Hydrogen generator

a generator and hydrogen technology, applied in the field of hydrogen generators, can solve the problems of high cost, high electrical power, and technological challenges, and achieve the effects of high strength, cost-effective containment solutions, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

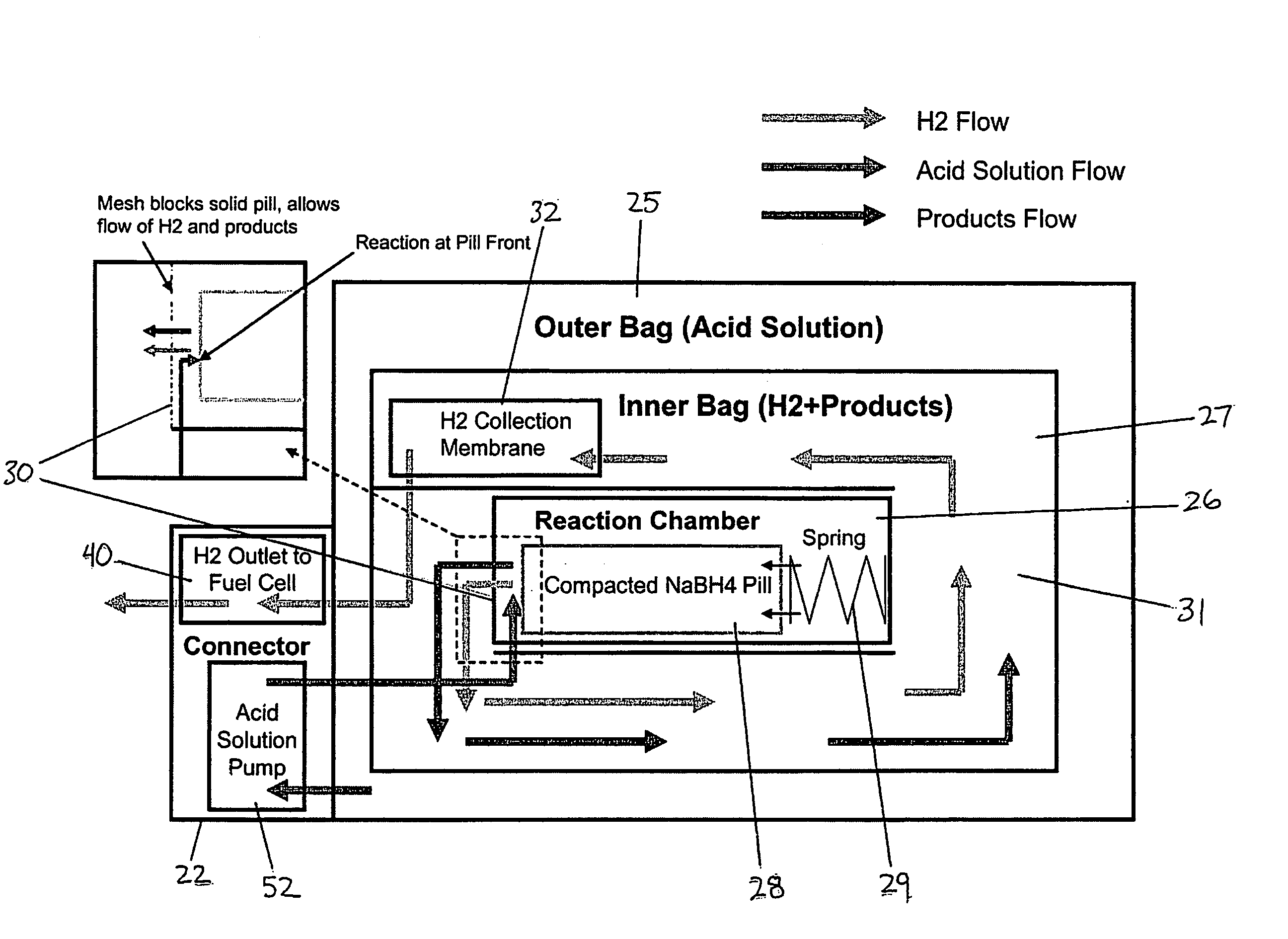

Method used

Image

Examples

Embodiment Construction

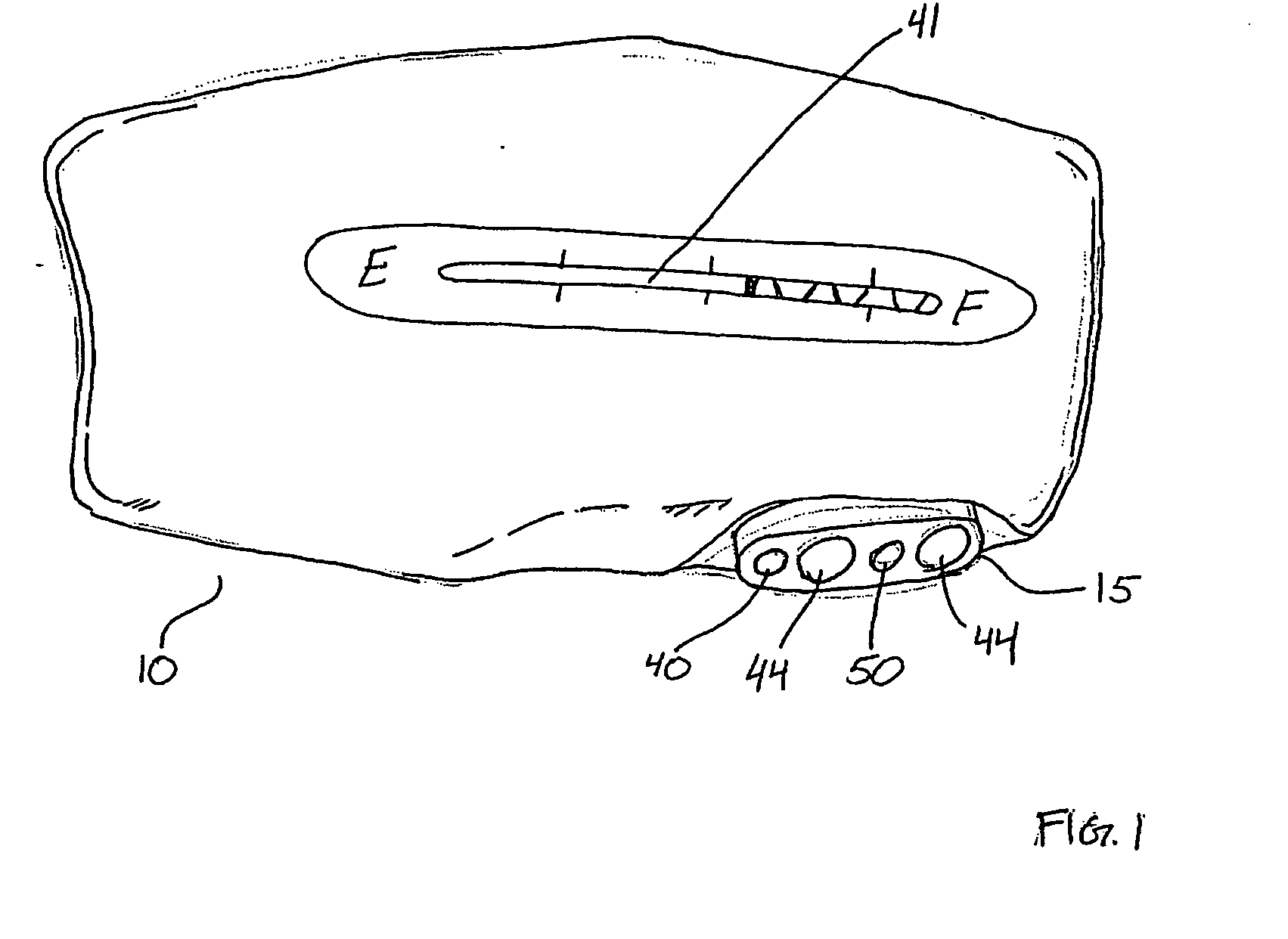

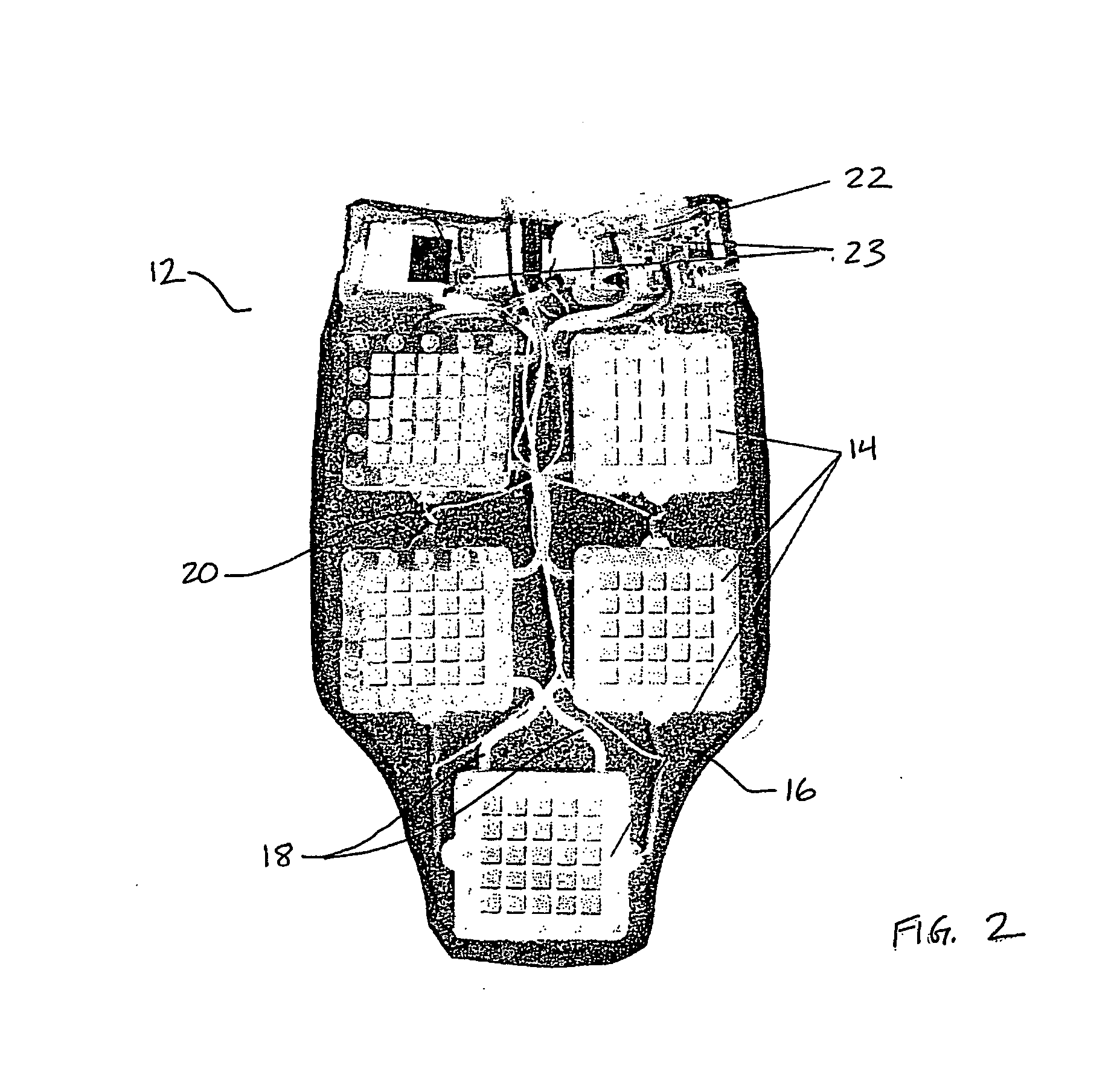

[0016] According to one embodiment of the invention and referring to FIG. 1, a portable fuel cartridge 10 generates hydrogen gas for use as fuel by a fuel cell. Referring to FIG. 2, a portable fuel cell system 12 comprises fuel cells 14 which generate electricity by electrochemically reacting hydrogen gas and oxygen in ambient air. The by-products of the electrochemical reaction also include water and heat. The generated electricity can be used to power portable electrical devices, and to provide heat. The portable fuel cartridge 10 has a connector sub-assembly 15 for physically and fluidly coupling the fuel cell cartridge 10 to the fuel cell system 12. Once coupled, hydrogen gas generated by the fuel cartridge 10 can be delivered into the fuel cell system 12 for use by the fuel cells 14.

[0017] One particular use contemplated for the fuel cartridge 10 and fuel cell system 12 is to provide heat and electrical power to personal apparel, such as a jacket. The fuel cell system 12 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com