Preparation method of high-performance modified polysulfone resin

A polysulfone resin, high-performance technology, applied in the field of preparation of high-performance modified polysulfone resin, can solve the problems of resin impact strength reduction, poor flexibility, low light transmittance, etc., achieve reduced dimensional stability, increase rigidity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

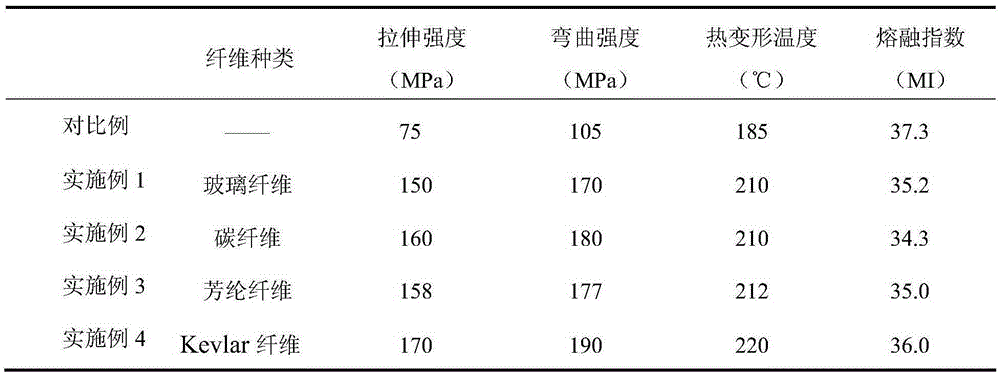

[0031] In the reaction kettle protected by inert gas, after adding the sulfolane solvent, start stirring and raise the temperature to 60°C~80°C, then add bisphenol A, 4,4'-dichlorodiphenylsulfone monomers in sequence, and after the monomers are completely dissolved, Then add the salt-forming agent, the amount of the salt-forming agent is 1.05-1.2 times the molar amount of bisphenol A, then add the water-splitting agent, continue to stir and heat up to 170°C-190°C, and the salt-forming reaction takes 1-2 hours; the salt-forming reaction After completion, steam all the water, then raise the temperature to 200°C-240°C, start stirring at a stirring speed of 50-70 rpm, keep the temperature for 1-2 hours, increase the stirring speed to 70-90 rpm, continue Constant temperature for 4 to 5 hours, then add chain extender, the molar amount of chain extender is 0.1% to 10% of the molar amount of bisphenol A, continue to react for 40 minutes, until the set viscosity is reached, polymerized ...

Embodiment 2

[0038] Same as Example 1, except that carbon fiber is used instead of glass fiber, other conditions are the same, and the test results are shown in the table below.

Embodiment 3

[0040] Same as Example 1, except that aramid fibers are used instead of glass fibers, other conditions are the same, and the test results are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| atomic number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com