Semiconductor device and method of manufacturing the same

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., to achieve the effect of improving the qualification rate and reducing the number of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

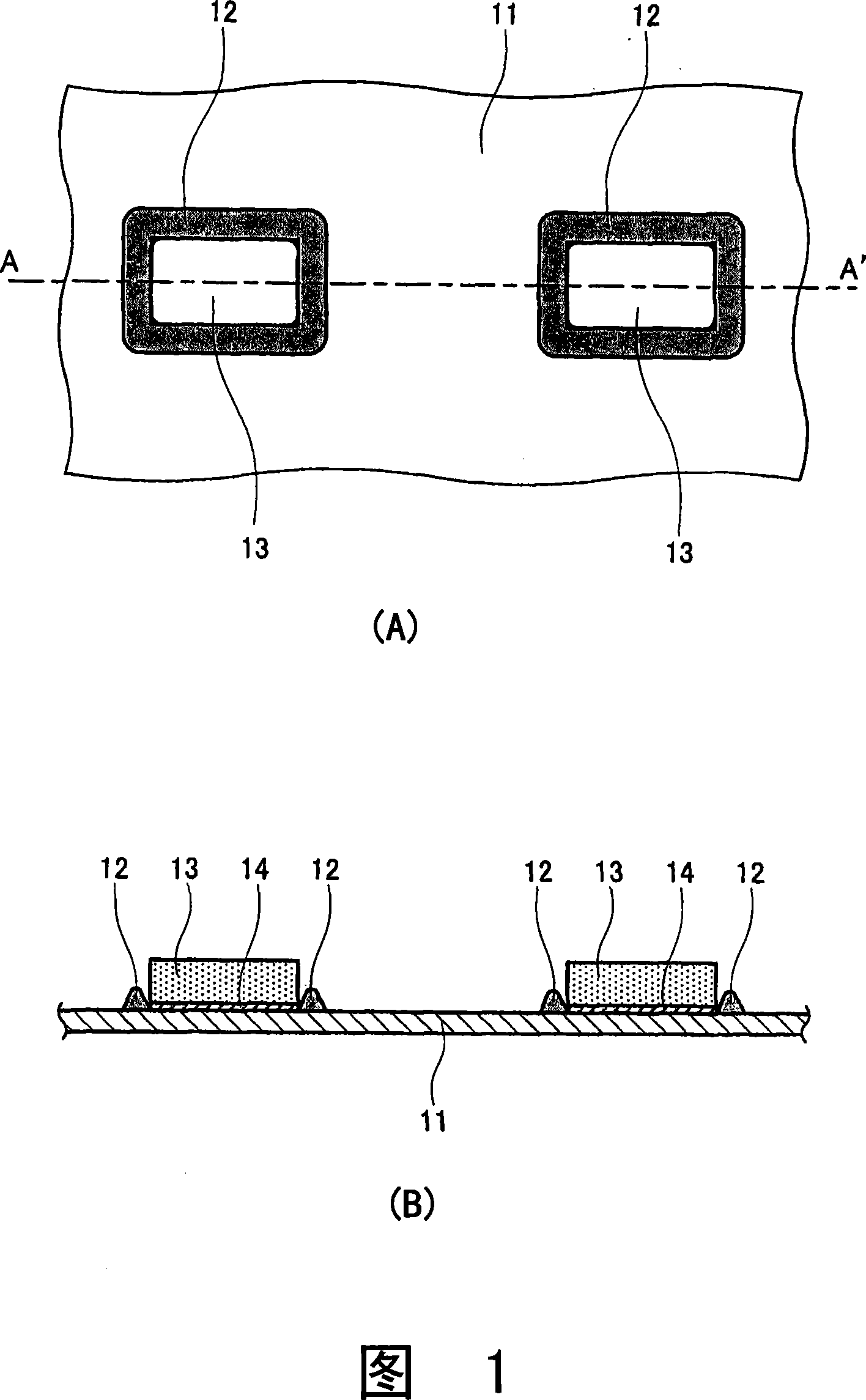

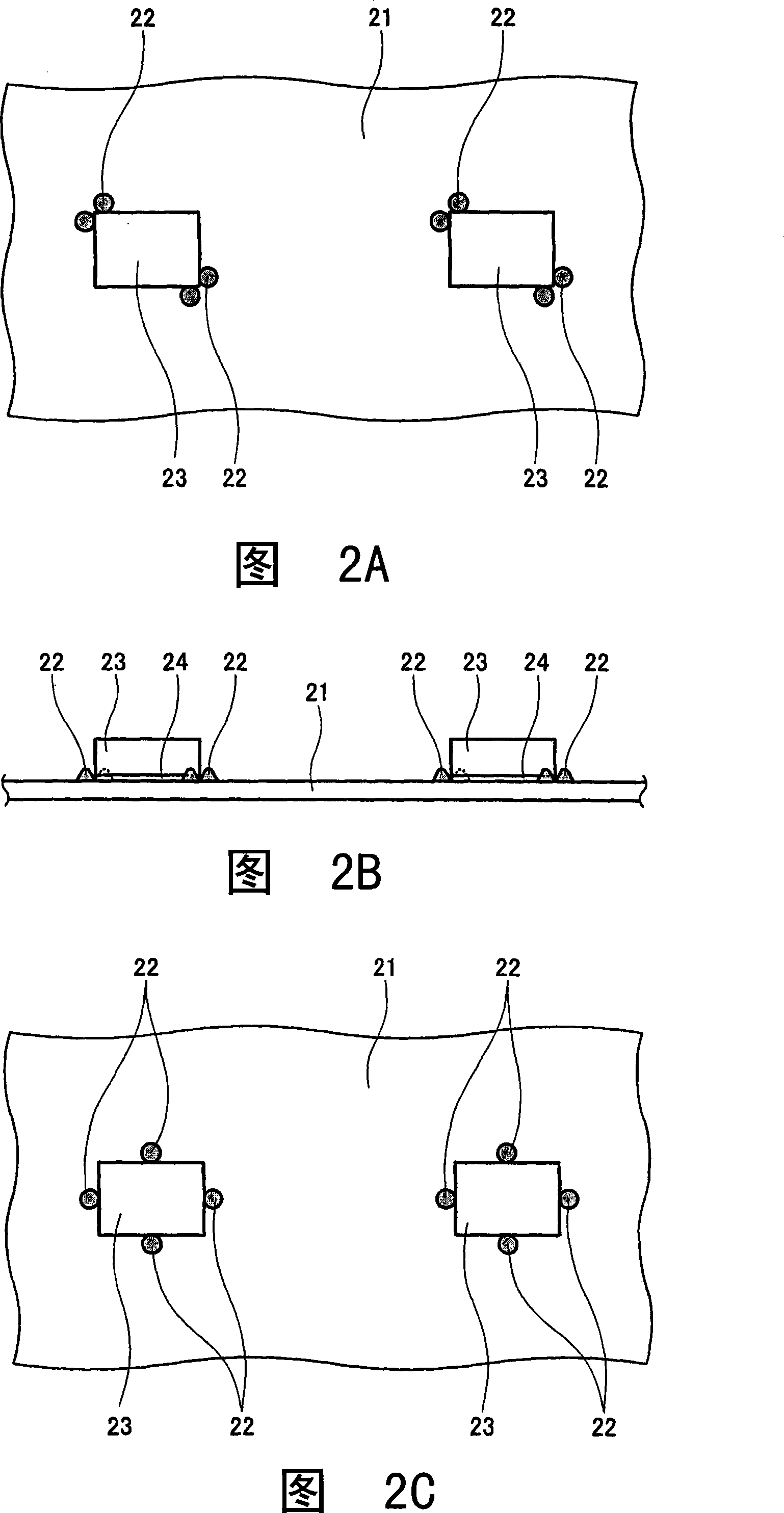

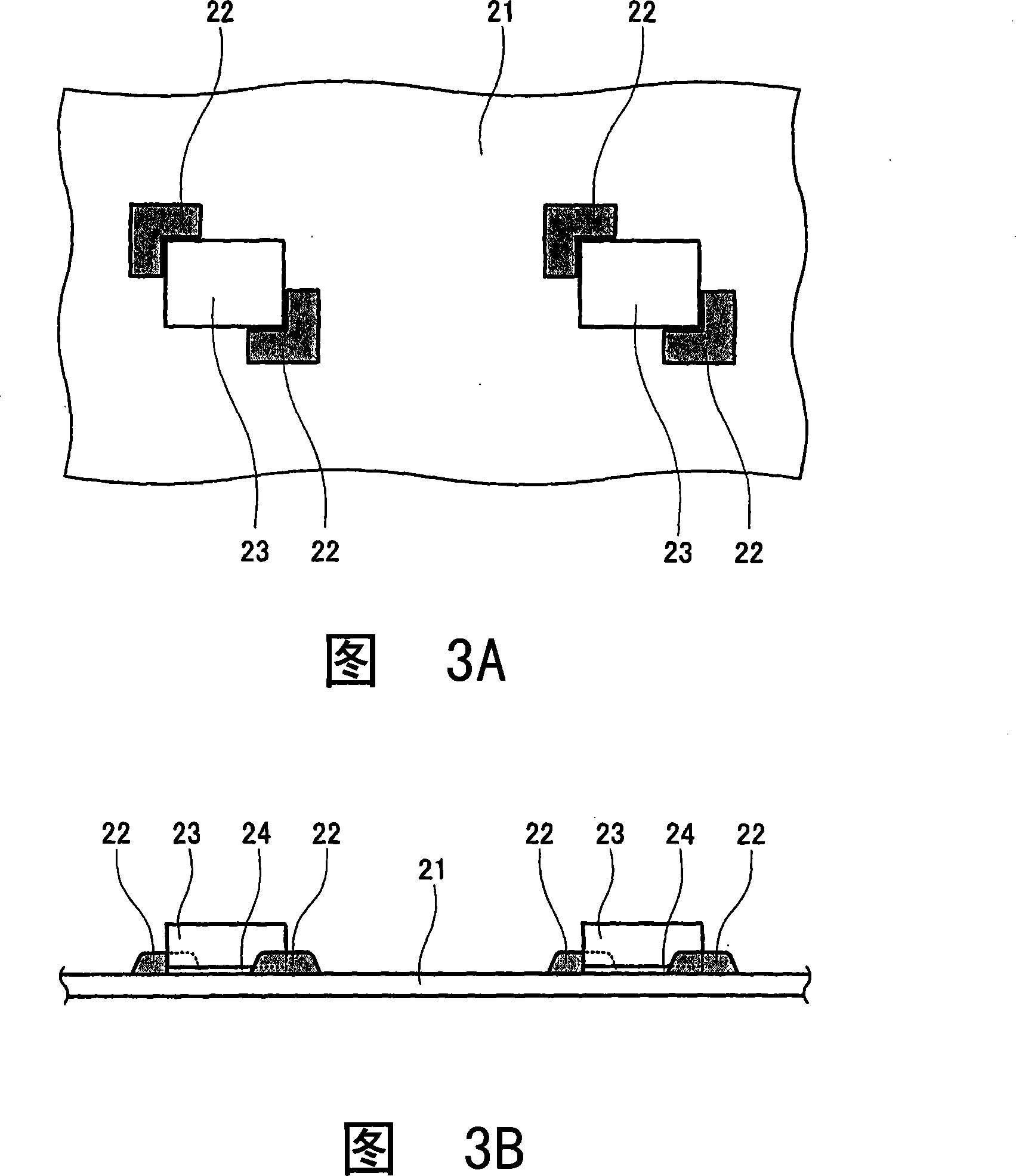

[0037] Hereinafter, a semiconductor device and a manufacturing method thereof according to an embodiment of the present invention will be described with reference to the drawings.

[0038] Here, a multi-chip module (resin-molded semiconductor device) is described as an example in which a plurality of semiconductor elements are arranged on the same surface, and one module is resin-sealed to realize multi-chip multi-chip.

[0039] Fig. 7 is a perspective view showing an example of the structure of a resin-molded semiconductor device according to an embodiment of the present invention. In the drawings, the sealing resin is not shown in order to show the structure of the resin-molded semiconductor device.

[0040] In FIG. 7 , 41 is a flat bare chip base (semiconductor element mounting portion) of the lead frame, 42 is a lead end of the lead frame, 43 is a suspension lead that is a part of the lead end, and 44 is a current that needs to flow to the bare chip base 41. 45 is a contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com