Ultraviolet light-heat dual-curing gloss oil, and preparation method and application thereof

A dual-curing, ultraviolet light technology, used in coatings, epoxy coatings, polyester coatings, etc., can solve problems such as unfavorable large-scale promotion and use, hazards, etc., to increase the characteristics of delayed curing, and the process is environmentally friendly , Good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

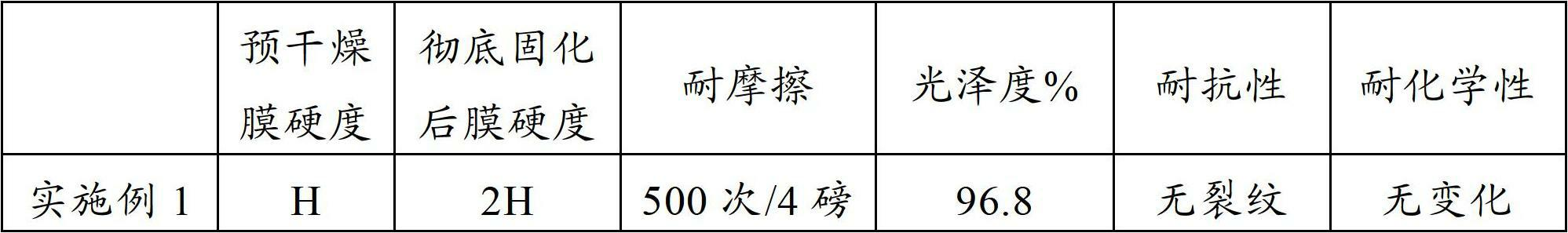

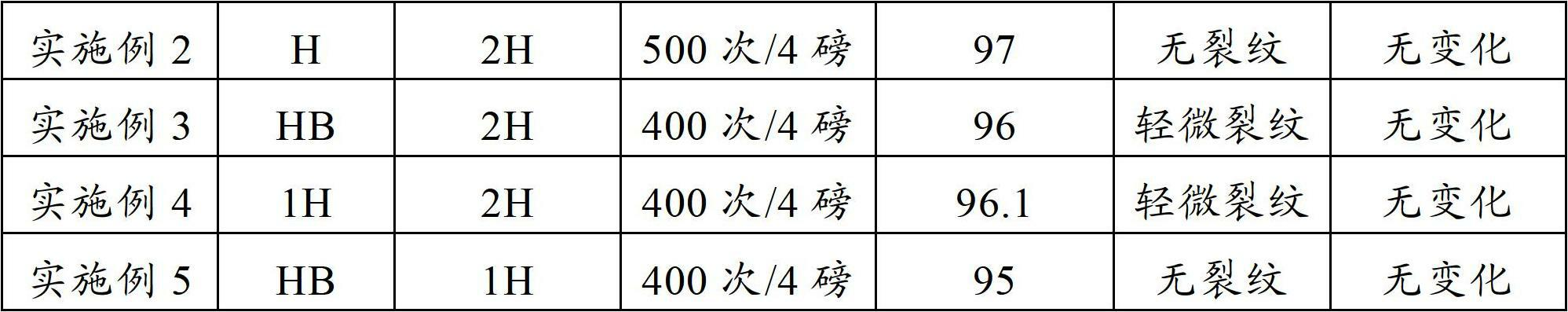

Examples

Embodiment 1

[0030] Prepare the following ingredients:

[0031] 20g of dual-curing resin composition, composed of isocyanate-containing aliphatic urethane acrylate resin (UAVPLS 2396, Bayer resin) and hydroxyl-containing polyacrylic resin (WB3011, Shanghai Wenshui Chemical Industry) in a weight ratio of 3:2;

[0032] Dilute monomer 10g, composed of pentaerythritol triacrylate (PETA, Tianjin Tianjiao Chemical) and caprolactone acrylate (AM2101, Shanghai Yingrui Chemical) in a weight ratio of 2:3.5;

[0033] 1g of photoinitiator is 1-hydroxycyclohexyl phenyl ketone 184 (Beijing Yingli Technology); 0.01g of polymerization inhibitor is hydroquinone (commercially available); 1g of leveling agent is polyether modified poly A mixture of siloxane (Teco 432) and isopropanol at a weight ratio of 1:1.55; 1 g of antifoaming agent is polydimethylsilicone oil; 1 g of substrate wetting agent is modified polysiloxane (Teco 245).

[0034] (1) Stirring and pre-dispersion: put 6g of the diluted monomer in ...

Embodiment 2

[0039] Prepare the following ingredients:

[0040] 70g of dual-curing resin composition, composed of isocyanate-containing aliphatic urethane acrylate resin (UAVPLS 2396, Bayer resin) and hydroxyl alkyd resin (3616X60, Jiangsu Sanmu Group) in a weight ratio of 1:1;

[0041] Diluted monomer 50g is composed of propoxylated trimethylolpropane triacrylate and pentaerythritol triacrylate in a weight ratio of 3:2;

[0042] 10g of photoinitiator is 1-hydroxycyclohexyl phenyl ketone 184 (Beijing Yingli Technology); 5g of polymerization inhibitor is hydroquinone (commercially available); 10g of leveling agent is polyether modified polysilicon A mixture of oxane (Teco 432) and isopropanol at a weight ratio of 1:1.55; 10g of antifoaming agent is polydimethylsilicone oil; 10g of substrate wetting agent is modified polysiloxane (Teco 245 ).

[0043] (1) Stirring pre-dispersion: put 30g of the diluted monomer in a beaker, slowly add the photoinitiator, stir for 25 minutes until the initia...

Embodiment 3

[0048] Prepare the following ingredients:

[0049] 35g of dual-curing resin composition, composed of aromatic urethane acrylate resin and hydroxyl-containing alkyd resin (WB101A, Xi'an North Huian Chemical Industry) in a weight ratio of 6:5;

[0050] Dilute monomer 10g, which is 2-hydroxyethyl methacrylate phosphate;

[0051] Photoinitiator 3g is 1-hydroxycyclohexyl phenyl ketone 184 (Beijing Yingli Technology); polymerization inhibitor 0.01g is hydroquinone (commercially available); leveling agent 1g is isopropanol; 1g of foaming agent is polydimethylsiloxane; 1g of substrate wetting agent is polyether modified silicone.

[0052] (1) Stirring pre-dispersion: put 6g of the diluted monomer in a beaker, slowly add the photoinitiator, stir for 20 minutes until the initiator is completely dissolved, then slowly add the leveling agent, continue stirring for 25 minutes, then add The dual-curing resin composition is heated and stirred evenly, wherein the heating temperature is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com