Functionalized carbon nitride photocatalyst capable of performing catalytic oxidization on benzene to synthesize phenol

A catalytic oxidation and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, preparation of organic compounds, etc., can solve the problem of reducing the contact area between active sites and reactants, activity and stability To solve the problems of improving performance and stability, etc., to achieve the effect of convenient separation and treatment, strong renewable ability and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

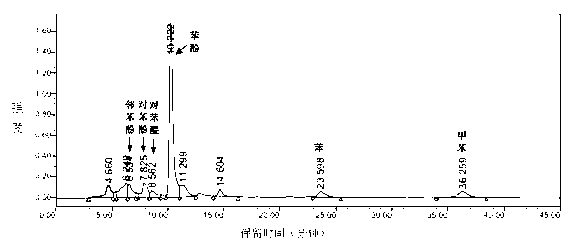

Examples

Embodiment 1

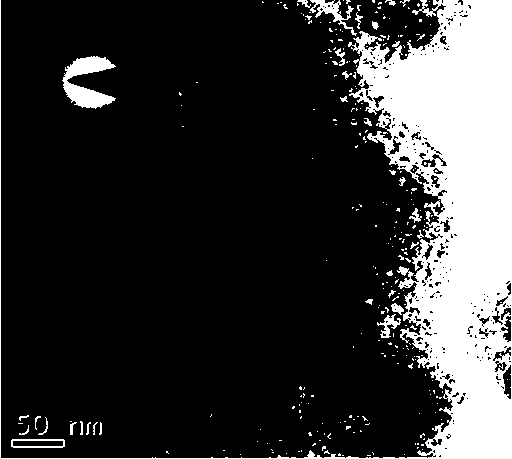

[0022] The first is the preparation of carbon nitride precursor

[0023] Weigh 5g of commercial cyanamide and dissolve it in 12.5g of commercial silica sol (containing 40% 12 nm SiO 2 ), heat and stir at 100°C until dry, and heat the obtained white sample at 500°C for 4h to obtain yellow powder. Add powder to 4M NH 4 HF 2 The solution was stirred for 24 hours to remove the template, filtered, washed with water, washed with ethanol, and dried under vacuum at 80°C to obtain a yellow powdered mesoporous carbon nitride photocatalyst.

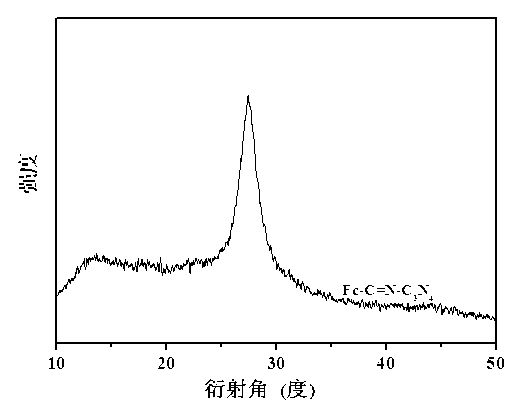

[0024] The second is the preparation of functionalized carbon nitride

[0025] Weigh 1g of mesoporous carbon nitride and disperse it in 50ml of absolute ethanol. Add 200ml of anhydrous ethanol solution with 1g of ferrocene formaldehyde and slowly drop it into the above solution through a constant pressure funnel, and then heat and stir at 60°C for 24h. The obtained solid is washed with ethanol several times, and finally dried in vacuum at 80° C. to obtai...

Embodiment 2

[0027] The first is the preparation of carbon nitride precursor

[0028] Weigh 5g commercial cyanamide and dissolve it in 2.5g commercial silica sol (containing 40% 12 nm SiO 2 ), heat and stir at 100°C until dry, and heat the obtained white sample at 600°C for 4h to obtain yellow powder. Add powder to 4M NH 4 HF 2 The solution was stirred for 24 hours to remove the template, filtered, washed with water, washed with ethanol, and dried under vacuum at 80°C to obtain a yellow powdered mesoporous carbon nitride photocatalyst.

[0029] The second is the preparation of functionalized carbon nitride

[0030] Weigh 1g of mesoporous carbon nitride and disperse it in 50ml of absolute ethanol. Add 200ml of anhydrous ethanol solution with 1g of ferrocene formaldehyde and slowly drop it into the above solution through a constant pressure funnel, then heat and stir at 60°C for 12h. The obtained solid is washed with ethanol several times, and finally dried in vacuum at 80°C to obtain a functiona...

Embodiment 3

[0032] The first is the preparation of carbon nitride precursor

[0033] Weigh 5g commercial cyanamide and dissolve it in 2.5g commercial silica sol (containing 40% 12 nm SiO 2 ), heat and stir at 100°C to dryness, and heat the obtained white sample at 700°C for 2h to obtain a yellow powder. Add powder to 4M NH 4 HF 2 The solution was stirred for 24 hours to remove the template, filtered, washed with water, washed with ethanol, and dried under vacuum at 80°C to obtain a yellow powdered mesoporous carbon nitride photocatalyst.

[0034] The second is the preparation of functionalized carbon nitride

[0035] Weigh 1g of mesoporous carbon nitride and disperse it in 50ml of absolute ethanol. Add 200ml of anhydrous ethanol solution with 1g of ferrocene formaldehyde and slowly drop it into the above solution through a constant pressure funnel, then heat and stir at 100°C for 48h. The obtained solid is washed with ethanol several times, and finally dried in vacuum at 80° C. to obtain a fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com