Heater including flexible printed wiring board and method for manufacturing same

A technology of a flexible printed circuit and a manufacturing method, which is applied to the manufacturing of printed circuits, printed circuits, printed circuits, etc., can solve the problems of low thermal conductivity and lack of reliability in the pasted state of the second insulating film 522, and achieves a reduction in the number of manufacturing processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

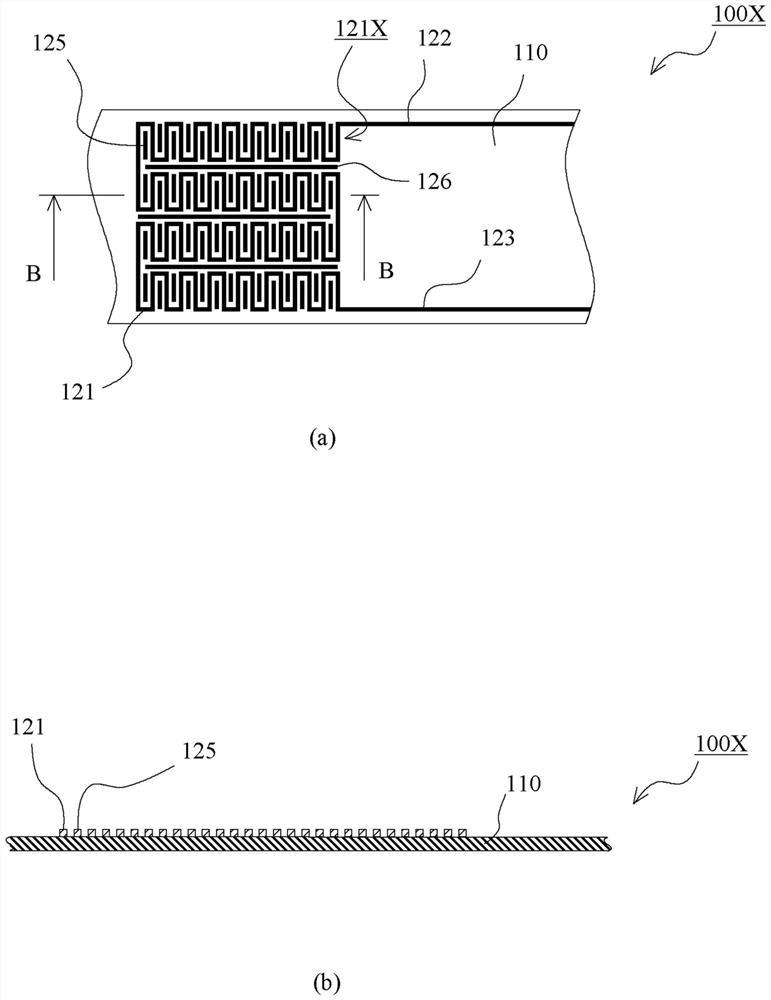

[0067] Image 6 Example 2 of the present invention is shown. In this embodiment, the configuration of the heater circuit portion is different from that of Embodiment 1 described above. Other structures and functions are the same as in Embodiment 1. The same reference numerals are assigned to the same components, and descriptions thereof are omitted.

[0068] Image 6 It is a plan view showing a heater circuit unit according to Embodiment 2 of the present invention. Also, for the sake of illustration, Image 6 The first intermediate product (product after the etching process) is shown in . In the configuration employed in the present embodiment, the meandering region 121X in the heater circuit portion 121 is provided with the linking portion 127 that short-circuits portions of a plurality of adjacent heater wires, respectively.

[0069] By etching the raw material 100 in the etching step, the connection portion 127 for short-circuiting portions of adjacent heater lines is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com