System and technology for processing low-concentration VOCs (volatile organic chemicals) waste gas

A low-concentration, waste gas technology, applied in the direction of vapor condensation, chemical instruments and methods, separation methods, etc., can solve problems such as difficulty in comprehensive treatment of VOCs, and achieve the effect of highly automated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

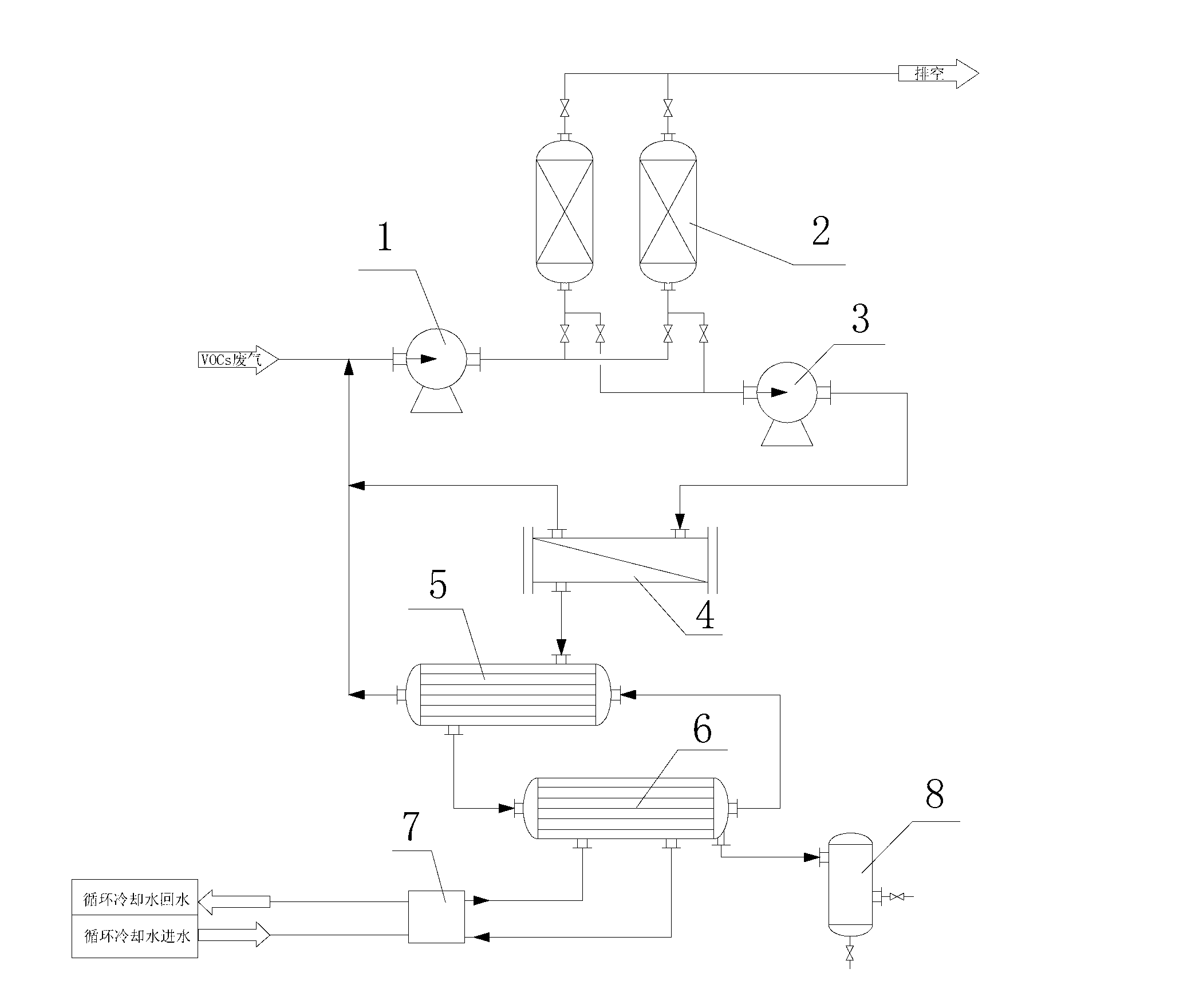

[0026] Example 1 Low-concentration VOCs waste gas treatment system

[0027] Low-concentration VOCs exhaust gas treatment system, the system includes: fan 1 that sends exhaust gas, fan 1 and adsorption device 2 are connected through an air guide pipe, and a switchable gas exhaust pipe is drawn from the top of the adsorption device 2; vacuum pump 3 passes through a switchable guide pipe. The gas pipeline connects the inlet port of the adsorption device 2 and the membrane separator 4, and the outlet port of the membrane separator 4 leads to two gas guide pipelines, one is connected to the precooler 5, and the other is connected to the inlet of the blower fan 1; Both ends are connected to the pre-cooler, and three air guide pipes are drawn from the bottom of the condenser 6, two of which are connected to RFG7 as air inlet and outlet pipes, and the other is connected to the collection tank 8; the other end of RFG7 leads to two pipes, which are respectively used as circulating cool...

Embodiment 2

[0028] Embodiment 2 low-concentration VOCs exhaust gas treatment process

[0029] (1) Use fan 1 to send low-concentration VOCs waste gas in the sewage pool to adsorption device 2 for initial concentration, after purification, the gas is emptied, and the adsorption is stopped when the adsorption of the adsorbent reaches saturation, and desorption is performed by vacuuming with vacuum pump 3;

[0030] (2) The desorbed gas is sent to the membrane separator 4 for secondary concentration, the permeated gas enters the condensation system, and the residual gas returns to the fan 1 inlet;

[0031] (iii) The permeated gas that has been enriched for the second time is pre-cooled and lowered through the pre-cooler 5, and then sent to the condenser 6 for condensation. The light hydrocarbons obtained from the condensation enter the collection tank 8 and are collected and returned to the production system. The non-condensable gas is used as a pre-cooler 5 cold source, its cooling capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com