Unsaturated polyester resin composition and encapsulated motor

A polyester resin, unsaturated technology, used in circuits, electrical components, electromechanical devices, etc., can solve the problems of inability to obtain thermal conductivity cured products, high molding shrinkage of cured products, prone to cracks, etc., and achieve good heat dissipation. , The effect of small molding shrinkage and excellent curability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0091] Put 100 moles of fumaric acid, 80 moles of propylene glycol, and 20 moles of hydrogenated bisphenol A into a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, and heat up to 200°C while heating and stirring under nitrogen flow , the esterification reaction is carried out according to the sequence of the conventional method, thereby obtaining an unsaturated polyester. The mass average molecular weight (MW) of this unsaturated polyester was measured under the above-mentioned conditions and found to be 10,000.

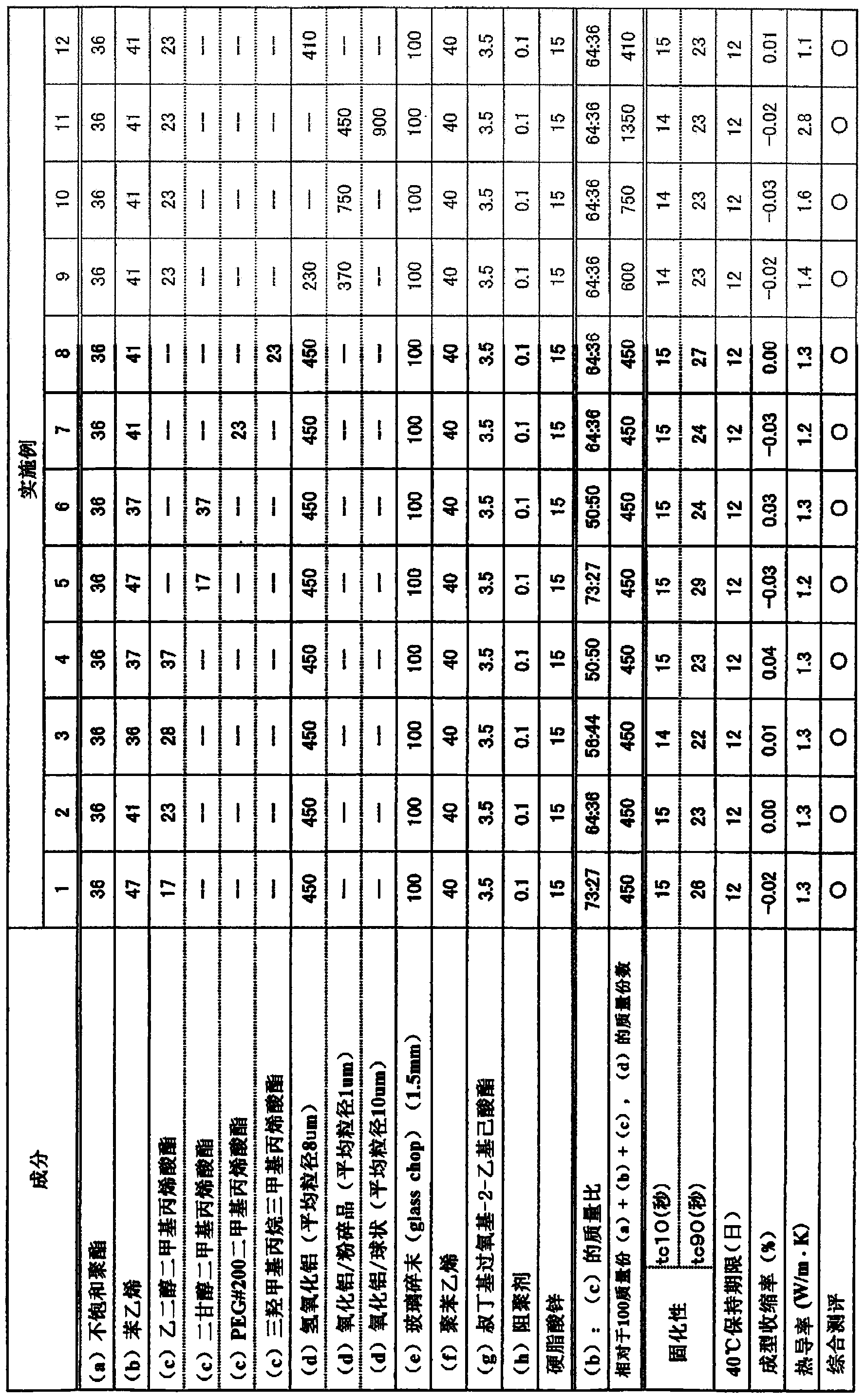

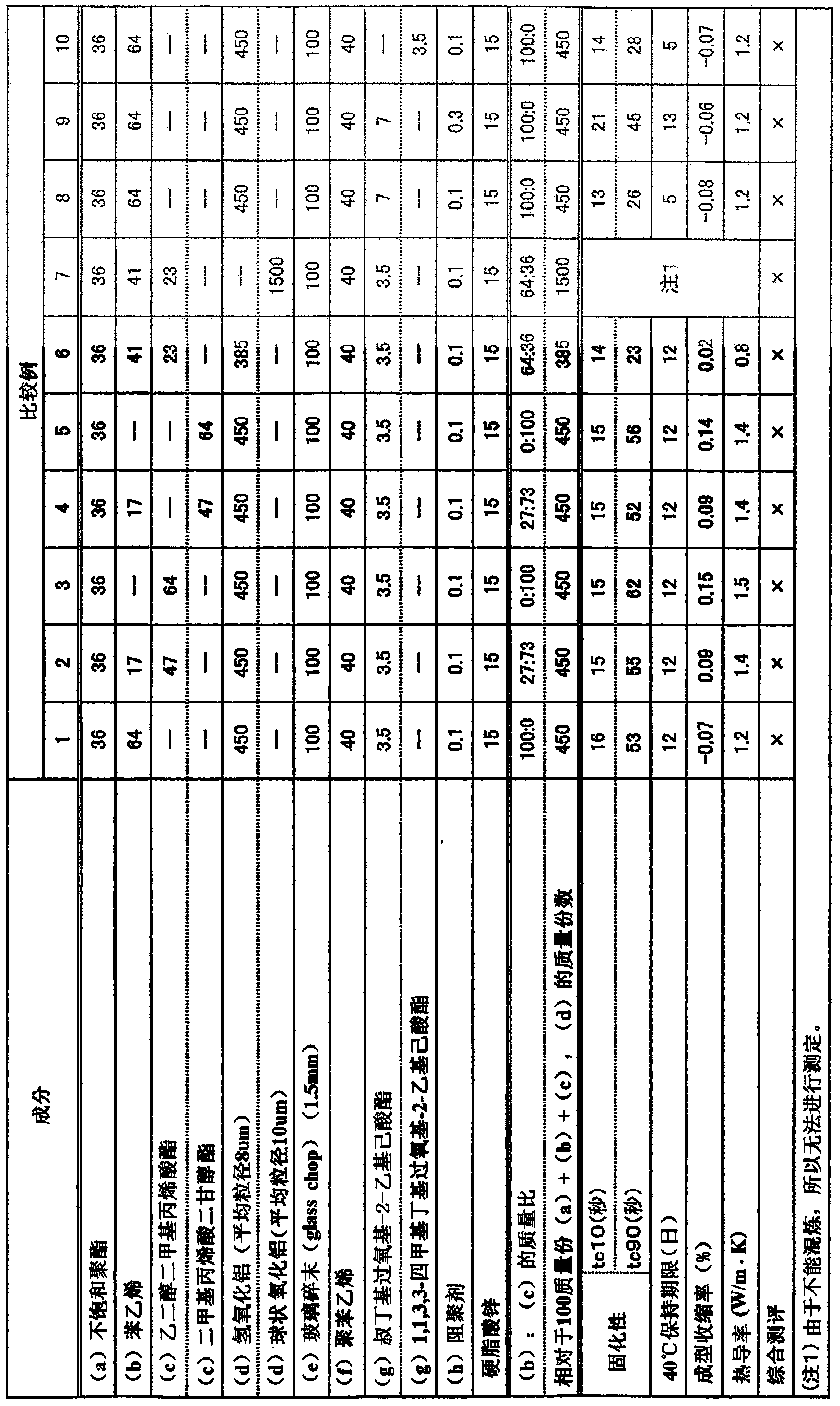

[0092] According to the ratio shown in Table 1, the unsaturated polyester obtained above and each component shown in Table 1 were kneaded using a double-bowl kneader to obtain an unsaturated polyester resin composition. Here, p-benzoquinone was used as (h) polymerization inhibitor. In addition, in Table 1, the unit of the compounding quantity of each component is mass parts.

[0093] Next, the above-mentioned ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com