Method for identifying casting DR image loose defects based on improved YOLOv3 network model

A network model and defect technology, applied in the field of workpiece casting, can solve the problems of affecting the local area effect of defects, it is not easy to distinguish the types of objects to be detected, and the recognition accuracy is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

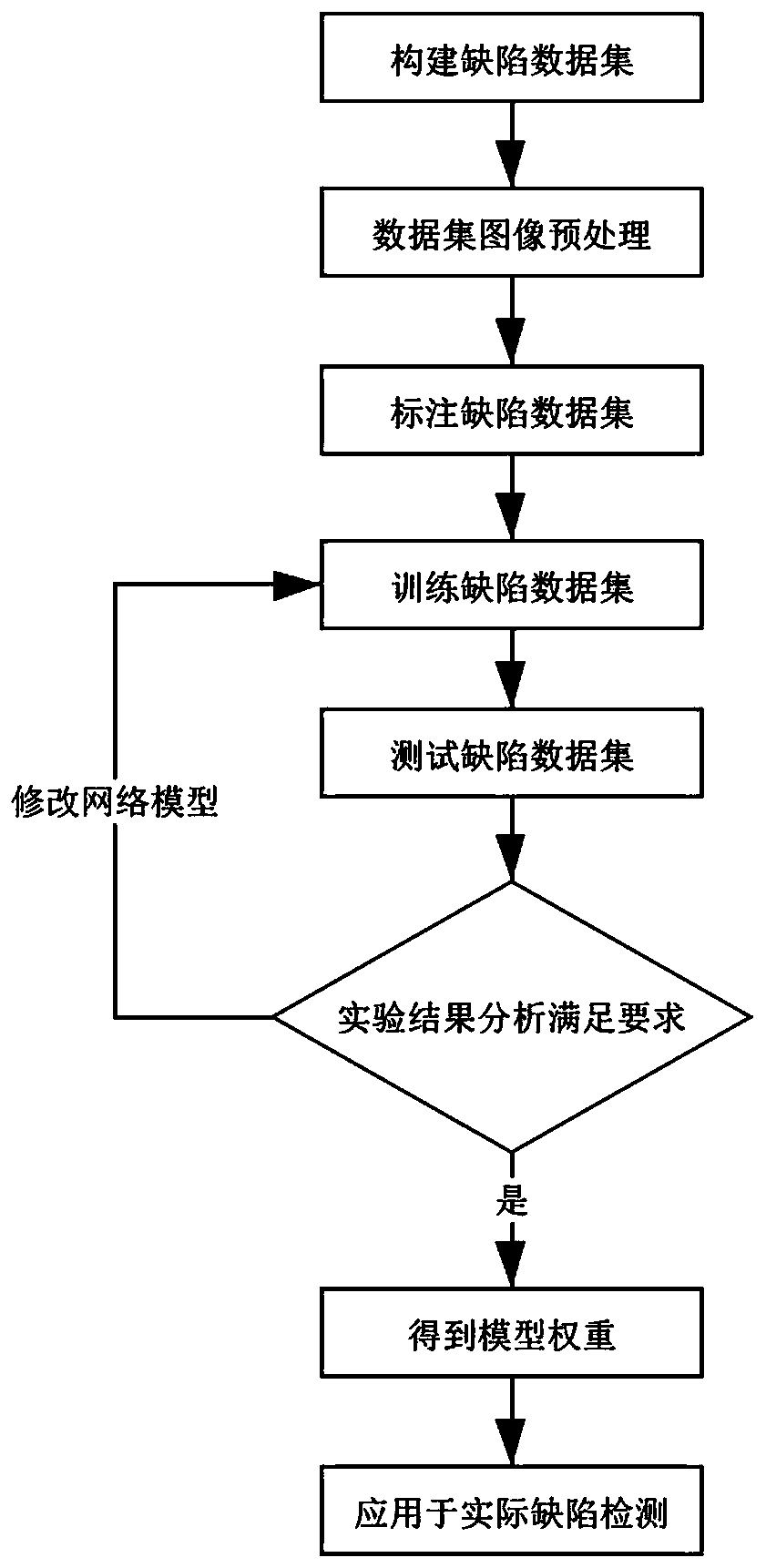

[0071] see Figure 1 to Figure 6 , a method based on the improved YOLOv3 network model to identify loose defects in casting DR images, mainly including the following steps:

[0072] 1) Obtain DR loose defect images of several castings.

[0073] The casting is a cast steel bolster or a side frame of a railway train bogie.

[0074] 2) Preprocessing the DR loose defect image and constructing a loose defect data set.

[0075] The main steps of preprocessing the DR original defect image are as follows:

[0076] 2.1) The DR original defect image is uniformly divided into defect images of N×N size.

[0077] 2.2) Perform data enhancement on defect images. The data augmentation methods include image flipping, image rotation and mirroring.

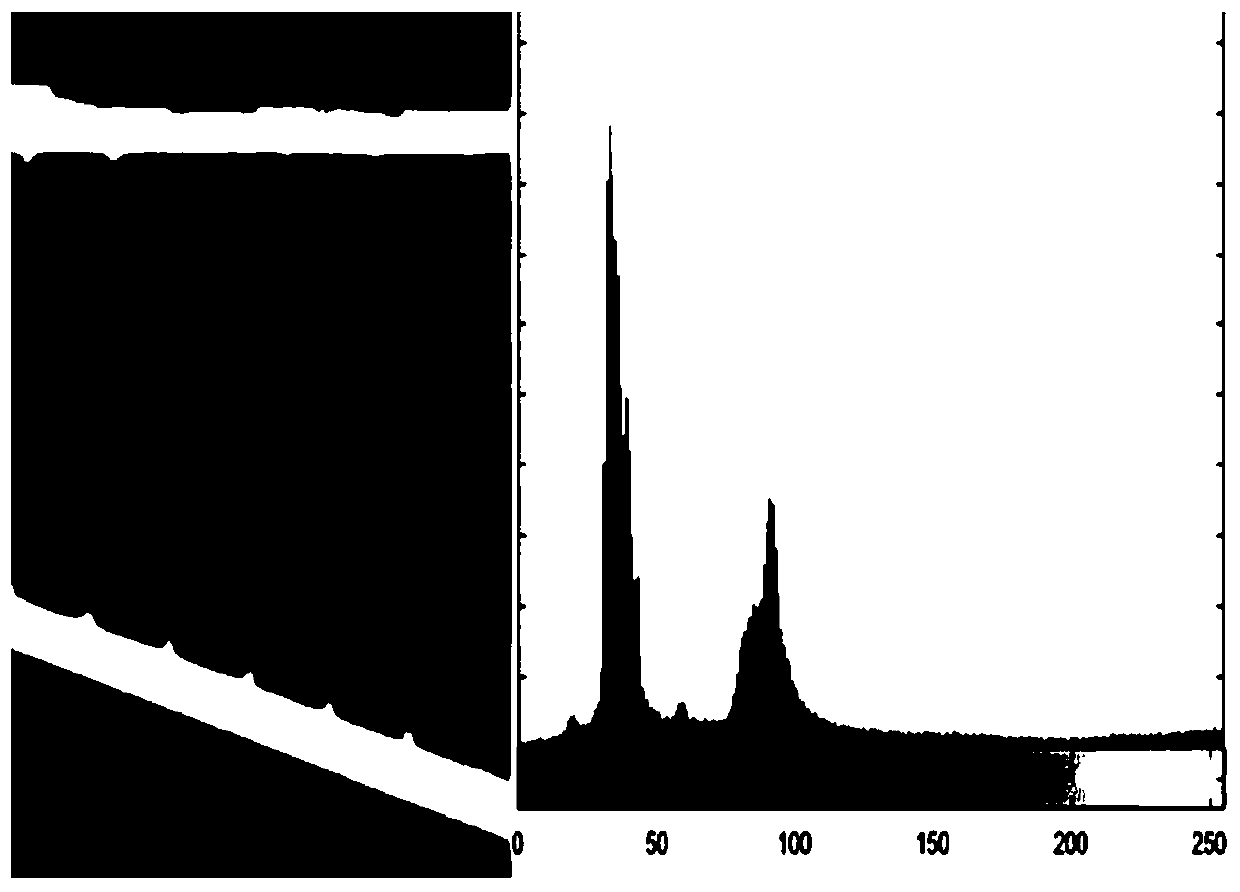

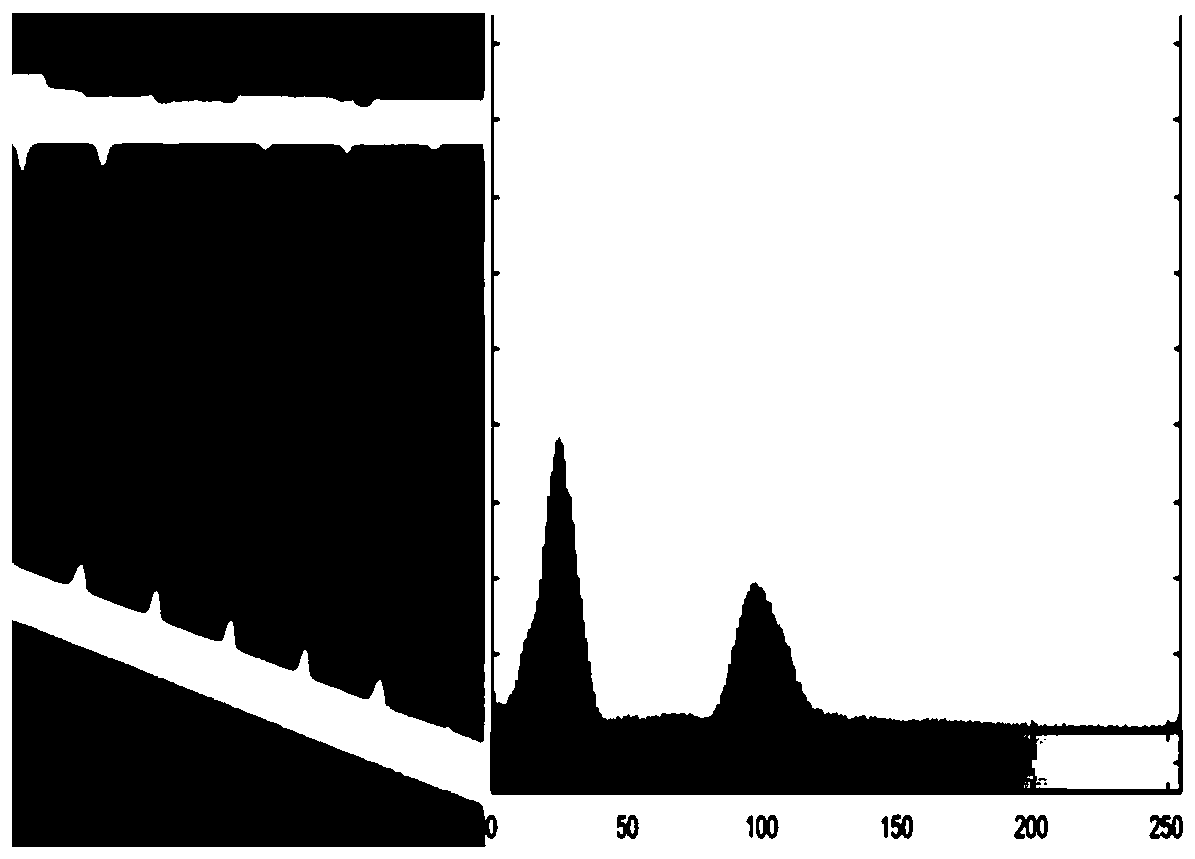

[0078] 3) Preprocessing the loose defect data set, enhancing the gray value of the loose defect data set, making it easier to distinguish from the gray value of the background, thereby improving the process of subsequent training models and tes...

Embodiment 2

[0140] A method for identifying loose defects in casting DR images based on the improved YOLOv3 network model, mainly comprising the following steps:

[0141] 1) Obtain DR loose defect images of several castings.

[0142] 2) Preprocessing the DR loose defect image and constructing a loose defect data set.

[0143] 3) Preprocessing the loose defect data set to enhance the gray value of the loose defect data set.

[0144] 4) Use the rectangular frame of the image annotation tool to mark the defect of the loose defect data set, and obtain the defect category, defect level, center point coordinates (X, Y) of the rectangular frame, rectangular frame width W and rectangular frame corresponding to each rectangular frame Height H. The sparse defect data set after defect labeling is randomly divided into a training set of sparse defect data and a test set of sparse defect data.

[0145] 5) Establish an improved YOLOv3 network model, and set the number of filters, COCO data set and V...

Embodiment 3

[0152] A method for identifying loose defects in casting DR images based on the improved YOLOv3 network model, the main steps are shown in Example 2, wherein the main steps of training the improved YOLOv3 network model are as follows:

[0153] 1) Divide each image of the loose defect data training set into s×s cells;

[0154] 2) Use the improved YOLOv3 network model to extract features from each cell, and produce feature images of 3 different scales;

[0155] 3) Using the regressor to predict several candidate target bounding boxes, the main steps are as follows:

[0156] 3.1) Set preset bounding box (c x , c y ,p w ,p h ); said (c x , c y ) is the center coordinate of the preset bounding box on the feature image; p w ,p h is the width and height of the preset bounding box on the feature map;

[0157] 3.2) Calculate the center offset of the predicted bounding box (t x , t y ) and aspect ratio (t w , t h );

[0158] 3.3) Update the predicted target bounding box (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com