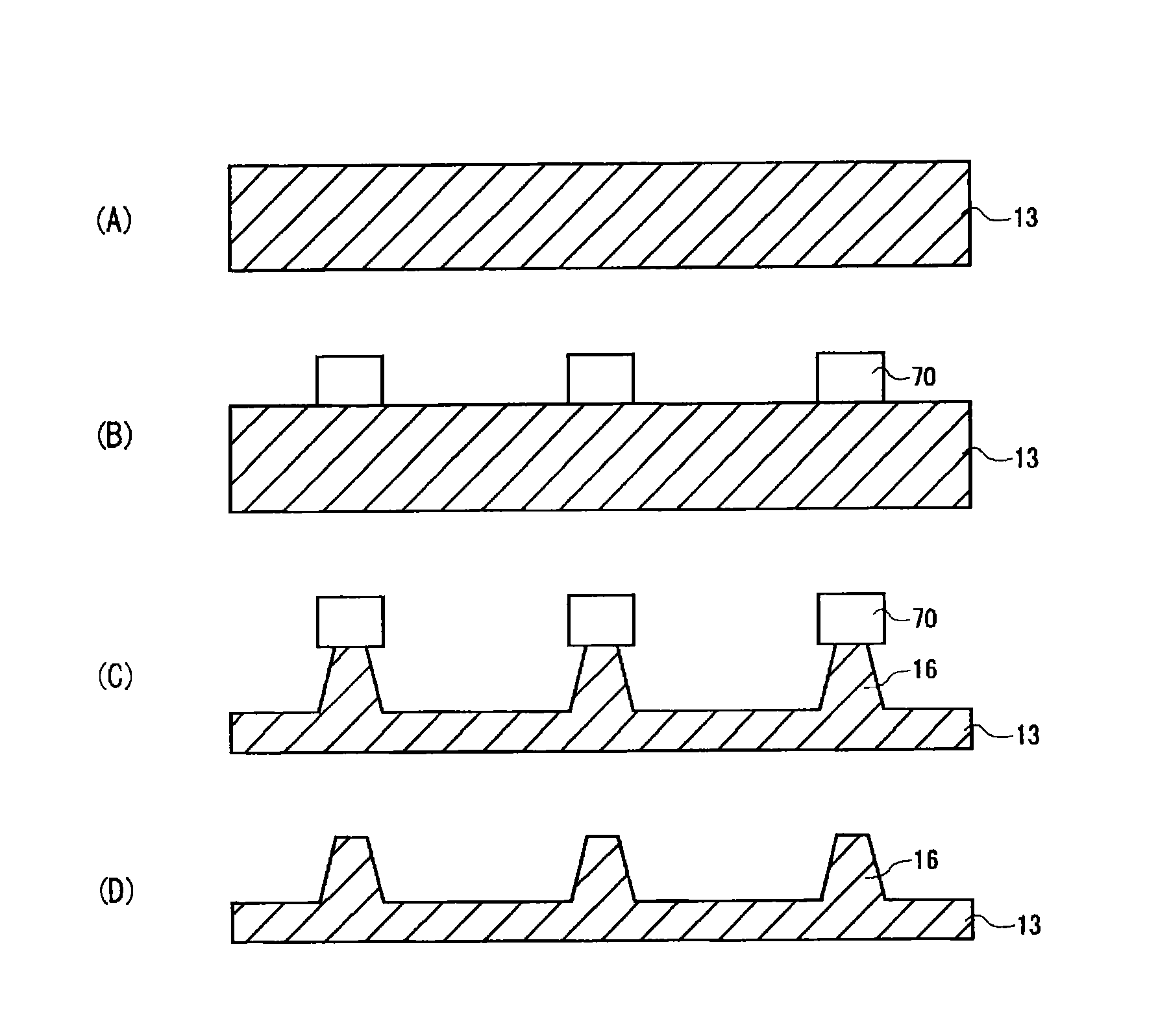

TFT backboard manufacturing method and structure suitable for AMOLED

InactiveCN104659285AThe production process is simpleIncreased subthreshold swingSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSubthreshold swing

The invention provides a TFT backboard manufacturing method and structure suitable for AMOLED. The method comprises the following steps: 1, providing a baseboard (10) and depositing a buffer layer (20); 2, forming a source layer (30) and a gate insulation layer (40) on the buffer layer (20) in sequence; 3, carrying out patterning processing on the gate insulation layer (40) to form a recession part (401); 4, forming a gate (50) for switching a thin film transistor and a gate (60) for driving the thin film transistor, wherein the gate (50) for switching the thin film transistor is positioned at the recession part (401); 5, depositing an interlayer insulation layer (70). According to the method, a single-layer gate insulation layer with height different is manufactured, so that the manufacturing process of the TFT backboards is simplified, the subthreshold swing of the gate (60) for driving the thin film transistor and the grey scale switching and control properties of the AMOLED panes are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

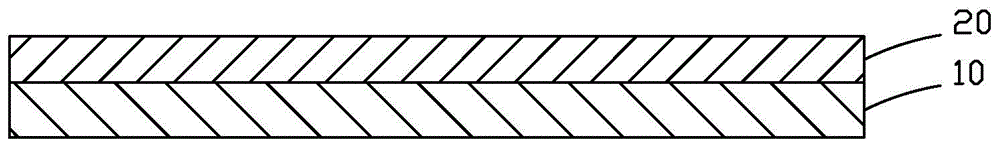

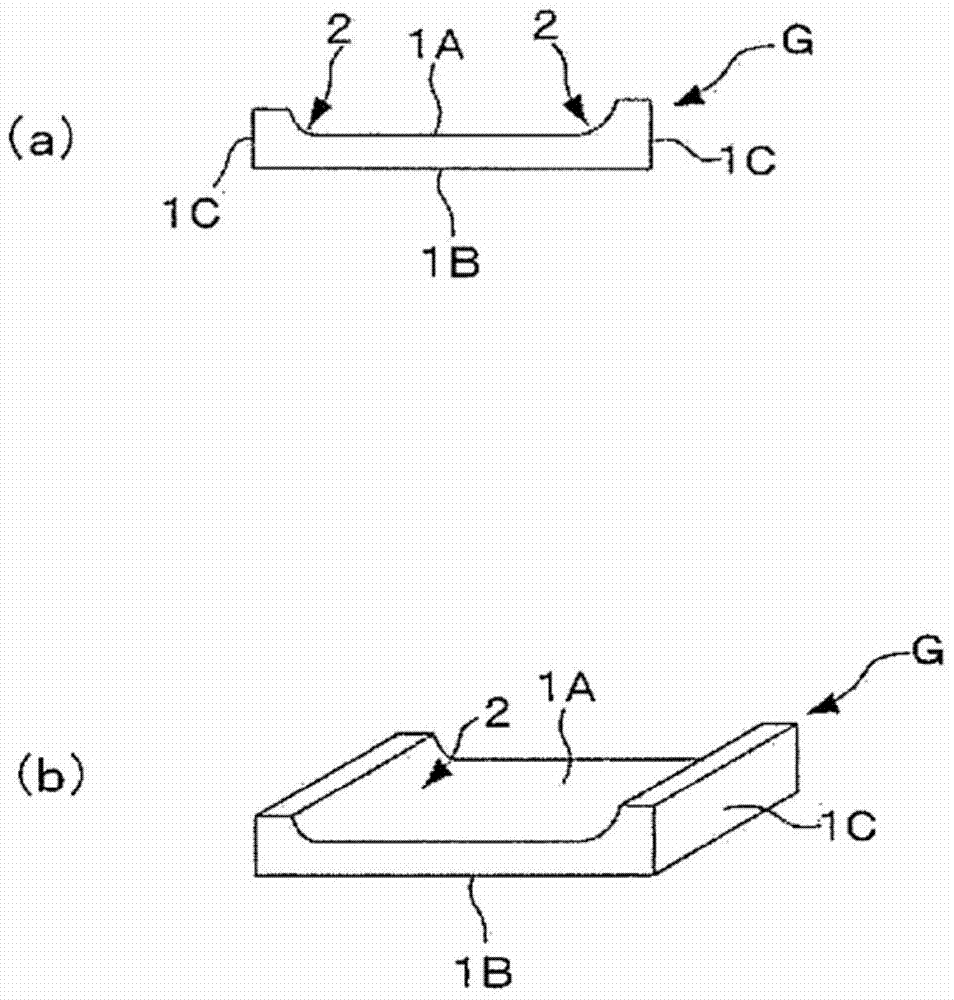

Electronic device cover glass blank, method for manufacturing same, electronic device cover glass, and method for manufacturing same

InactiveCN103946166AIncrease freedomImprove appearance qualityGlass pressing apparatusGlass press-moulding apparatusEngineeringCover glass

An electronic device cover glass blank (G) to be used as a substrate of an electronic device cover glass includes a pair of main surfaces (1A, 1B), and end surfaces that adjoin the pair of main surfaces (1A, 1B). The main surfaces are shaped so as to be asymmetric to each other in the thickness direction. The main surfaces (1A, 1B) are press-molded surfaces formed by direct pressing. A method for manufacturing the cover glass blank includes a molding step in which a pair of dies is used for press molding a mass of molten glass supplied from a molten glass supplying unit. The pressing surface of at least one of the pair of dies has a shape for forming the main surfaces and an interposed surface.

Owner:HOYA CORP

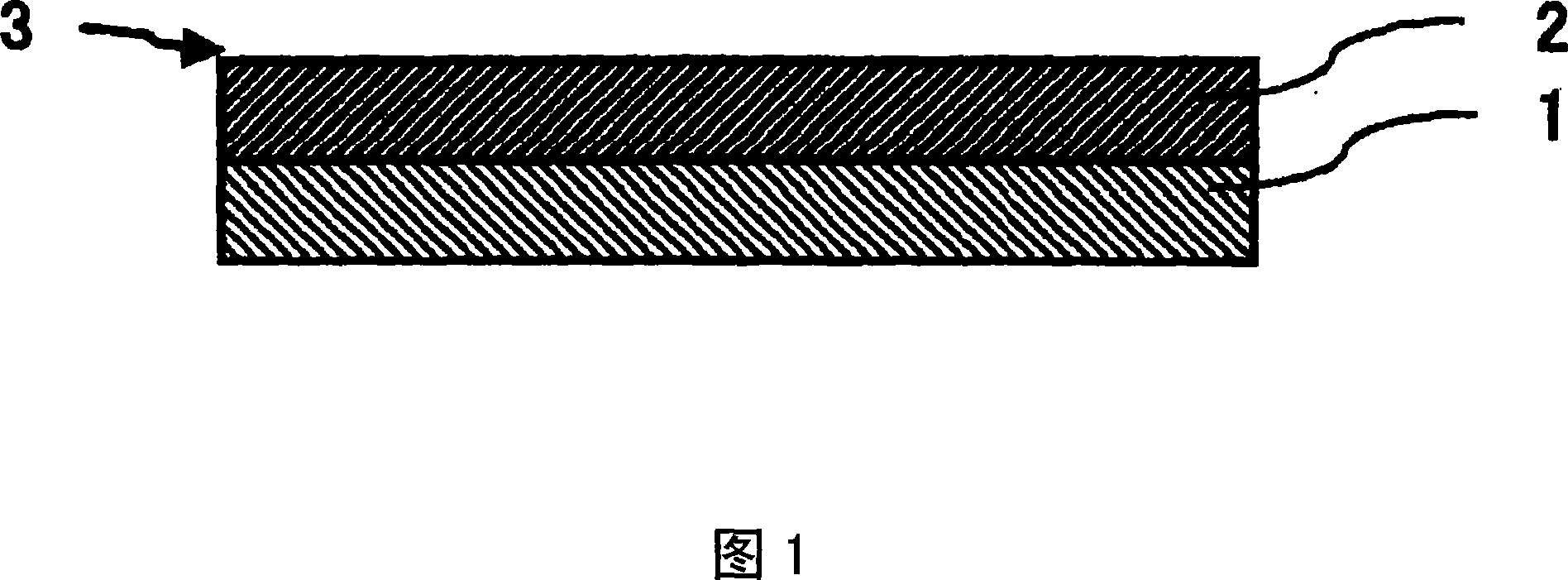

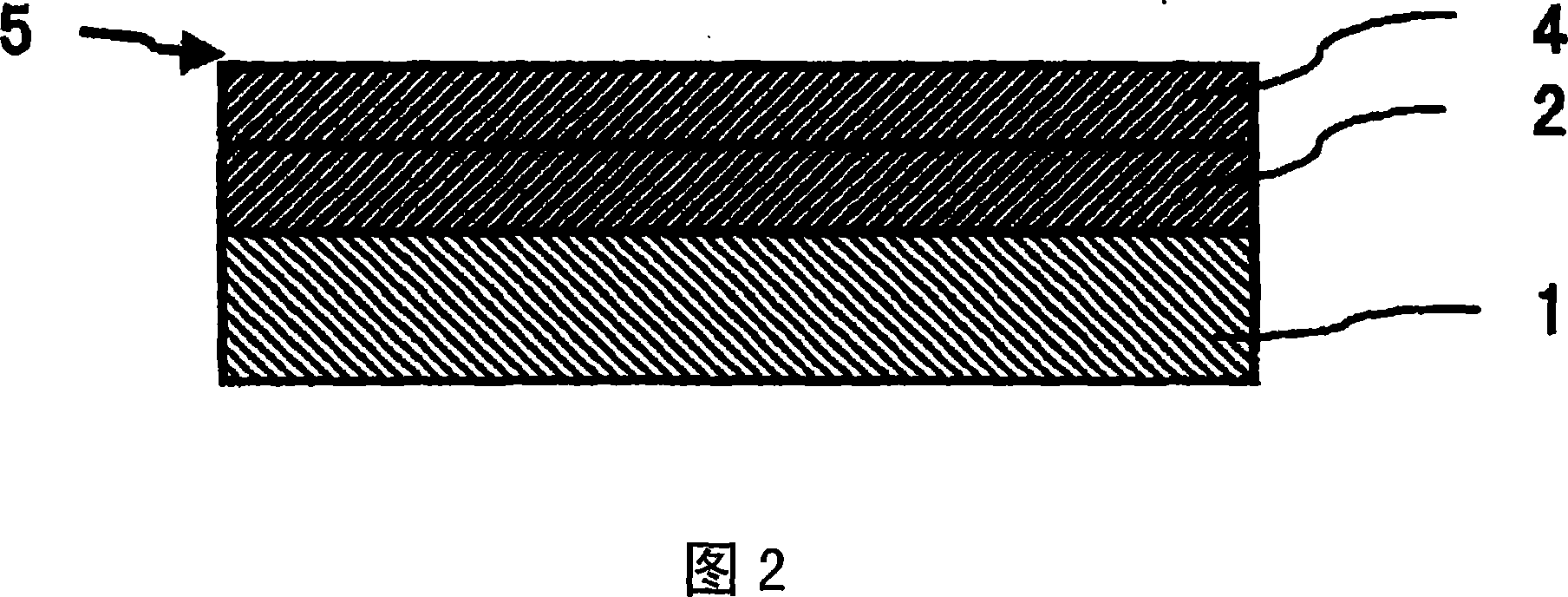

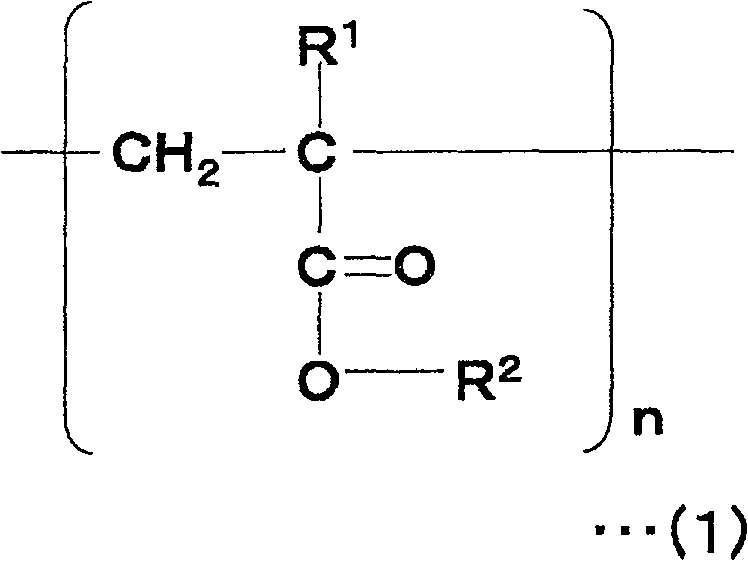

Hard-coated film, method of manufacturing the same, optical device, and image display

InactiveCN101045347AReduce the number of manufacturing processesSolve the lack of hardnessSynthetic resin layered productsLaminationMethacrylatePolyol

A hard-coating layer is formed on at least one surface of a transparent plastic film substrate using a material for forming a hard-coating layer. The material contains Components A, B, and C. Component A is at least one of urethane acrylate and urethane methacrylate. Component B is at least one of polyol acrylate and polyol methacrylate. Component C is a polymer containing a repeating unit represented by General Formula 1 indicated below.

Owner:NITTO DENKO CORP

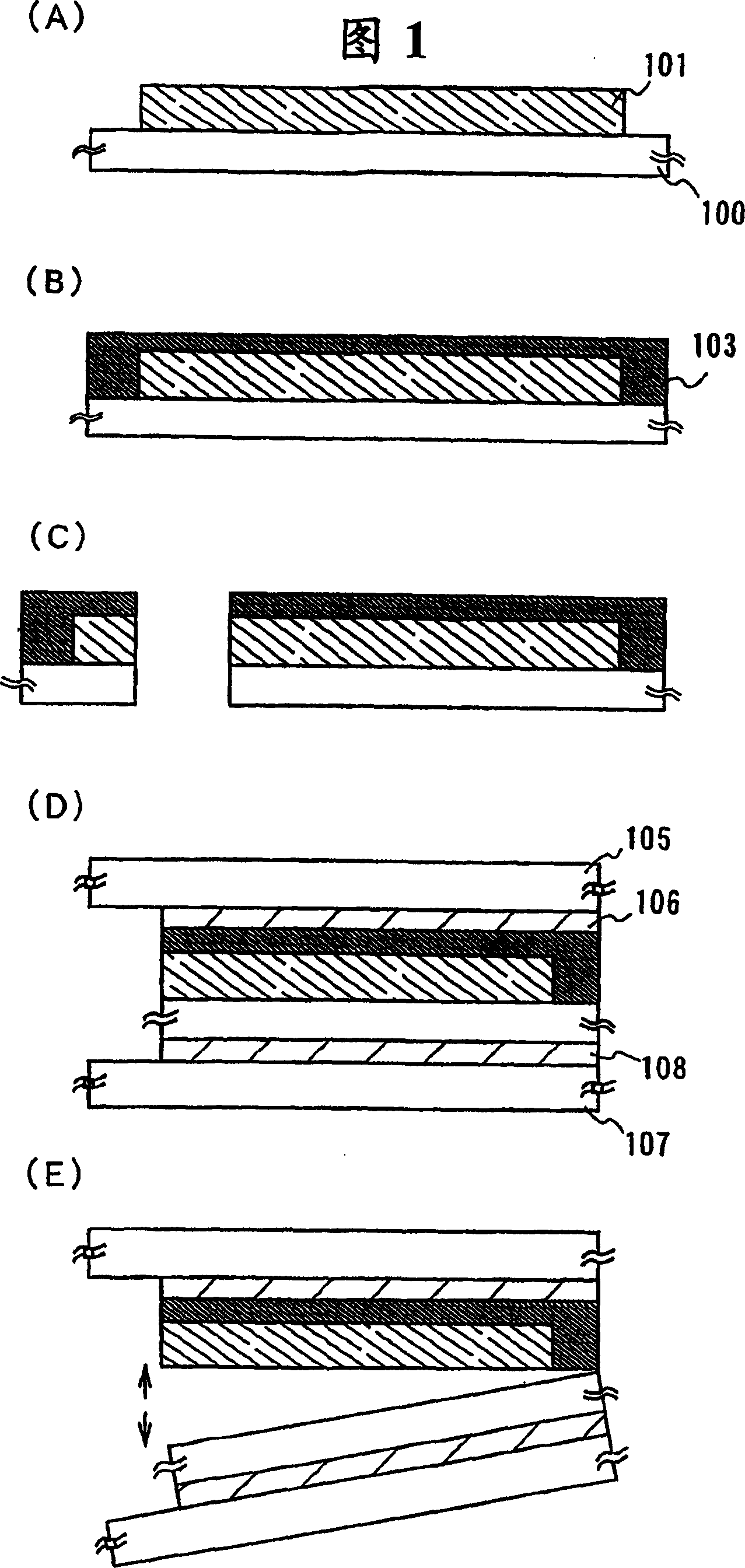

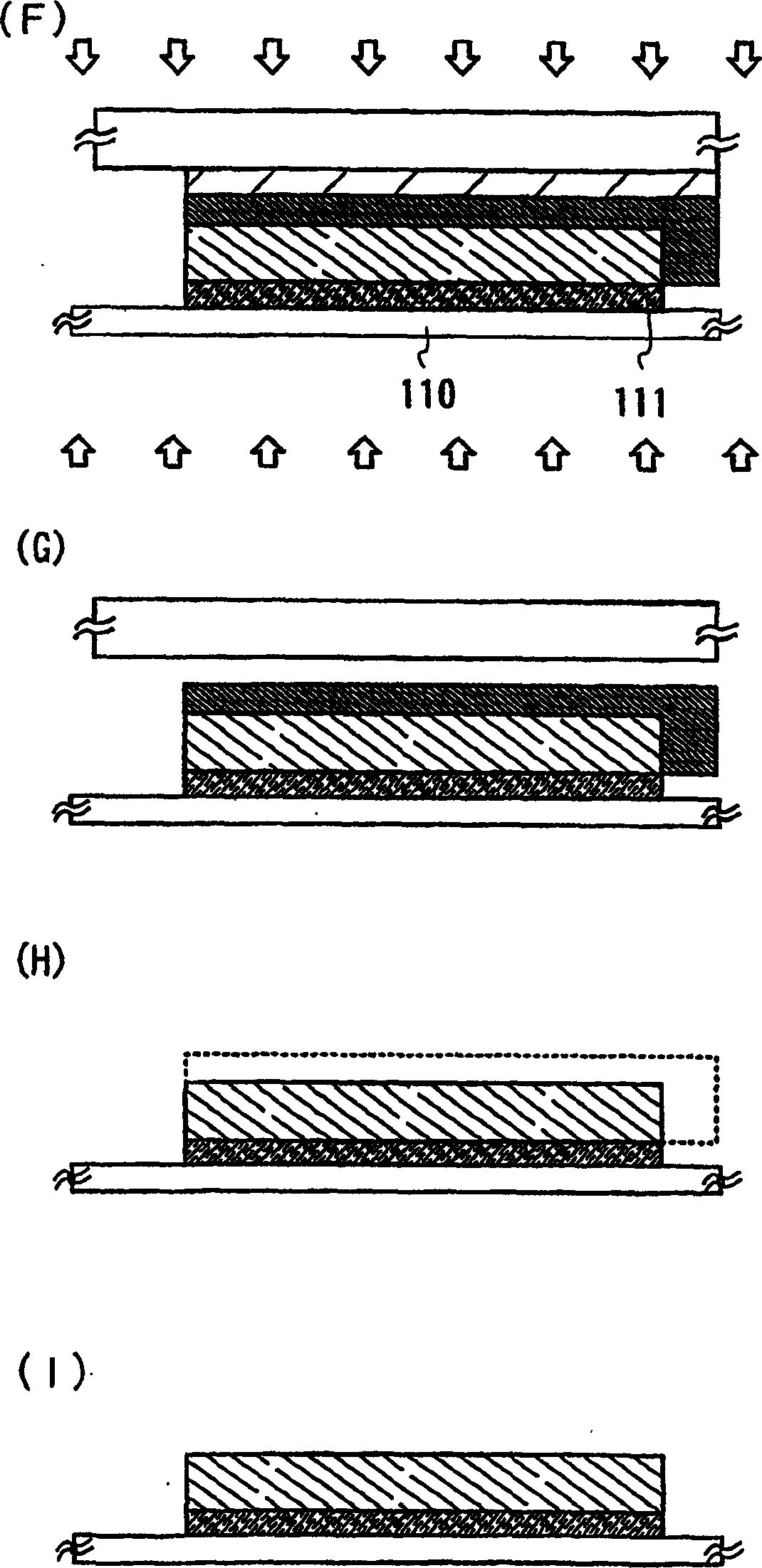

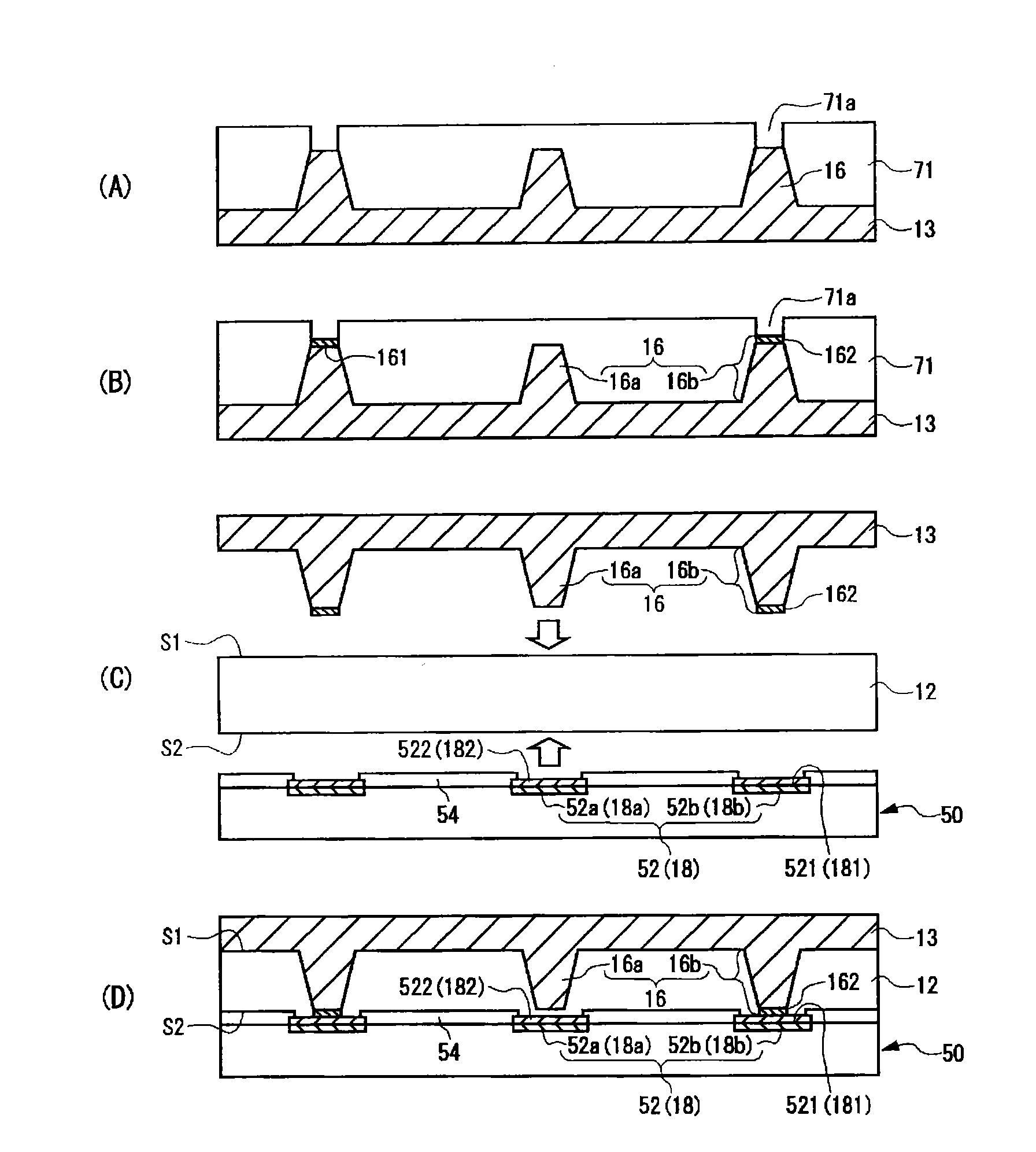

Peeling method and method for manufacturing display device using the peeling method

InactiveCN1739129ASimplify the manufacturing processImprove pass rateElectroluminescent light sourcesSolid-state devicesAdhesiveDisplay device

The present invention provides a simplifying method for a peeling process as well as peeling and transcribing to a large-size substrate uniformly. A feature of the present invention is to peel a first adhesive and to cure a second adhesive at the same time in a peeling process, thereby to simplify a manufacturing process. In addition, the present invention is to devise the timing of transcribing a peel-off layer in which up to an electrode of a semiconductor are formed to a predetermined substrate. In particular, a feature is that peeling is performed by using a pressure difference in the case that peeling is performed with a state in which plural semiconductor elements are formed on a large-size substrate.

Owner:SEMICON ENERGY LAB CO LTD

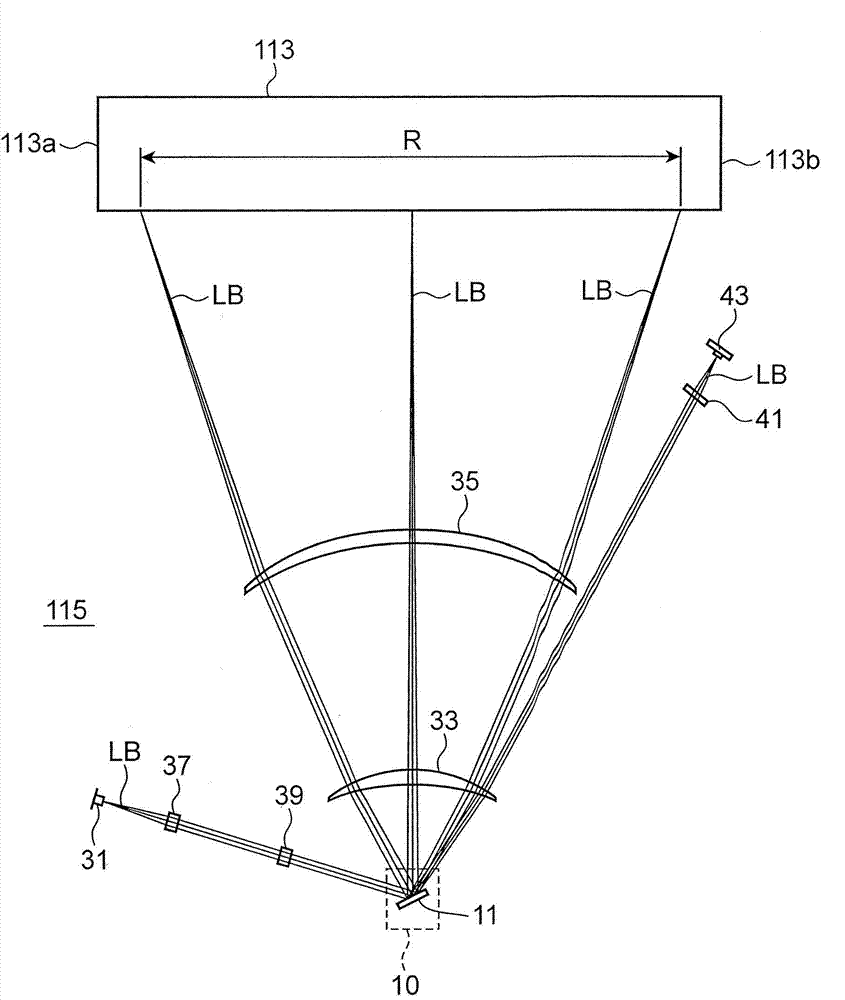

Light deflector, optical scanning device and image forming apparatus

ActiveCN104216109AShake suppressionCurb bendingElectrographic process apparatusOptical elementsEngineeringMechanical engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Wiring circuit board, manufacturing method for the wiring circuit board, and circuit module

InactiveCN1571621AReduce the number of manufacturing processesReduce parasitic resistancePrinted circuit assemblingSemiconductor/solid-state device detailsSolder ballEngineering

Owner:INVENSAS CORP

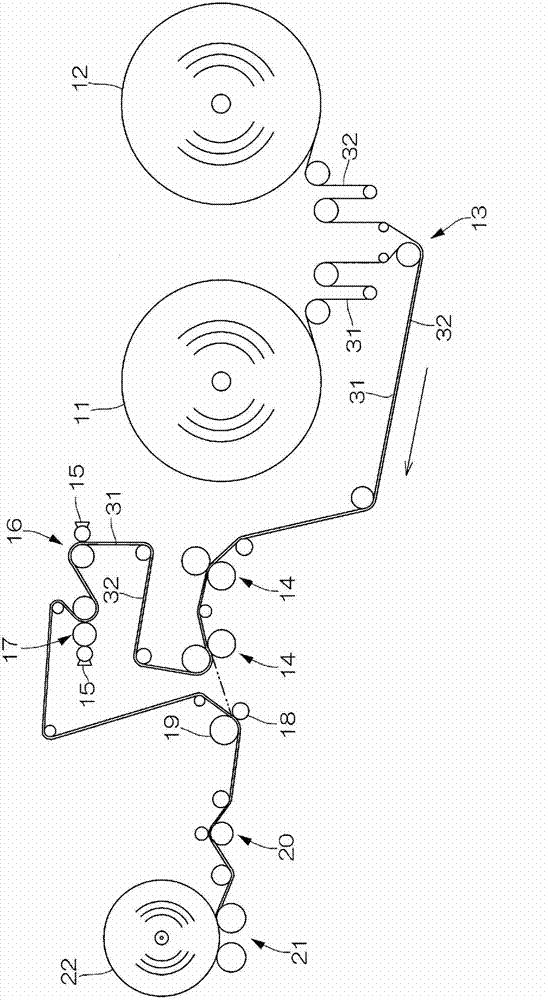

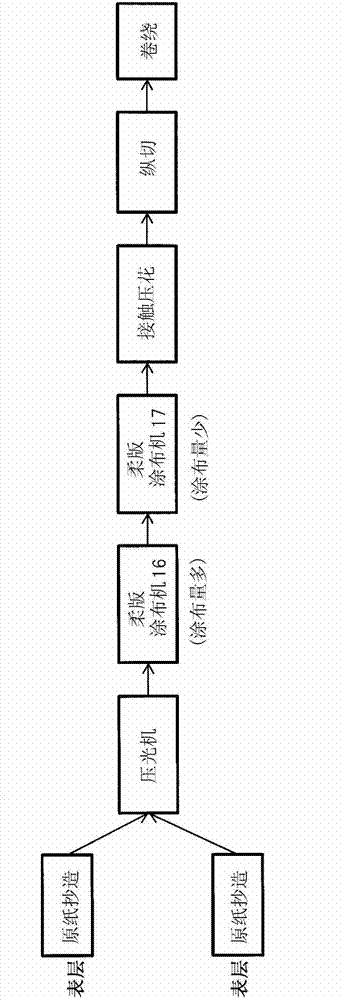

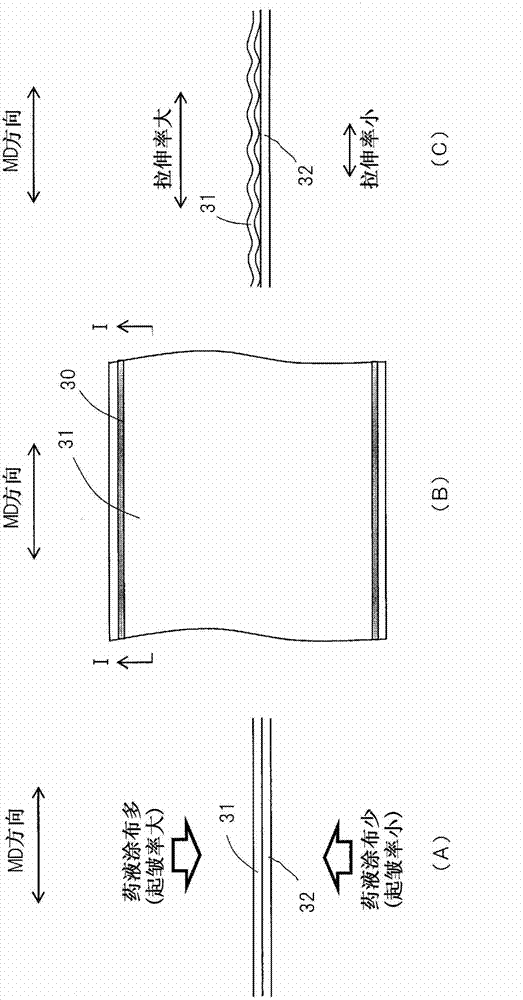

Method of manufacturing secondary whole roll for tissue paper product

ActiveCN102711571ASoft feelImprove wiping effectSpecial paperBathroom accessoriesChemical solutionBiomedical engineering

Disclosed is a tissue paper manufactured so as to be bulky without using bulking agents and the like and without increasing the number of manufacturing processes. Also disclosed is a method of manufacturing secondary whole rolls for a tissue paper product, which comprises (1) a laminating step of forming a laminated continuous sheet by laminating primary whole rolls fed from a plurality of primary whole rolls in a direction along which the rolls continue; (2) a chemical-solution applying step of applying chemical solution only to one of the top layers of the laminated continuous sheet or applying more chemical solution to one of the top layers than to the other top layer; (3) a joining step of forming linear joint portions that prevent layer separation on the laminated continuous sheet by nipping the laminated continuous sheet between a receiving roller and a driven roller. (4) a slitting step of slitting the laminated continuous sheet into sheets having a width or a several-fold width of a tissue paper product; and (5) a coiling step of forming a plurality of secondary whole rolls having the width or the several-fold width of the tissue paper product by coaxially coiling the slit laminated continuous sheets.

Owner:DAIO PAPER CORP

Film transistor array substrate and mfg. method thereof

ActiveCN1905166AHigh-resolutionAvoid misalignmentSemiconductor/solid-state device detailsSolid-state devicesTransistor arrayEngineering

The invention discloses a thin film transistor (TFT) array substrate and the making method thereof. And the making method only needs six or even less photo-mask manufacturing processes to be able to make a TFT array substrate integrated with color filter pattern. Therefore, the making method is relatively simple to implement and has lower production cost. Besides, the making method need not form contact windows in thicker films, such as flat layer or color filter layer, to connect pixel electrodes with sources / drains, thus able to effectively reduce the difficulty of the manufacturing process.

Owner:AU OPTRONICS CORP

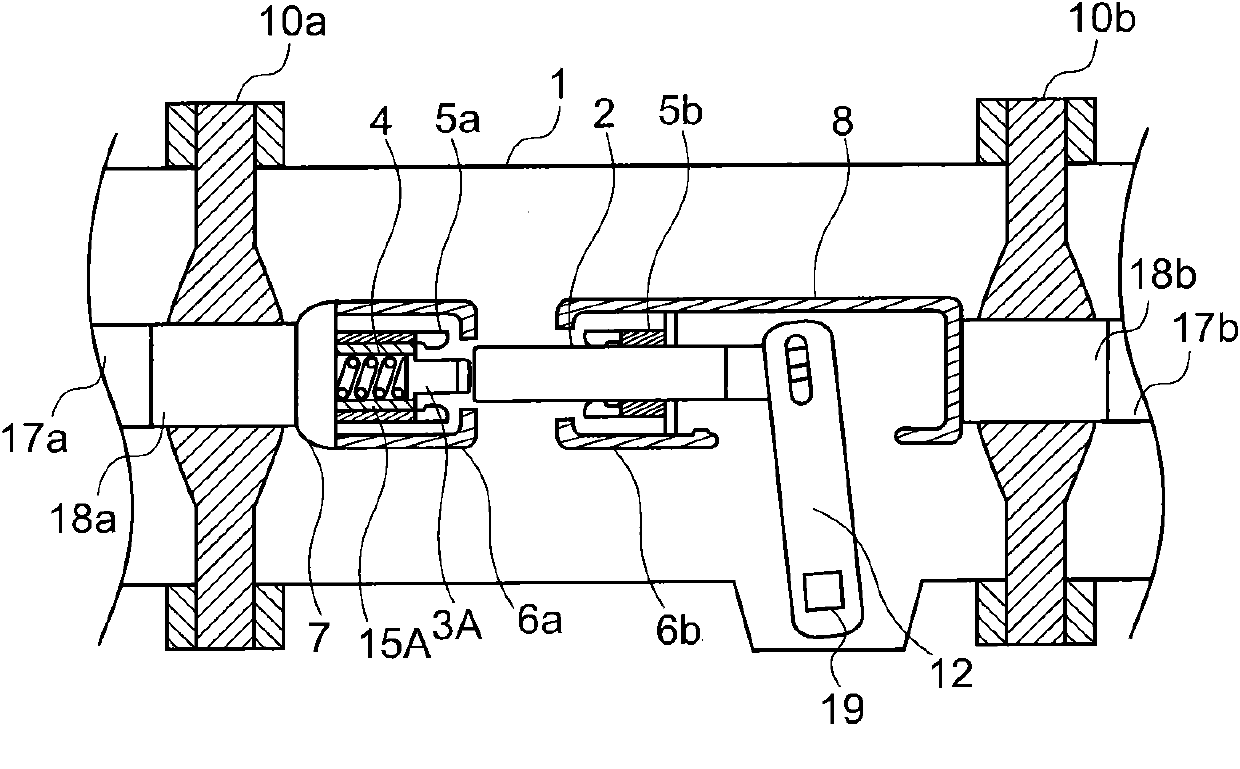

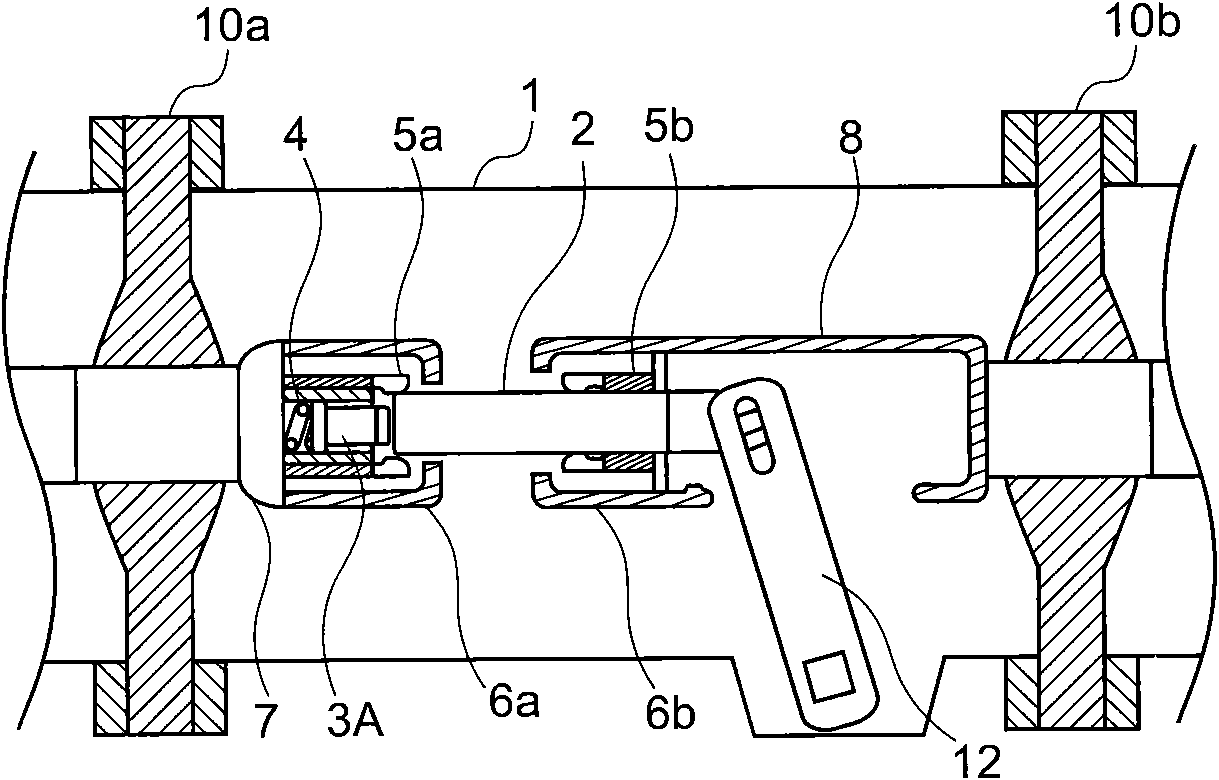

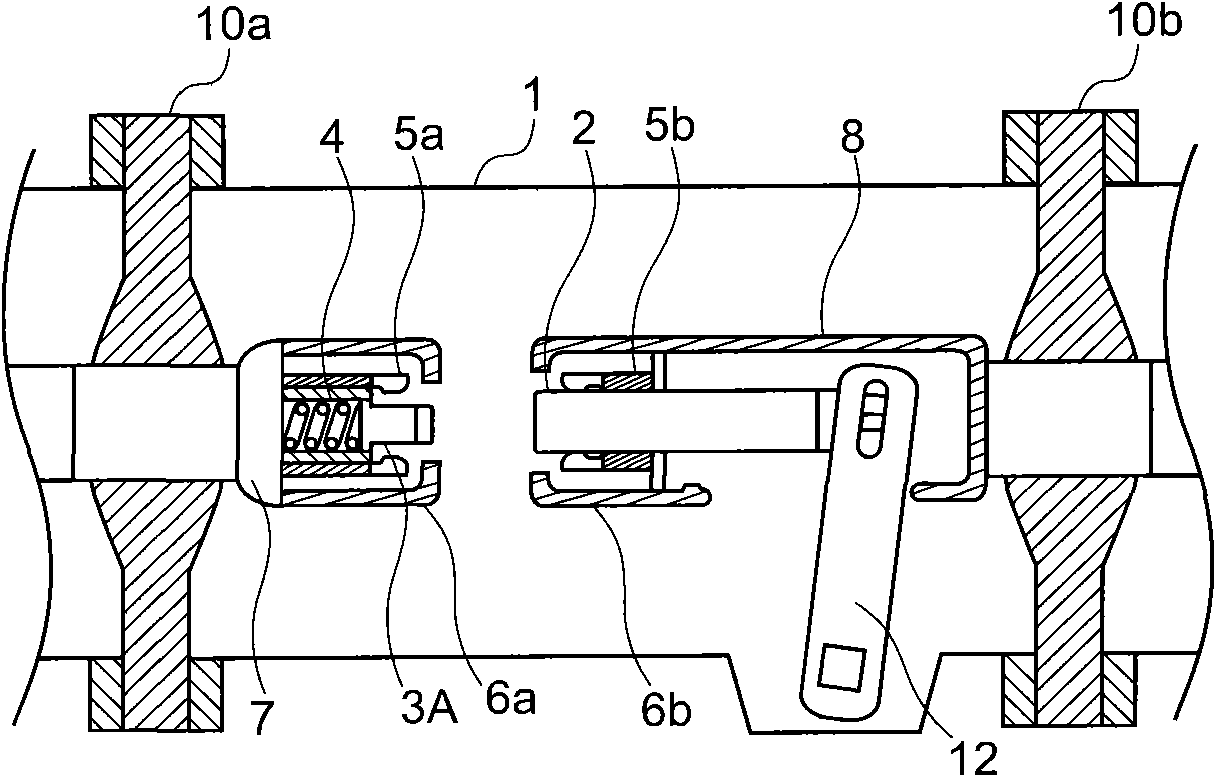

Circuit breaker

InactiveCN102024610AReduce deteriorationReduce the risk of consumptionHigh-tension/heavy-dress switchesAir-break switchesElectrical conductorInductor

The invention relates to a circuit breaker for improving insulating property while being capable of reducing the diameter of a metal container of the circuit breaker. The following components are arranged in the sealed container isolated by insulating clapboard of central conductor and filled with insulting gas: a fixed side conductor installed on the central conductor of insulating clapboard of one side; a fixed side contact element connected with the fixed side conductor; an electric arc contact terminal installed on the inner side of the fixed side contact element; a fixed side shielding hood allocated to surround the fixed side contact element; a movable element in contact with the fixed side contact element and the electric arc contact terminal and firstly cut off from the fixed side contact element before being turned off with the electric arc contact terminal; a spring driving the electric arc contact terminal to move along the axial direction if the movable element is cut off; and a following device of supporting framework; besides, a serially connected inductor provided with coil part or magnet is inserted between an electric arc extinguishing part of the electric arc contact terminal and the fixed side conductor.

Owner:HITACHI LTD

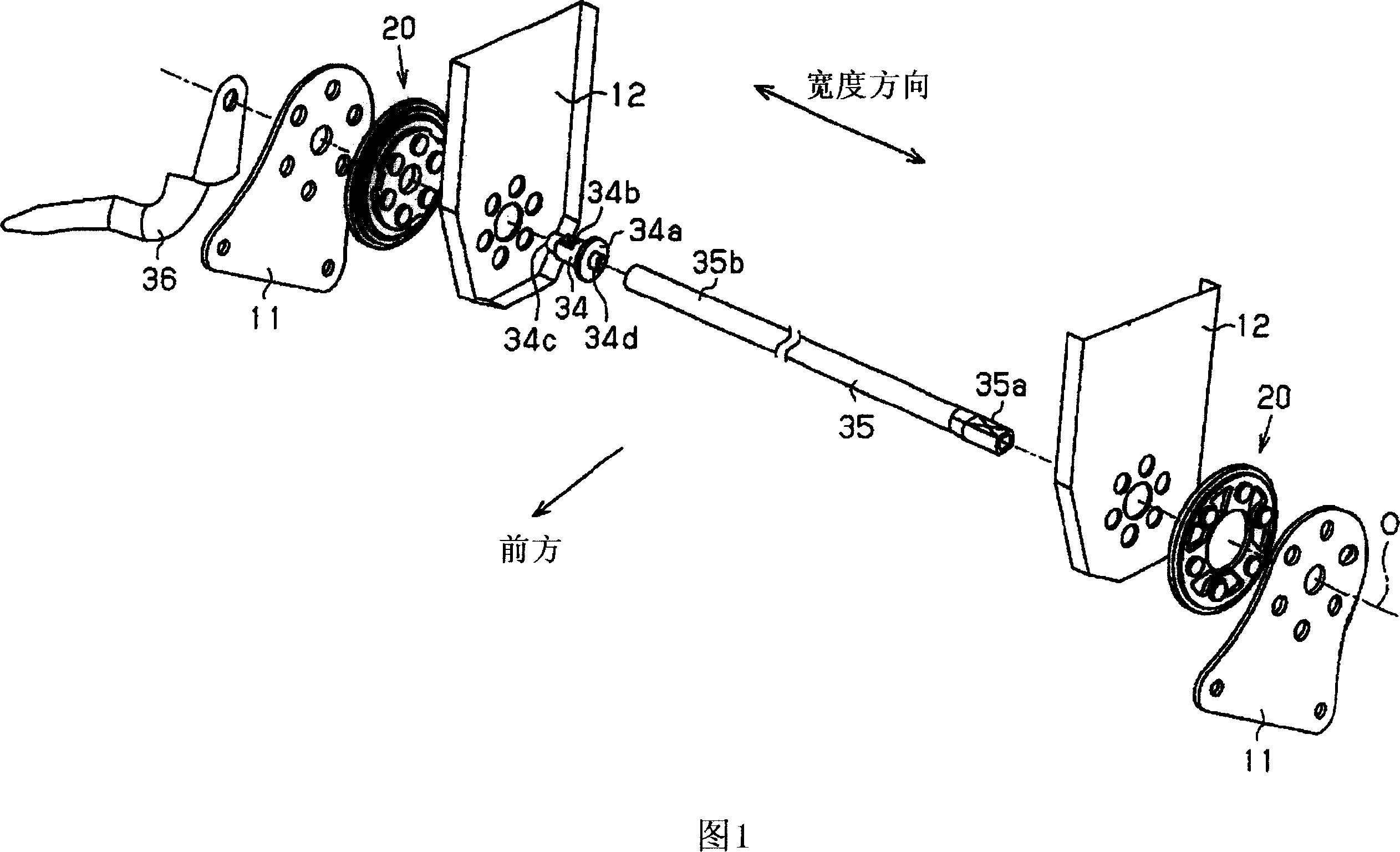

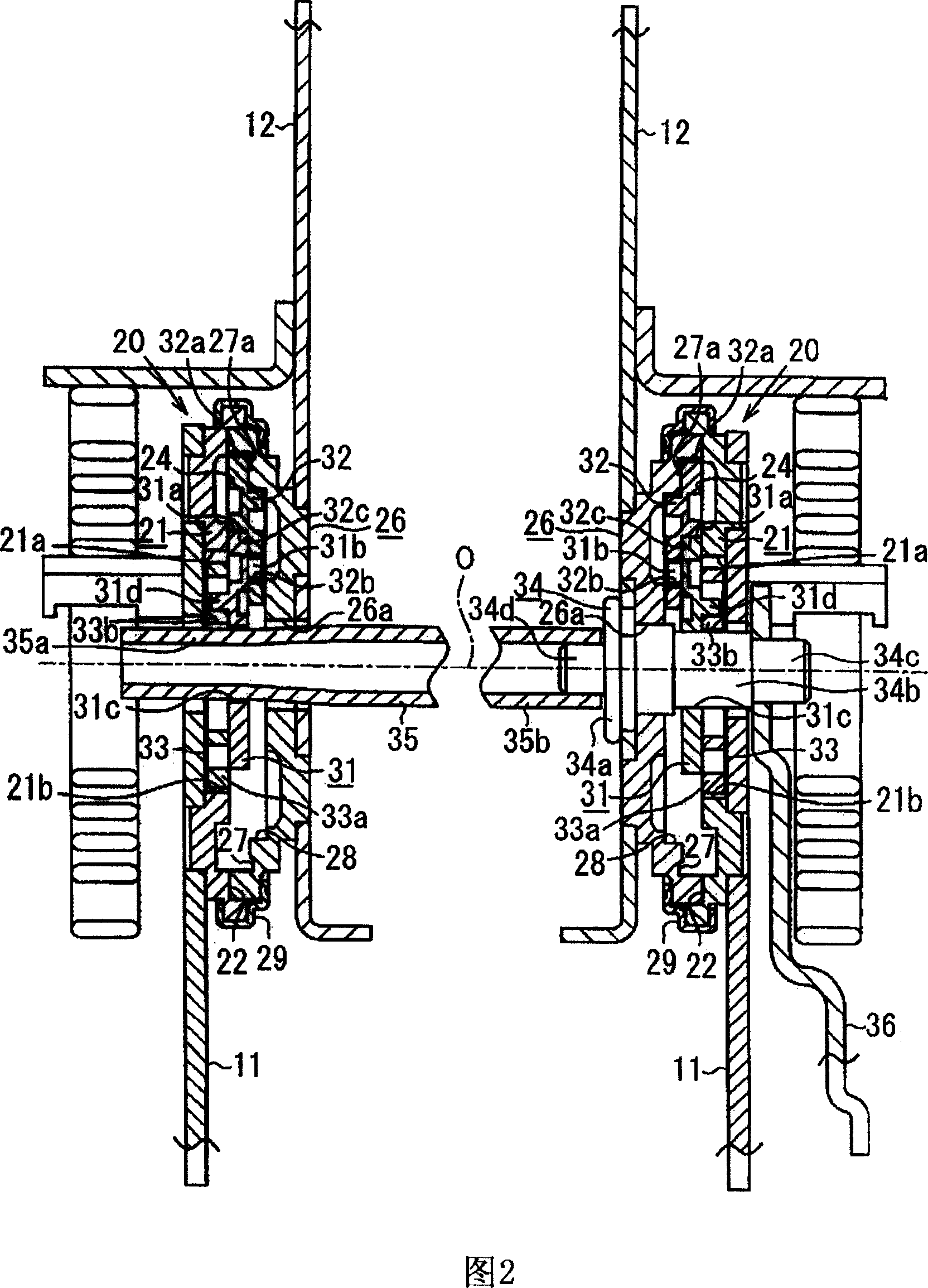

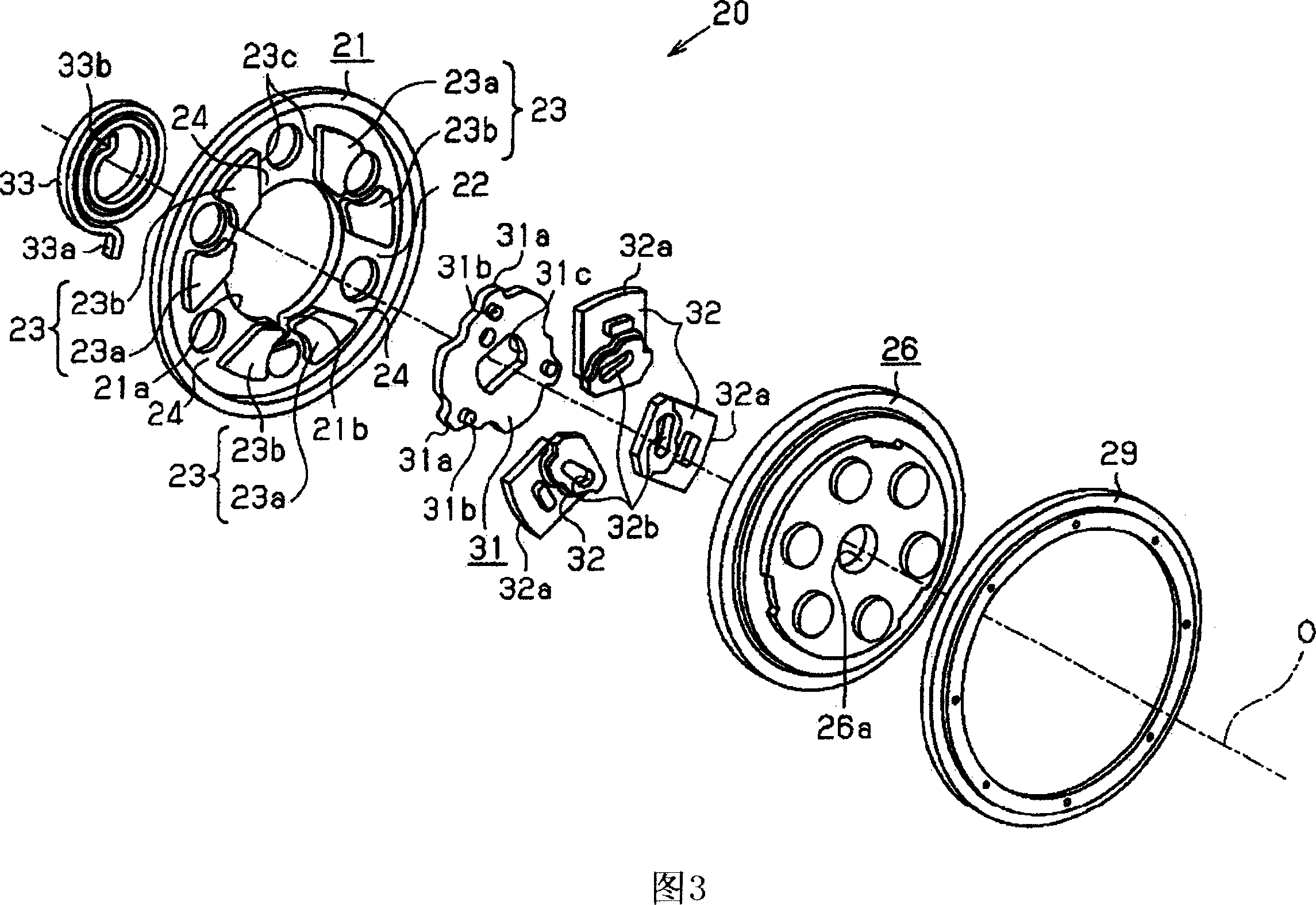

Seat reclining apparatus for vehicle

InactiveCN1982118AReduced parts countReduce manufacturing processMovable seatsRotational axisCushion

A vehicle seat reclining device includes a lock mechanism at each side of the vehicle seat for restricting or allowing a rotational movement of a seat back relative to a seat cushion. The lock mechanism includes a cam mechanism rotating around a rotational axis of the seat back relative to the seat cushion for restricting or allowing the relative rotation between the seat back and the seat cushion. The cam mechanism includes an engagement hole and a first shaft provided at the lock mechanism having an engagement portion engaging with the engagement hole with a clearance The other side lock mechanism includes a second shaft and a connecting portion for connecting the second shaft with the first shaft, wherein the second shaft is connected with the first shaft in such a manner that a rotation position of the second shaft is adjusted to agree with a rotation allowing timing of the relative rotation between the seat back and the seat cushion by the lock mechanisms.

Owner:AISIN SEIKI KK

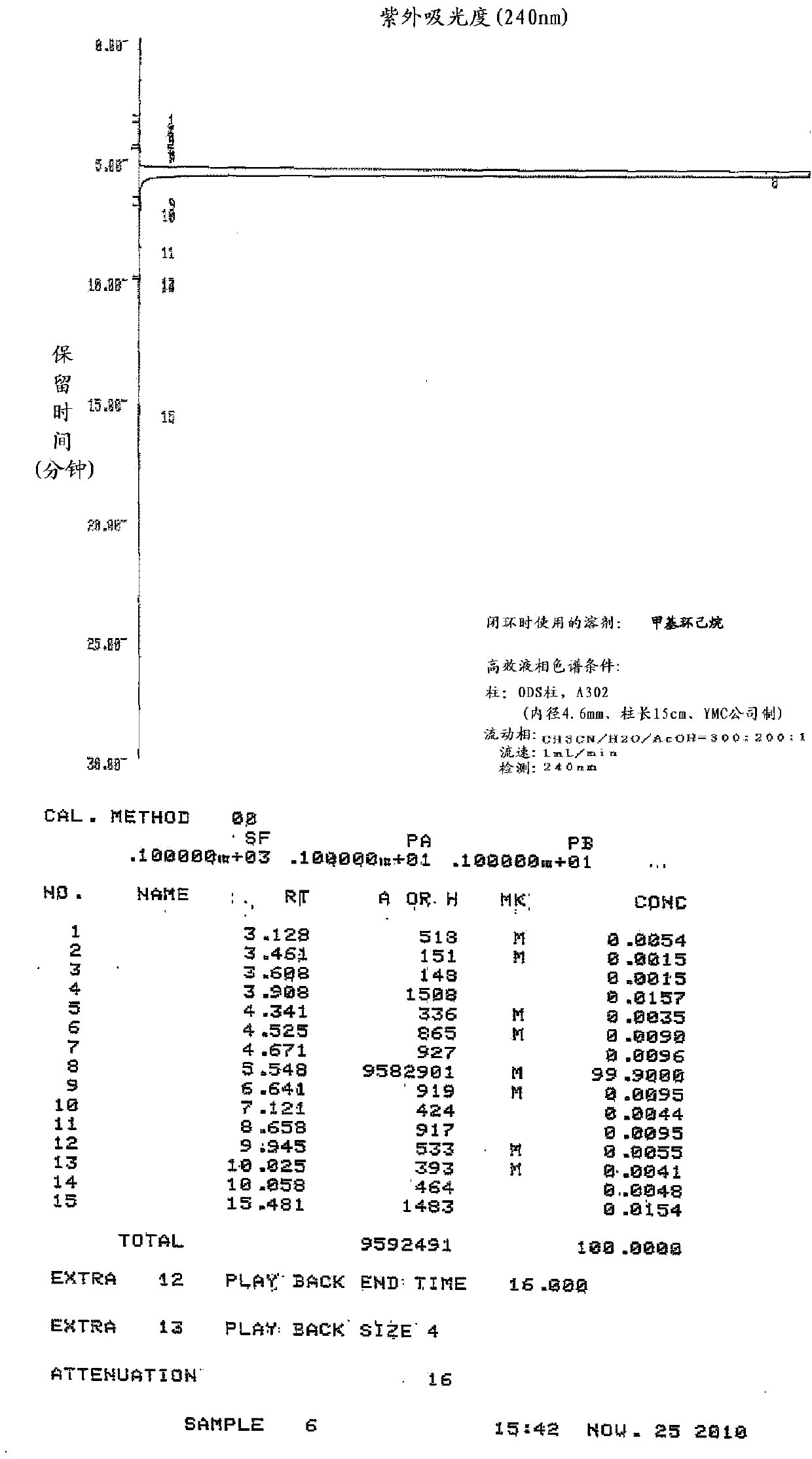

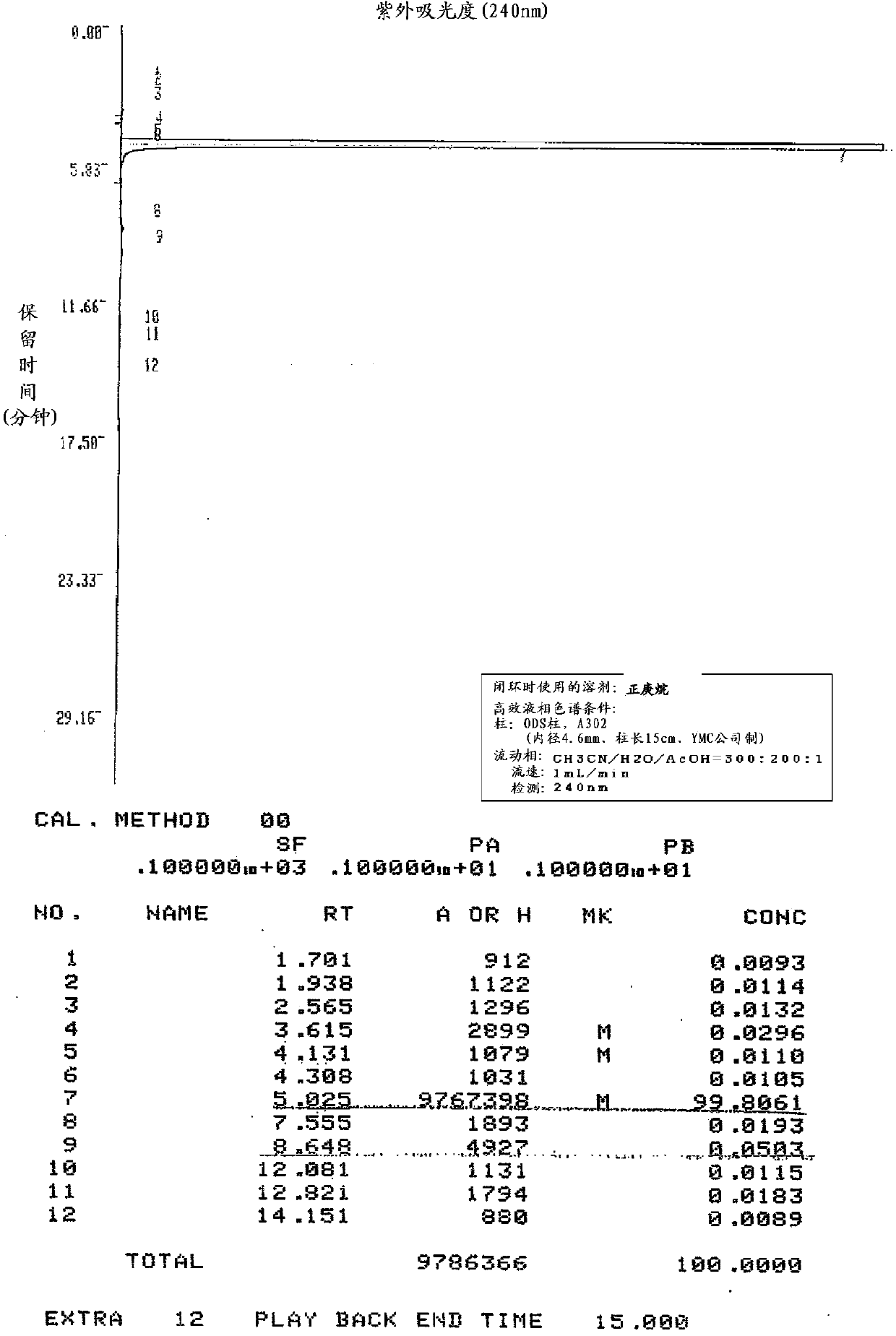

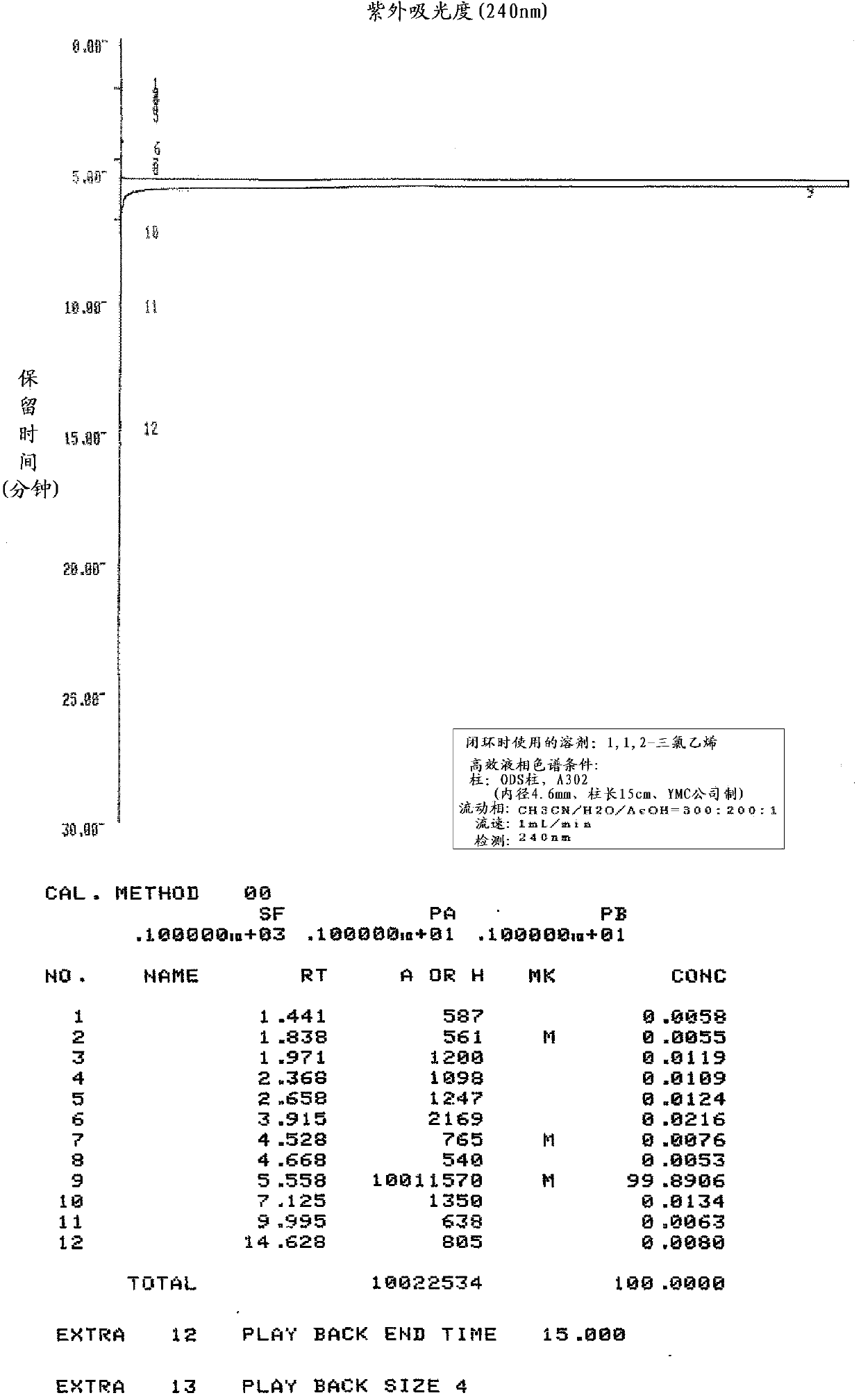

Method for producing zaltoprofen and derivative thereof

ActiveCN104185633ADon't worry about pollutionReduce usageOrganic chemistryAntipyreticOrganic solventActive ingredient

The invention pertains to a method for producing zaltoprofen or a zaltoprofen derivative by an intramolecular cyclization reaction of the Friedel-Crafts reaction type, wherein zaltoprofen or a zaltoprofen derivative is produced at an industrially usable yield, simply, economically, and on an industrial scale at adequate purity for use as a pharmaceutical active ingredient without generating detectable amounts of dimer or other such impurities, using polyphosphoric acid in a quantity of 6.5 times or less the uncyclized raw material compound as a condensing agent. Specifically, the invention pertains to a method for producing zaltoprofen or a zaltoprofen derivative by cyclization of an uncyclized raw material compound in the presence of one or more organic solvents selected from the group consisting of 1,1,2-trichloroethene, methyl cyclohexane, cyclohexane, n-heptane, and the like.

Owner:NIPPON CHEMIPHAR CO LTD

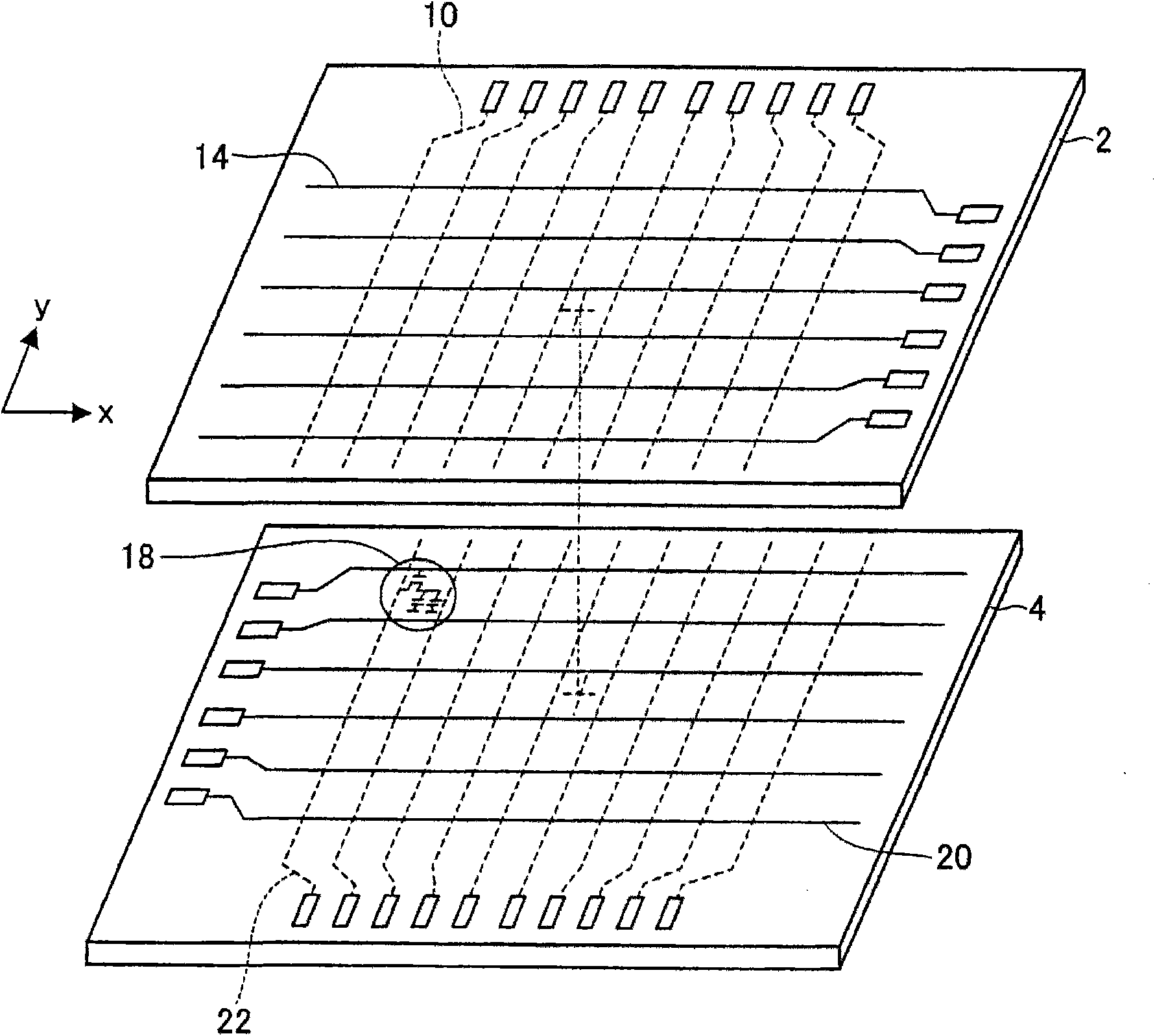

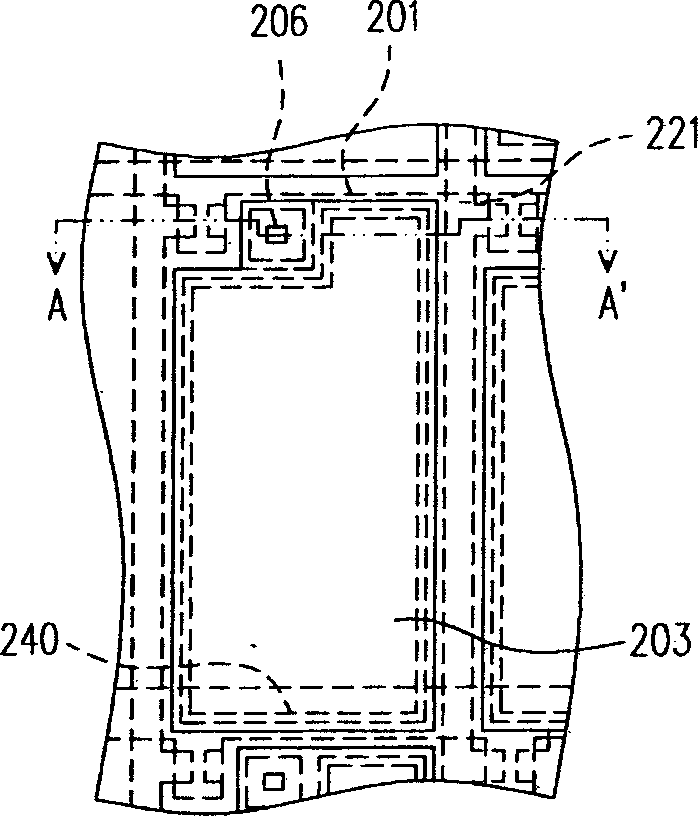

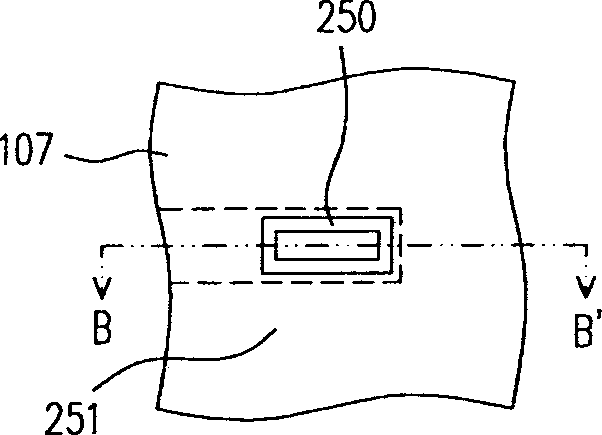

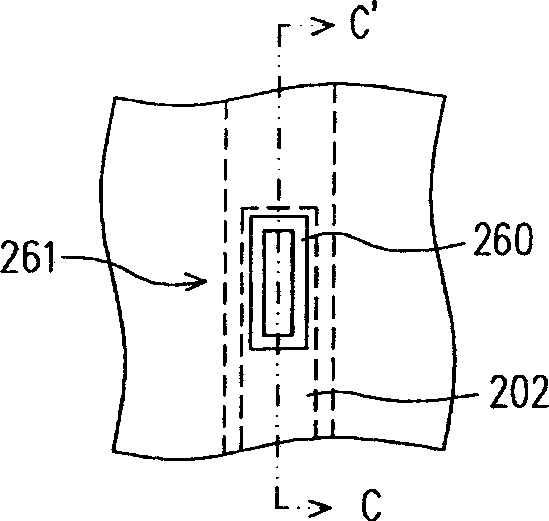

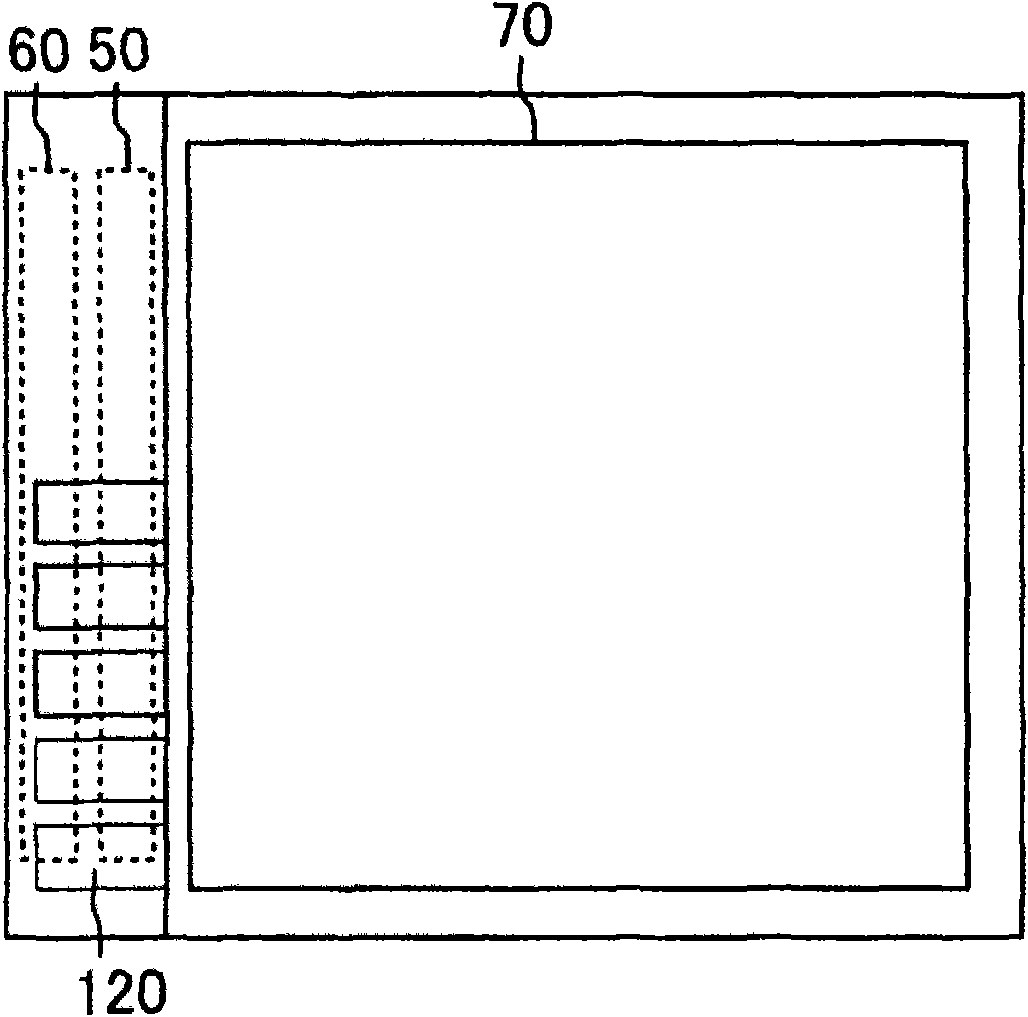

Circuit board, display device and liquid crystal display device

InactiveCN101681072AAvoid corrosionAvoid disconnectionPrinted circuit detailsNon-linear opticsDriver circuitLiquid-crystal display

Provided is a monolithic circuit board, which has, on a substrate, a driver circuit for driving a pixel, and an external connecting terminal for supplying the driver circuit with signals and power for driving the circuit from the external, and has a reduced frame area. A display device and a liquid crystal display device provided with the circuit board are also provided. In the circuit board, thedriver circuit for driving the pixel and the external connecting terminal are arranged on the substrate. The circuit board has wiring arranged on a lower layer of an external connecting terminal.

Owner:SHARP KK

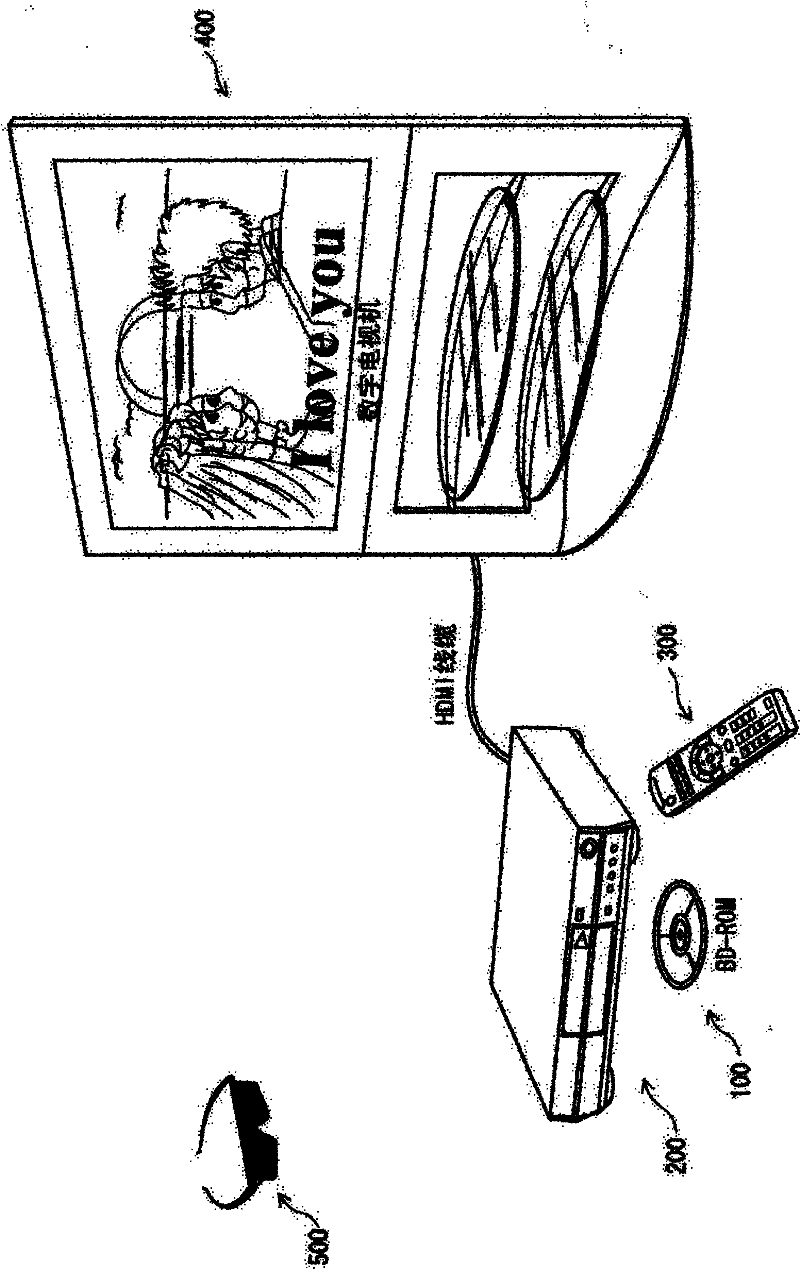

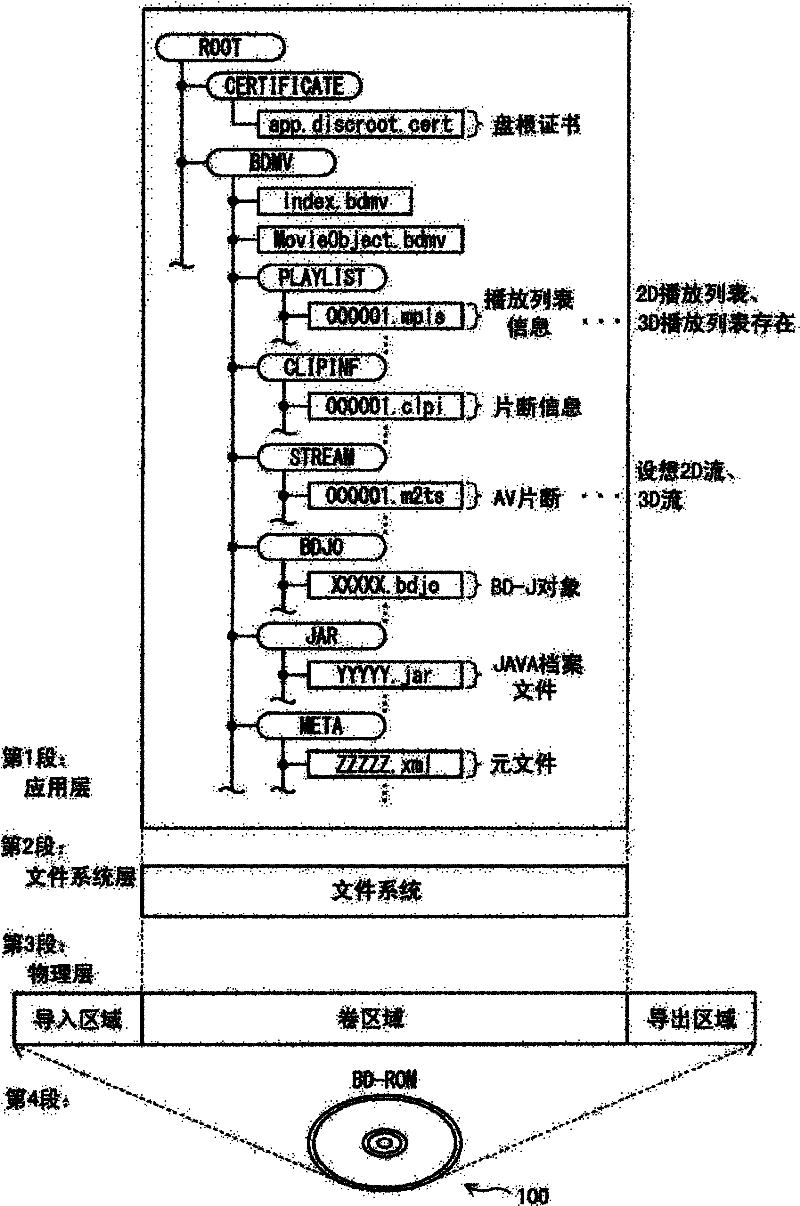

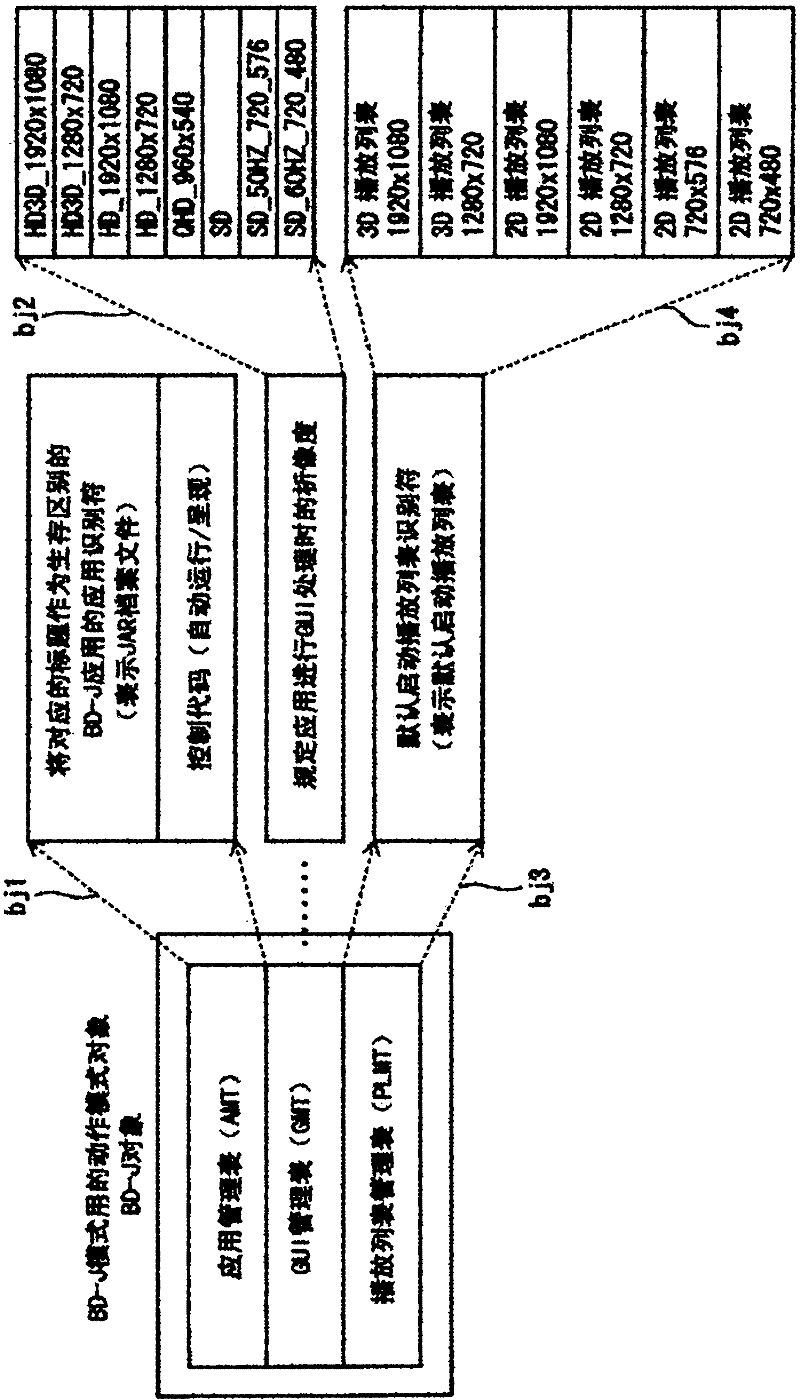

Playback device capable of stereoscopic playback, playback method, and program

InactiveCN102100076AProper stereopsis reproductionSkip the manufacturing processTelevision system detailsRecord information storageGraphicsLeft direction

Disclosed is a playback device that provides stereopsis by outputting each of a plurality of video frames stored in a video plane as a right-view video frame and a left-view video frame. A graphics plane stores image data with resolutions of 1920x1080 and 1280x720 as graphics data, and a shift engine shifts the coordinates of each item of image data in the graphics plane in either the right or left directions to execute left-view output while also shifting the coordinates of each item of image data in the graphics plane in the direction opposite from the left view to execute right-view output.

Owner:PANASONIC CORP

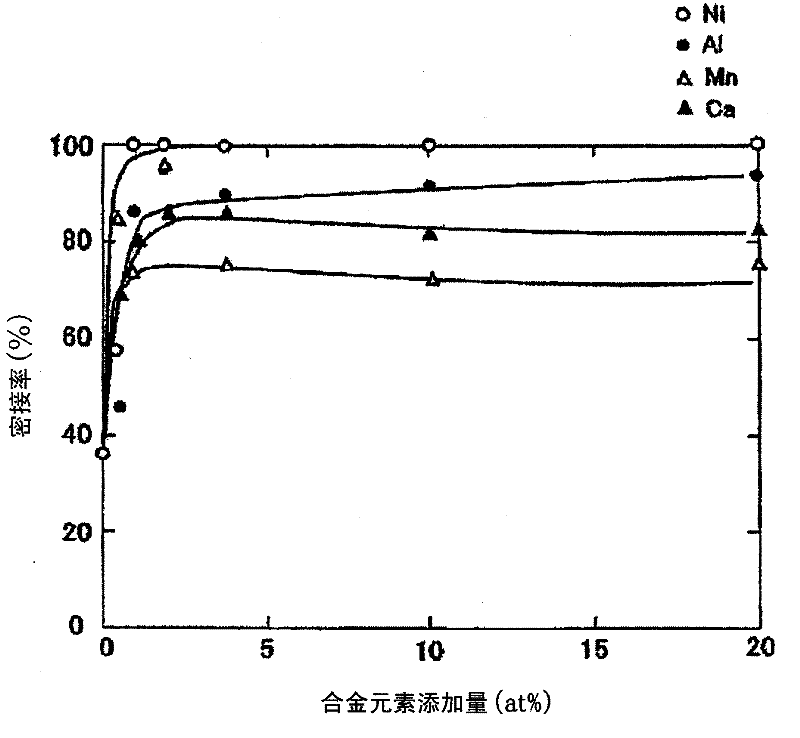

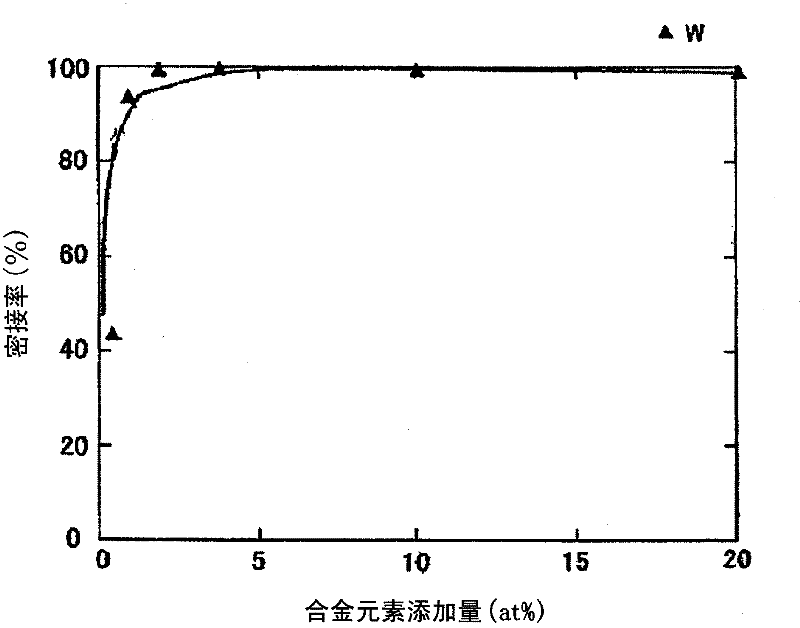

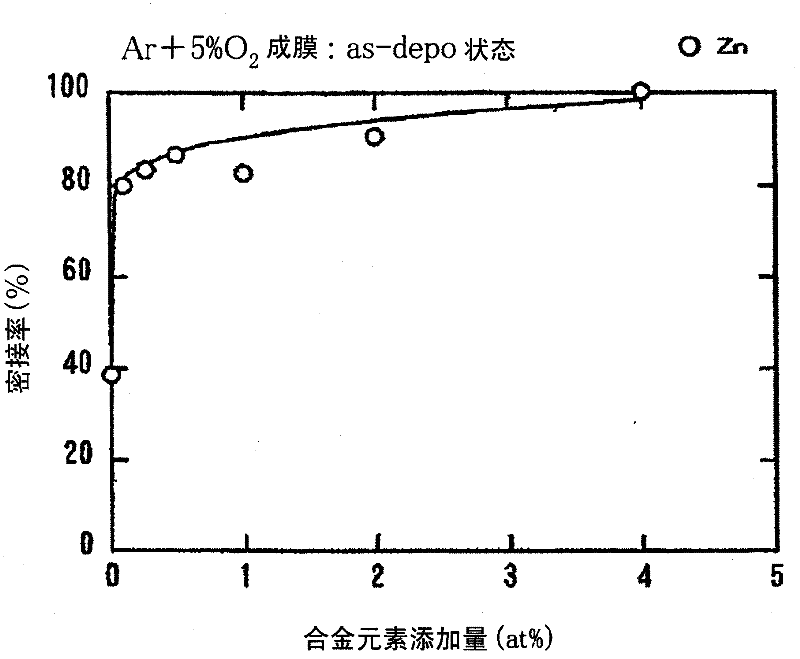

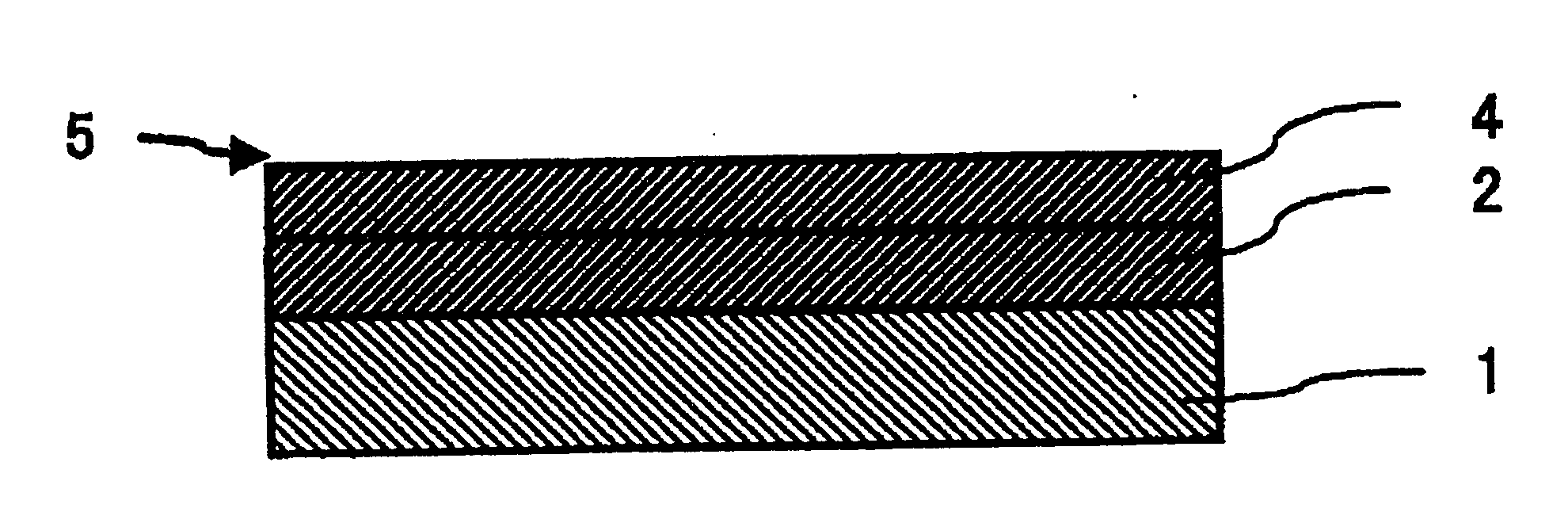

Cu alloy film and display device

InactiveCN102246311AExcellent adhesionLow resistivityTransistorSemiconductor/solid-state device detailsDisplay deviceAlloy

Disclosed is a Cu alloy film which has high adhesion to a transparent substrate or a semiconductor layer, a low electrical resistivity and excellent wet etching properties. Specifically disclosed is a Cu alloy film for use in a display device, which is an oxygen-containing alloy film that meets the following requirements (1) and (2): (1) the Cu alloy film contains at least one element selected from a group consisting of Ni, Al, Zn, Mn, Fe, Ge, Hf, Nb, Mo, W and Ca in the total amount of 0.10 to 10 at.% inclusive; and (2) the Cu alloy film has an under layer and a top layer having different oxygen contents from each other, wherein the under layer is contacted with the transparent substrate or the semiconductor layer and has an oxygen content higher than that in the top layer.

Owner:KOBE STEEL LTD

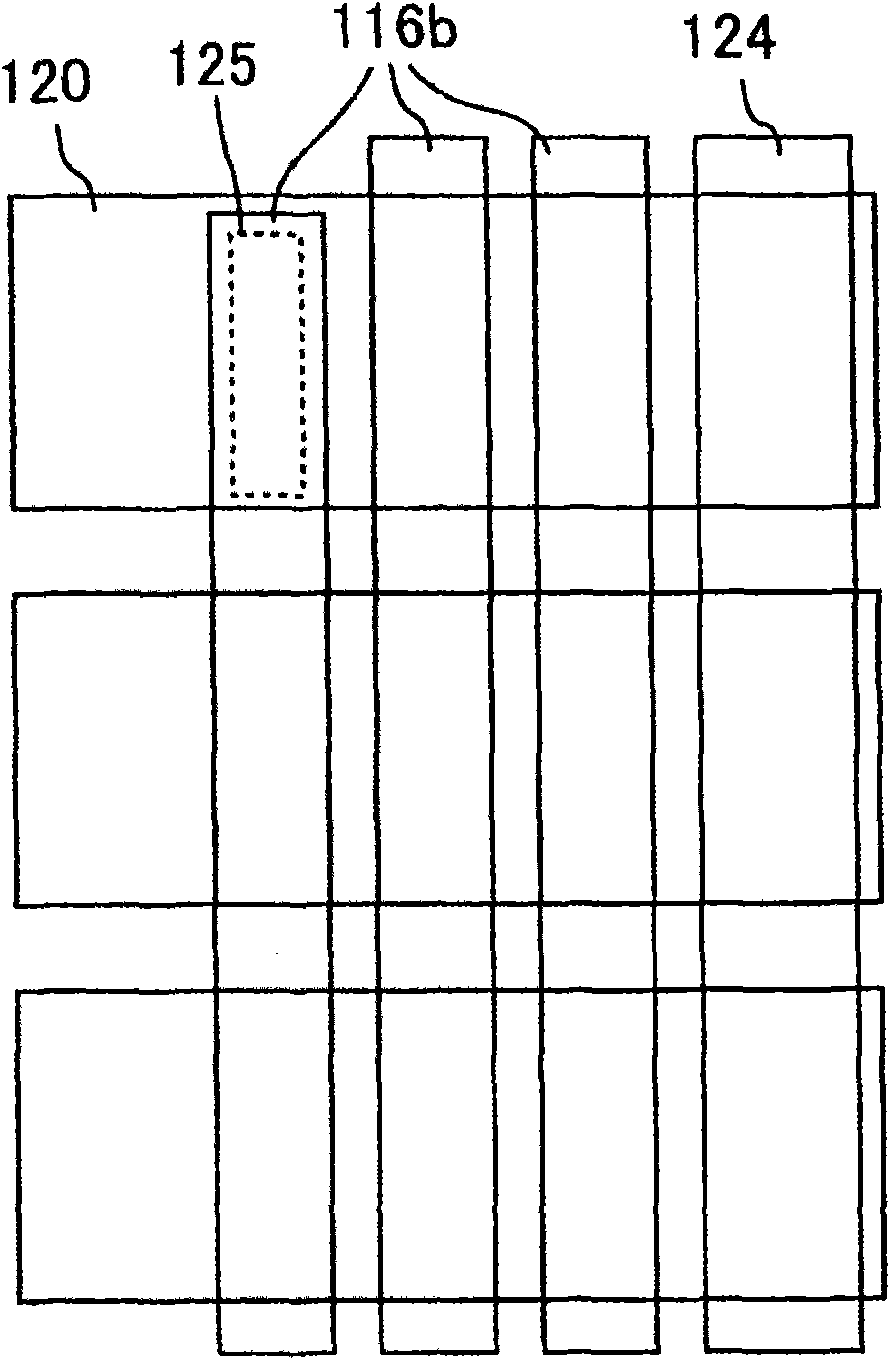

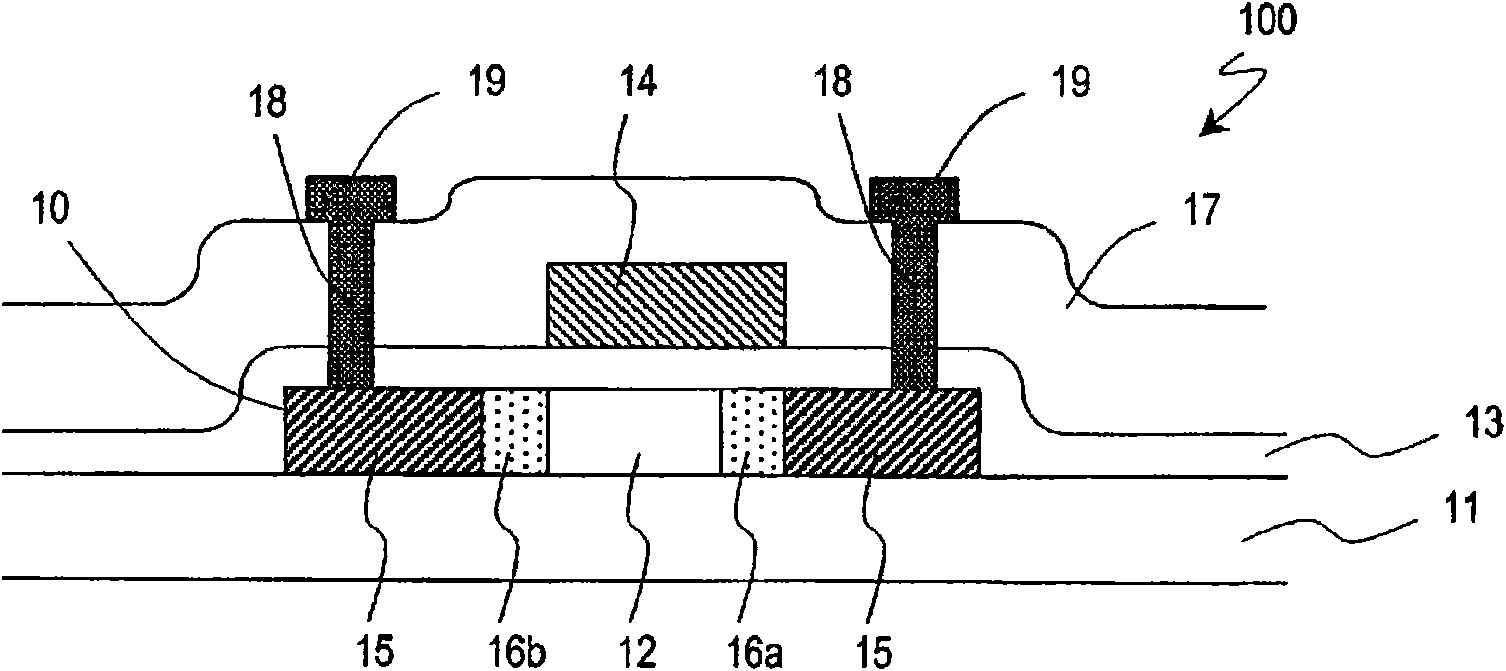

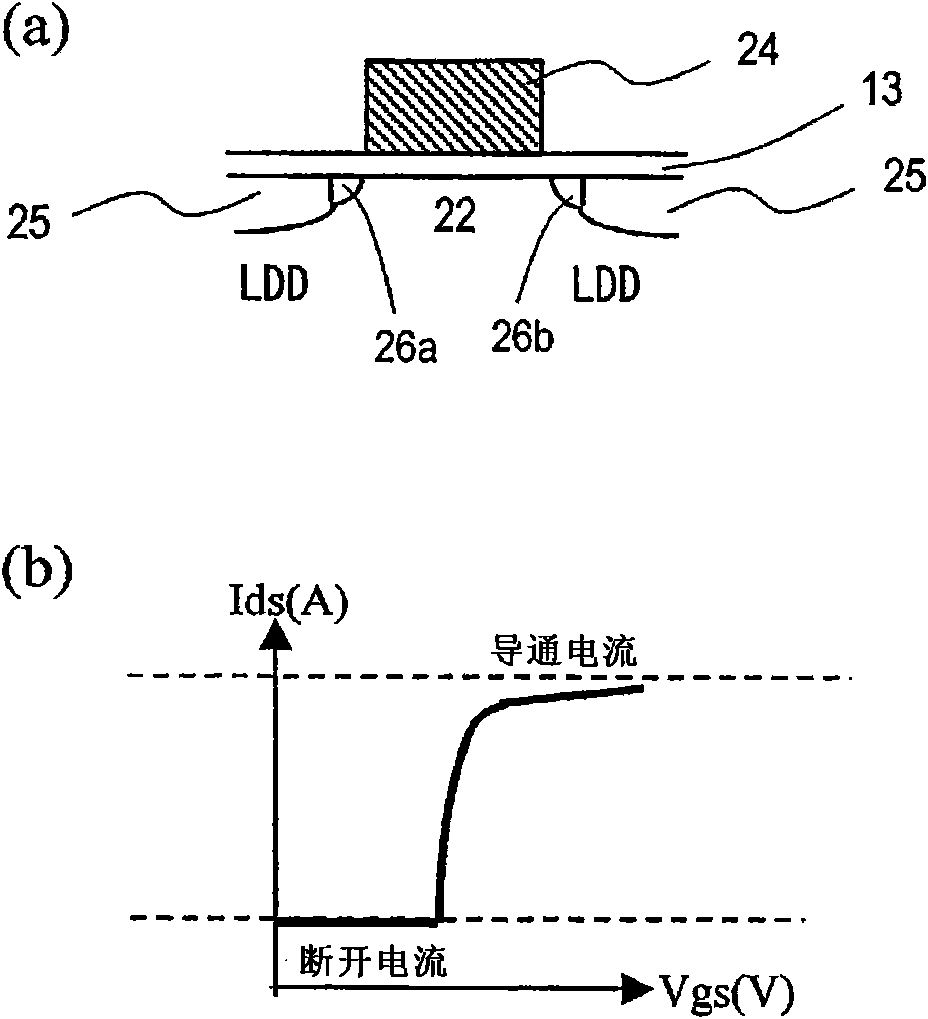

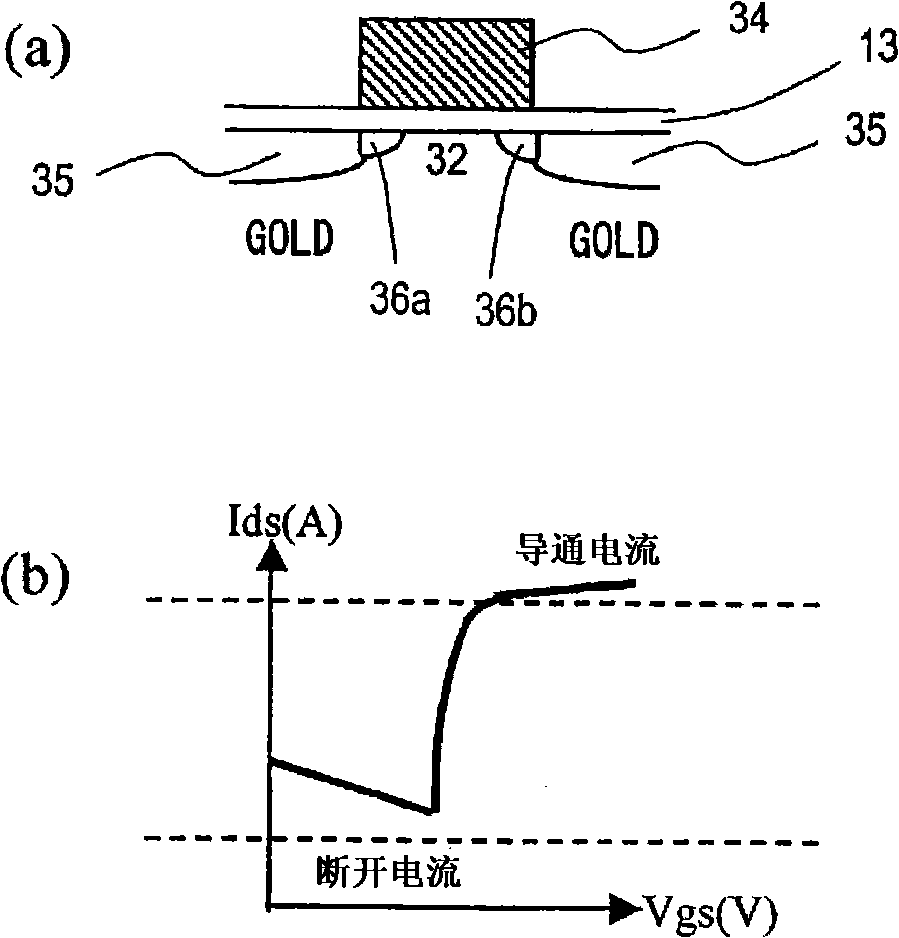

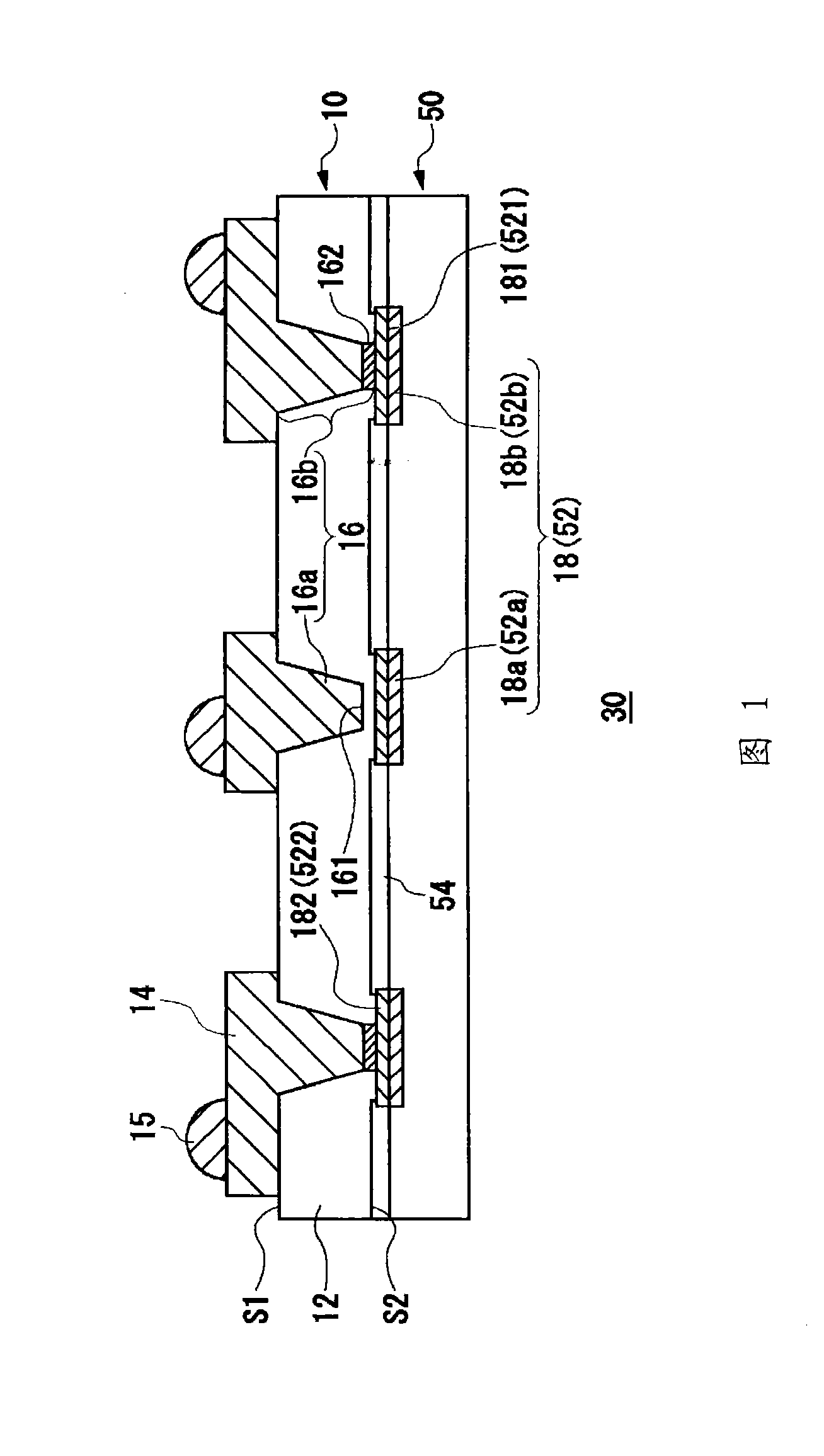

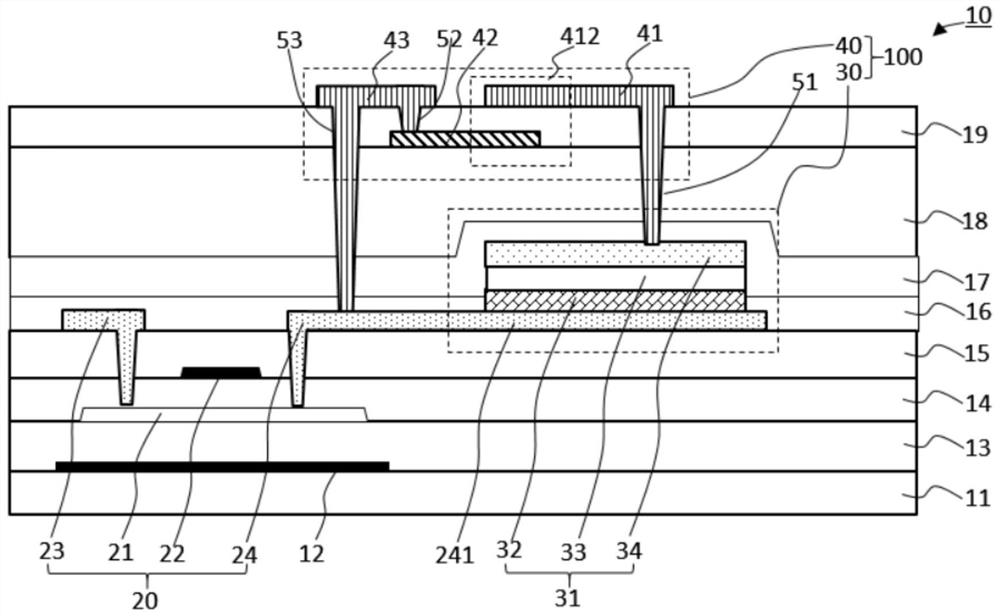

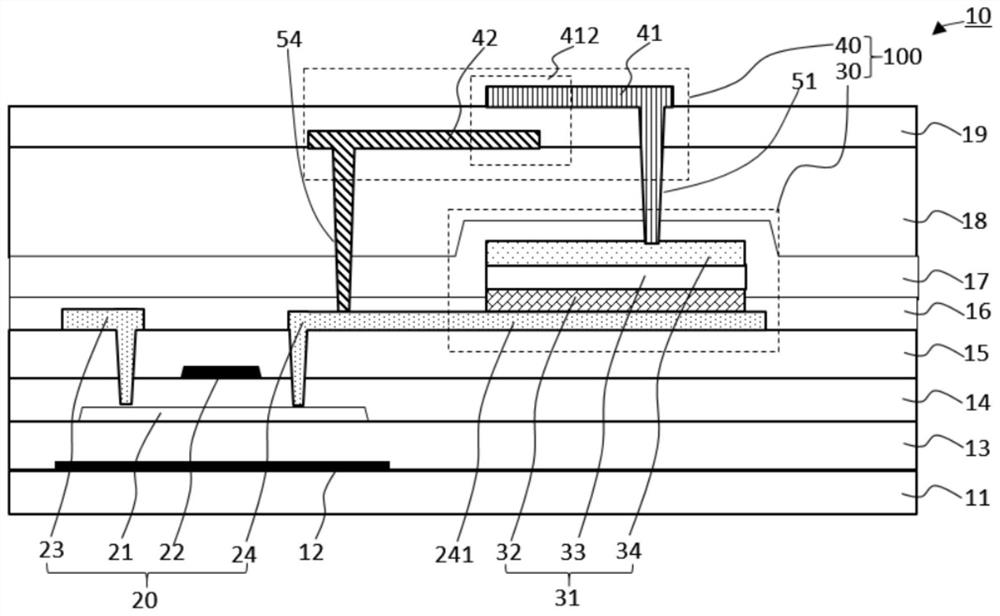

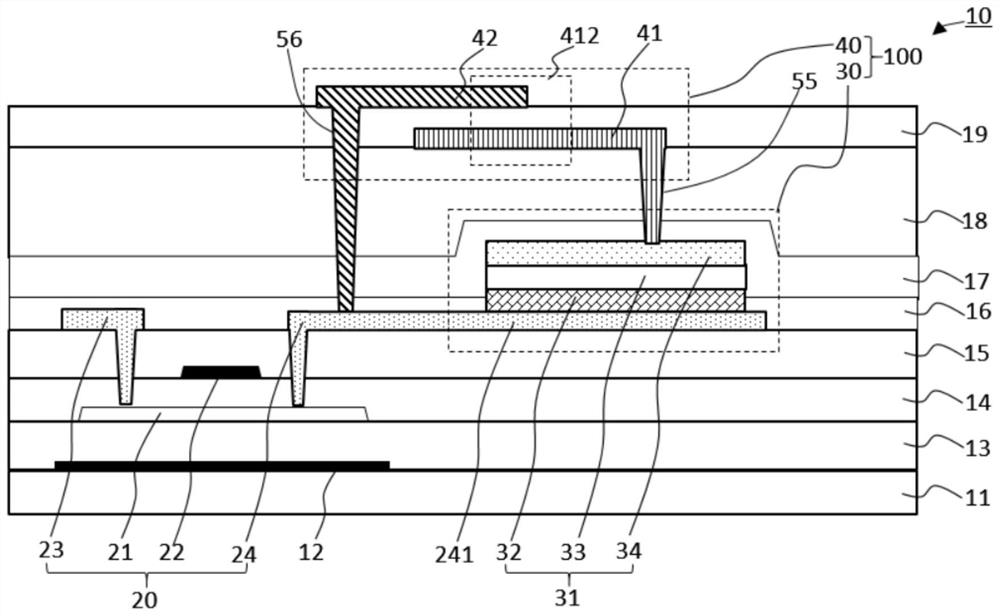

Semiconductor device and method for manufacturing the same

InactiveCN101925988AEnsure current driving forceReduce the number of manufacturing processesTransistorSemiconductor/solid-state device manufacturingImpuritySemiconductor

Provided is a semiconductor device wherein a gate electrode (14) of a thin film transistor (100) is formed of a single conductive film, and a semiconductor layer (10) is provided with a first low-concentration impurity region, which is arranged between the channel region (12) and the source region (15), and has an impurity concentration lower than the impurity concentrations of the source region and the drain region (15), and a second low-concentration impurity region, which is arranged between the channel region (12) and the drain region (15), and has an impurity concentration lower than the impurity concentrations of the source region and the drain region (15). A region (16a), which is one of the first and the second low-concentration impurity regions, entirely overlaps with the gate electrode (14), and a region (16b), which is the other one of the first and the second low-concentration impurity regions, does not overlap with the gate electrode (14).

Owner:SHARP KK

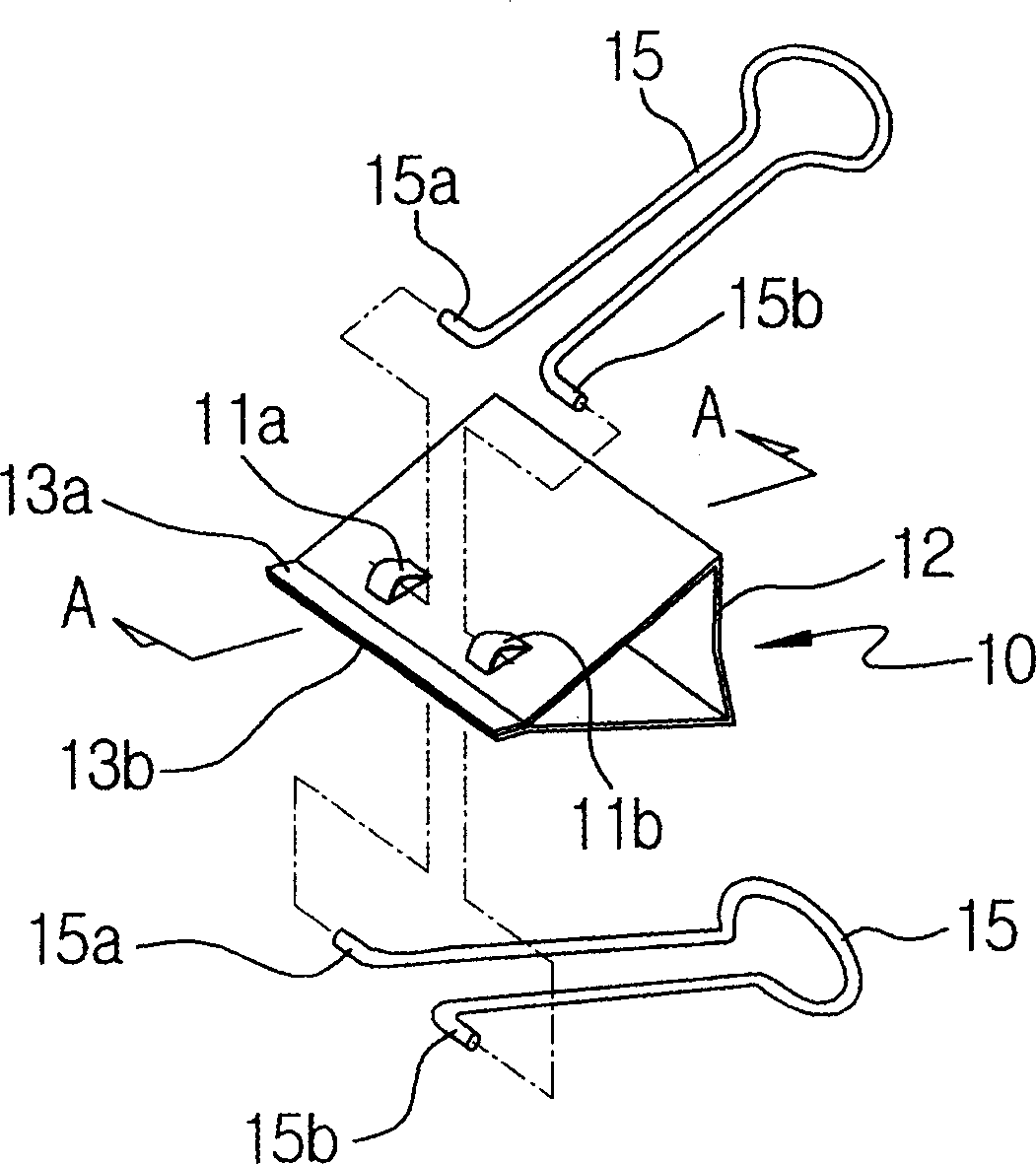

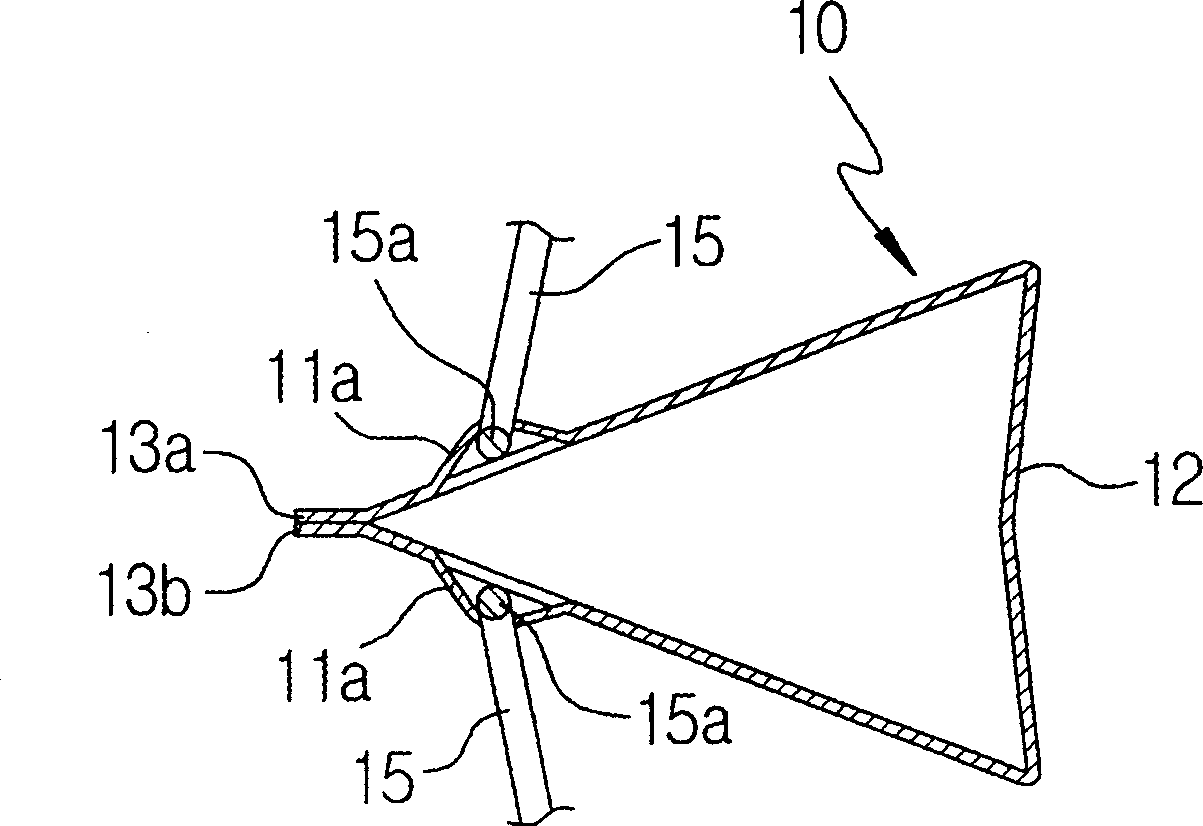

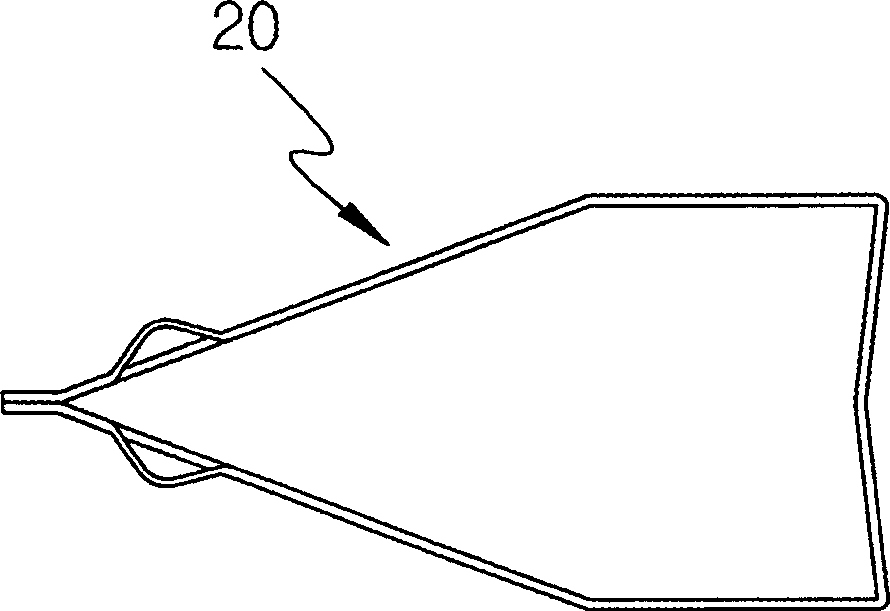

Clip for office

InactiveCN1880102AReduce manufacturing costsReduce the number of manufacturing processesSheet bindingEngineeringSheet material

The invention provides a clip for office use, which comprises a main body made of sheet material, a bended portion with a center, two pairs of hook-like cramping grooves, two outward projections, a pair of handles and a pair of inserted protrusions.

Owner:金荣熙

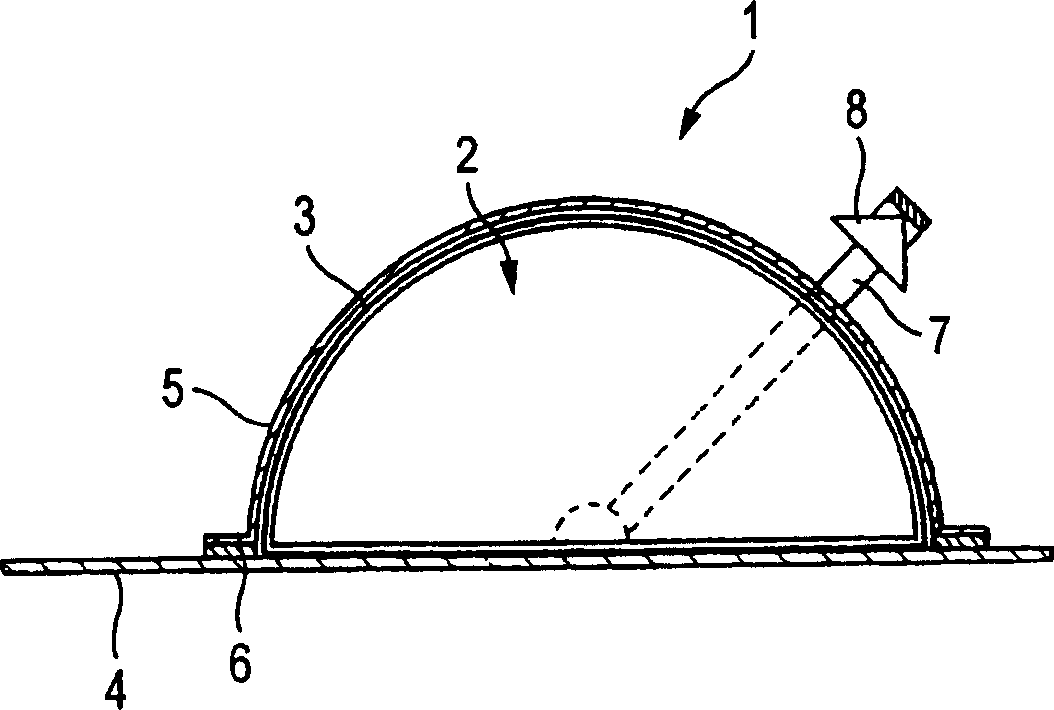

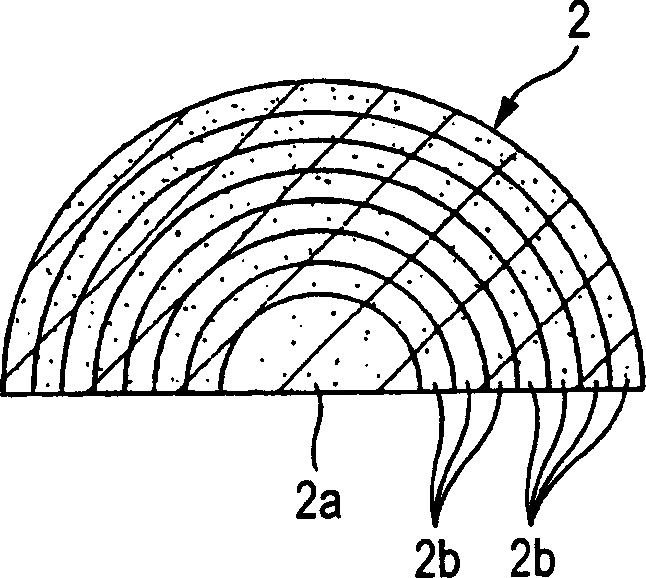

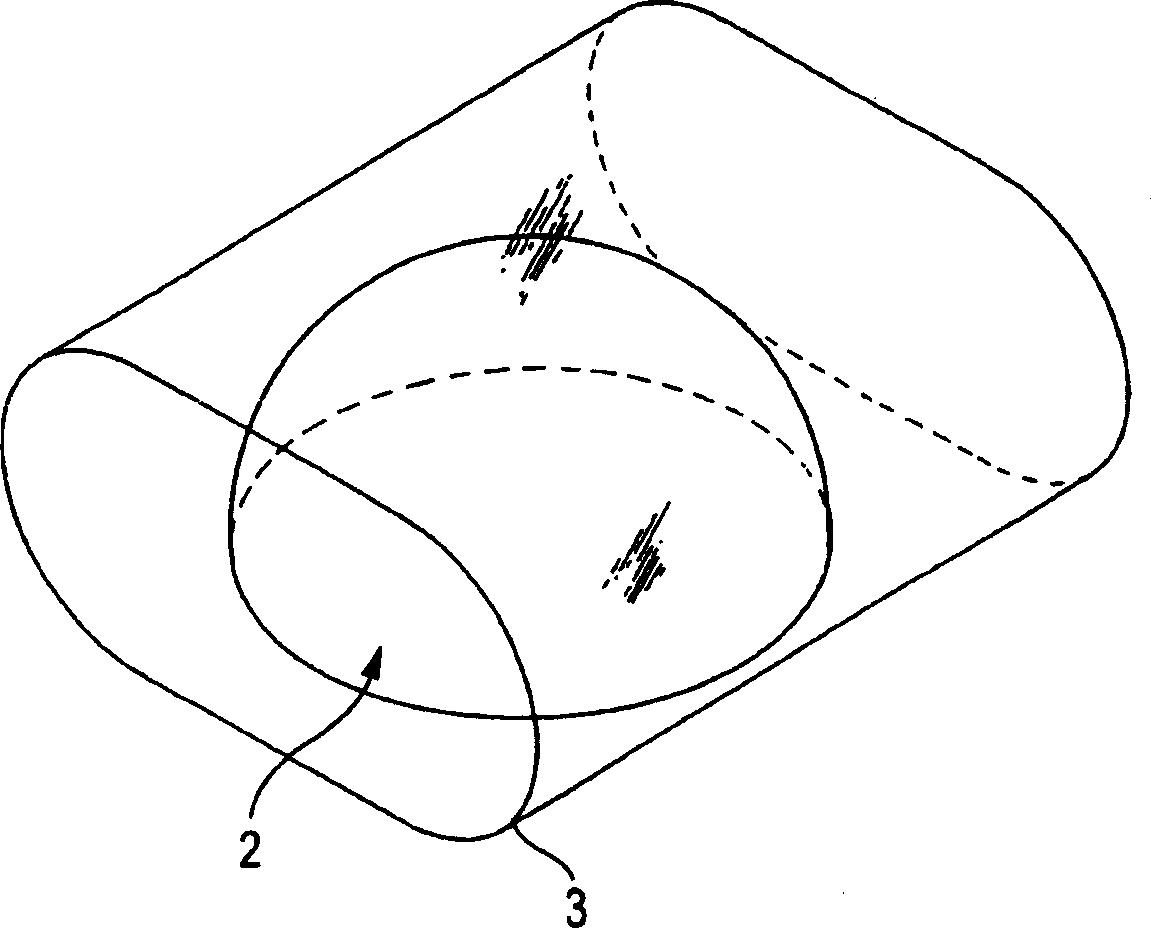

Luneberg lens and antenna device using the same

InactiveCN1864304AEliminate displacementImprove moisture resistanceAntennasComputational physicsSynthetic resin

A luneberg lens, which is configured by combining a plurality of lens parts, has a problem on keeping of a combined condition of lens parts and securement of good moisture prevention, and displacement of lens parts not only becomes a cause of cost-up but also has a bad influence on an electric performance, and furthermore, intrusion of moisture and humidity deteriorates an electric performance, and therefore, these problems are solved by a simple and inexpensive method. A lens portion 2, which is configured by combining lens parts of spherical core and spherical shell-like resin foams, is configured by a luneberg lens which is sealed by a synthetic resin film 3 which is formed along a surface of that lens portion 2 and in which a thickness is 100 m or less and of which own relative dielectric constant is higher than a relative dielectric constant of the outermost layer of the above-mentioned lens portion.

Owner:SUMITOMO ELECTRIC IND LTD

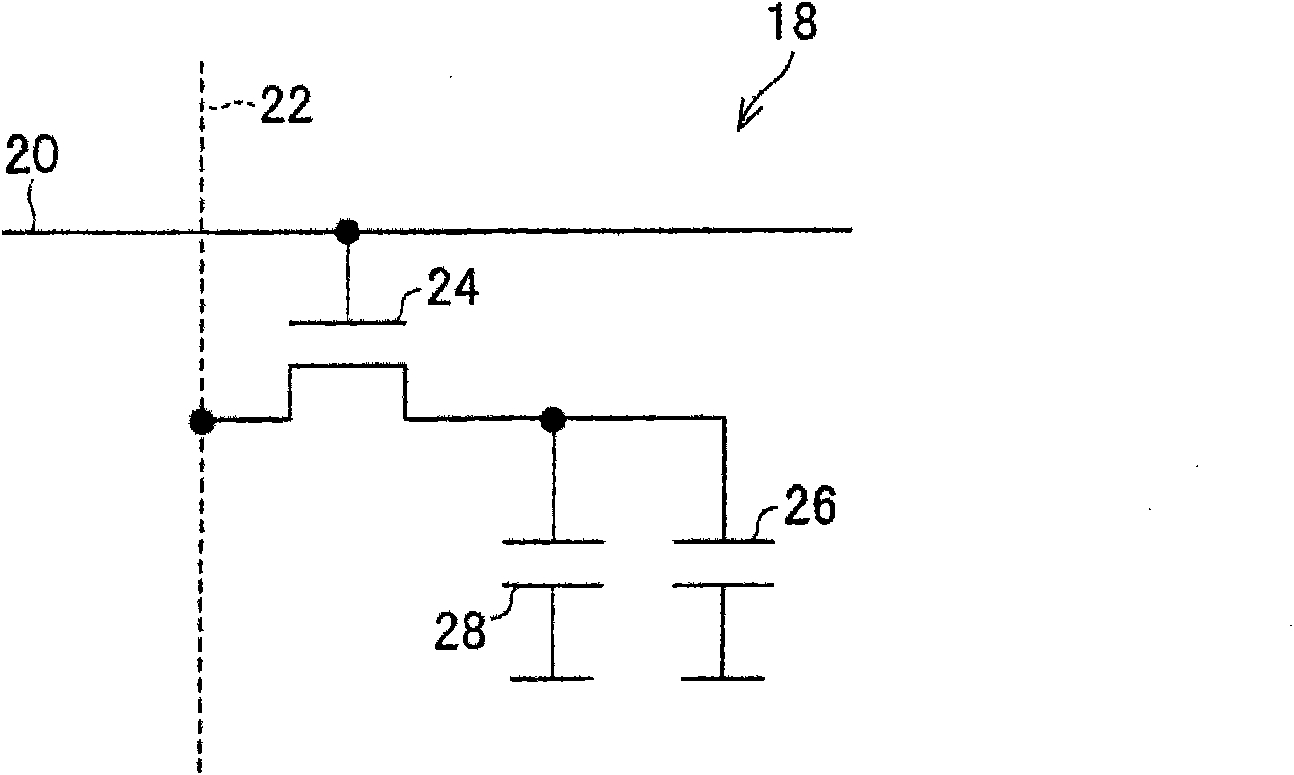

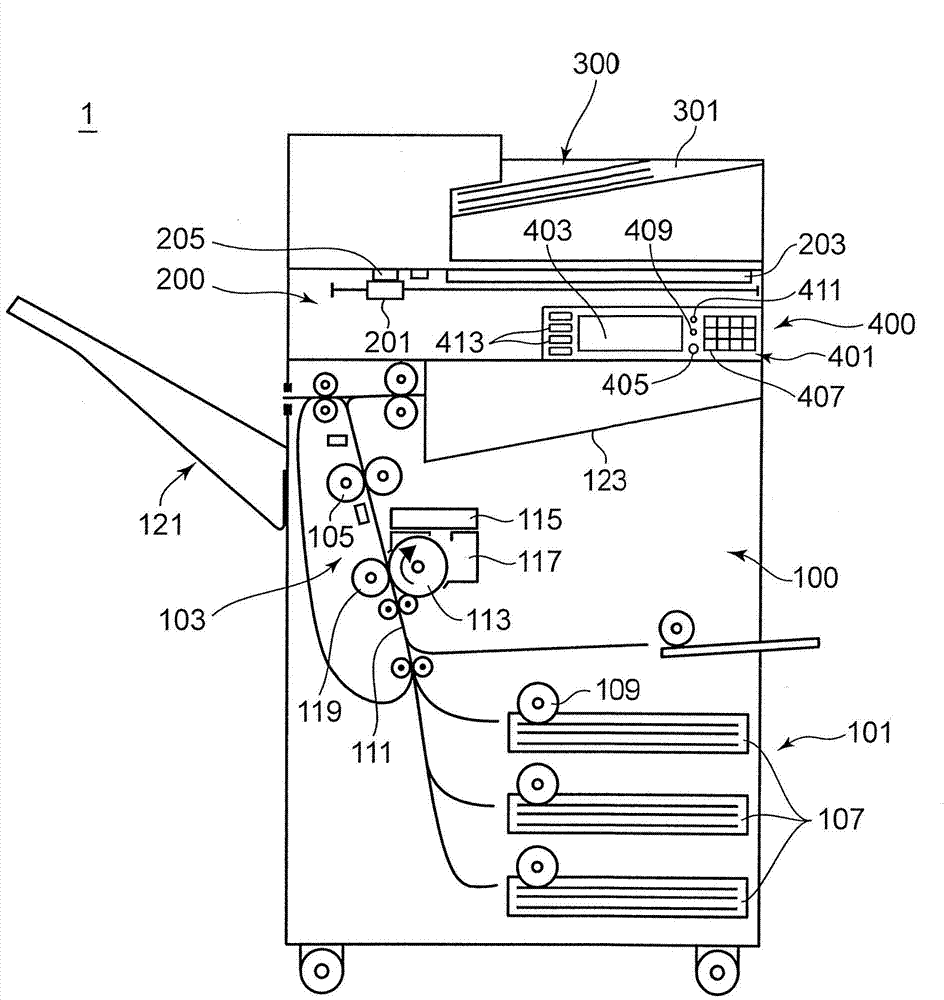

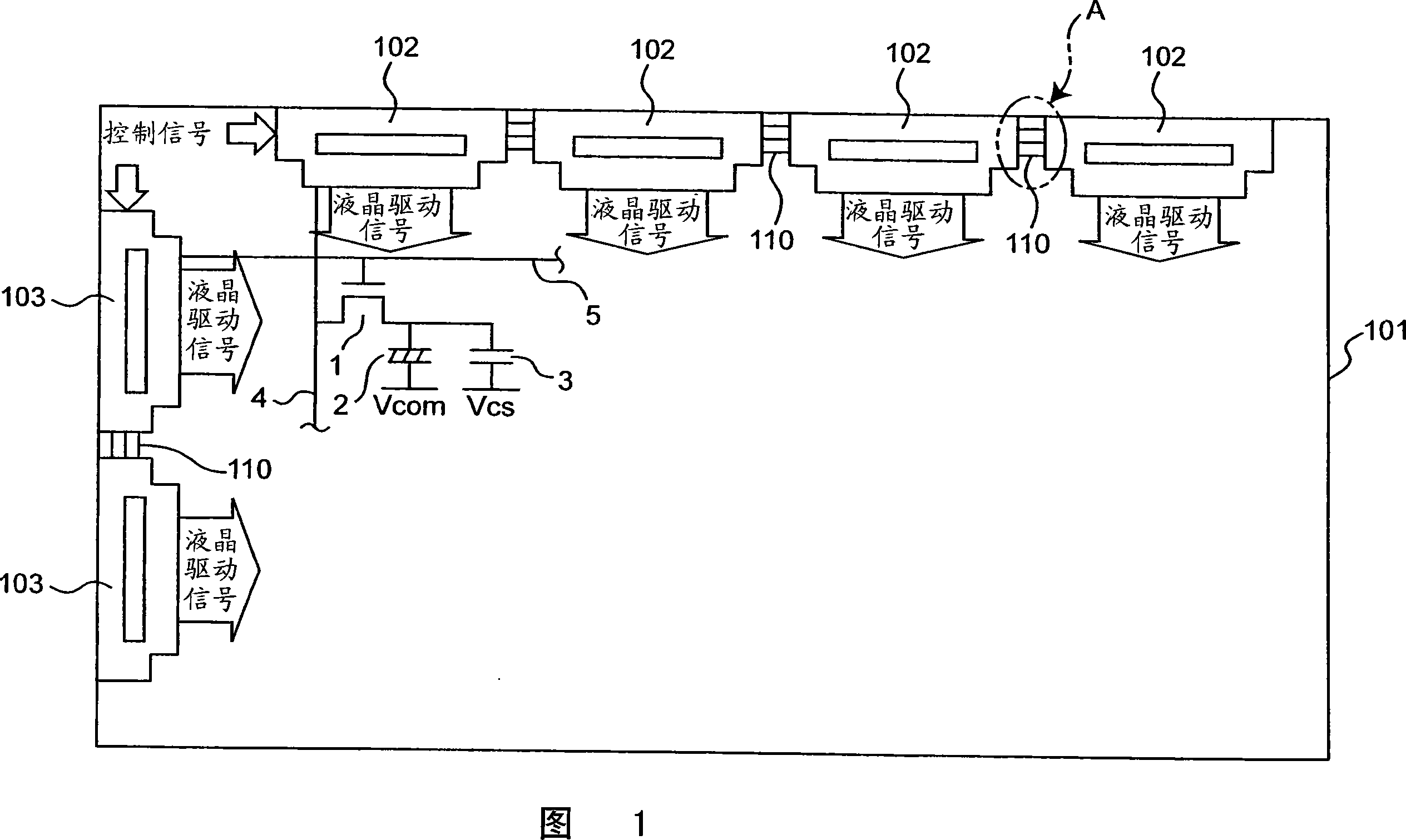

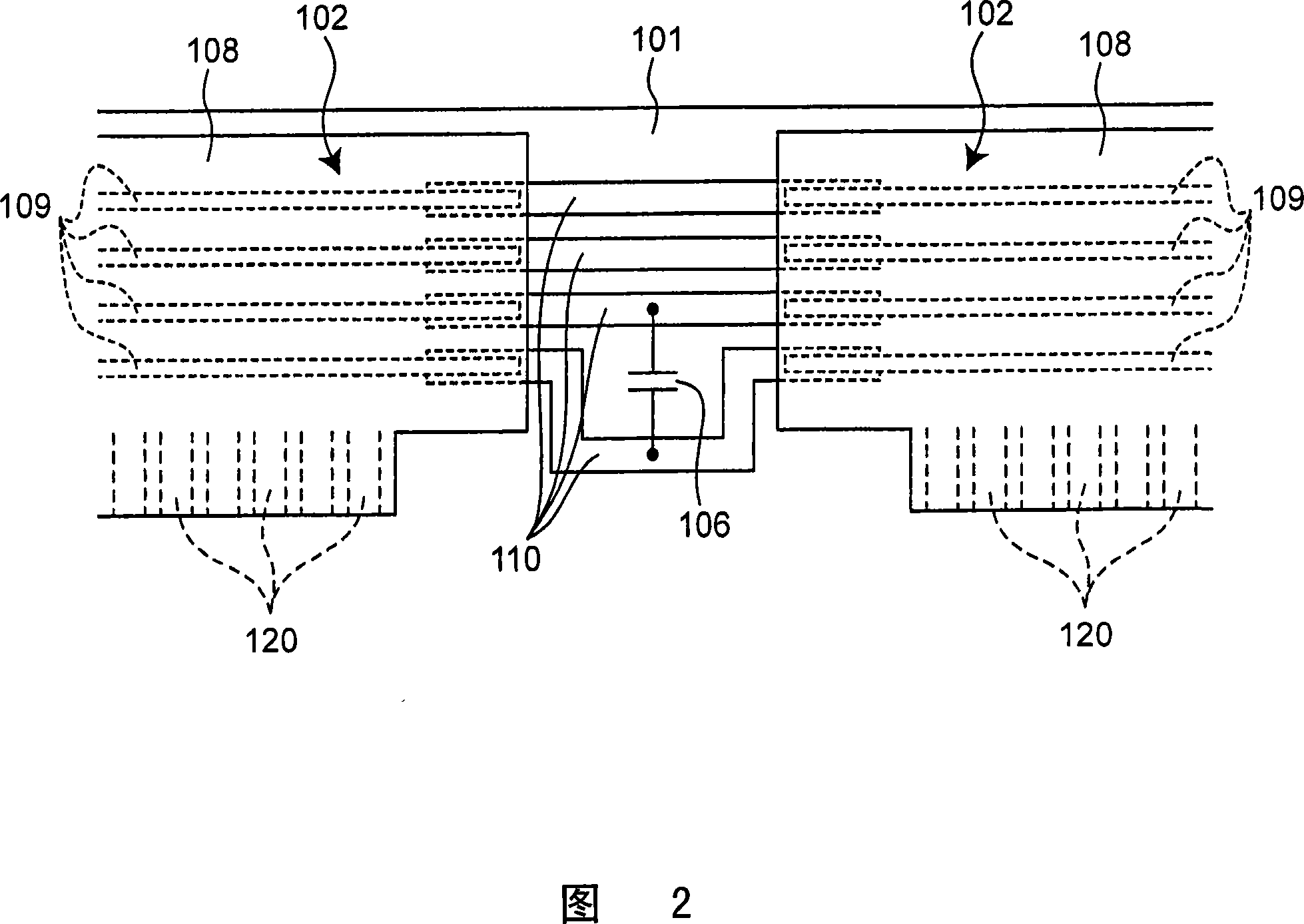

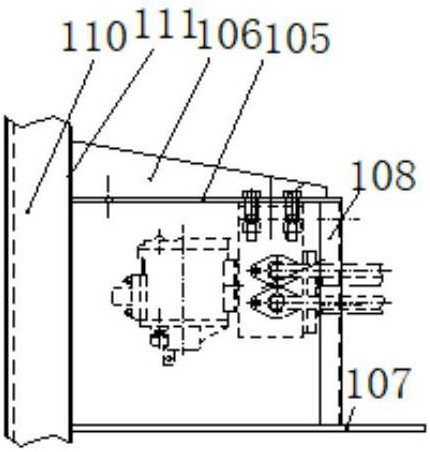

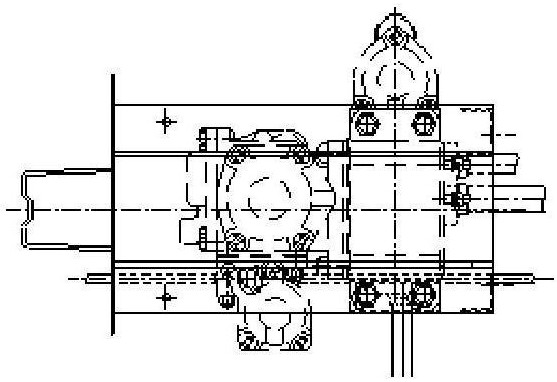

Display device

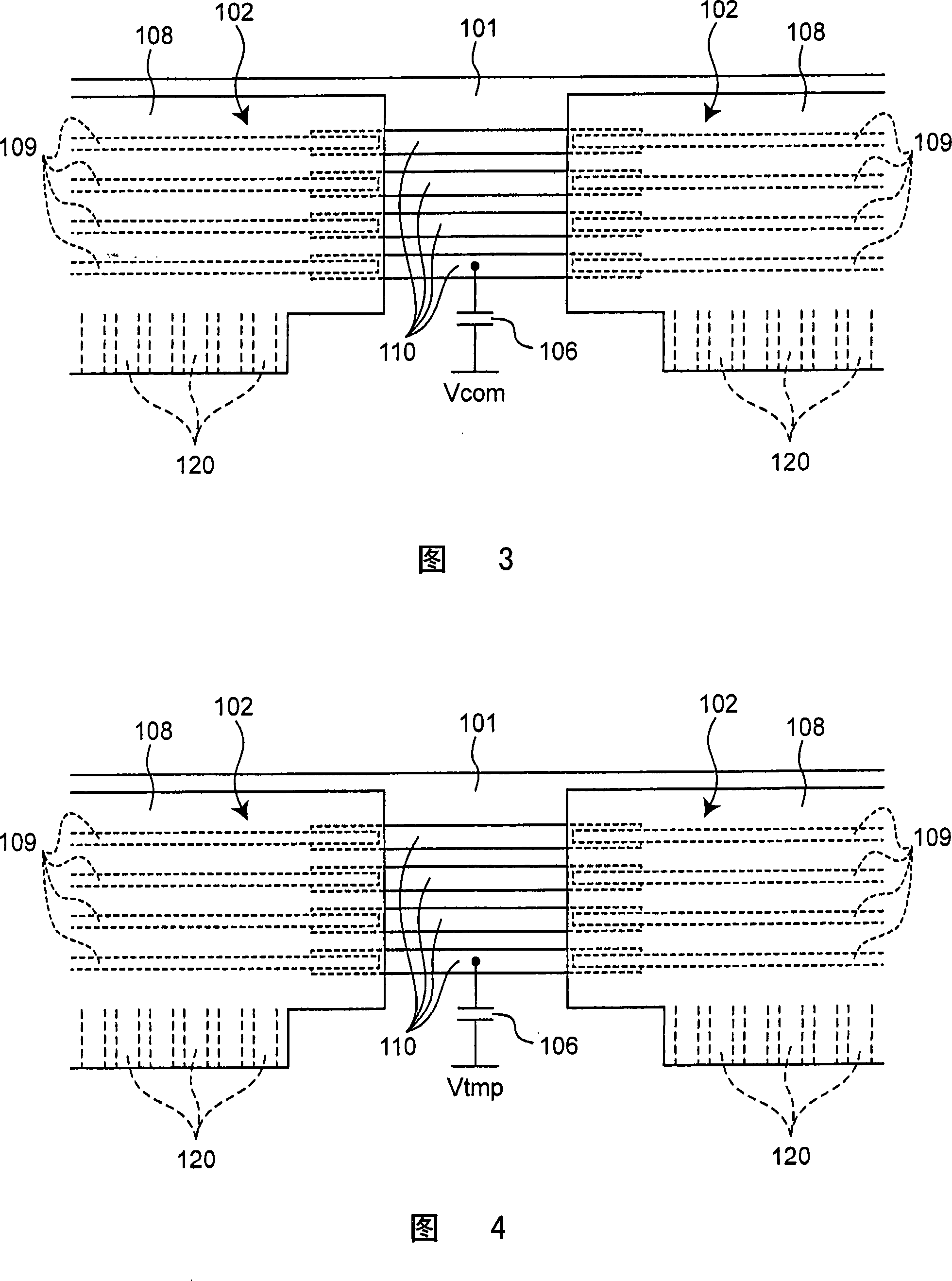

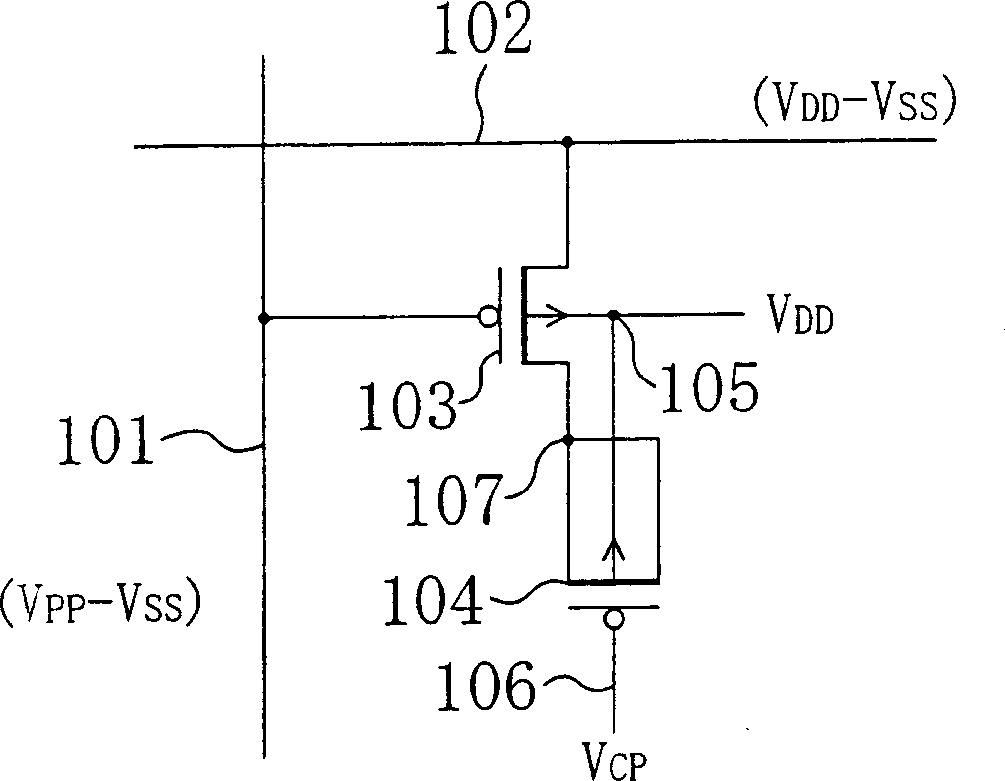

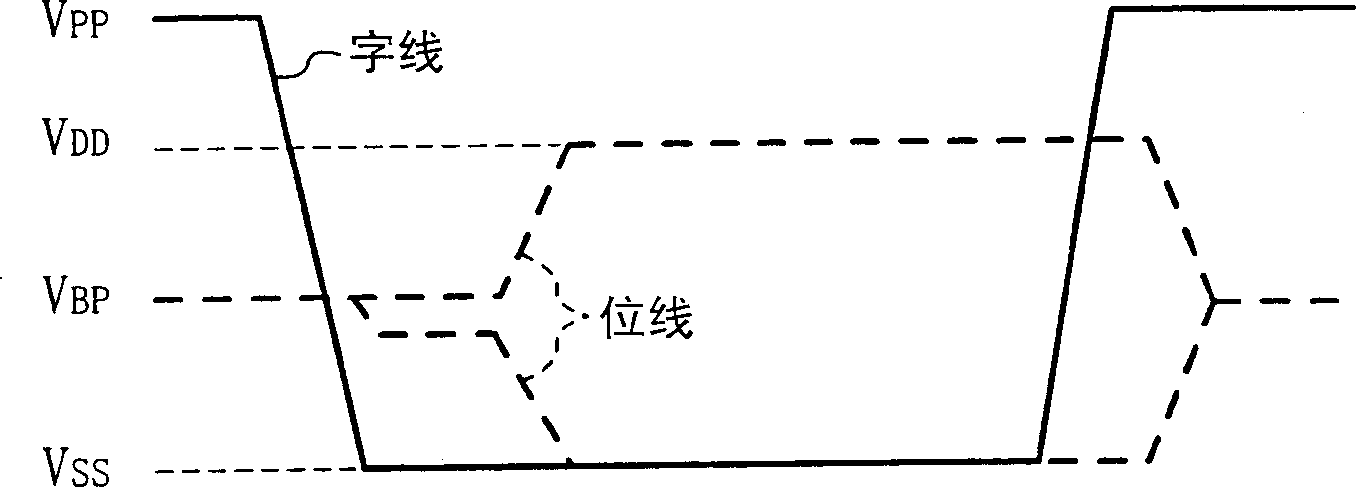

InactiveCN101093648AReduce the number of manufacturing processesLow costStatic indicating devicesNon-linear opticsDisplay deviceCapacitor

The LCD panel 101 of the present invention includes a panel side wiring 110 that electrically connects mutually adjacent source side drivers 102, 102 and a capacitor 106 connected to the panel side wiring 110 . Therefore, by collectively fabricating the capacitor 106 on the LCD panel 101 together with LCD pixels in a step of fabricating the LCD pixels on the LCD panel 101 , it becomes unnecessary to mount the capacitor 106 on the source side driver 102 , and the cost of the source side driver 102 can be reduced.

Owner:SHARP KK

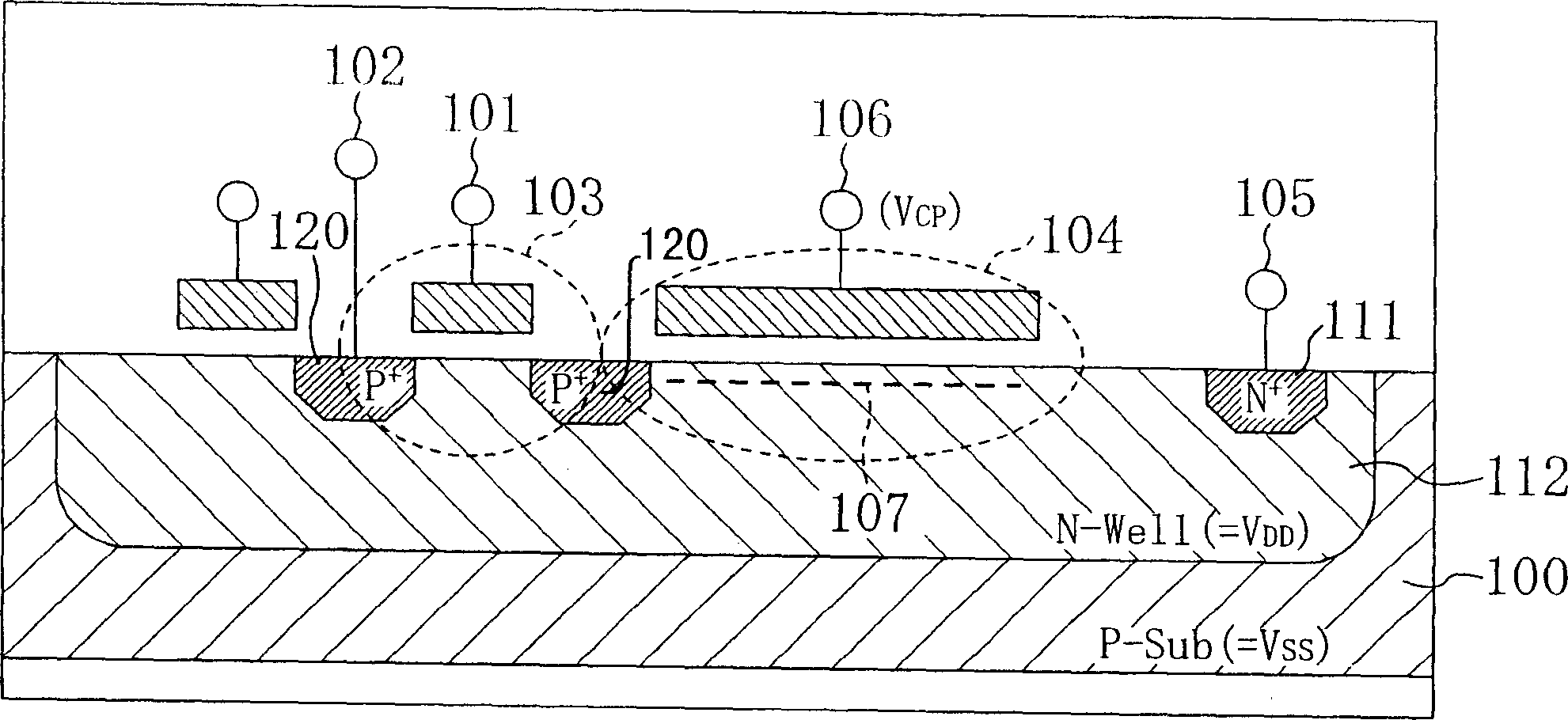

Semiconductor storage device and semiconductor integrated circuit device

InactiveCN1516193AReduce the number of manufacturing processesTransistorSolid-state devicesMOSFETDram memory

Owner:CETUS TECH INC

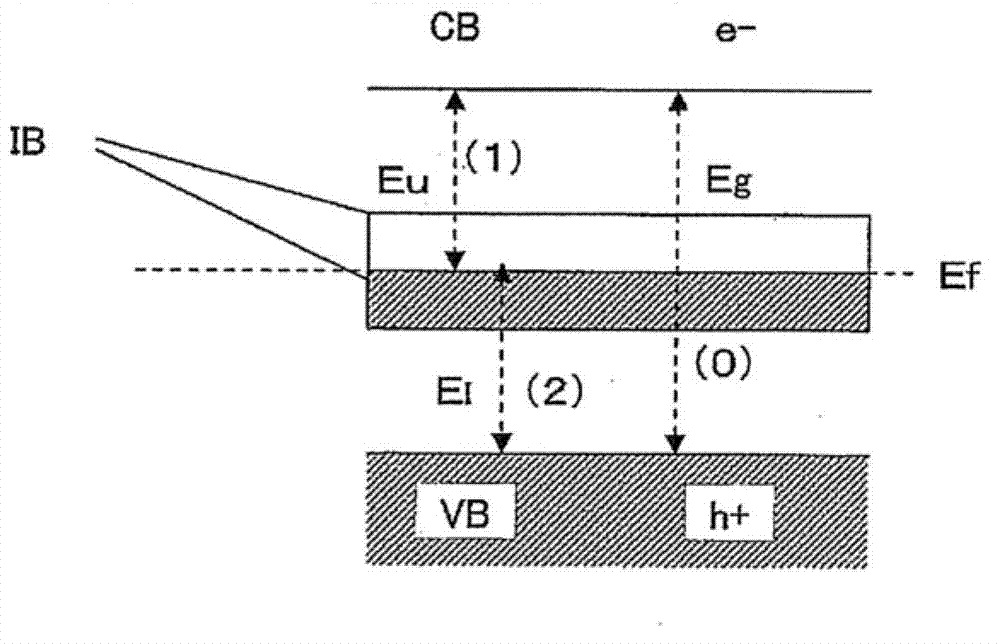

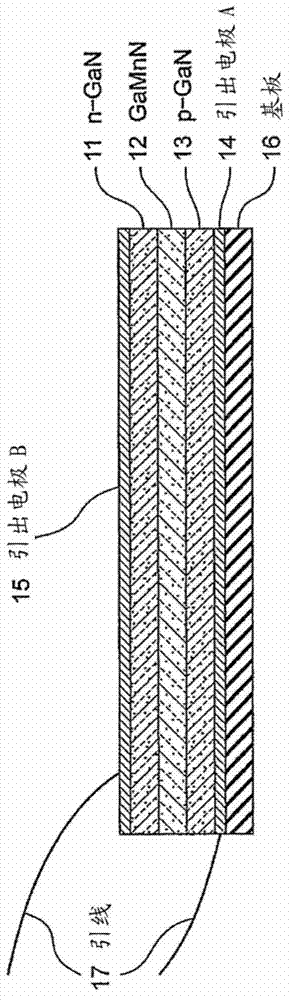

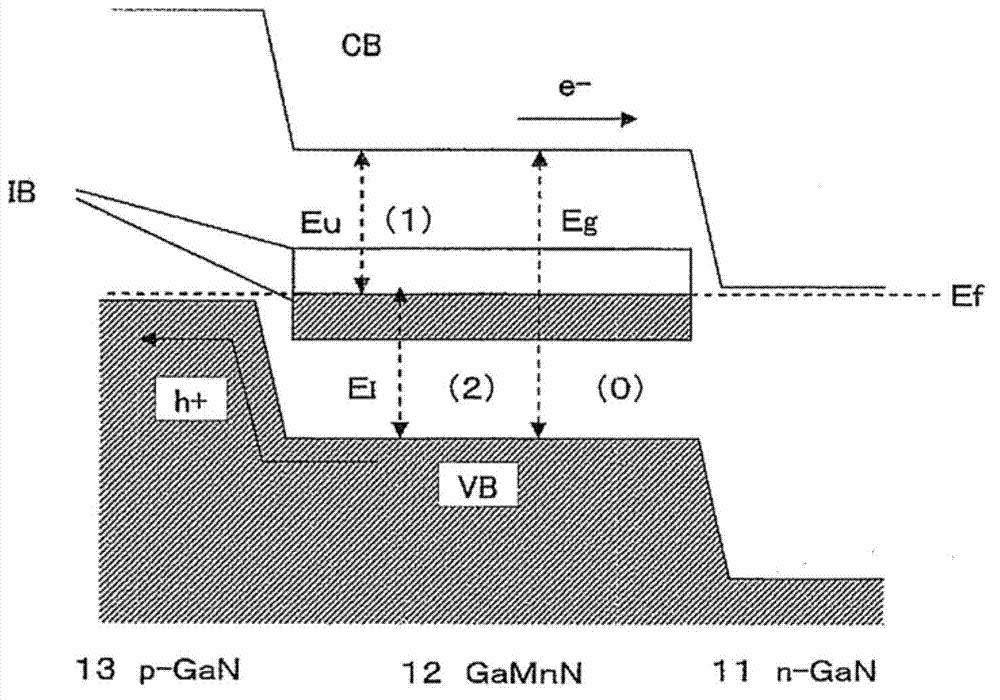

Llight-absorbing material and photoelectric conversion element using same

InactiveCN102792457AImprove conversion efficiencyDark current value is smallPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionSolar cell

The invention provides a new light-absorbing material that can increase the conversion efficiency of a solar cell. Further disclosed is a photoelectric conversion element using same. The light-absorbing material comprises a nitride compound semiconductor-which is a compound semiconductor represented by Al1-yGayN (0 <= y <= 1) of which a portion of the Al and / or Ga has been replaced by a 3d transition metal-has at least one impurity band, and has an optical absorption coefficient of at least 1000 cm-1 in the entire wavelength region that is between 300 nm and 1500 nm, inclusive.

Owner:NAT UNIV KYOTO INST OF TECH +1

Hard-coated film, method of manufacturing the same, optical device, and image display

InactiveCN100560353CReduce the number of manufacturing processesSolve the lack of hardnessSynthetic resin layered productsLaminationHardnessPlastic film

A hard-coated antiglare film is provided that has high hardness, high scratch resistance, and good antiglare properties. In the hard-coated antiglare film of the present invention including a transparent plastic film substrate, a hard-coating layer containing fine particles is formed on at least one surface of the transparent plastic film substrate, the hard-coating layer has a thickness in the range of 15 to 30 mum, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating layer, the average tilt angle thetaa of the unevenness of the hard-coating layer surface is in the range of 0.4 DEG to 1.5 DEG , and the hard-coating layer is formed using a resin for forming the hard-coating layer containing three specific resin components.

Owner:NITTO DENKO CORP

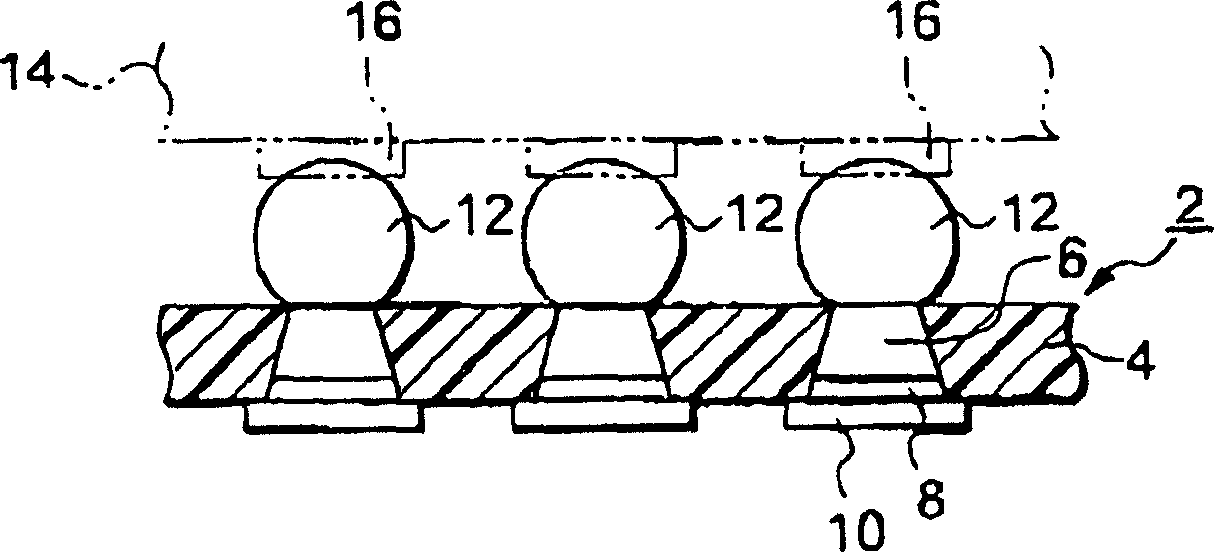

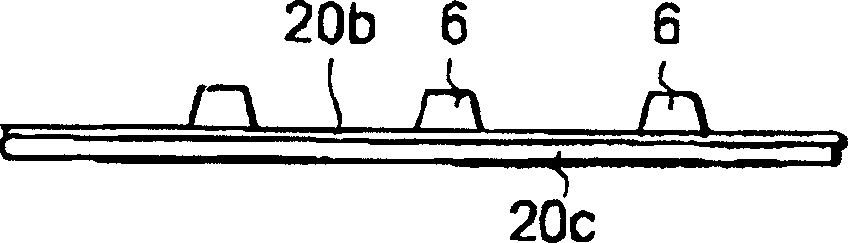

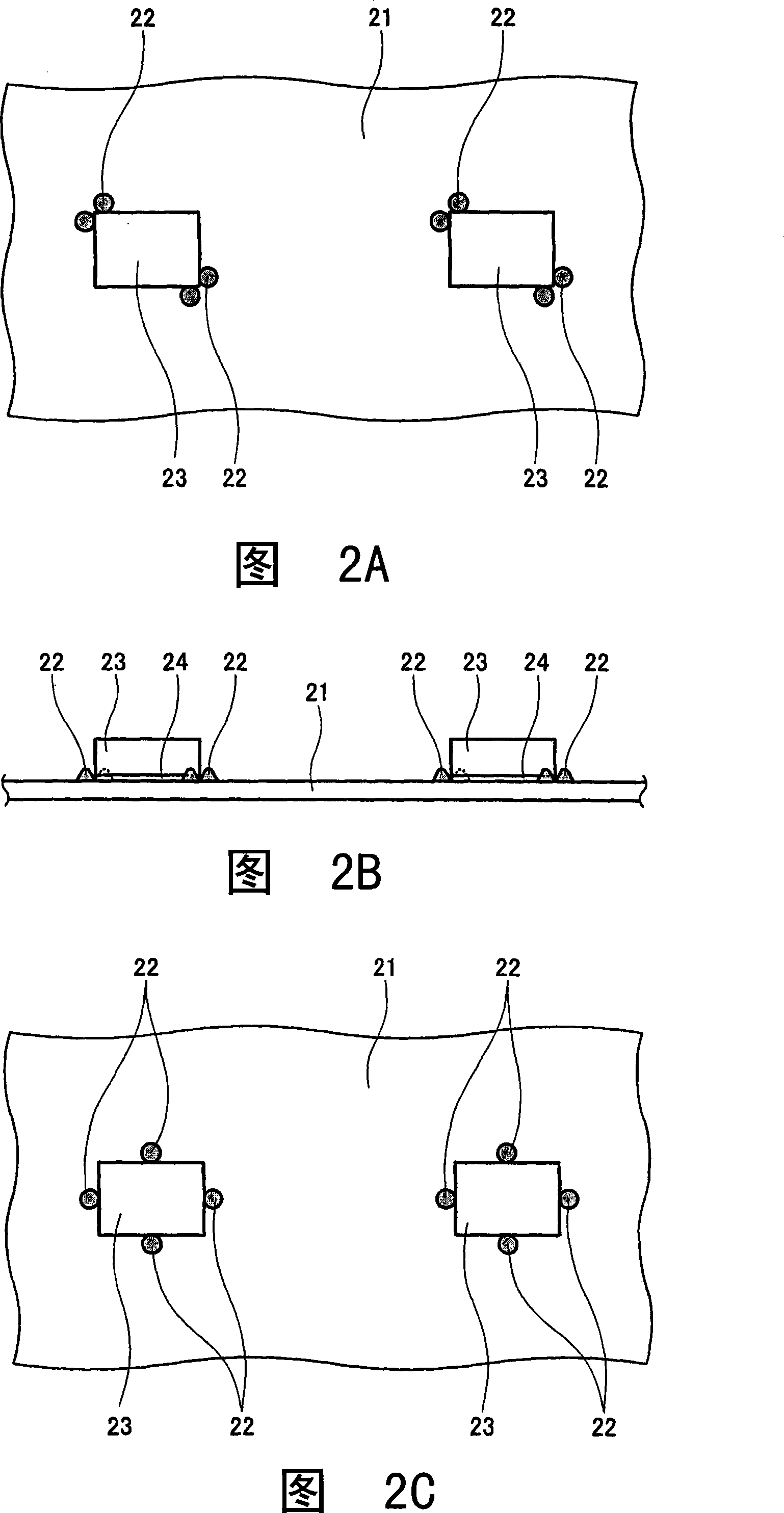

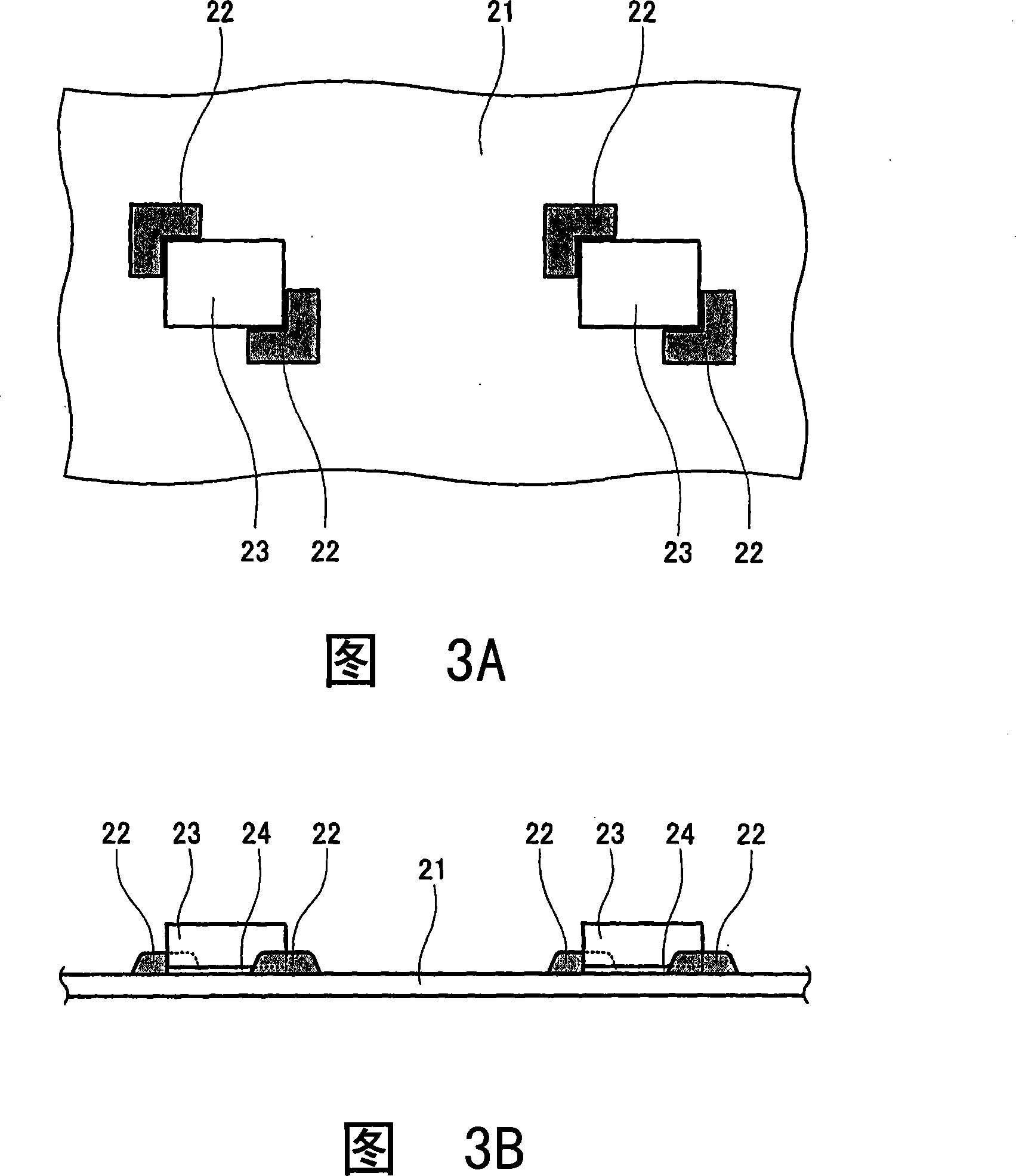

Substrate for mounting device, semiconductor module and method for producing the same, and portable apparatus

InactiveCN101494213AReduce the number of manufacturing processesImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

A substrate for mounting a device comprises: an insulating resin layer; a plurality of projected electrodes that are connected electrically to a wiring layer provided on one major surface of the insulating resin layer, and that project toward the insulating resin layer from the wiring layer; and a counter electrode provided at a position corresponding to each of the plurality of projected electrodes on the other major surface of the insulating resin layer. Among the projected electrodes, a projected length of part of the projected electrodes is smaller than that of the other projected electrodes; and the projected electrode and the counter electrode corresponding thereto are capacitively-coupled, and the projected electrode and the counter electrode are connected electrically.

Owner:SANYO ELECTRIC CO LTD

Array substrate, array substrate manufacturing method and display panel

ActiveCN113362721AReduce the number of manufacturing processesReduce the number of layersSolid-state devicesSemiconductor/solid-state device manufacturingActive layerMaterials science

The invention discloses an array substrate, an array substrate manufacturing method and a display panel. The array substrate comprises a substrate; a thin film transistor which is arranged on the substrate and comprises a grid electrode, an active layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are connected with the active layer; and a photosensitive sensor which comprises a photosensitive module and a storage module, wherein the photosensitive module comprises a photosensitive semiconductor layer, and the storage module comprises a first electrode plate and a second electrode plate; wherein the photosensitive semiconductor layer is arranged on the extension part of the drain electrode, the first electrode plate is electrically connected with one side, far away from the extension part of the drain electrode, of the photosensitive semiconductor layer, and the second electrode plate is electrically connected with the drain electrode. The array substrate comprises the photosensitive sensor, the number of film layers of the photosensitive sensor is reduced, the number of manufacturing procedures of the array substrate can be reduced, and a photomask is saved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

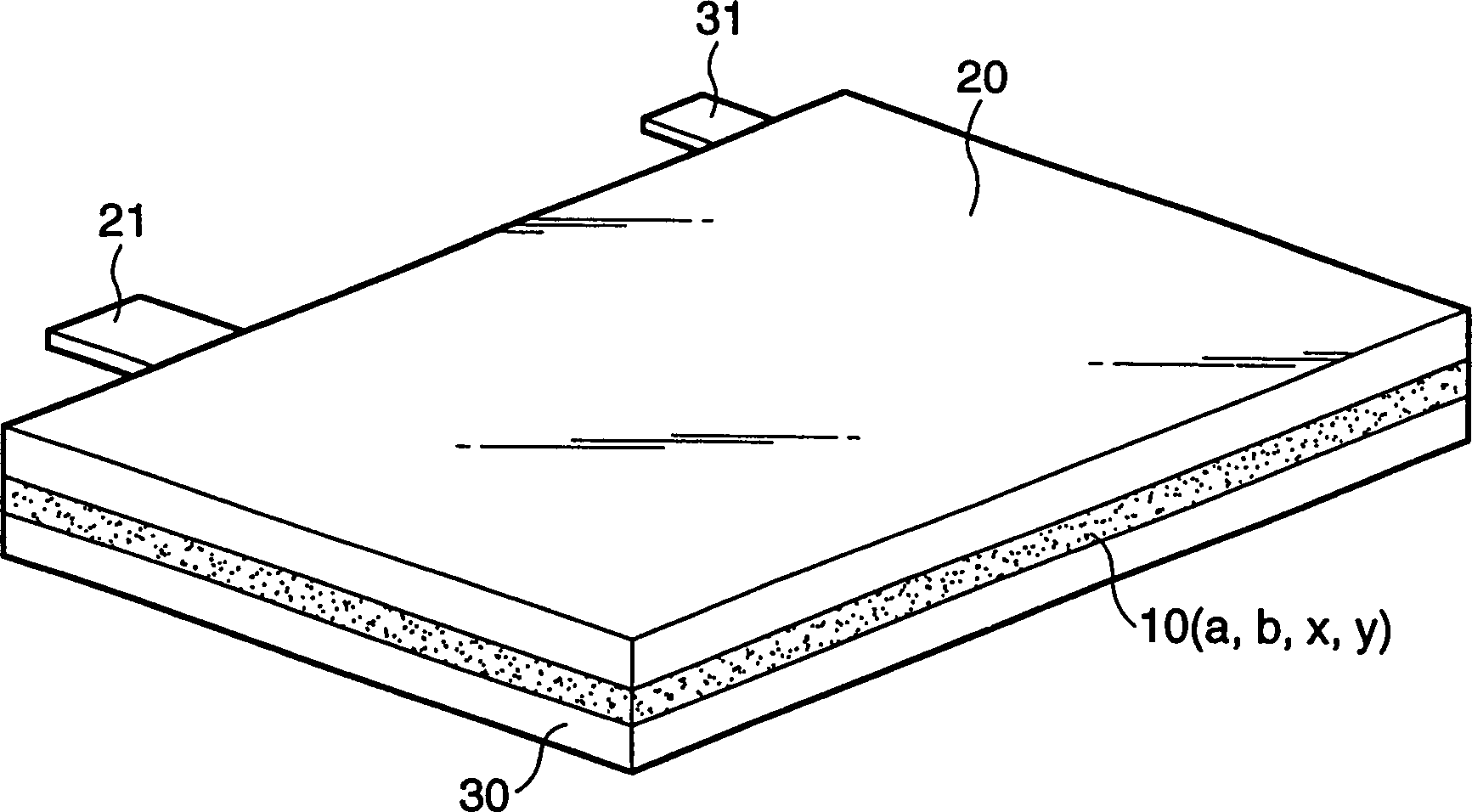

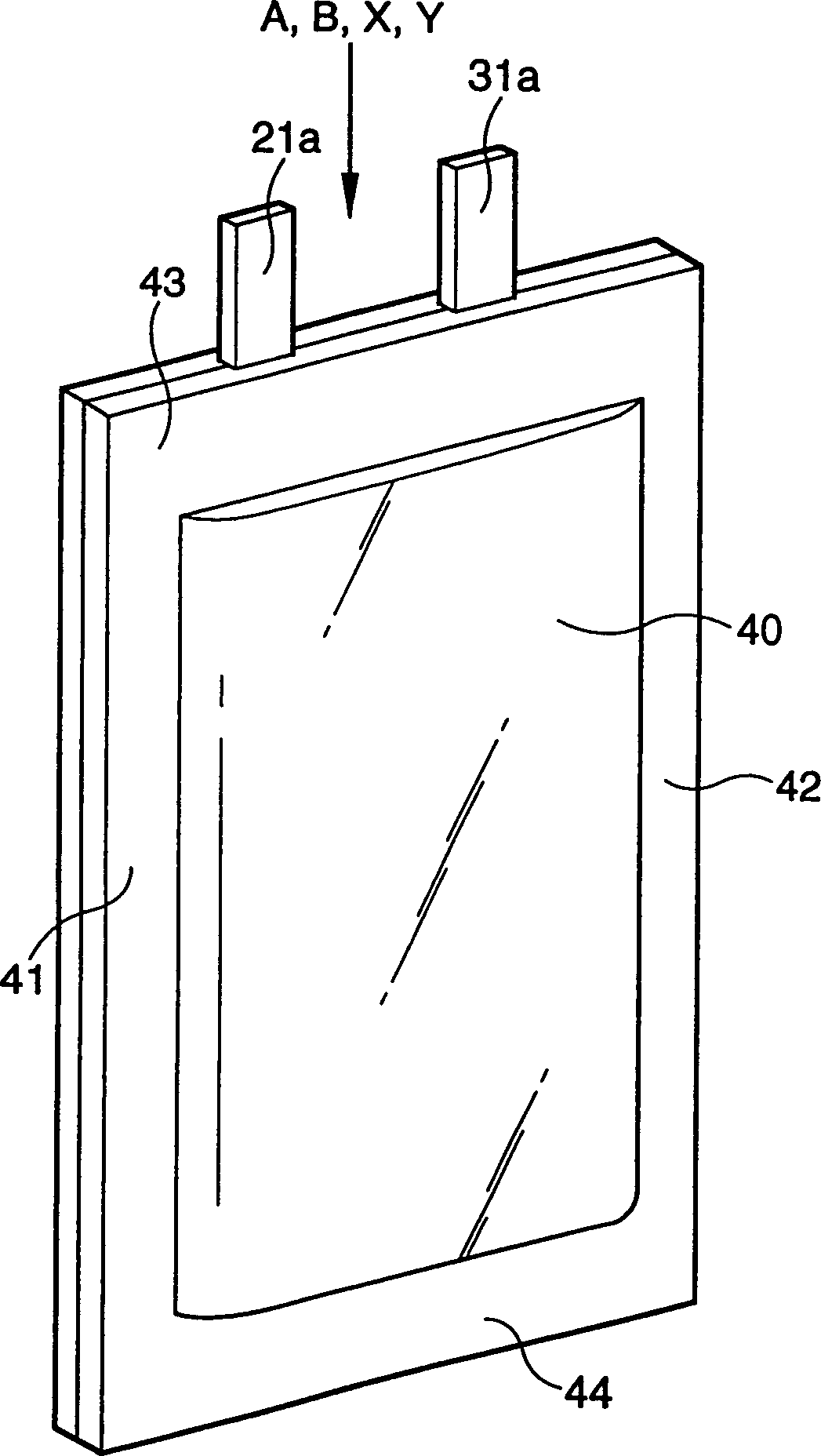

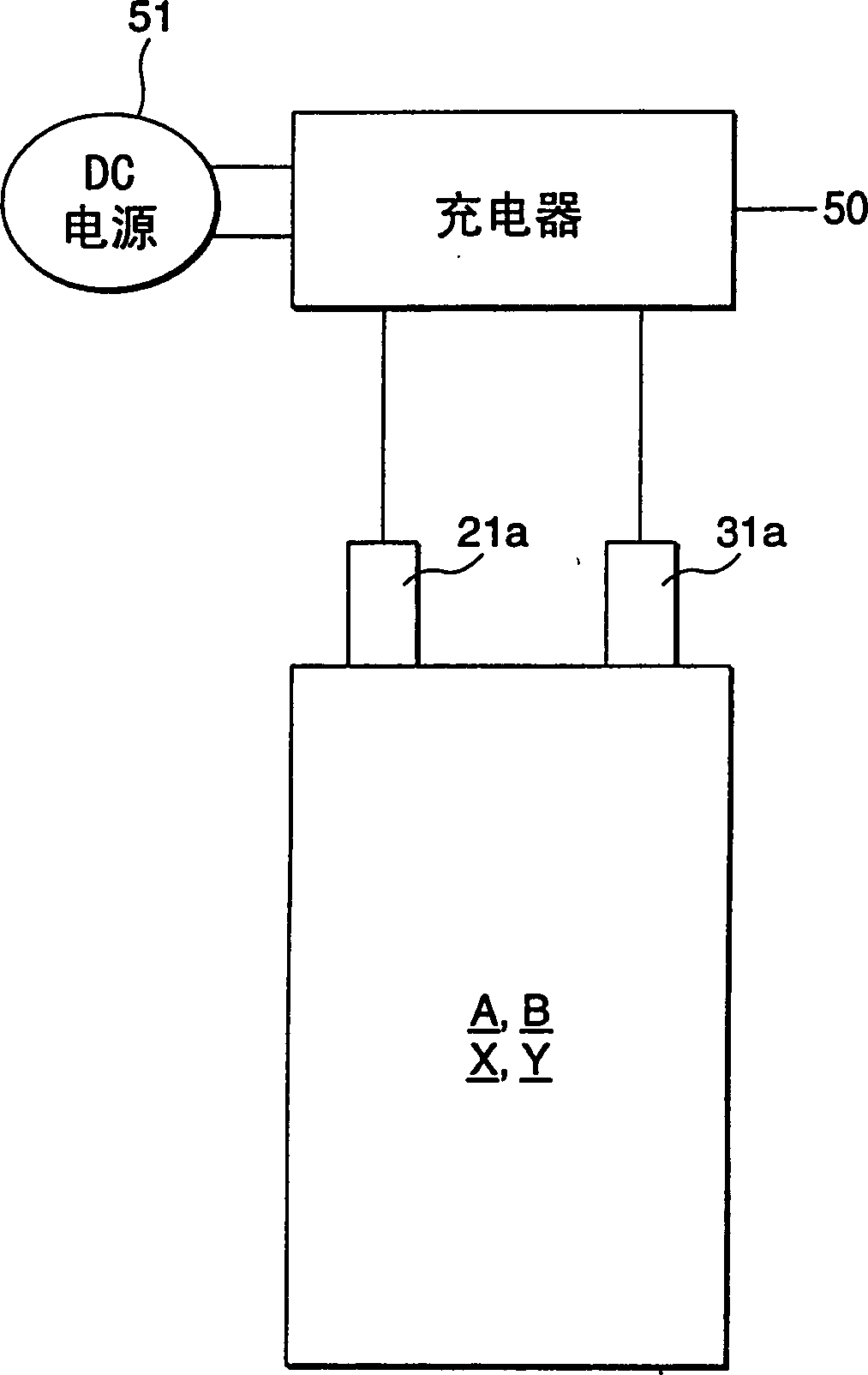

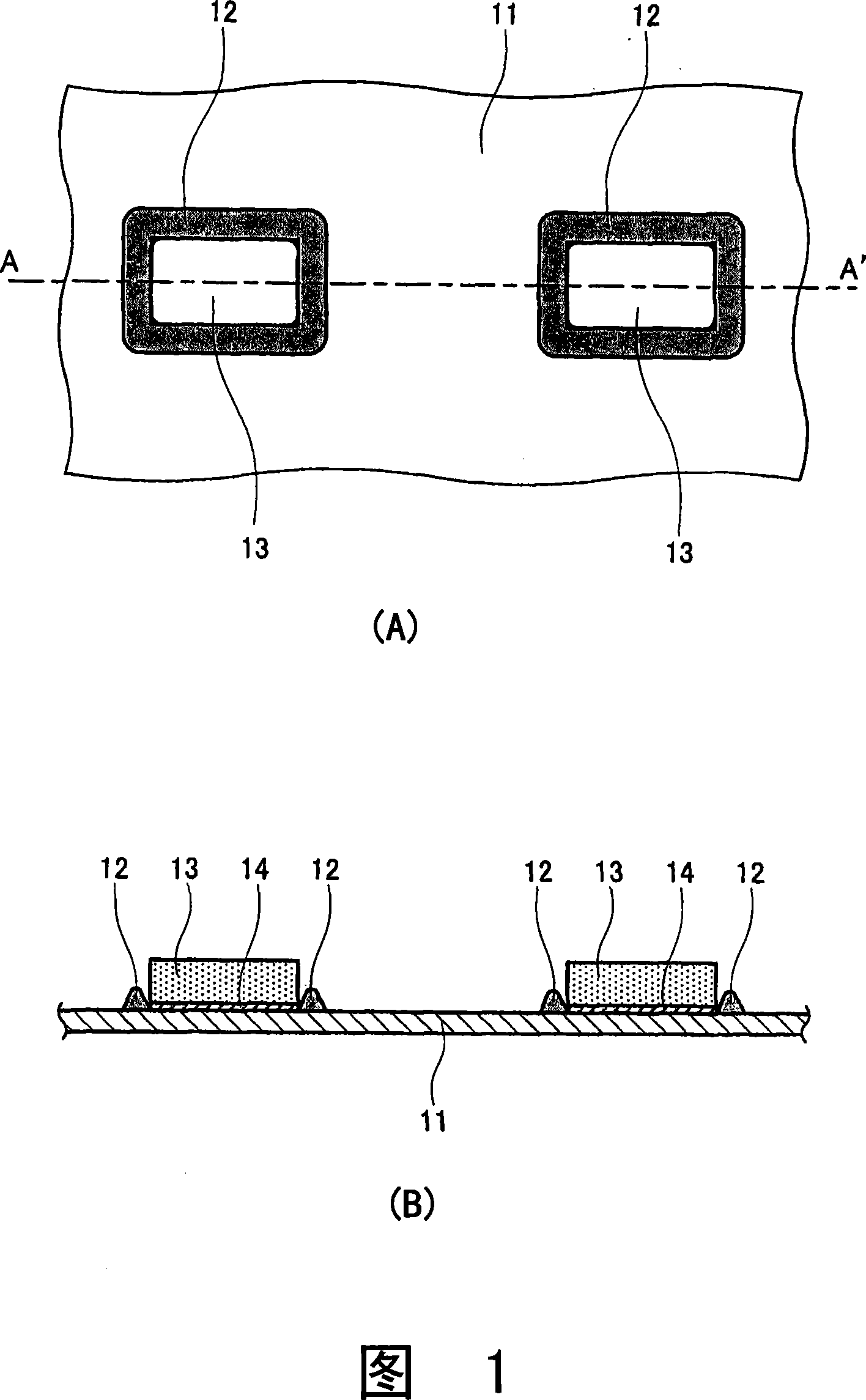

Lithium battery and battery apparatus having said battery

InactiveCN1171349CReduce the number of manufacturing processesCell seperators/membranes/diaphragms/spacersCell electrodesGraphitePolyvinylidene difluoride

Provided are a lithium secondary battery that does not cause overcharged state and a battery apparatus equipped with the battery that does not need a protective circuit by means of the lithium secondary battery. The lithium secondary battery is constituted by disposing a negative pole (e.g. graphite) that can absorb and desorb lithium ions and a positive pole using lithium-contained metal oxide (e.g. Li-contained cobalt oxide) as a substance to activate the positive pole by sandwiching a separator containing poly-vinylidene fluoride(PVdF) in between the two poles, and then by injecting a nonaqueous electrolyte. In the lithium secondary battery constituted like this, battery voltage does not rise above the rated voltage even when overcharged.

Owner:SANYO ELECTRIC CO LTD

Semiconductor device and method of manufacturing the same

InactiveCN101252124AImprove pass rateReduce the number of manufacturing processesSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

The present invention discloses a semiconductor device and manufacture method thereof, variations in fastening positions of semiconductor elements are eliminated by forming protrusions on a die pad so as to enclose the semiconductor elements before an adhesive that fastens the semiconductor elements to the die pad is wetted and spread.

Owner:PANASONIC CORP

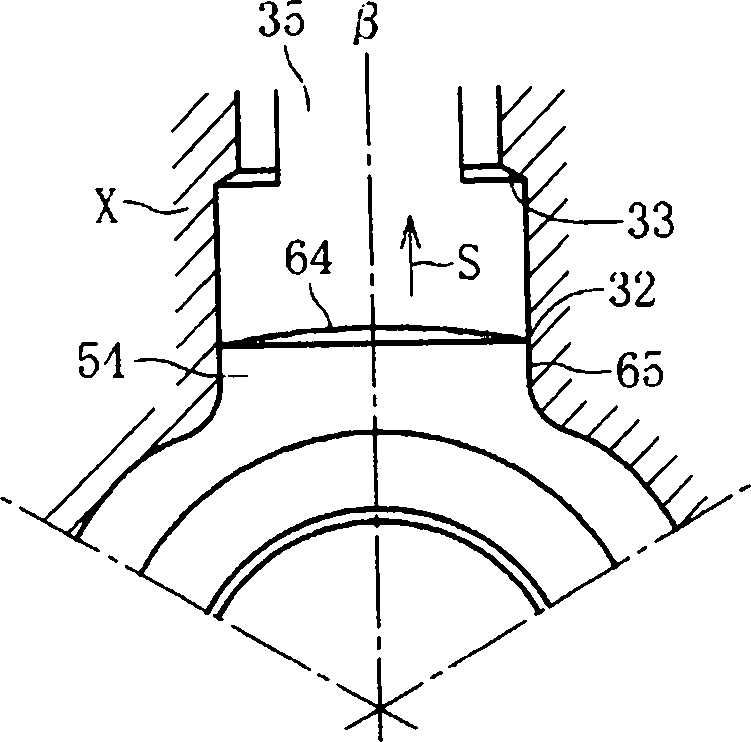

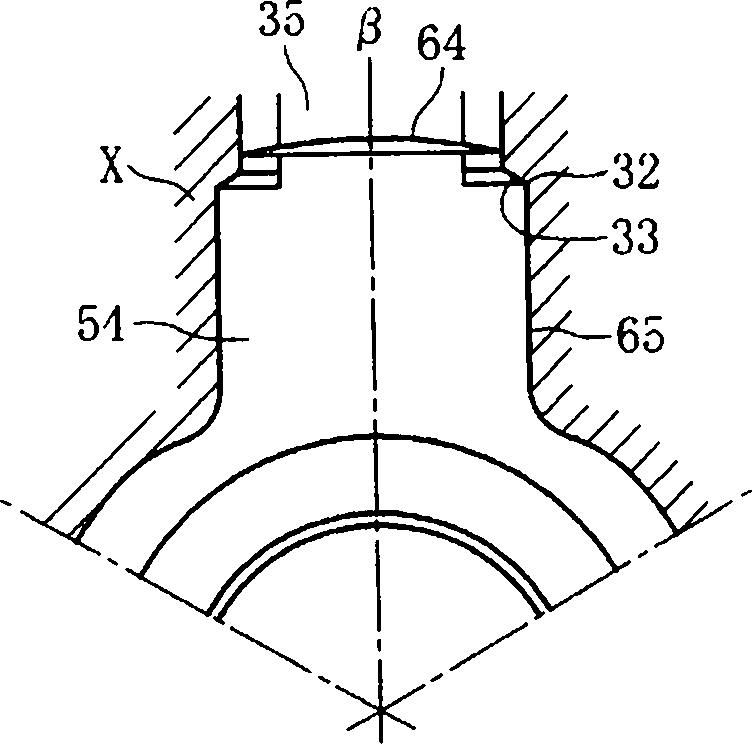

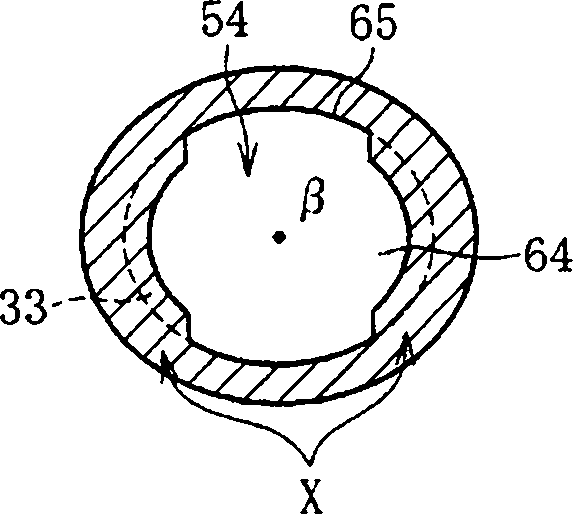

Tripod uniform-motion universal joint and method for manufacturing same

ActiveCN102124242BEasy to manufactureReduce the number of manufacturing processesYielding couplingMetal-working apparatusEllipseUniversal joint

Provided are a tripod-type constant-velocity universal joint which is capable of reducing weight of a journal raw profile to thereby reduce the number of manufacturing steps and in which forging of journals is facilitated, and a method of manufacturing the same. A leading end corner portion (32) of a journal raw profile (54) is held with use of a die (X) and forged. In this case, in a state in which a relief portion (35) is provided on a leading end side of the die (X), a part including an elliptically longitudinal side of the leading end corner portion (32) of the journal raw profile (54) is held with use of the die (X). In the die (X), inner walls of a part at which the leading end corner portion (32) of the journal raw profile (54) is held constitute tapering surfaces (33). By the forging, at the part including the elliptically longitudinal side relatively on a leading end portion side of an outer peripheral surface (30) of each of journals (4), edge portions (21) reducing a lateral sectional area of each of the journals (4) toward a leading end side thereof are formed, and tapered surfaces (20) are formed on the leading end side of the edge portions (21). Centering on each of the journals (4) is performed by causing two points on an elliptically longitudinal side of the edge portions (21) to abut against a centering jig.

Owner:NTN CORP

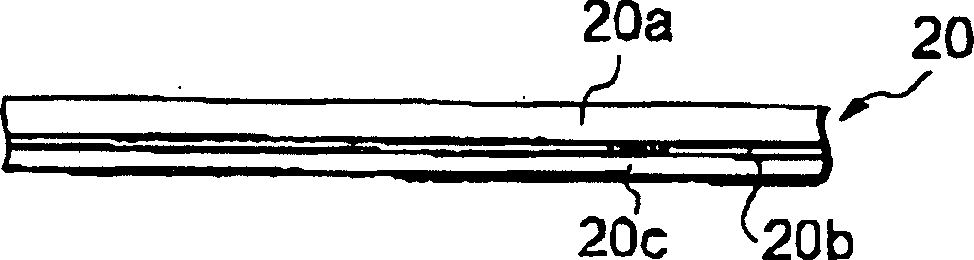

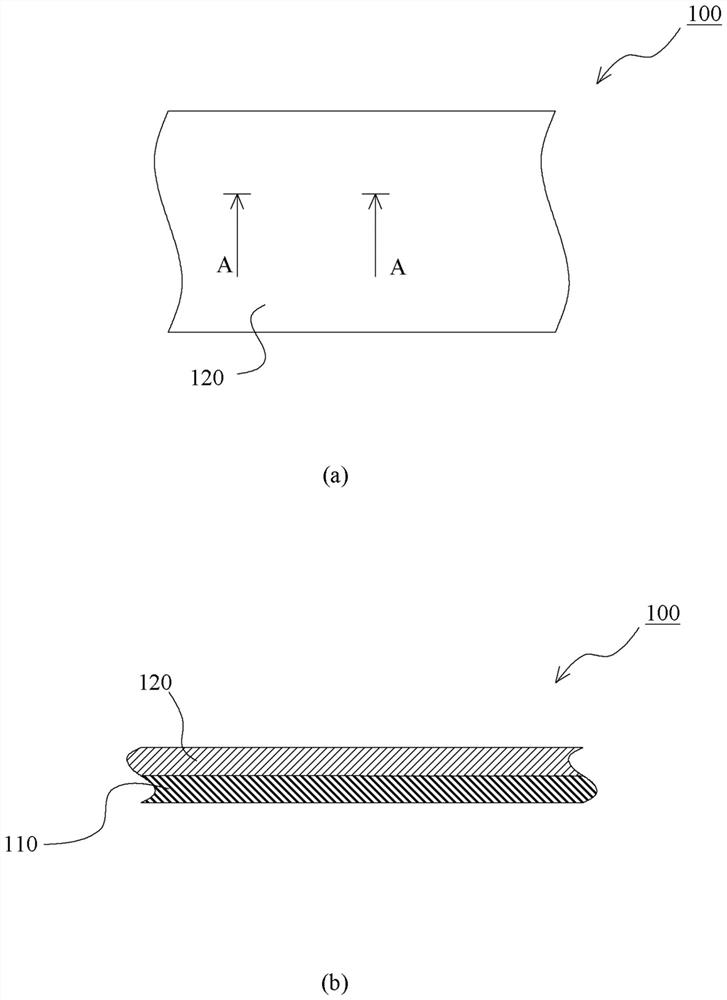

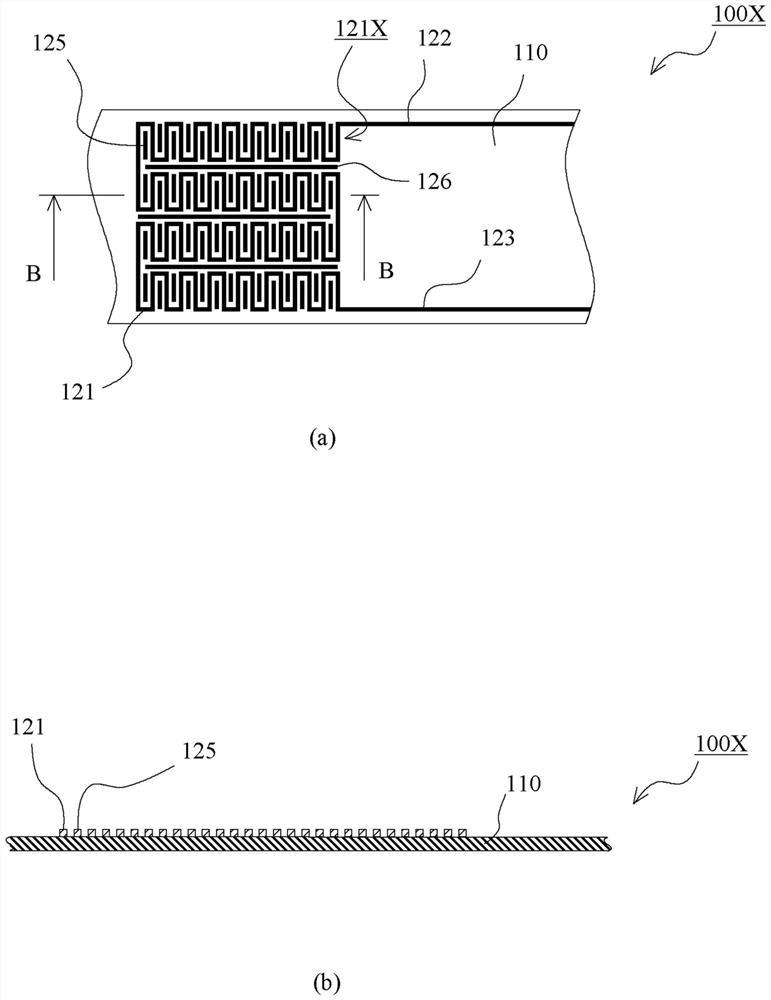

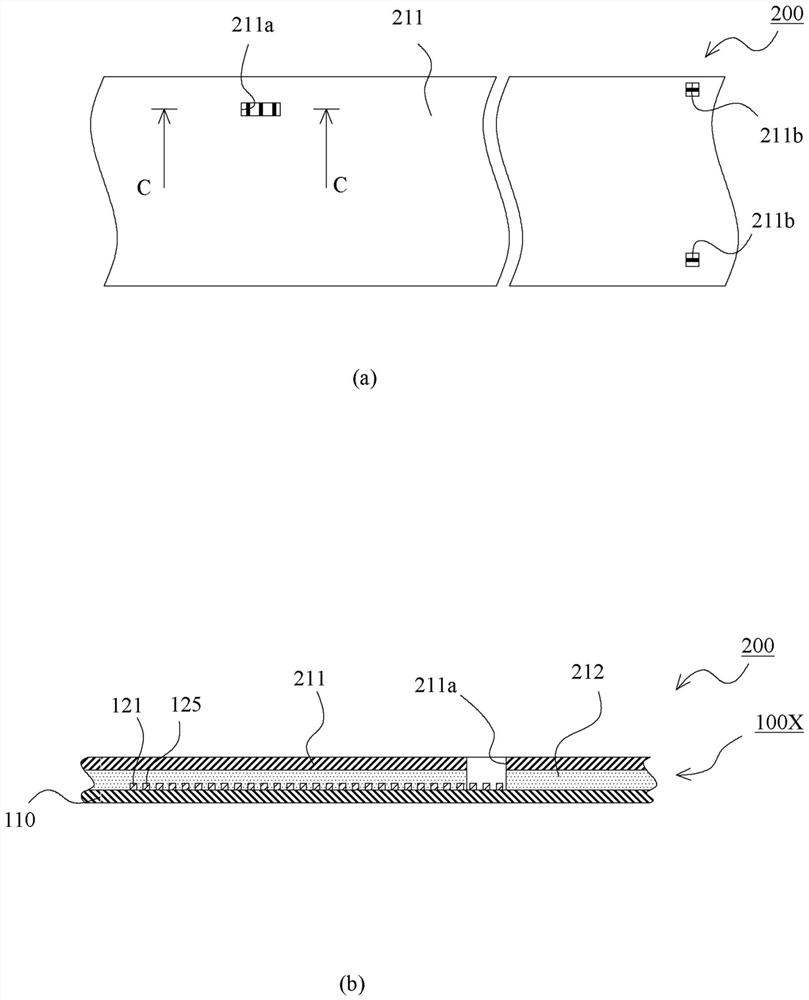

Heater including flexible printed wiring board and method for manufacturing same

PendingCN113453391AReduce the number of manufacturing processesPrinted circuit aspectsTransparent/reflecting heating arrangementsMetal foilFlexible electronics

The invention provides a heater including a flexible printed wiring board and a method of manufacturing the same. A heater includes: a flexible printed wiring board including a base film and a metal foil provided on one side of the base film; a heater circuit portion that is formed from the metal foil and generates heat when energized; and a heat conductive foil portion that is formed from the metal foil at a position away from the heater circuit portion and is maintained in a non-energized state.

Owner:NIPPON MEKTRON LTD

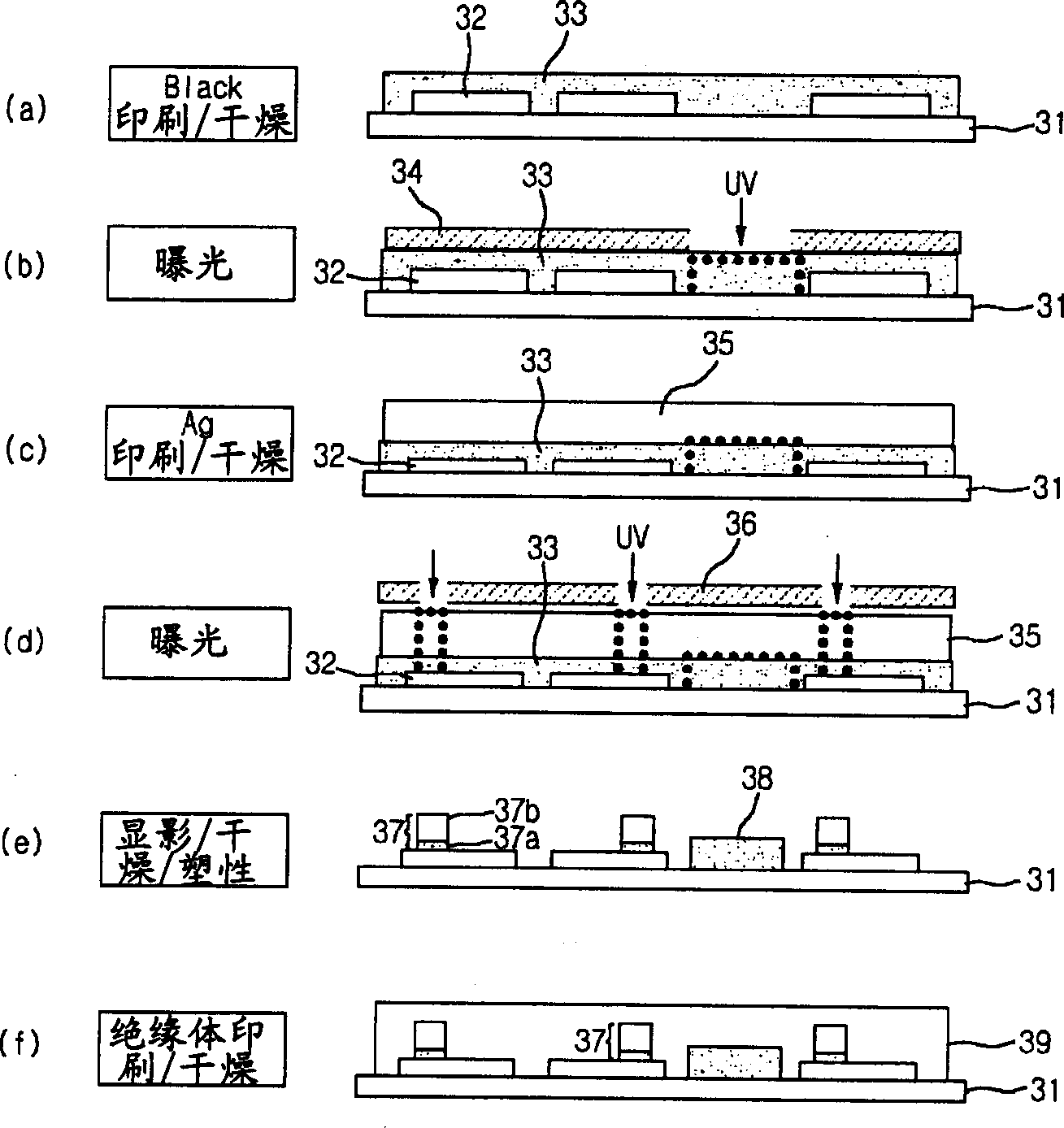

Method for manufacturing plasma display device

InactiveCN1770356AReduce the number of manufacturing processesReduce engineering costsCold cathode manufacturePlasma displayDisplay device

This invention relates to one plasma display process method to simplify the process, which comprises the following steps: Pressing the pre-made green light band on the upper base board with transparent electrode; sustainable exposing by ultraviolet with different wavelengths; developing the exposed green light band and drying and shaping to form metal electrodes. So, this invention can reduce process to save cost.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

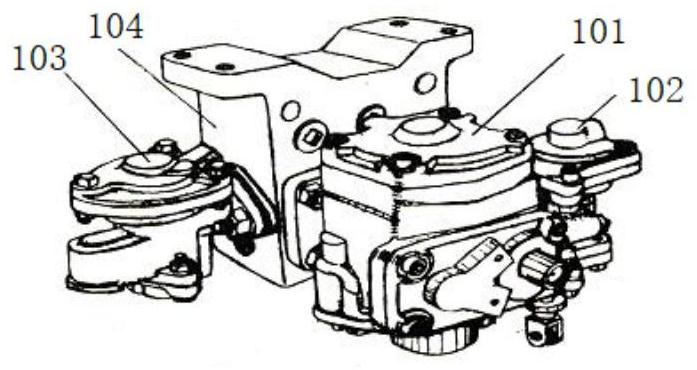

Mounting device for hanging type 120-type air control valve

ActiveCN113428126AImprove rainwater corrosion resistanceExtended maintenance cycleAerodynamic brakesPiping arrangementsControl valvesChassis

The invention discloses a mounting device for a hanging type 120-type air control valve. The device comprises a mounting seat which comprises a lifting plate, an outer side plate and an inner side plate, the lifting plate, the outer side plate and the inner side plate are connected to form a U shape, the lower end of the mounting seat and a chassis of a vehicle form a floor, the lifting plate is used for mounting the hanging type 120-type air control valve, a first opening is formed in the inner side plate, and two sides of the mounting seat are open; the device further comprises a front protective cover and a rear protective cover which are detachably connected with the mounting seat, wherein the front protective cover and the rear protective cover can block the two open sides of the mounting seat respectively, and clamping hook structures are arranged on the front protective cover and the rear protective cover; the device further comprises locking mechanisms which are arranged on the two sides of the mounting seat, the locking mechanisms are matched with the clamping hook structures, the locking mechanisms can lock the clamping hook structures, and the front protective cover and the rear protective cover are fixed to the mounting seat; the mounting seat, the detachable front protective cover and the detachable rear protective cover are adopted to form a mounting and protecting structure, so that reliable mounting of the hanging type 120-type air control valve can be guaranteed, and the hanging type 120-type air control valve can be conveniently disassembled.

Owner:CRRC TAIYUAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com