Vision guiding type automatic dispensing system and operating method thereof

An automatic dispensing and vision-guided technology, which is applied to coatings and devices for coating liquid on the surface, etc., can solve the problems of low production efficiency, low yield rate and large error of manual operation, and avoid uneven dispensing , high dispensing precision and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

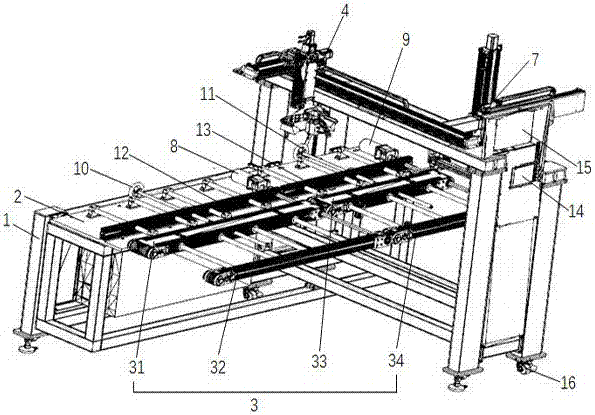

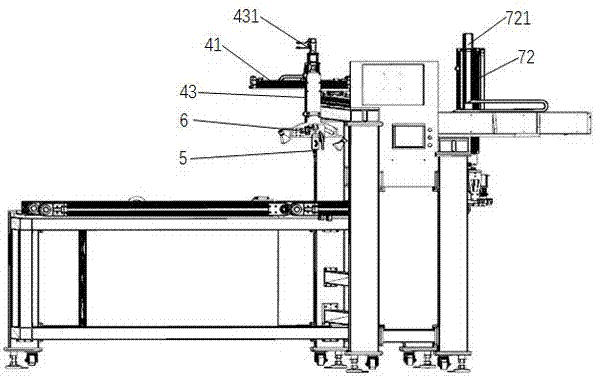

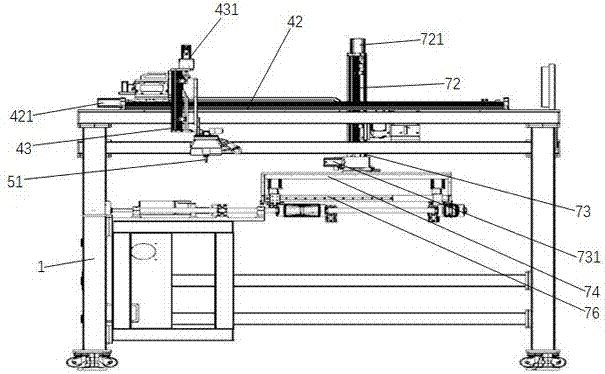

[0040] Such as Figure 1-10 As shown, a vision-guided automatic dispensing system includes a frame 1, a flow channel 3, an XYZ platform 4, a visual scanning recognition mechanism 6, a dispensing device 5, an XZR platform 7 and a PLC control system (not shown);

[0041] The frame 1 is in the shape of a cuboid and is placed on the ground, and a table 2 is provided on the frame 1;

[0042] The flow channel 3 is arranged above the frame 1 and is located on the front side of the table 2, and the flow channel 3 is divided into a feed delivery channel section and a processing flow channel section, and the feed delivery flow section The channel section includes a first feed delivery channel 31 and a second feed delivery channel 32, the first feed delivery channel 31 and the second feed delivery channel 32 are arranged in parallel and the first feed The delivery channel 31 is set close to the table 2 on the frame 1, the second feed delivery channel 31 is set away from the frame 1 tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com