Llight-absorbing material and photoelectric conversion element using same

A technology for photoelectric conversion elements and light absorbing materials, applied in electrical components, photovoltaic power generation, circuits, etc., can solve problems such as technologies that have not yet been found to be practical, and achieve the effects of strong mechanical properties, stable chemical properties, and small dark current values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0227] Embodiment 1 ((Al 1-y Ga y ) 1-x T x Fabrication of N film)

[0228] use Figure 19 The sputtering setup shown was fabricated (Al 1-y Ga y ) 1-x T x N film. This apparatus has a vacuum chamber 72, and a gas introduction nozzle 76 and an exhaust port 77 for introducing sputtering gas are provided on the side wall thereof. As the sputtering gas, a mixed gas of argon and nitrogen was used. In the vacuum chamber 72 , a target 74 is provided on the cathode, and a plurality of substrates 71 are provided on the substrate holder 70 facing it. As the target, a mixed crystal having an Al / Ga ratio of 0.1 / 0.9 was used. Chips of any one of V, Cr, Mn, Co, and Ni are provided on the target as chips of 3d transition metals (not shown). The 3d transition metal chip is sputtered with (AlGa) N at the same time, and reacts with the nitrogen contained in the sputtering gas, and the Al and Ga elements in the (AlGa) N film made by the 3d transition metal are replaced. The amount ...

Embodiment 2

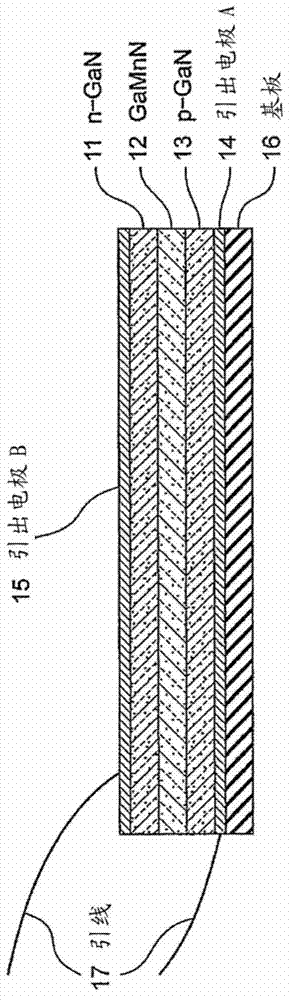

[0240] Example 2 (production of photoelectric conversion element)

[0241] In Example 1 (Al 0.1 Ga 0.9 ) 0.90 Ni 0.10 In the sputtering film formation of the N layer, a part of the surface of the p-GaN substrate 2 preformed on the single crystal sapphire 1 set on the substrate holder is covered with a metal mask, and the sputtered film is formed on the substrate. Non-film department. After sputtering film formation, in (Al 0.1 Ga 0.9 ) 0.90 Ni 0.10 Part of the surface of the n-layer 3 and the non-film-forming part were evaporated to form an n-layer electrode 4 and a p-layer electrode 5, respectively, to fabricate a photoelectric conversion element.

[0242] Figure 26 Shown is the voltage-current when irradiating AM1.5 light energy (equivalent to sunlight on the ground) and when not irradiating a single-cell structure test piece of a pn-type photoelectric conversion element with an AlGaNiN film formed on p-GaN characteristic. It does not generate electricity when it...

Embodiment 3

[0243] Example 3 (Membrane Formation by MBE Method)

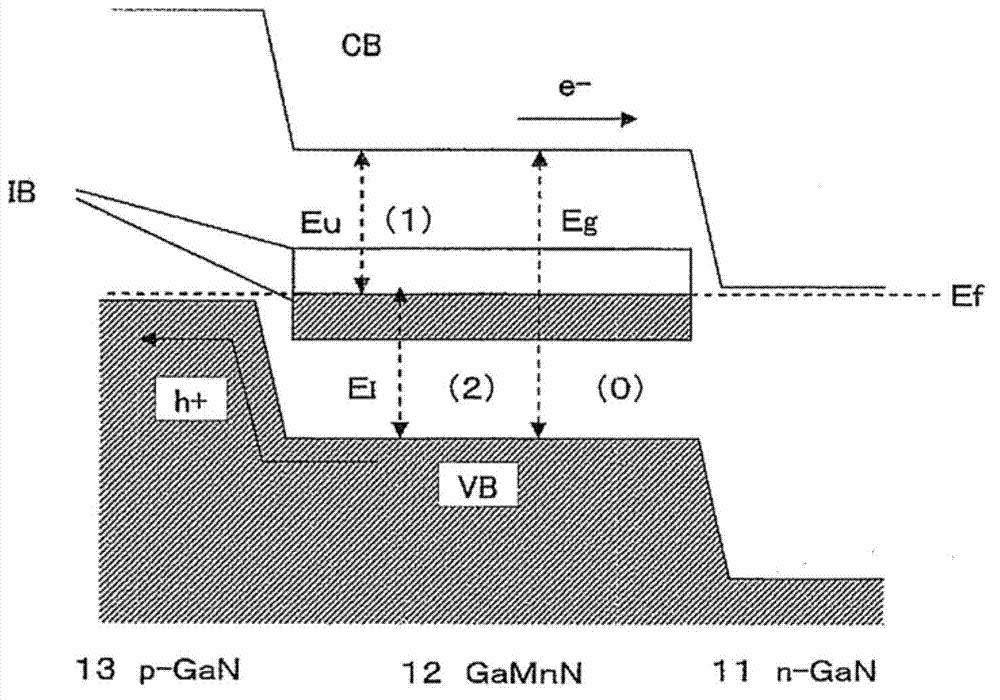

[0244] A sapphire substrate was placed on a substrate holder in a vacuum chamber equipped with a Ga and Mn vapor deposition source connected to a gas introduction nozzle for introducing ammonia gas. There is a heater on the back of the substrate holder. Turn on the heater to generate heat, heat the sapphire substrate to 950°C for purification, then lower the temperature of the sapphire substrate to 550°C, spray ammonia gas from the gas nozzle, blow it to the sapphire substrate, and place the first evaporation source The first metal material is heated to generate a metal molecular beam with Ga as the main component, which is irradiated on the surface of the sapphire substrate to form a buffer layer composed of a GaN thin film.

[0245] After the buffer layer is formed to a specified film thickness (0.2μm), the sapphire substrate is raised to 720°C, and the gas containing nitrogen atoms (here, ammonia gas) is blown directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com