Wiring circuit board, manufacturing method for the wiring circuit board, and circuit module

A technology of wiring circuit substrate and manufacturing method, which is applied in the directions of printed circuit manufacturing, multilayer circuit manufacturing, removing conductive materials by chemical/electrolytic methods, etc., can solve the problems of time-consuming, low production efficiency of wiring circuit substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

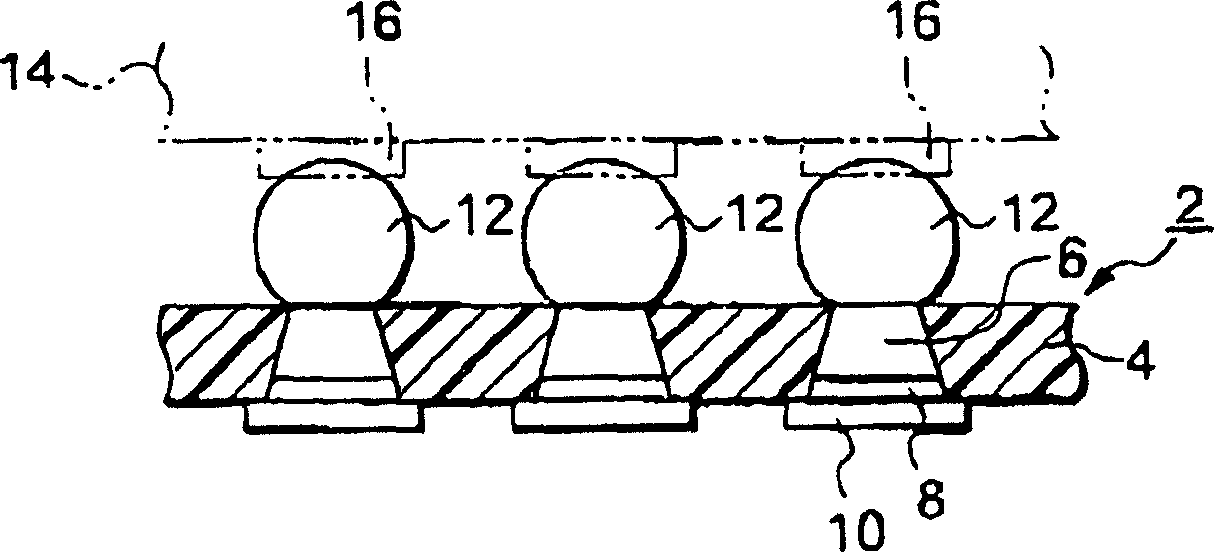

[0129] like figure 1 As shown, the wired circuit board 2 related to the first embodiment is composed of an insulating film 4 , a bump 6 , an etching stopper layer 8 , and a wiring layer 10 . The insulating film 4 is made of polyimide resin. The bump 6 is made of copper and formed to penetrate the insulating film 4 . In addition, the protrusion 6 has a conical shape. In more detail, the cross-sectional shape of the protrusion 6 is circular, and the vertical cross-section is roughly trapezoidal. In addition, the trapezoidal shape of the longitudinal section of the projection 6 is convenient for explanation, and the hypotenuse may also be curved. In addition, the longitudinal cross-sectional shape may be substantially rectangular, and the shape of the protrusion 6 may be substantially cylindrical instead of substantially conical. Even in such a case, the hypotenuse may be curved. In addition, the top surface of each protrusion 6 is exposed from the insulating film 4 , and i...

Embodiment 2

[0154] Next, refer to Figure 4 A wired circuit board related to Embodiment 2 of the present invention will be described. Figure 4 It is a cross-sectional view showing a wired circuit board related to Example 2. The wired circuit board related to Embodiment 2 has the same figure 1 The wired circuit boards related to the first embodiment shown have almost the same configuration, but differ in that the top surfaces 6 a of the protrusions 6 are formed as concave spherical surfaces. Therefore, the solder ball 12 is formed on the concave spherical surface.

[0155] Thus, according to the wired circuit board 2' related to the second embodiment, since the top surface 6a of each protrusion 6 is formed on the concave spherical surface, the connection area between the top surface 6a and the solder ball 12 is increased. As a result, the connection strength can be increased, the reliability of the printed circuit board can be improved, and the lifetime can be increased.

[0156] In ...

Embodiment 3

[0161] Next, refer to Figure 6A ~ Figure 6E A method of manufacturing a wired circuit board according to Embodiment 3 of the present invention will be described. Figure 6A ~ Figure 6E This is a cross-sectional view of the board showing the method of manufacturing the wired circuit board according to the third embodiment in order of steps. The method of manufacturing the wired circuit board according to the third embodiment is a method in which a part of the method of manufacturing the wired circuit board according to the first embodiment is modified.

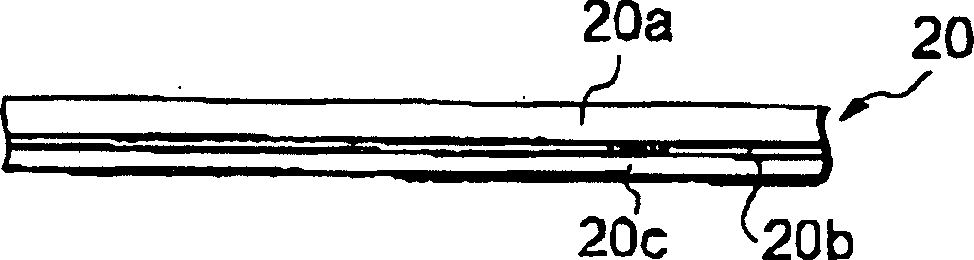

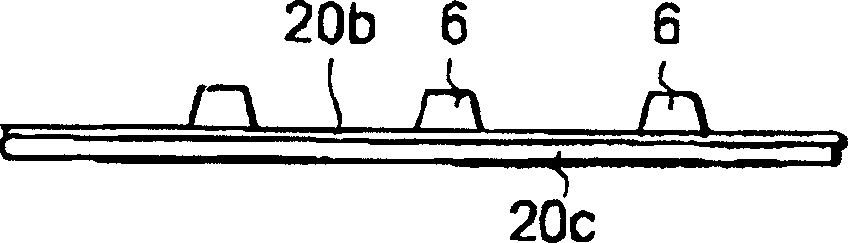

[0162] As shown in FIG. 6, the board|substrate 21 with a protrusion which formed the protrusion 6 on the one surface of the metal layer 20c for wiring layer formation via the etching stopper layer 20b is prepared. Through Example 1 Figure 2A ~ Figure 2C The procedure shown produces the substrate. Here, simply explain Figure 6A The fabrication method of the substrate is shown.

[0163] First, the multilayer metal plate 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com