Automatic rubber powder plasticizing process and apparatus thereof

A technology of rubber powder and process, which is applied in the field of automatic rubber powder plasticization, can solve the problems of complex process, unstable quality, poor quality control, etc., and achieve the effect of simple process, significant social benefits and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

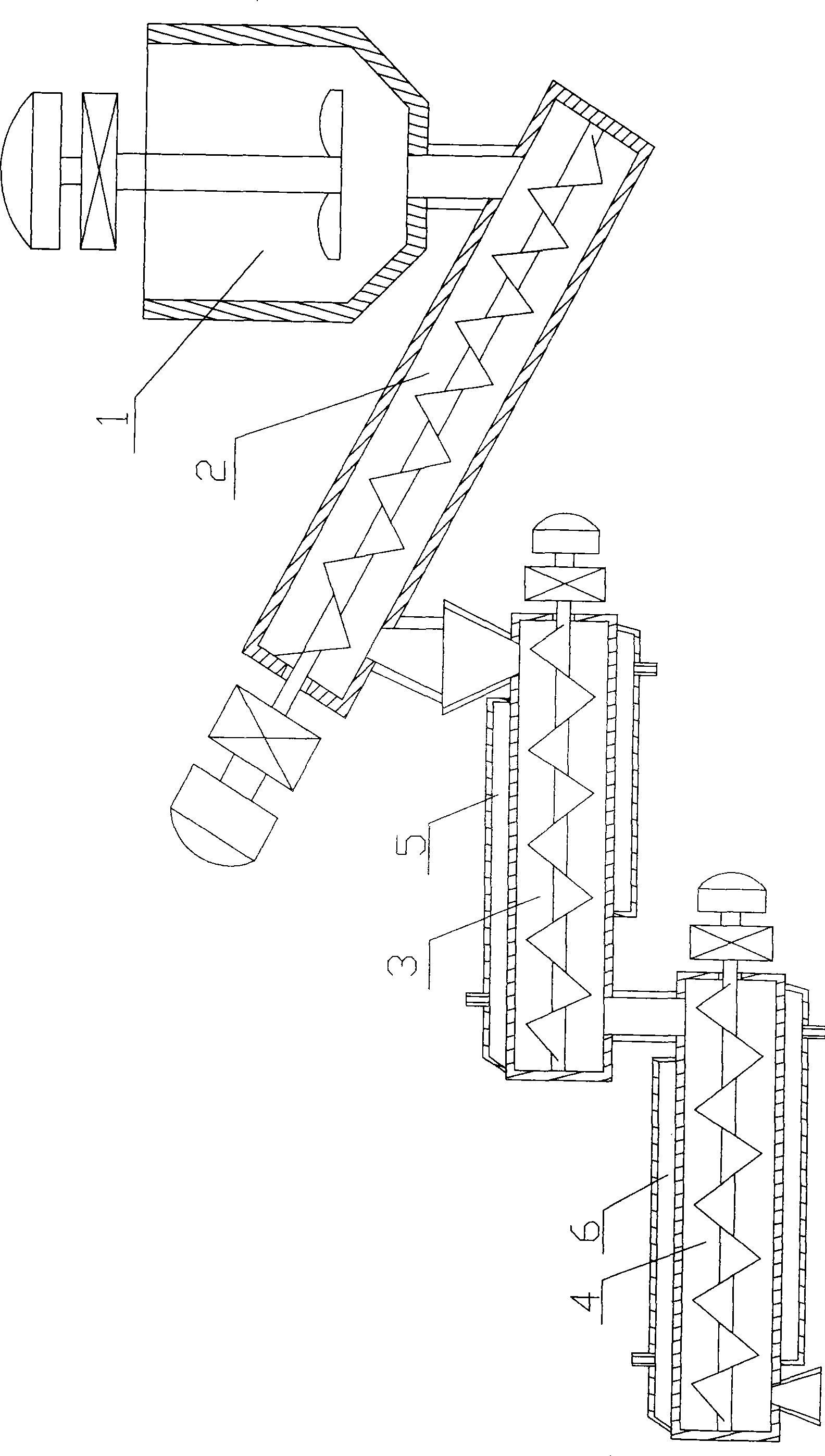

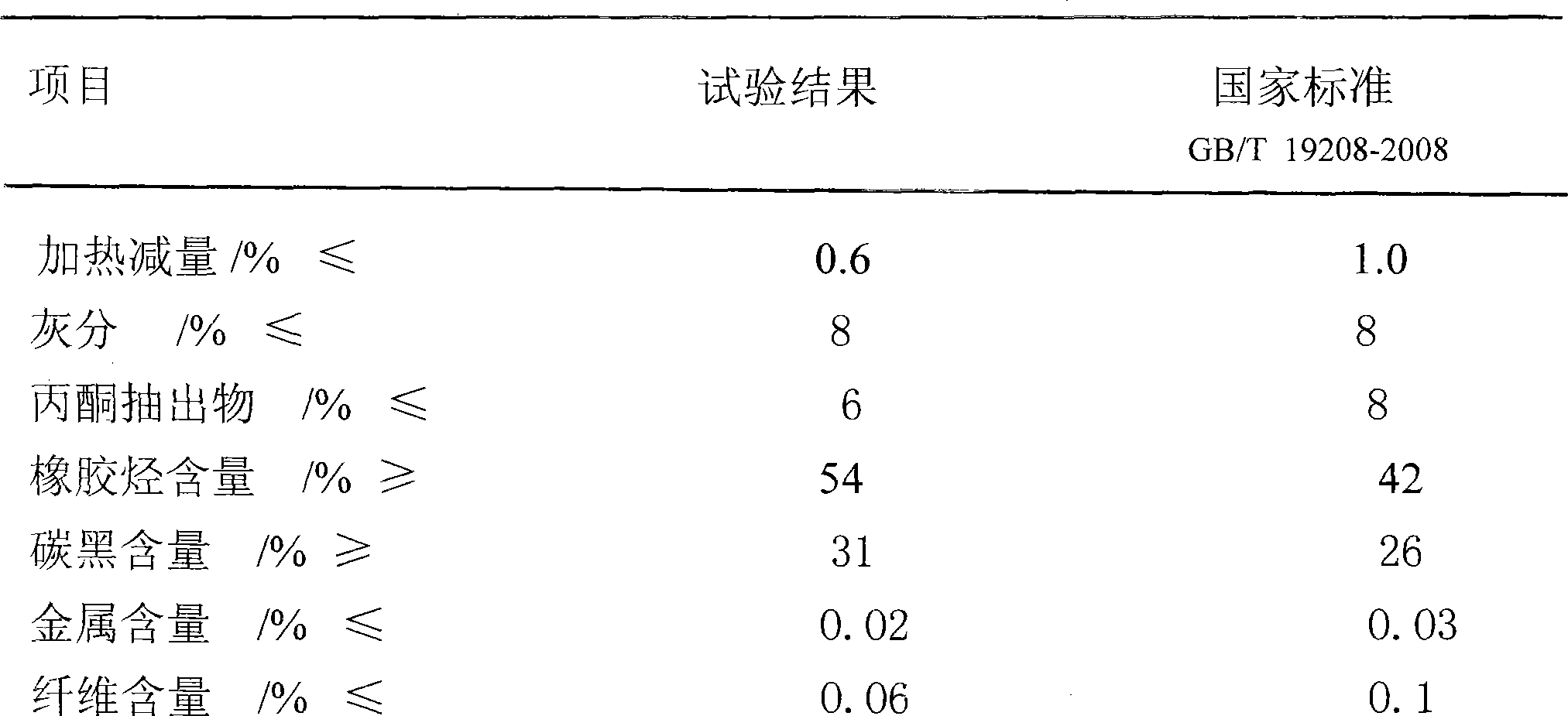

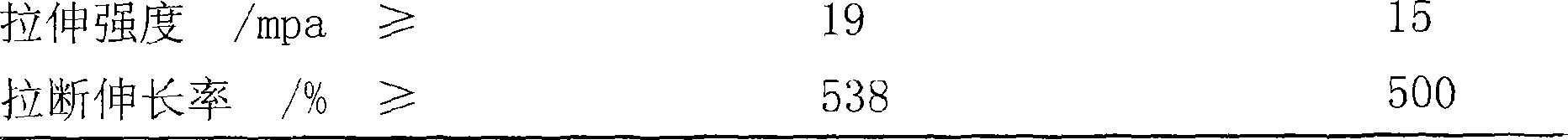

[0038] Add an activator and a softener to rubber powder of 10-20 mesh waste rubber, and the activator is one of commonly used activators such as 450B, 510, and 420. The softener is one of commonly used coal tar, pine tar and the like. According to its weight ratio: rubber powder: activator: softening agent=1: 0.3~0.4%: 8~10%, mix uniformly in stirring device 1. Send it into the thermal reaction device 3 through the feeding device 2, heat it to 280-300 ° C, and keep it warm for 13-15 minutes under the agitation of the screw conveying device II, so that the rubber powder is heated evenly. Fully desulfurized and plasticized under the action of softener. Then send it to the cooling device 4 to cool to 80°C and below, and then send it out of the cooling device 4 for the production of regenerated rubber products.

Embodiment 2

[0040] Add activator and softening agent in the rubber powder of waste rubber of 30~40 purposes, activator and softening agent are with embodiment one, are by its weight ratio: rubber powder: activator: softening agent=1: 0.3~0.4%: 16 to 18%, mixed uniformly in the stirring device 1. Send it into the thermal reaction device 3 through the feeding device 2, heat it to 200-220 ° C, and keep it warm for 8-10 minutes under the agitation of the screw conveying device II, so that the rubber powder is heated evenly. Fully desulfurized and plasticized under the action of softener. Then send it to the cooling device 4 to cool to 80°C and below, and then send it out of the cooling device 4 for the production of regenerated rubber products.

Embodiment 3

[0042]Add activator and softening agent in the rubber powder of waste rubber of 20~30 purposes, activator and softening agent are with embodiment one, are by its weight ratio: rubber powder: activator: softening agent=1: 0.3~0.4%: 12-14%, mixed uniformly in the stirring device 1. Send it into the thermal reaction device 3 through the feeding device 2, heat it to 240-260 ° C, and keep it warm for 10-12 minutes under the agitation of the screw conveying device II, so that the rubber powder is heated evenly. Fully desulfurized and plasticized under the action of softener. Then send it to the cooling device 4 to cool to 80°C and below, and then send it out of the cooling device 4 for the production of regenerated rubber products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com