Method for manufacturing plasma display device

A technology of a plasma display and a manufacturing method, which are applied in the manufacture of discharge tubes/lamps, cold cathode manufacture, electrode system manufacture, etc., can solve the problems of waste of manufacturing engineering cost and complicated engineering, and achieve saving engineering cost and simple manufacturing process. The effect of reducing the number of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

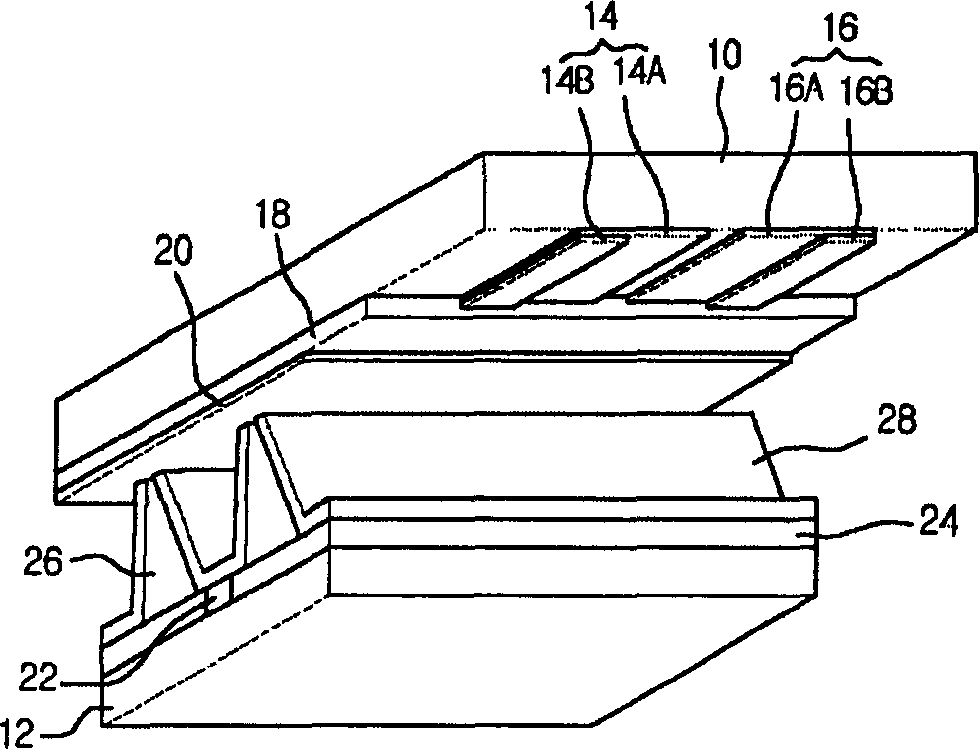

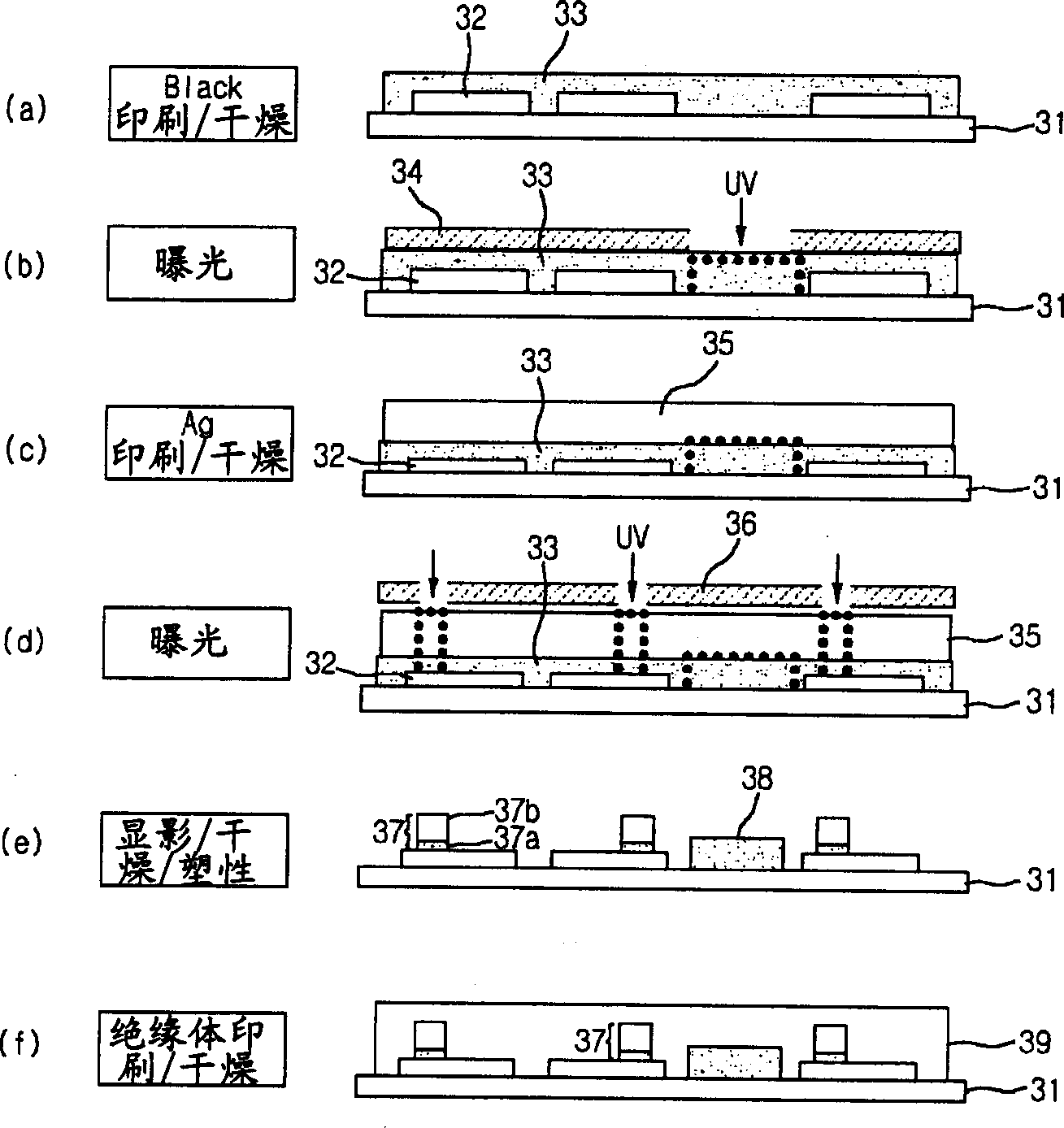

[0028] Hereinafter, embodiments of the plasma display and its manufacturing method of the present invention will be described in detail with reference to the accompanying drawings.

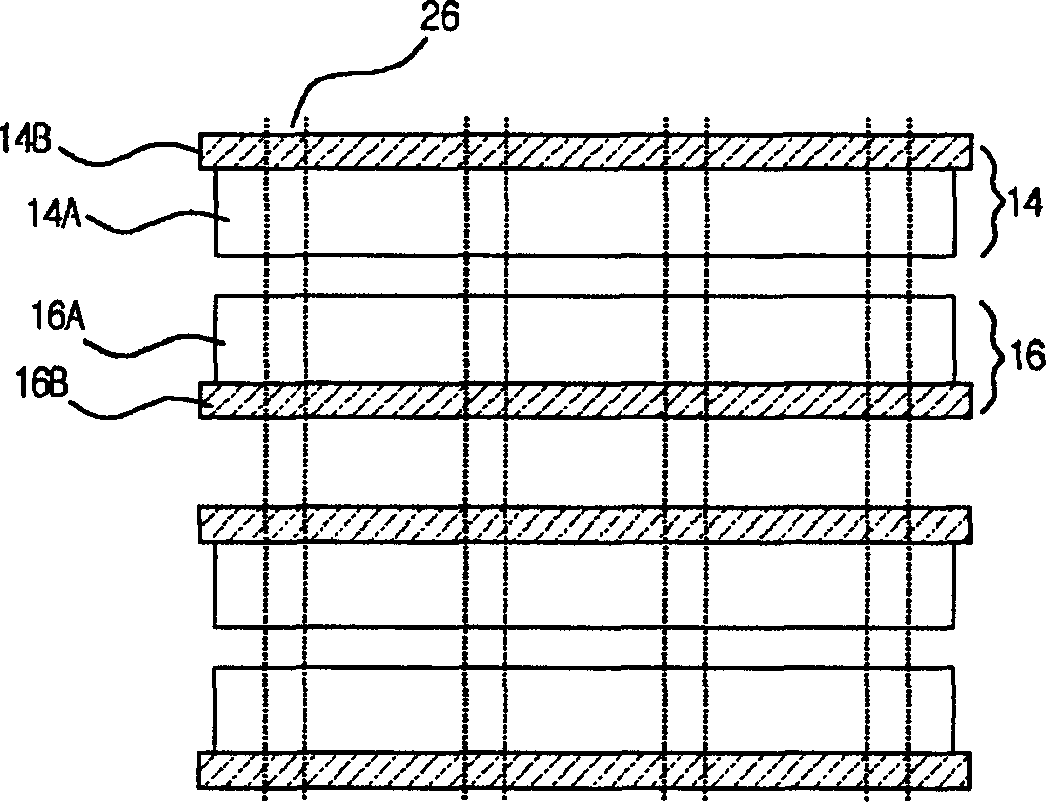

[0029] The plasma display of the present invention is composed of the following parts, and is characterized in this way: a plurality of first sustain electrode groups formed on the first transparent electrode and the first metal electrode formed on the upper substrate; The distance between the second transparent electrode and the second metal electrode formed in parallel is a plurality of second sustain electrode groups; it is at right angles to the first and second sustain electrode groups, crossing, and a plurality of address electrodes formed on the lower substrate; In order to isolate the upper substrate and the lower substrate, a plurality of partition walls are formed on the lower substrate in parallel with the address electrodes.

[0030] The above-mentioned first and second metal electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com