Film transistor array substrate and mfg. method thereof

A technology of thin film transistors and array substrates, applied in the field of thin film transistor array substrates and its production, can solve the problems of increasing the difficulty of manufacturing processes, affecting the pass rate of manufacturing processes, and high production costs, so as to reduce the number of photomask manufacturing processes and manufacture The process is simple and the effect of improving the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

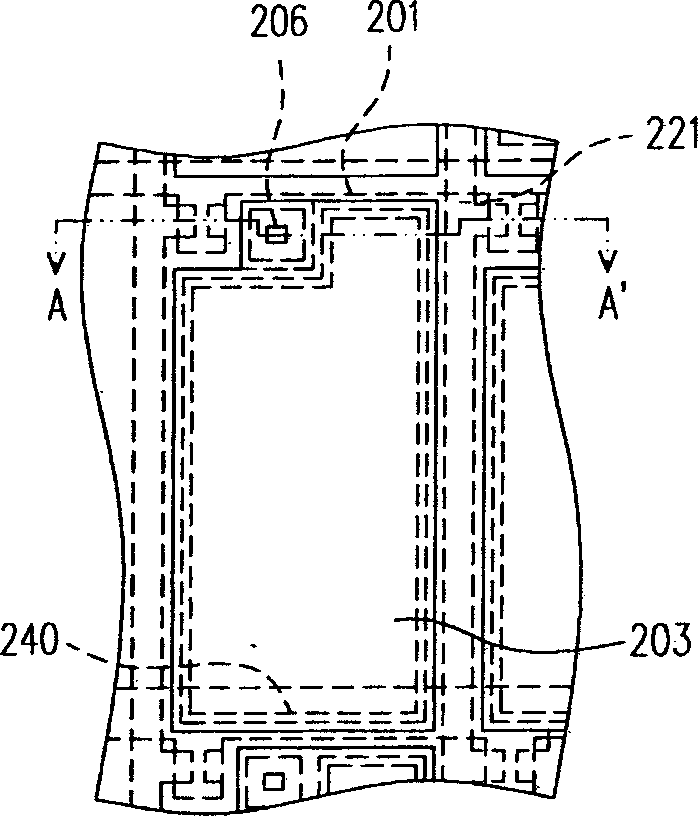

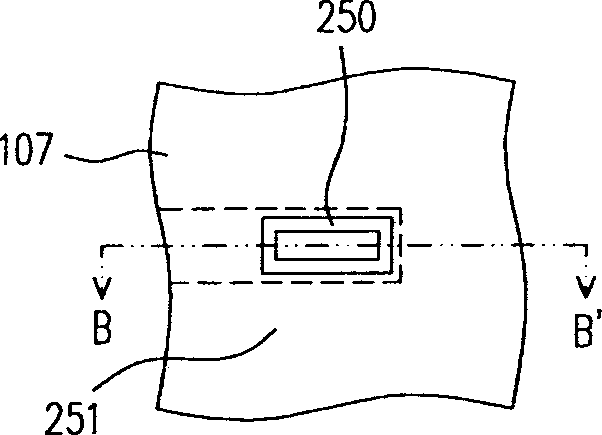

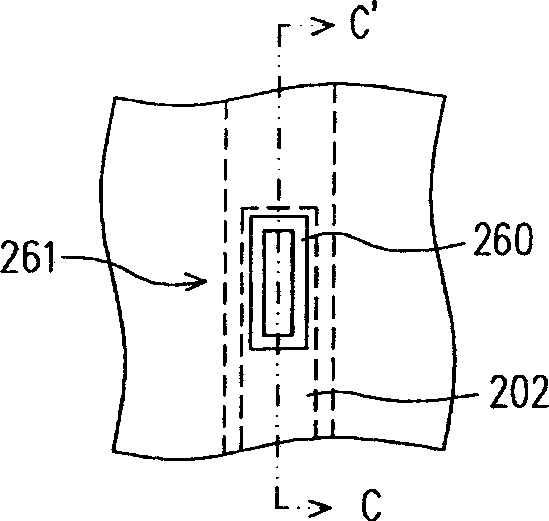

[0081] Figure 3A-3G The sequence is a top view of a manufacturing method of a thin film transistor array substrate according to a preferred embodiment of the present invention, and Figure 4Aa-4Ad ~ Figure 4Ga-4Gd are shown in sequence Figure 3A-3G The A-A' section, the B-B' section, the C-C' section and the D-D' section.

[0082] First, if Figure 3A and Figure 4Aa-4Ad As shown, a substrate 302 is provided, such as a transparent substrate made of glass, and the substrate 302 is divided into a plurality of sub-pixel regions 302a. Next, a plurality of film layers are sequentially formed on the substrate 302 , including a first conductive layer 312 , an insulating layer 314 and a channel layer 316 . Wherein, the first conductive layer 312 may be a metal stack composed of titanium / aluminum / titanium (Ti / Al / Ti), and the method of forming the first conductive layer 312 is, for example, sequentially through sputtering. Metal layers such as titanium / aluminum / titanium are depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com