Luneberg lens and antenna device using the same

A kind of lens and Bobo technology, applied in the direction of antennas, electrical components, etc., can solve the problems of irremovable, reduced electrical performance, weakened sealing function, etc., to achieve the effect of suppressing the decline of electrical performance, reducing the number of manufacturing processes, and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

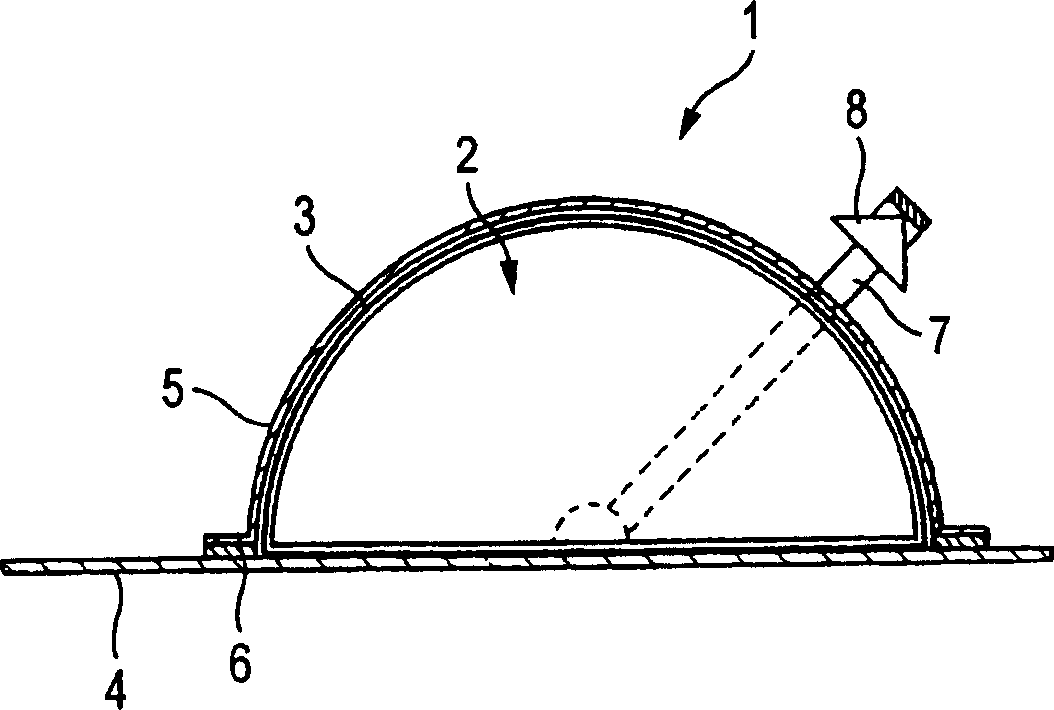

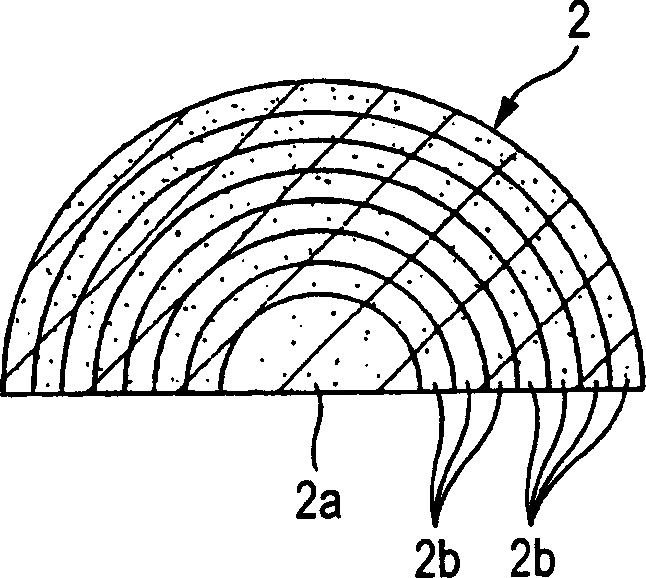

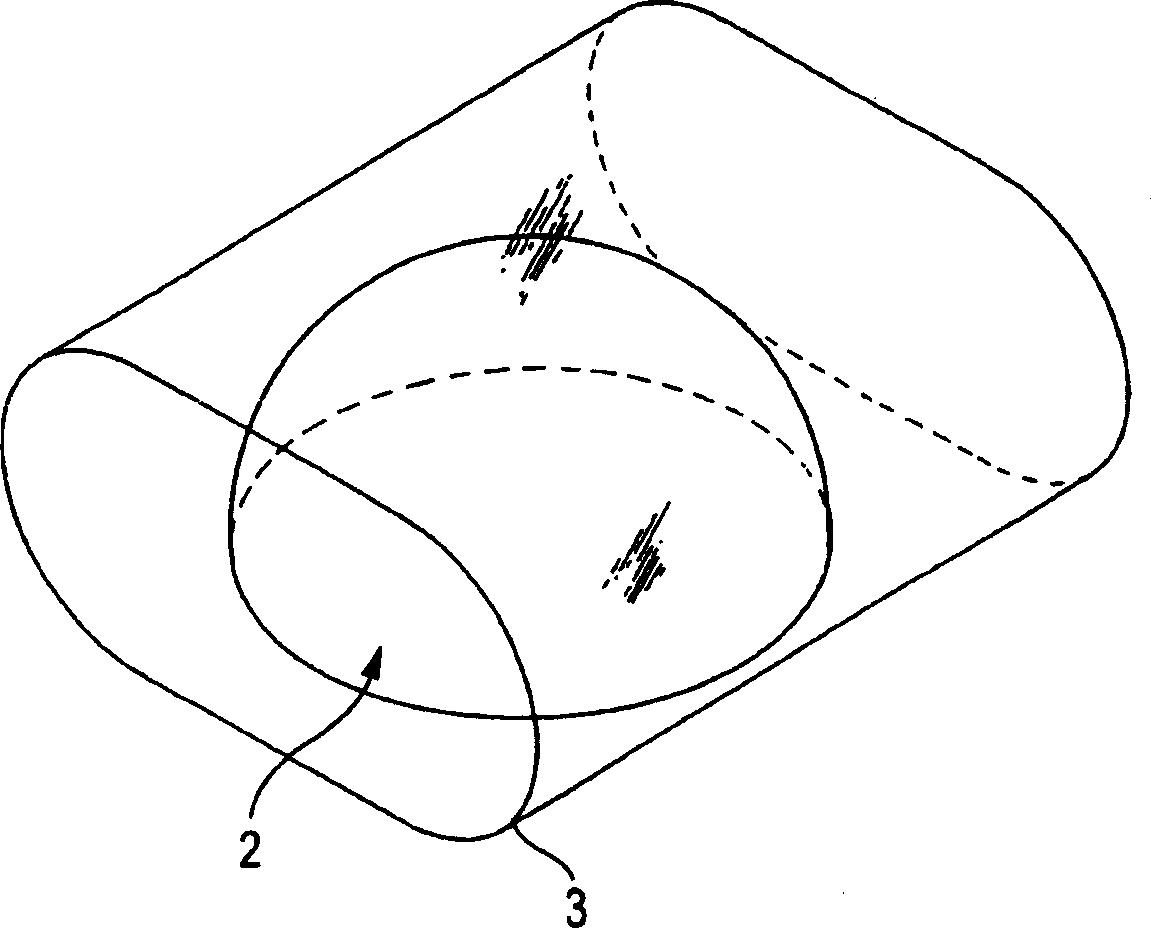

[0050] Such as image 3 As shown, a hemispherical lens 2 with a diameter of 45 cm is placed in a cylindrical PP shrink film 3 (magic wrap PP PA (30 μm thick) produced by Gunze Co., Ltd.), and the upper and lower sides of the shrink film 3 are fused to be in the The flat end surface of the lens (the surface in contact with the reflector) is drawn into a circle approximately 10 mm outside, and sealed ( Figure 4 The 9 in represents the sealing part), and cut off the excess edge. Next, a small hole for releasing the air inside the shrink film 3 is formed by a needle on the center portion of the flat end face side of the lens 2, thereafter, the entire area of the film is heated by a dryer whose temperature is adjusted to approximately 100° C., and then , obtained a film-sealed Lunberg lens, the shrink film 3 of which fits closely on the surface of the lens 2 .

[0051] Next, this lens was subjected to a moisture resistance test after closing the holes for air release. The tes...

Embodiment 2

[0055] The film-sealed hemispherical Lunberg lens prepared in Example 1 was stored in a dark place (in a warehouse at a temperature of approximately 20° C.) for one month, after which it was placed on a reflective plate, and the gains before and after storage were measured and compared. As a result, the gain before and after storage was 33.5 dB, and the influence due to moisture absorption was not found.

Embodiment 3

[0059] A hemispherical lens 2 with a diameter of 45 cm was placed in a cylindrical EVA shrink film (SUNTEC S CF100 (10 μm thick, produced by Asahi Kasei Co., Ltd.)), and in the same manner as in Example 1, the upper and lower sides of the shrink film were sealed so that The position approximately 10 mm outside the bisected section of the spherical surface of the lens (the surface in contact with the reflector) is drawn into a circle, and the redundant edge is cut off. Next, a small hole for releasing the air inside to shrink the film 3 is formed by a needle on the center portion of the flat end face side of the lens 2, thereafter, the entire area of the film is heated by a dryer whose temperature is adjusted to approximately 100° C., and Subsequently, Lunberg lenses of the film-sealed type were obtained, the shrink film of which closely fits the surface of the lens.

[0060] Then, the lens is placed on the reflector and covered with a cover that fits tightly on the outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com