Patents

Literature

44results about How to "Production needs to be good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and preparation method thereof

ActiveCN101971868AElasticity adjustableIncrease elasticityDough treatmentModified nutritive productsAlcohol sugarsFermentation

The invention discloses pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and a preparation method thereof. The pre-mixed flour of mochi bread comprises the following components: 30 to 50% of modified starch, 5 to 10% of water-milled glutinous rice flour, 7 to 13% of non reducing sugar, 6 to 10% of sugar alcohol, 1.8 to 3.8% of edible colloid, 2 to 3% of edible emulsifier, 1 to 3% of salt, 1 to 3% of full-cream milk powder and 20 to 30% of self-raising flour. To produce the mochi bread from the pre-mixed flour of the mochi bread, the pre-mixed flour of the mochi bread is uniformly mixed with whole eggs, water, syrup and soybean oil to obtain the required properties, and then the mixture is baked to obtain the mochi bread without fermentation. The preparation method of the mochi bread is simple, and the prepared mochi bread has honeycomb internal phase and is softer than the common bread and not sticky; moreover, the shelf life of the mochi bread is obviously prolonged that the mochi bread can be stored for a month at normal temperature.

Owner:广州合诚实业有限公司

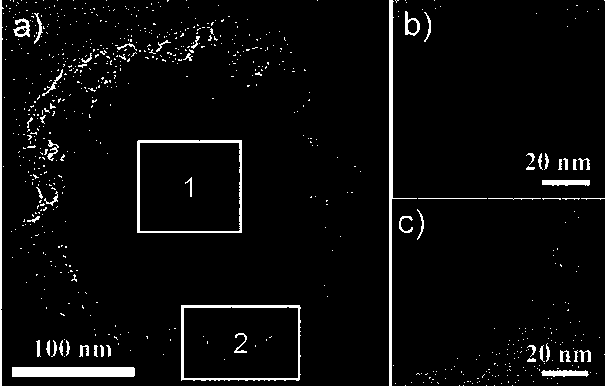

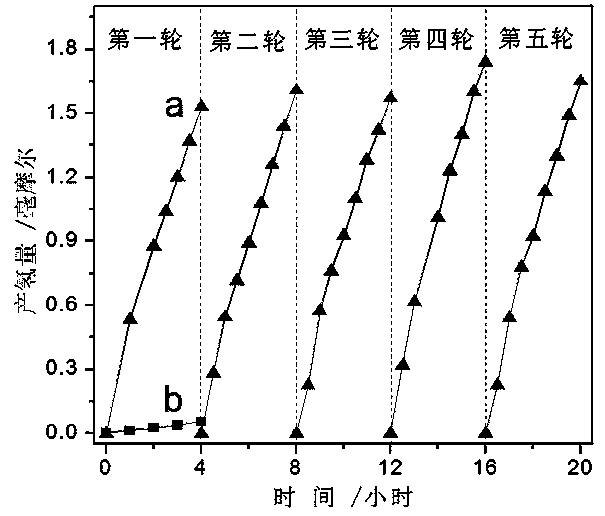

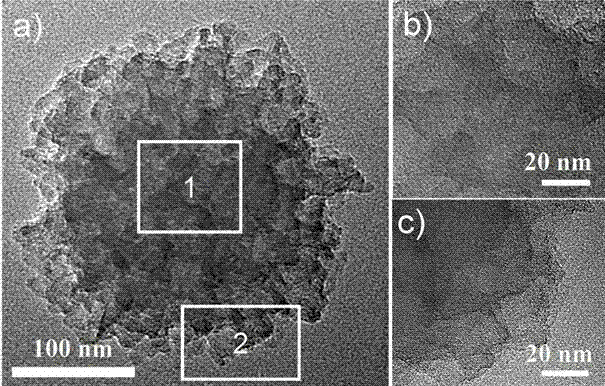

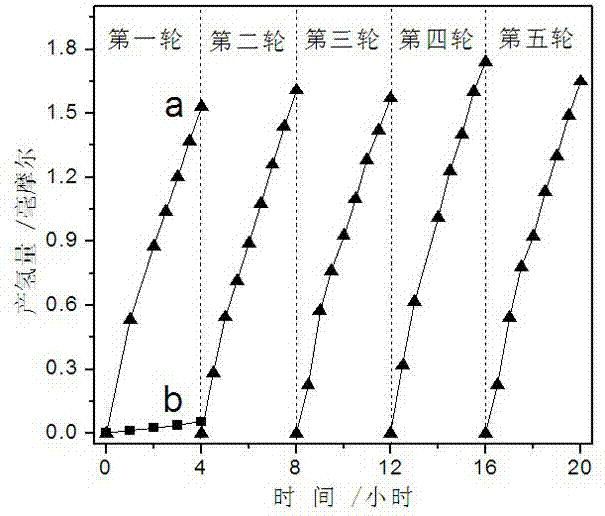

Spherical mesoporous carbon nitride photocatalyst with multistage nano structure

ActiveCN103623856AThe synthesis process is simpleImprove stabilityMaterial nanotechnologyPhysical/chemical process catalystsPhoto catalysisHydrogen production

The invention discloses a spherical mesoporous carbon nitride photocatalyst with a multistage nano structure and a preparation method and application thereof and belongs to the technical field of material preparation and photocatalysis. The spherical mesoporous carbon nitride photocatalyst with the multistage nano structure is prepared by using cyanamide as a precursor, using spherical mesoporous silicon dioxide with a highly open structure as a hard template, carrying out thermal thermal polymerization and removing the hard template. The spherical mesoporous carbon nitride prepared by the preparation method has the characteristic that nanosheet or nanosheet-like small particles are uniformly diffused around from the sphere center to form a spherical micro nano structure of which the surface structure is highly open; compared with conventional bulk phase carbon nitride, the spherical mesoporous carbon nitride photocatalyst can obviously improve the specific surface area and the mass transfer effect and has efficient photocatalytic hydrogen production performance in the visible light. The spherical mesoporous carbon nitride photocatalyst adopts a simple synthetic process, has high catalysis efficiency and has wide application prospect in the field of catalysis / photocatalysis.

Owner:FUZHOU UNIVERSITY

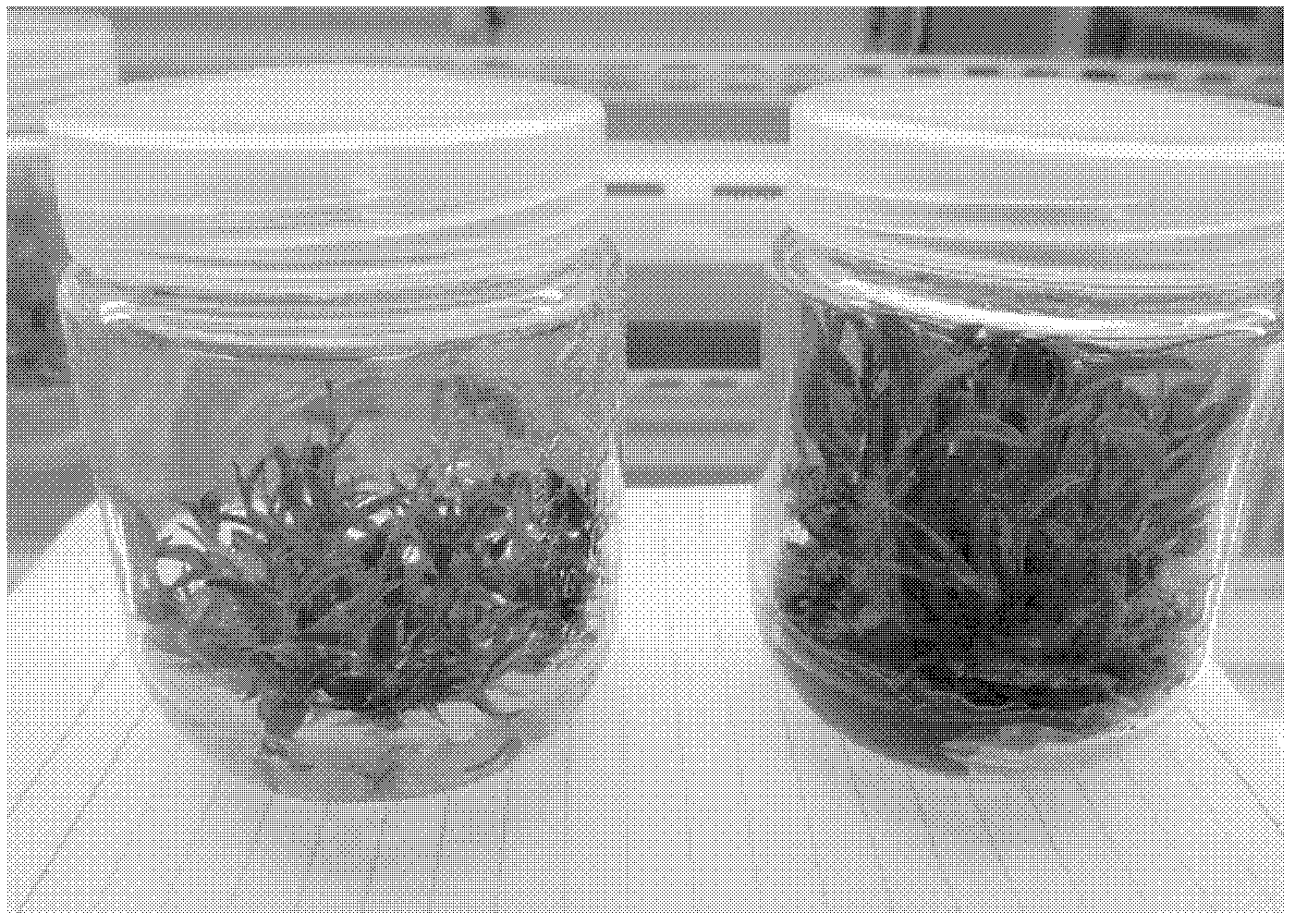

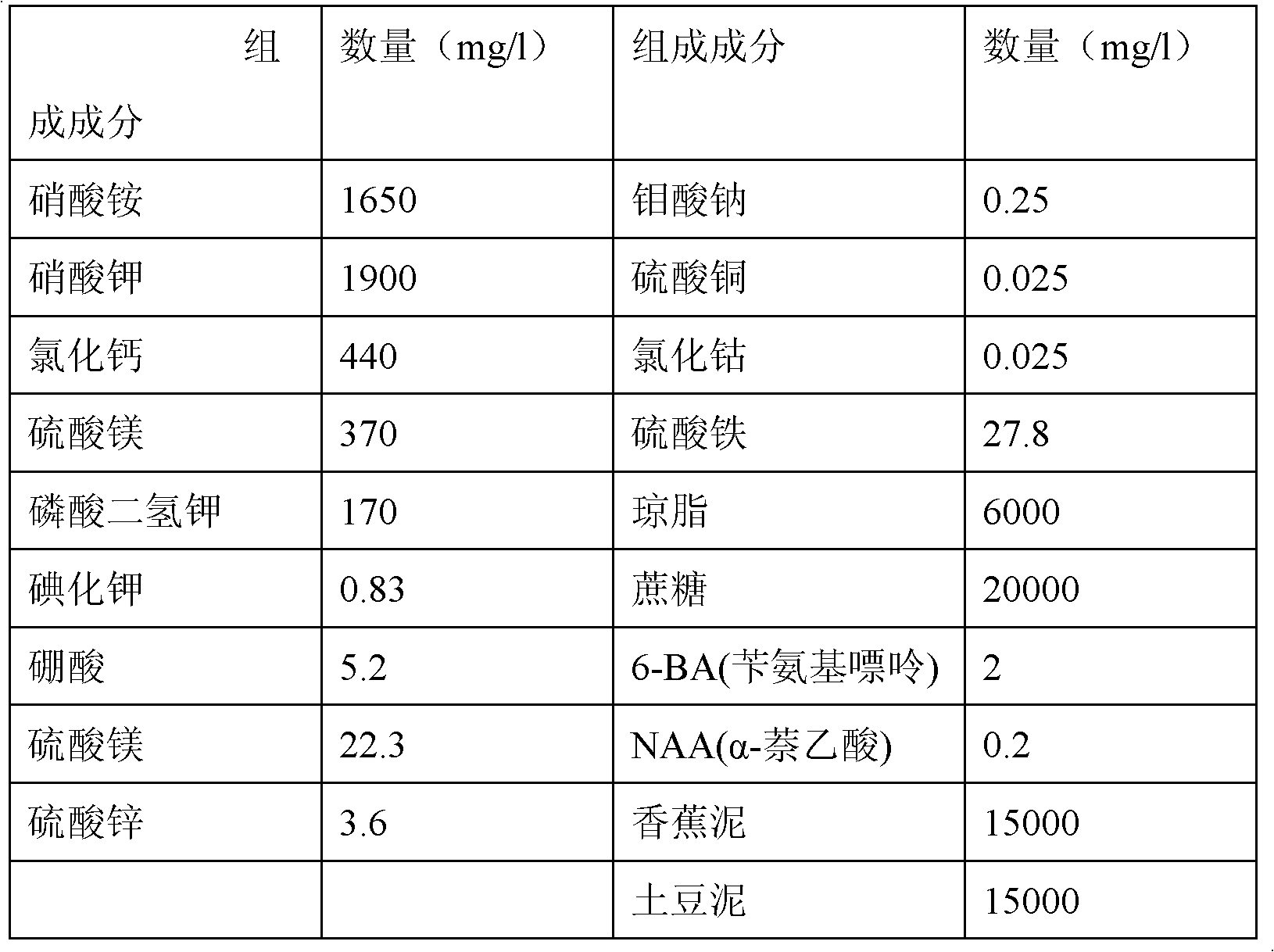

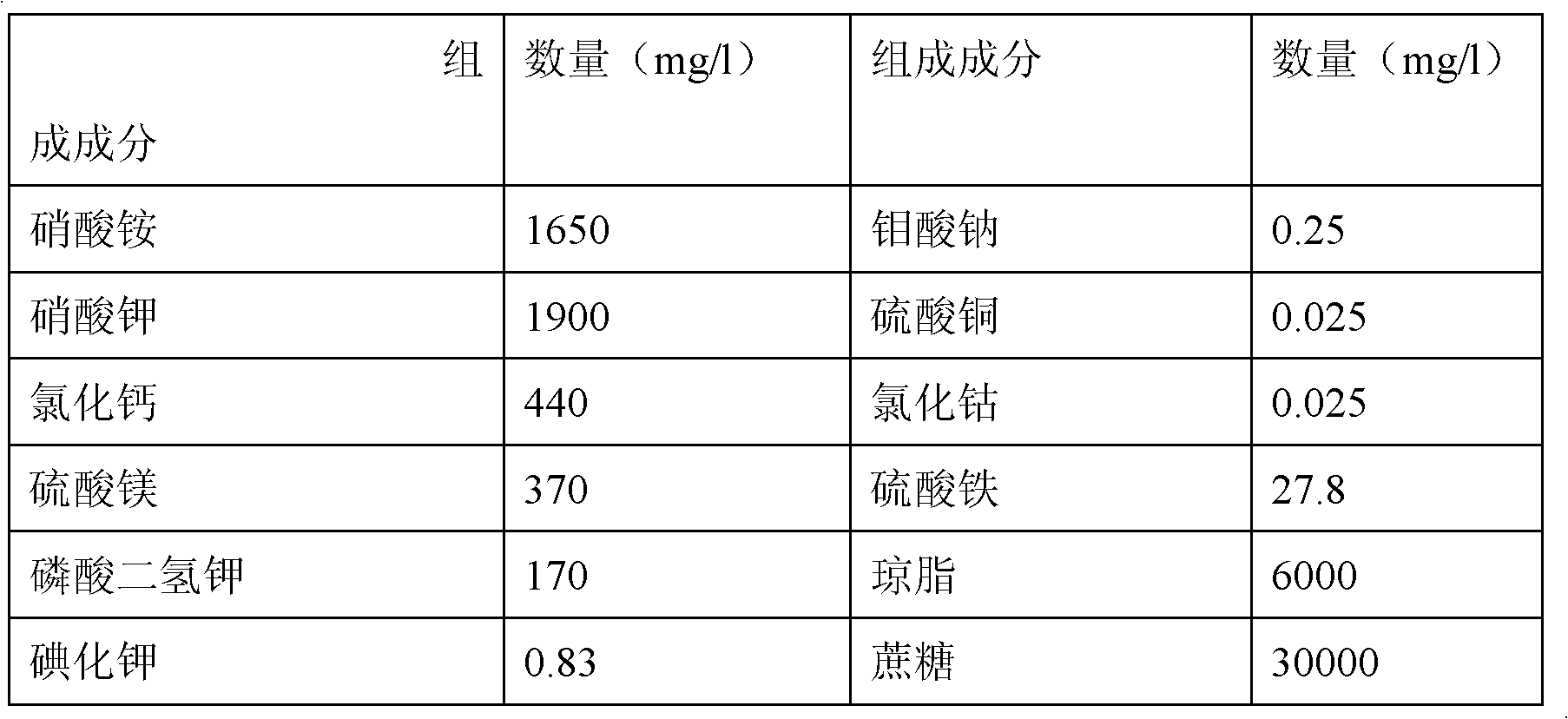

Modified medium for improving propagation of stems of Dendrobium officinale and propagation method

InactiveCN102613082AAchieve high efficiencyAchieve securityPlant tissue cultureHorticulture methodsAxillary budSucrose

The invention discloses a modified medium for improving propagation of stems of Dendrobium officinale and a propagation method. The medium comprises MS (Murashige and Skoog) basal medium, cane sugar 20g / l, agar 6g / L, 6-BA (benayl aminopurine) 2mg / l, NAA (alpha-naphthaleneacetic acid) 0.2-0.5mg / l, banana mash 15-20g / l, potato mash 15-20g / l, and common tap water replacing distilled water. The modified MS medium is used to propagate the stems with axillary buds of Dendrobium officinale, alkaloid and polysaccharide content of Dendrobium officinale is evidently increased, and Dendrobium officinale grow normally. By the method, consumption of cane sugar is reduced, the tap water is used to replace the distilled water, and accordingly tissue culture technology for Dendrobium officinale is more convenient, more efficient and resource-saving.

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation method of bioorganic fertilizer

InactiveCN105669260AReduce resource consumptionNo pollution in the processBio-organic fraction processingClimate change adaptationIrritationRoom temperature

The invention discloses a preparation method of a bioorganic fertilizer. The method comprises the following steps: 1, preparing a substrate: naturally solarizing or drying pig dung, carrying out ultraviolet lamp irradiation disinfection for 30-120min, and overturning the pig dung 2-3 times in the irritation process to prepare the fermentation substrate; 2, carrying out two stage fermentation: sterilizing the fermentation substrate at 121DEG C for 20-30min, cooling the sterilized substrate to room temperature, adding water, and uniformly stirring to prepare a solid fermentation medium, inoculating a lactobacillus strain liquid, carrying out anaerobic fermentation for 48h, inoculating a Candida utilis strain liquid, introducing aseptic air, and carrying out aerobic fermentation for 48-72h to obtain a fermentation product; 4, drying: drying the fermentation product at 55-60DEG C; and 5, proportioning: adding a biological regulator to the dried fermentation product according to a weight ratio of 100:(0.2-1) in order to prepare the bioorganic fertilizer, wherein the biological regulator is photosynthetic bacteria and azotobacteria. The bioorganic fertilizer prepared in the invention can greatly improve the output per 666.7m<2> of land of crops.

Owner:FUJIAN AGRI & FORESTRY UNIV

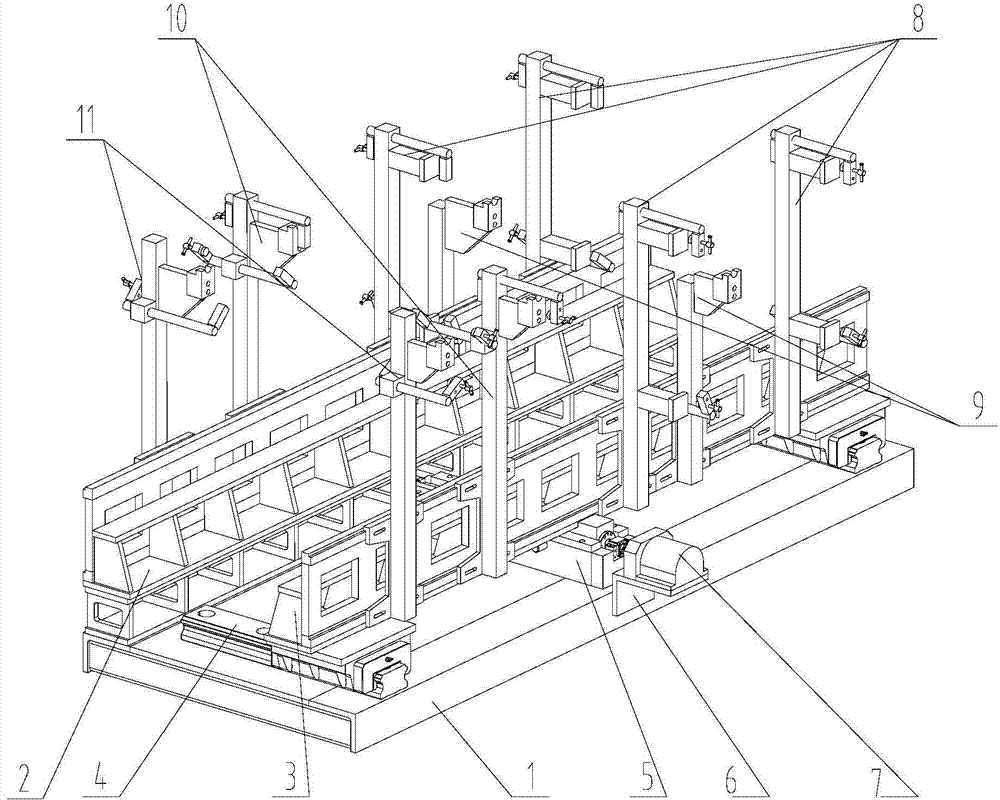

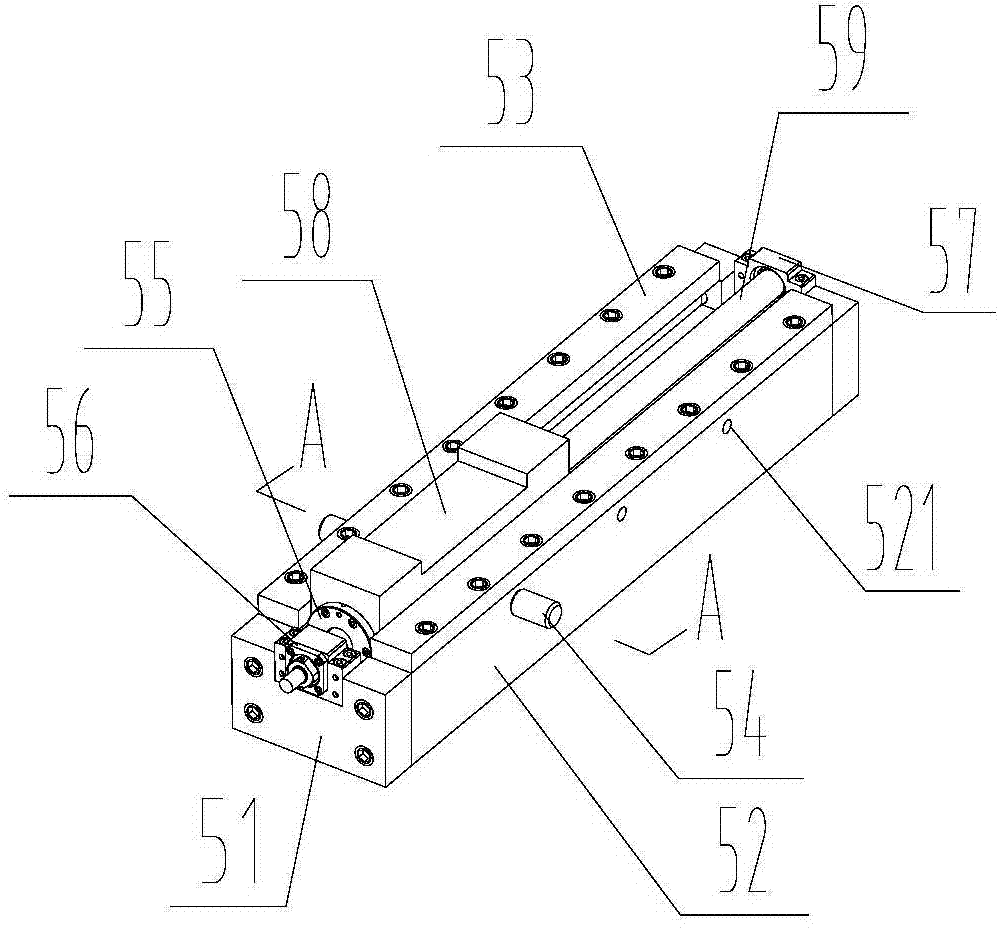

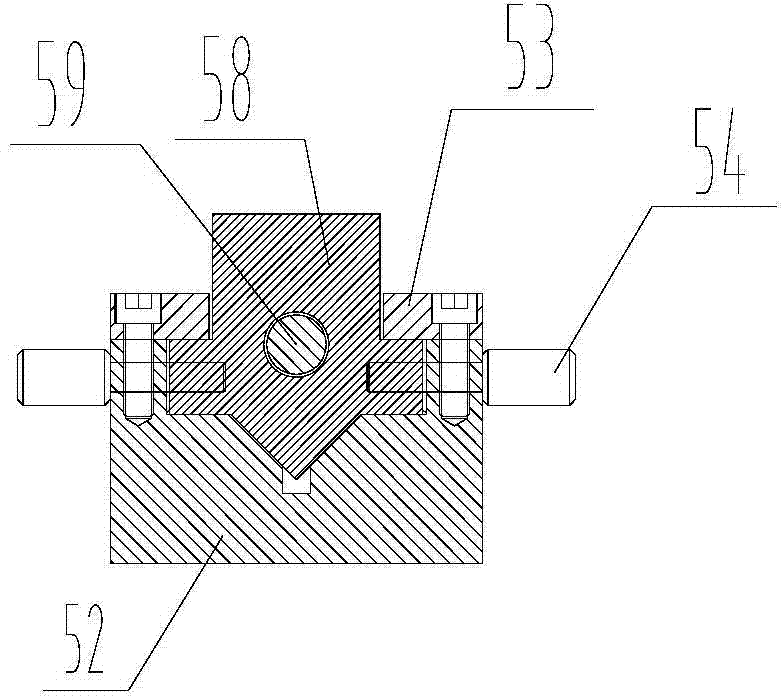

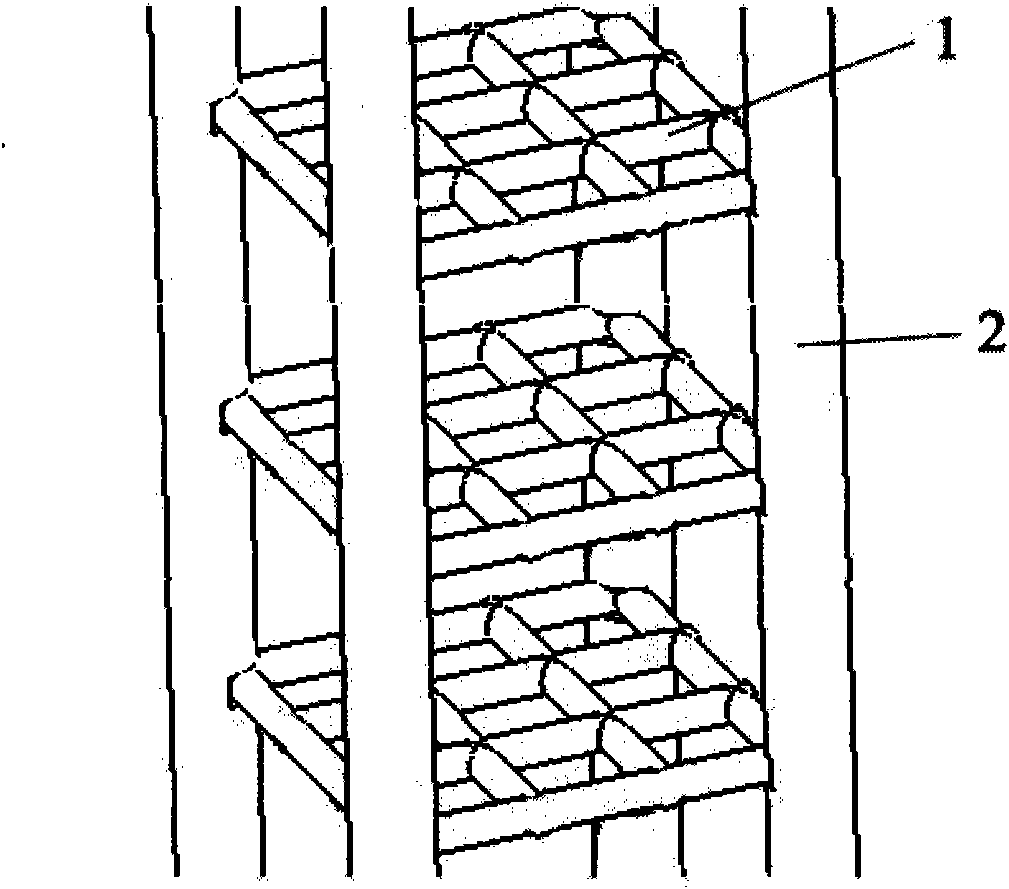

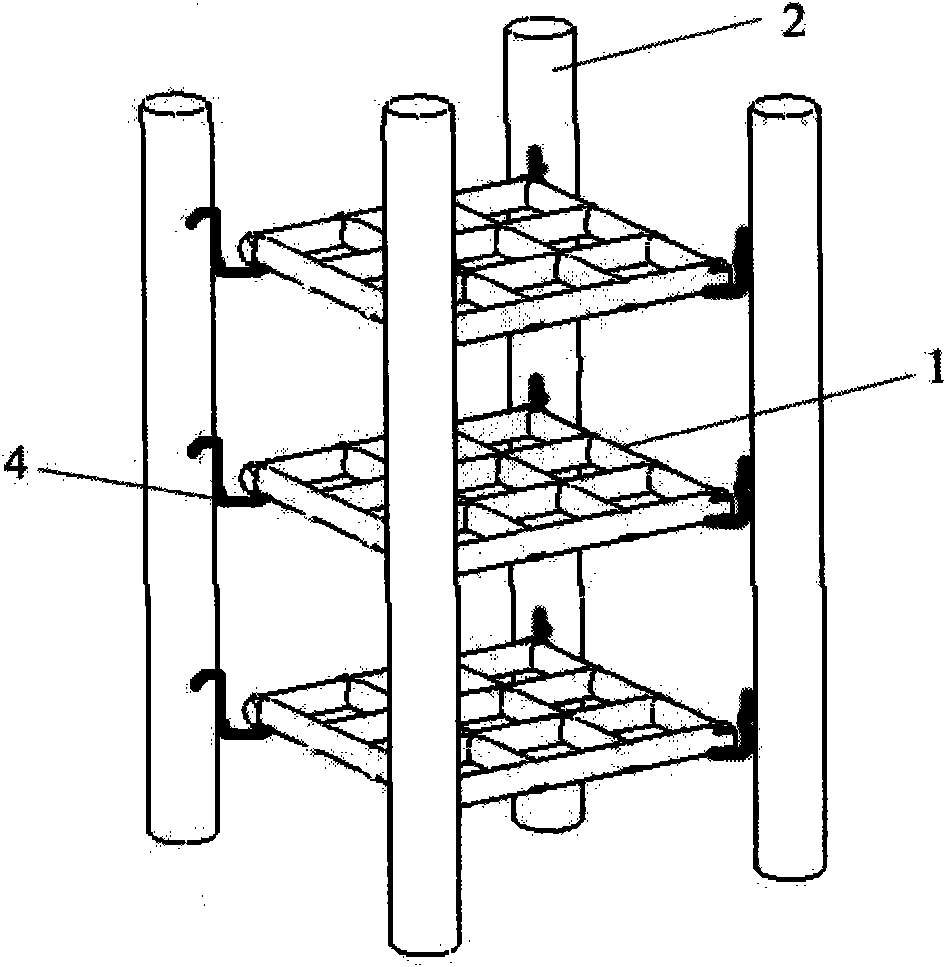

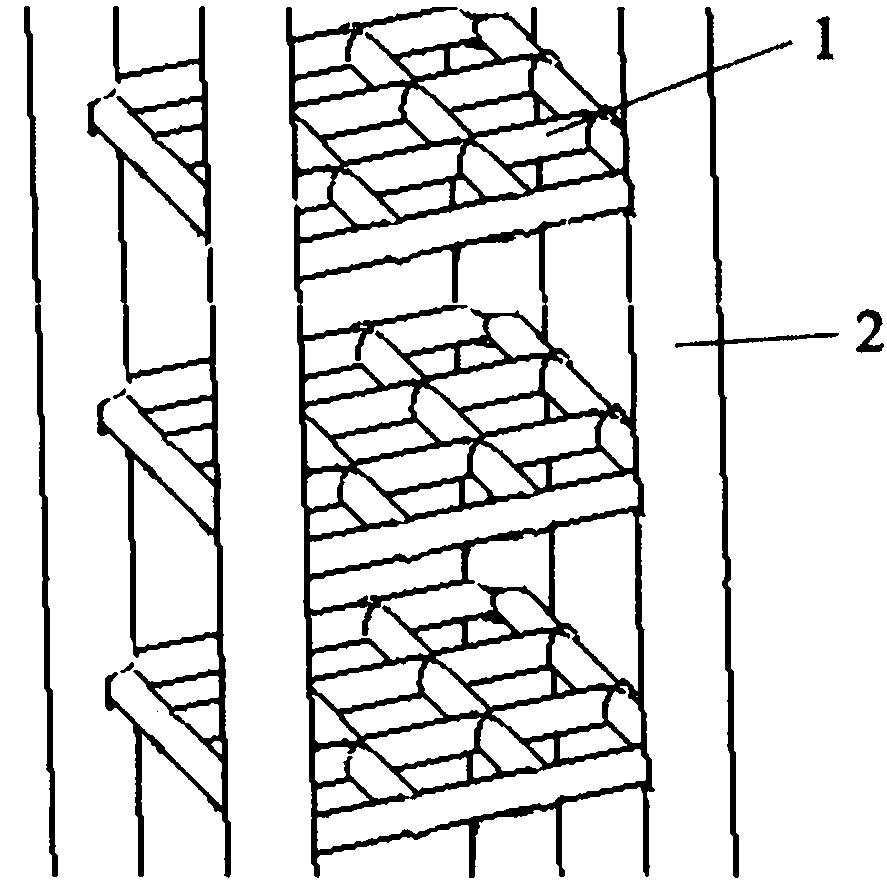

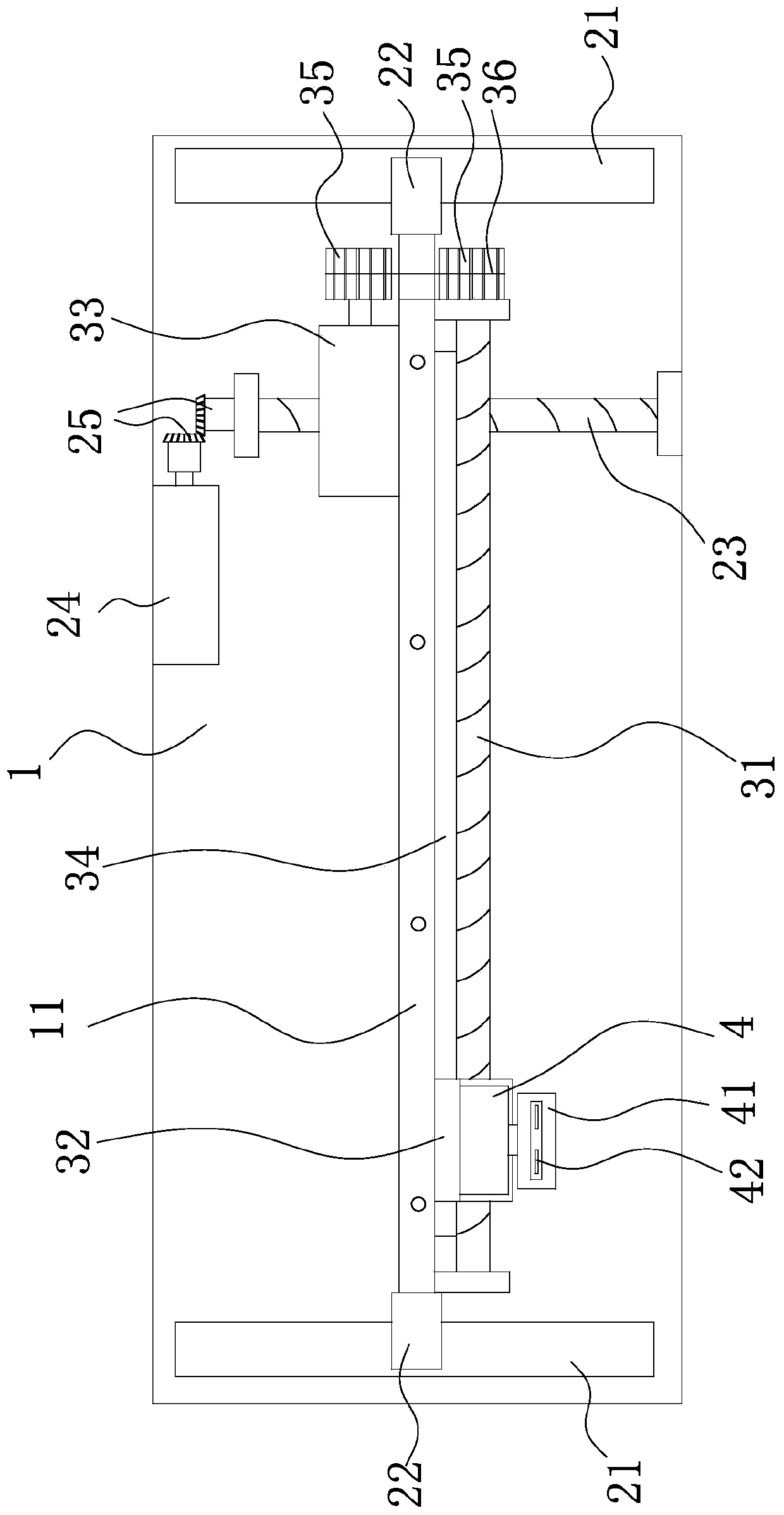

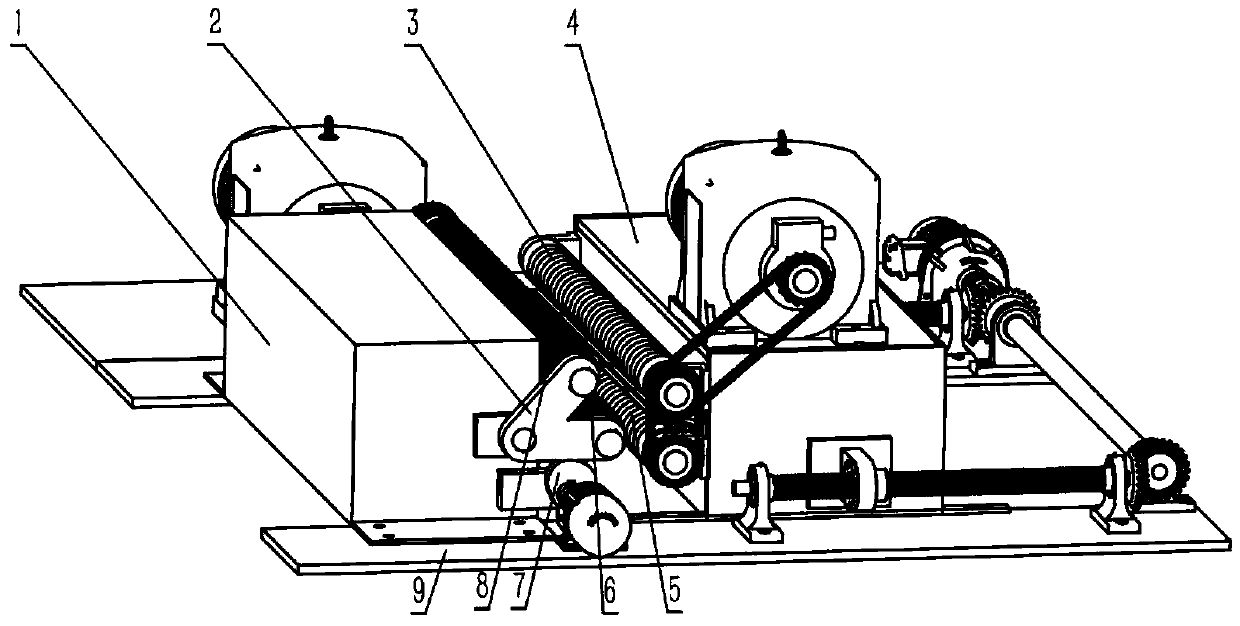

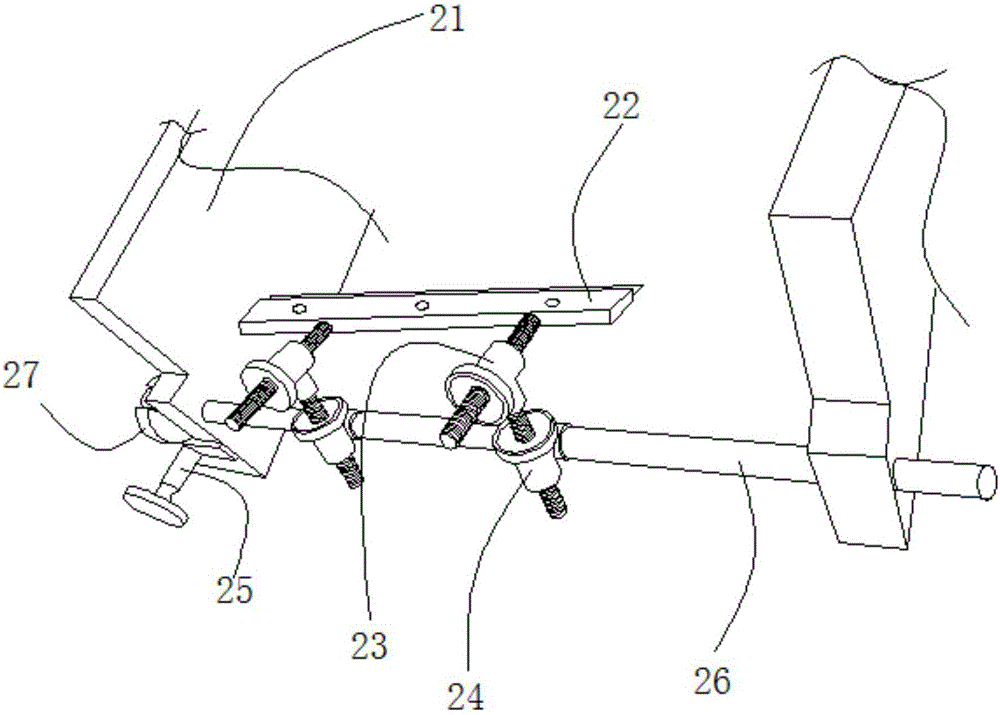

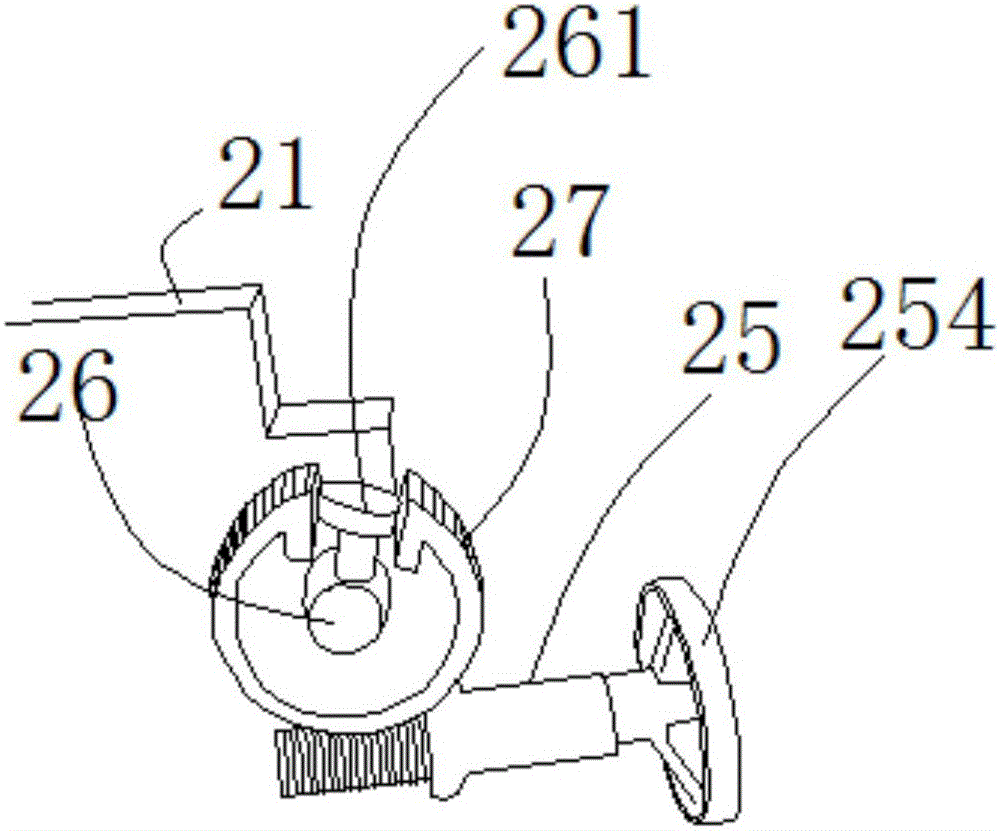

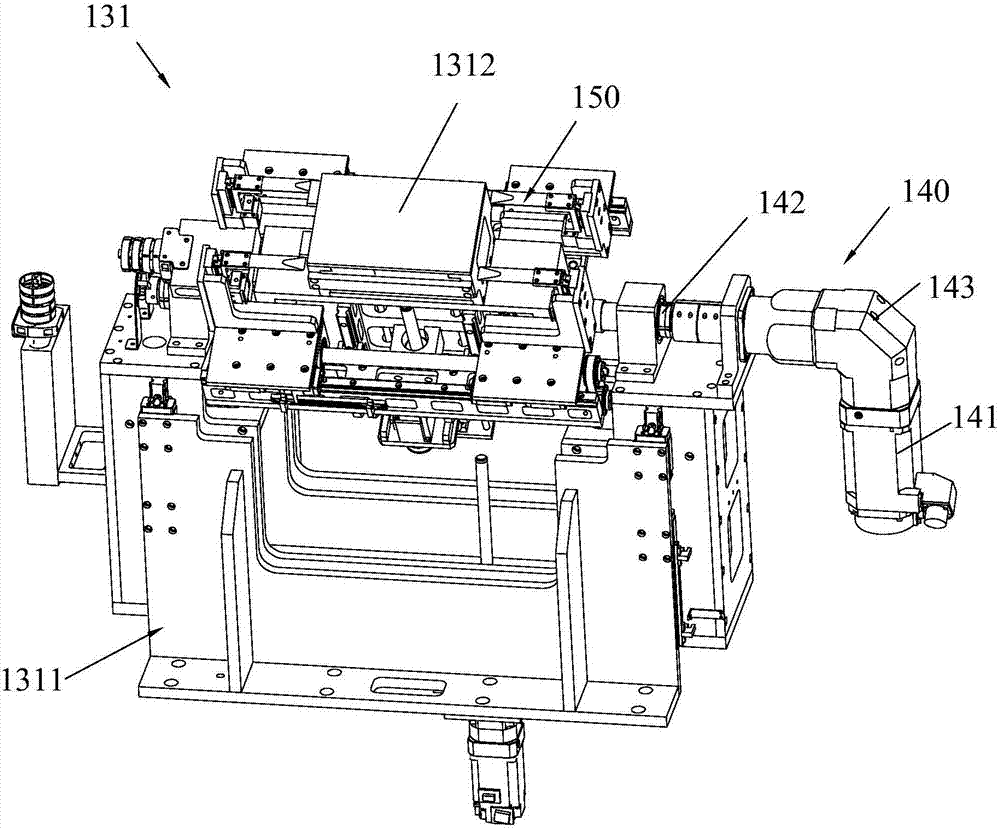

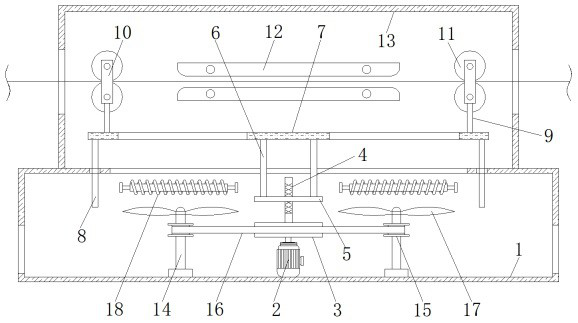

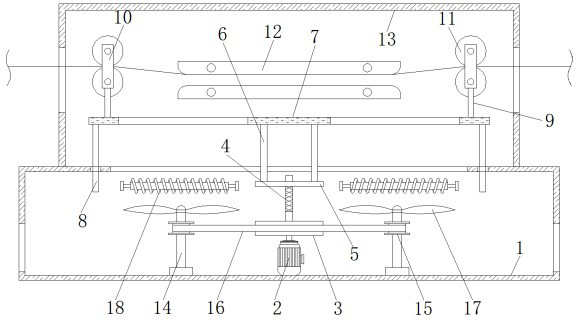

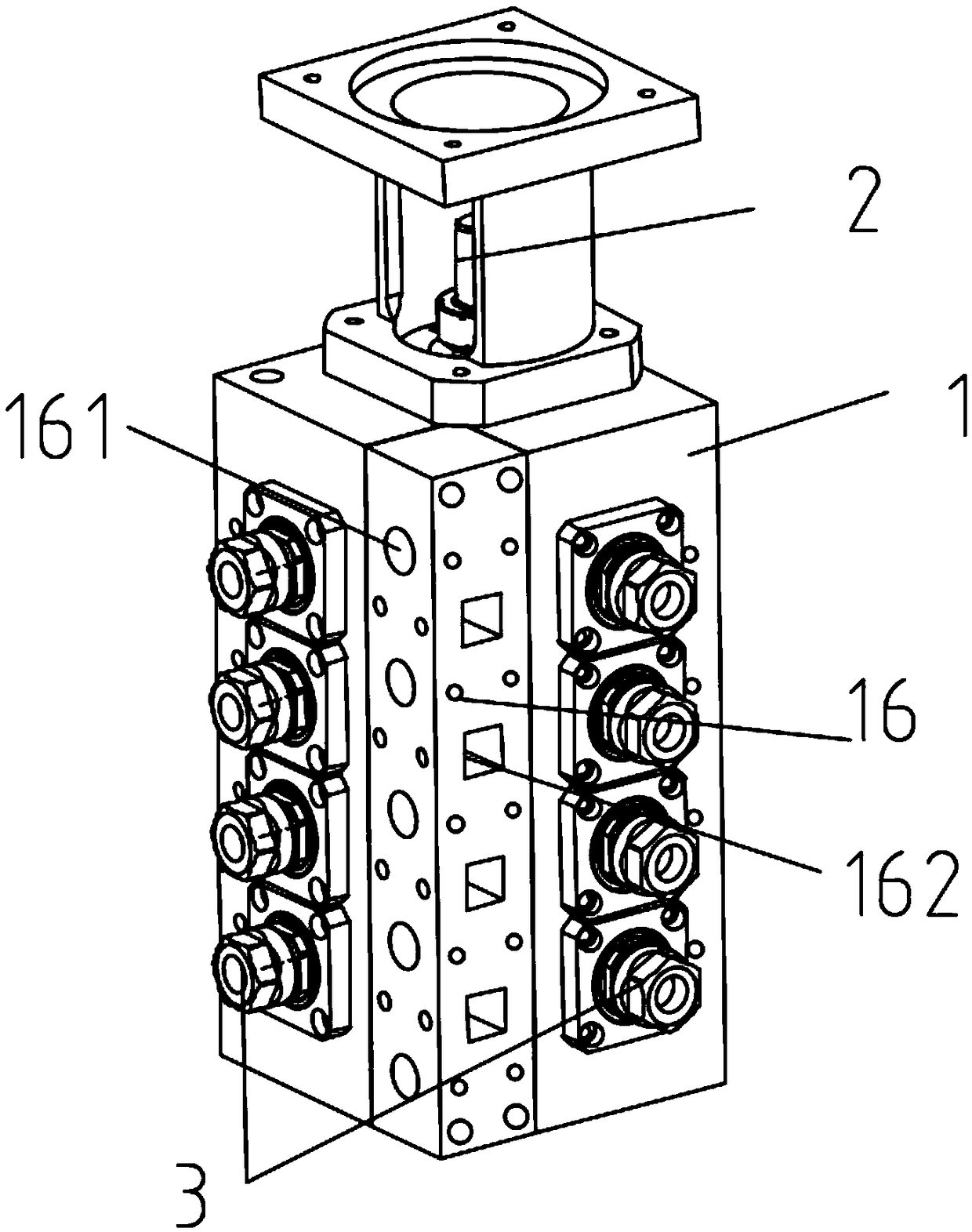

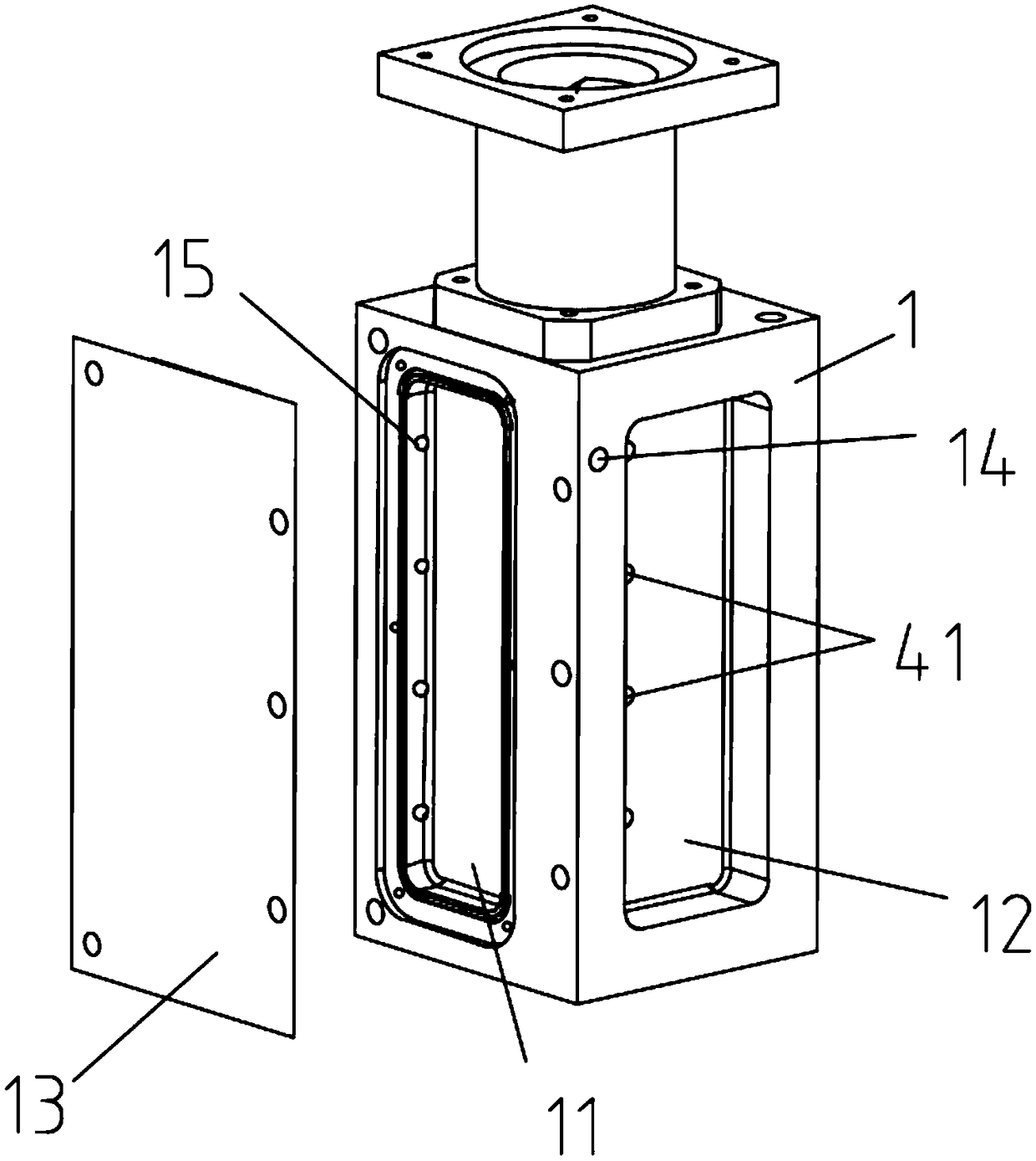

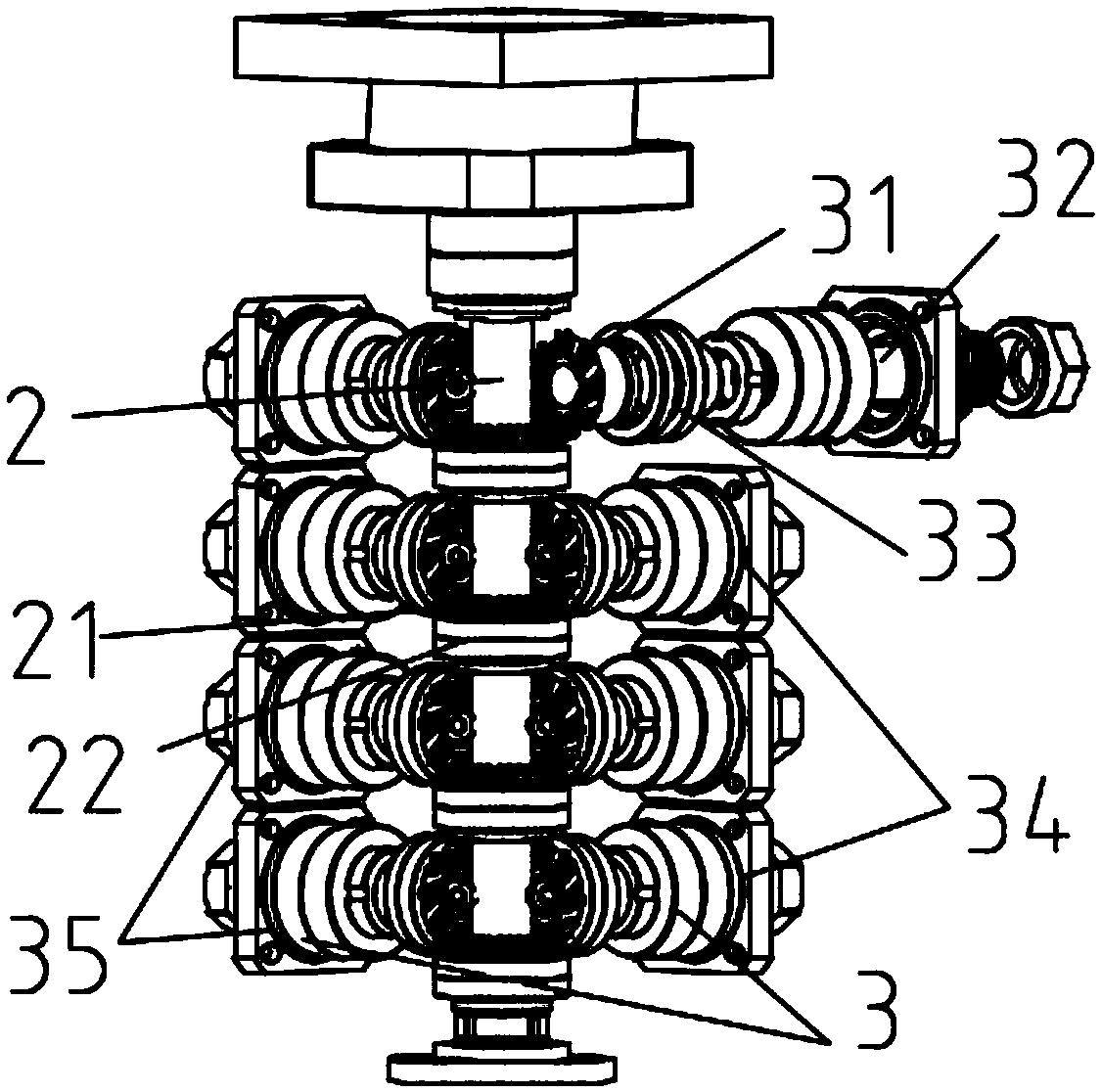

3D assembling tool clamp for escalator

ActiveCN104759806AProduction needs to be goodReduce alignment accuracy requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:GUANGZHOU GUANGRI ELEVATOR IND

Method for removing chlorobenzene in water body with cladophora glomerata

InactiveCN102101727AWide variety of sourcesIncrease productionWater contaminantsBiological water/sewage treatmentChemistryEcosystem

The invention relates to a method for purifying a water body. The method for purifying a water body comprises the following steps of: (A) selecting cladophora glomerata with vigorous growth and the cladophora glomerata height of larger than 2cm, preferably 2-10cm to be placed into tap water for domesticating and culturing for 1-2 days, wherein the domesticating conditions comprise the light intensity of 2,500-3,500lx, the temperature of 10-25 DEG C and the light and darkness period ratio of 12:12; and (B) simultaneously placing the domesticated cladophora glomerata into water with the different depths of 0-1.1m for culturing at preset intervals (water submerges the cladophora glomerata), wherein the treatment conditions comprise the natural illumination, the temperature of 10-25 DEG C, cladophora glomerata replacement once every 3-5 days and total replacement for 2-4 times. The method for purifying the water body can realize sewage recycling, ensures that the sewage treatment energy consumption and cost are reduced, can obtain maximal economic benefit in the minimal water body and establish a multistage ecological system for purifying sewage.

Owner:TAIYUAN NORMAL UNIV

Mosquito dispelling and air refreshing stonewort sustained release agent, and its preparation method

The invention relates to a mosquito dispelling and air refreshing stonewort sustained release agent. The mosquito dispelling and air refreshing stonewort sustained release agent provided in the invention is characterized in that the agent comprises 15-20wt% of essential oil from stonewort, 5-10wt% of sodium percarbonate, 1-5wt% of a solubilizer, 2-5wt% of a superabsorbent resin, 0.5-1wt% of an antiseptic, a proper amount of a perfume, and the balance purified water. The agent provided in the invention has a natural fragrant taste, and simultaneously has a very good mosquito dispelling effect.

Owner:TAIYUAN NORMAL UNIV

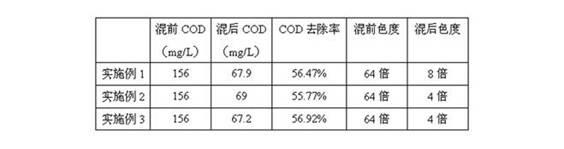

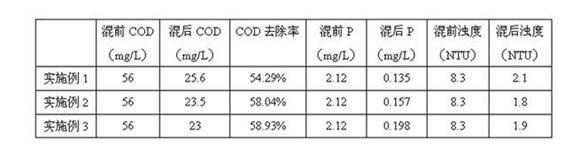

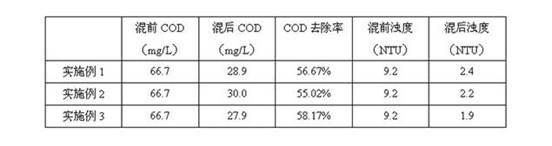

Complex coagulant for advanced treatment of biochemical tail water, and its preparation method and application

ActiveCN102219290ADense flocEasy to reuseWater/sewage treatment by flocculation/precipitationAlkaline hydrolysisToxic industrial waste

The invention discloses a complex coagulant for advanced treatment of biochemical tail water, and its preparation method and application. The complex coagulant is characterized in that the complex coagulant is an inorganic polymer complex coagulant prepared form industrial waste or nonmetallic mineral materials as main materials under heating conditions through the processes of alkaline hydrolysis, acid leaching oxidation, hydrolyzation and polymerization; and the complex coagulant prepared by the preparation method contains 20 to 35% of silicon, 15 to 25% of aluminum, 6 to 11% of iron and 3 to 6% of boron. Compared with the prior arts, the preparation method has the advantages of easy acquirement of raw materials, simple process, and good economical efficiency and applicability. The inorganic polymer complex coagulant prepared by the preparation method has the advantages of good performances of adsorption and bridging, charge neutrality, bonding and gathering, and decoloration, big flocs, fast sedimentation velocity of flocs, and low use amount. The complex coagulant can be widely utilized for the field of wastewater treatment, and is especially suitable for advanced treatment ofbiochemical tail water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mosquito-expelling and killing composition

InactiveCN100364413CWide variety of sourcesEasy to trainBiocidePest repellentsBiotechnologyControl mosquito

The mosquito killing composition contains stonewort powder or coarse stonewort extract and different supplementary material, and may be prepared into different mosquito killing products, such as mosquito killing stonewort incense, mosquito killing stonewort tablet, mosquito killing stonewort paper, etc. Stonewort is widely growing water plant, and this result in rich material source of the mosquito killing composition. The mosquito killing composition is safe and low in cost.

Owner:SHANXI UNIV

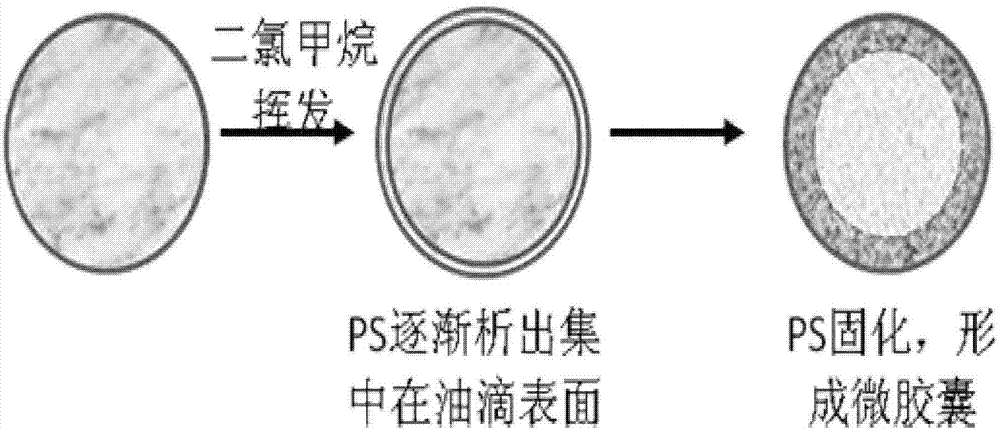

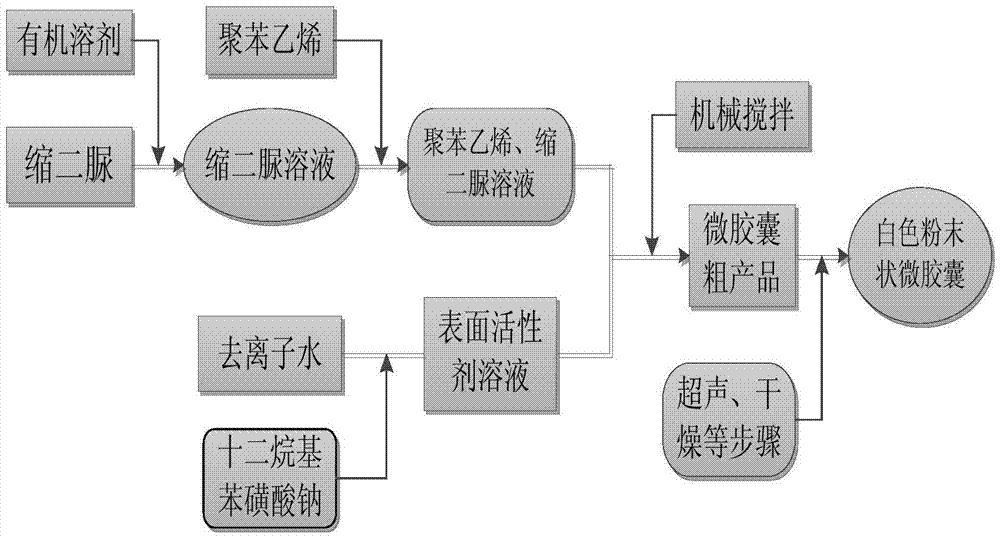

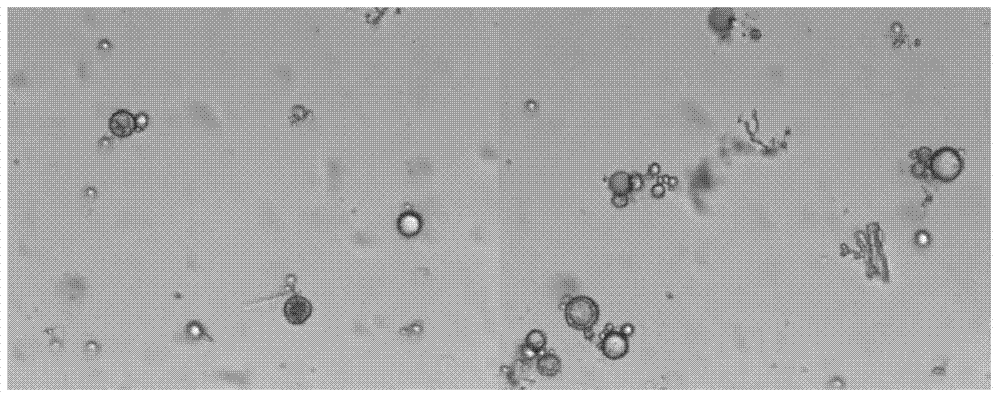

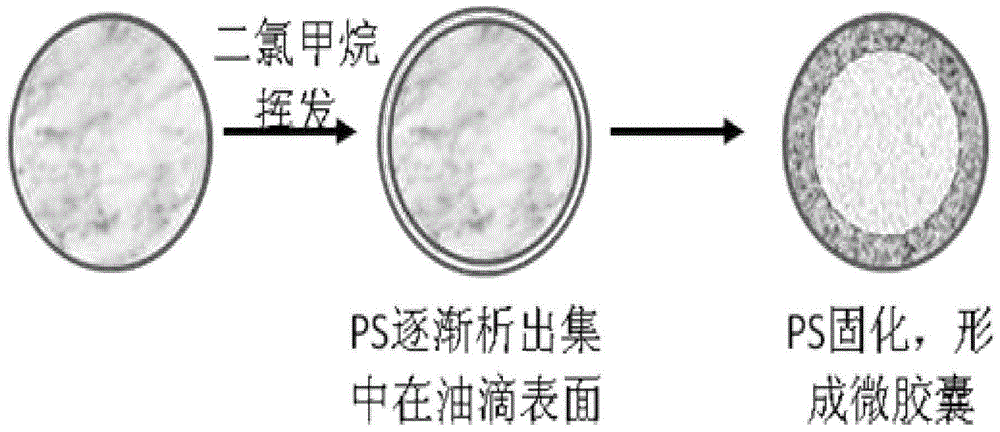

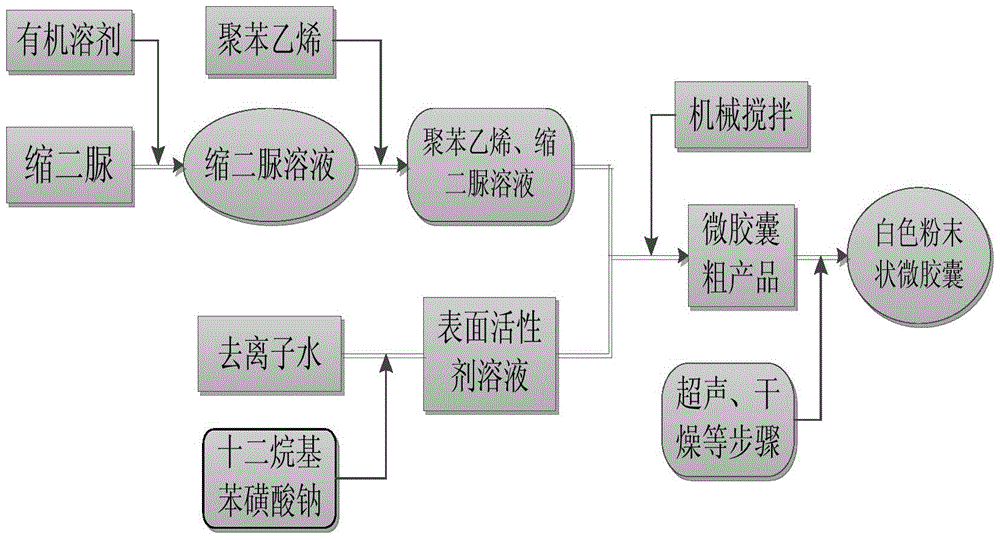

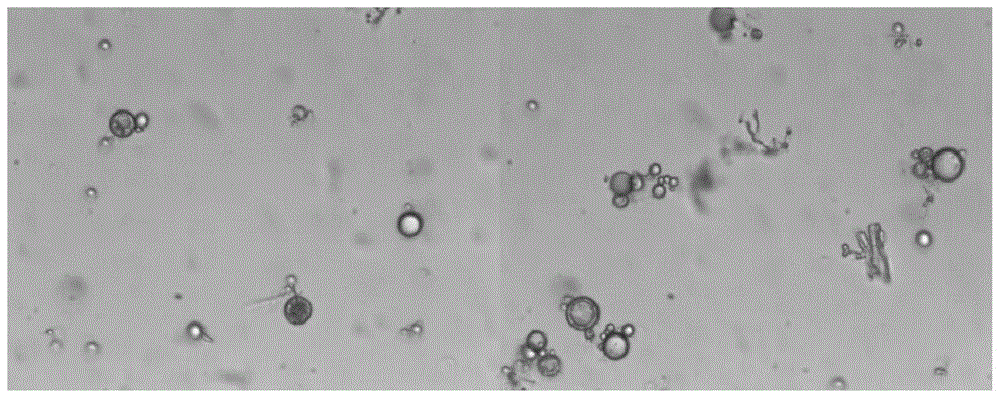

Preparation and separation and purification method for latent curing agent microcapsule with temperature responsive controlled release characteristic

ActiveCN104772085AExtended storage timeImprove applicabilityMicroballoon preparationMicrocapsule preparationThermoplasticControl release

Relating to synthesis and optimization of latent curing agents, the invention provides a preparation and separation and purification method for a specific curing agent controlled release system with temperature responsiveness. According to the invention, a specific method is employed to prepare the specific curing agent so as to obtain a microcapsule with specific purpose. Through optimization of the preparation process, the use of polyvinyl alcohol and other stabilizers can be avoided, thus being conducive to separation and purification and drying at the later period. Also, the used reagents are all low toxic or non-toxic, and have very low environmental pollution. Single and pure thermoplastic plastic like polystyrene is selected as the coating material, which can melt at certain temperature and the release the curing agent so as to carry out curing reaction. Through selection of the solvent, rotation speed and feed ratio, microcapsules with different particle size distribution and curing agent content can be obtained. After centrifugation, a discontinuous timing ultrasonic method is carried out in absolute ethanol to prepare the curing agent microcapsule with very little impurity content and very good dispersibility, and agglomeration phenomenon does not appear.

Owner:北京中杰瑞康科技有限公司

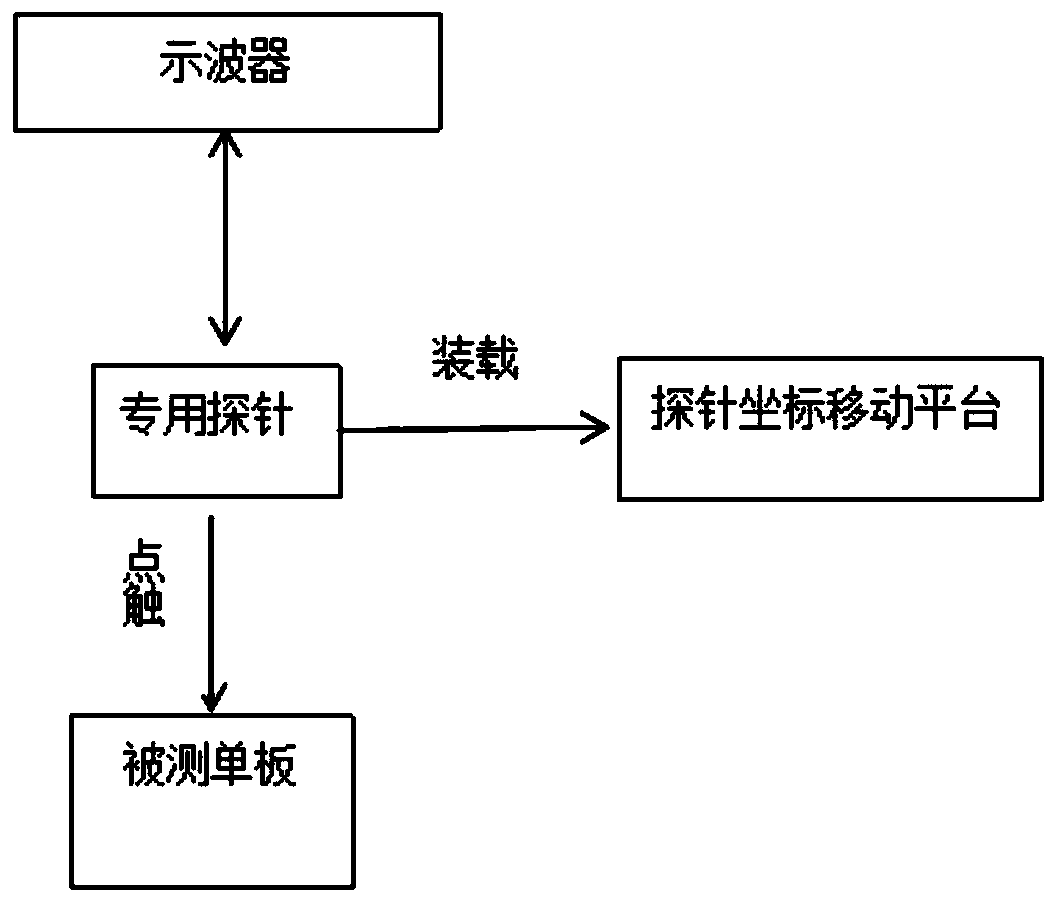

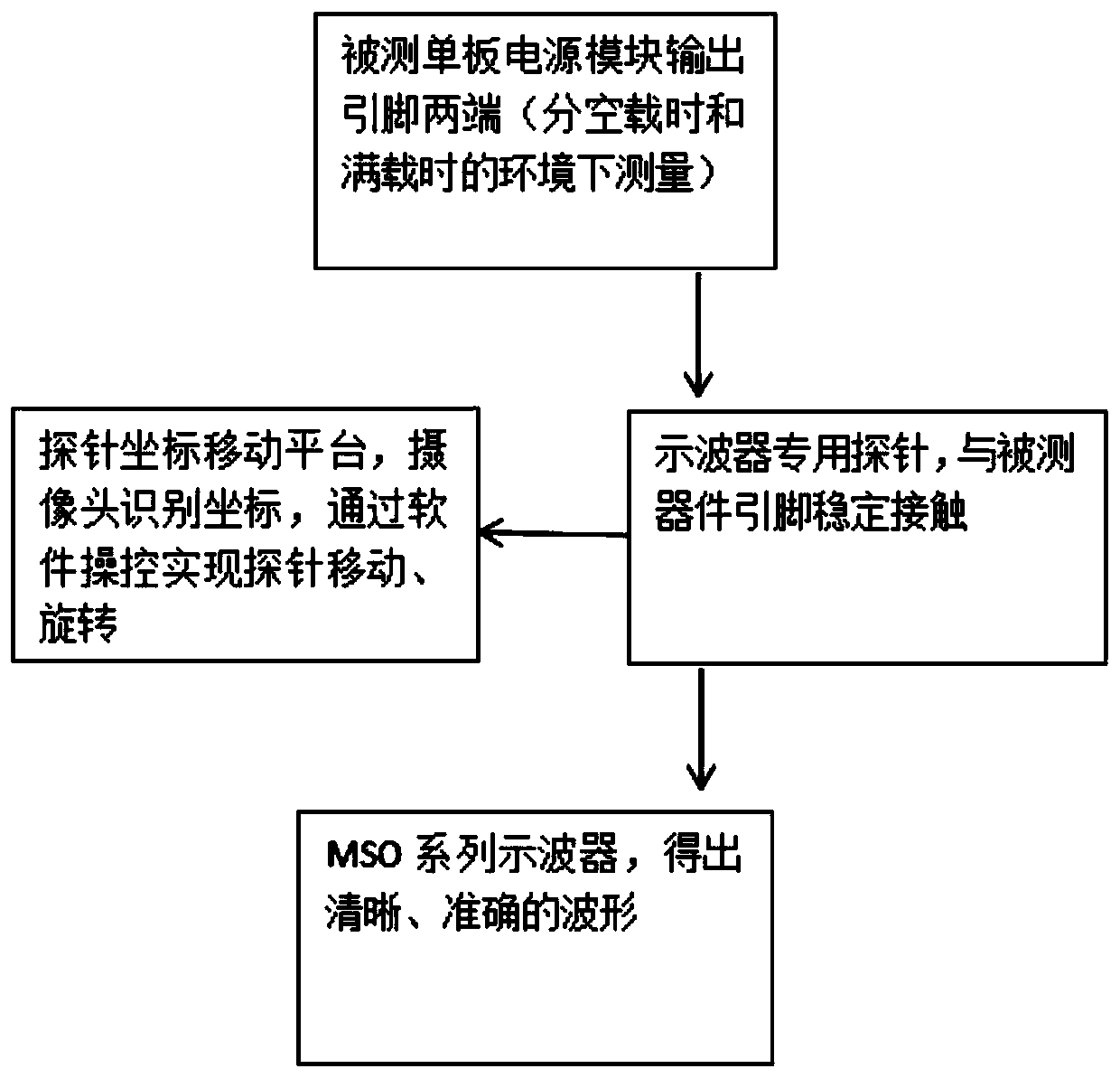

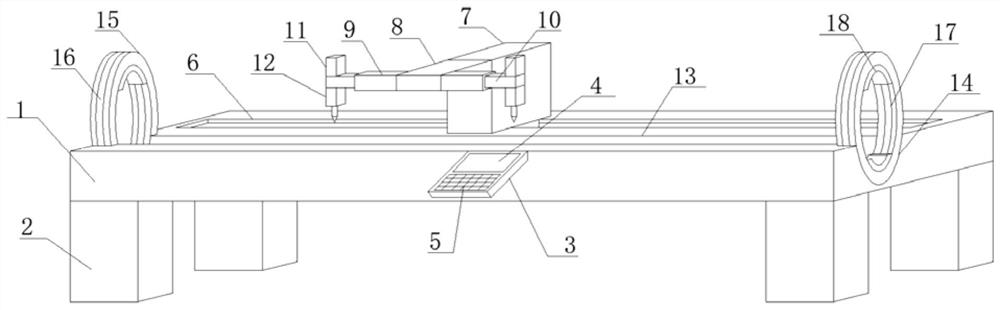

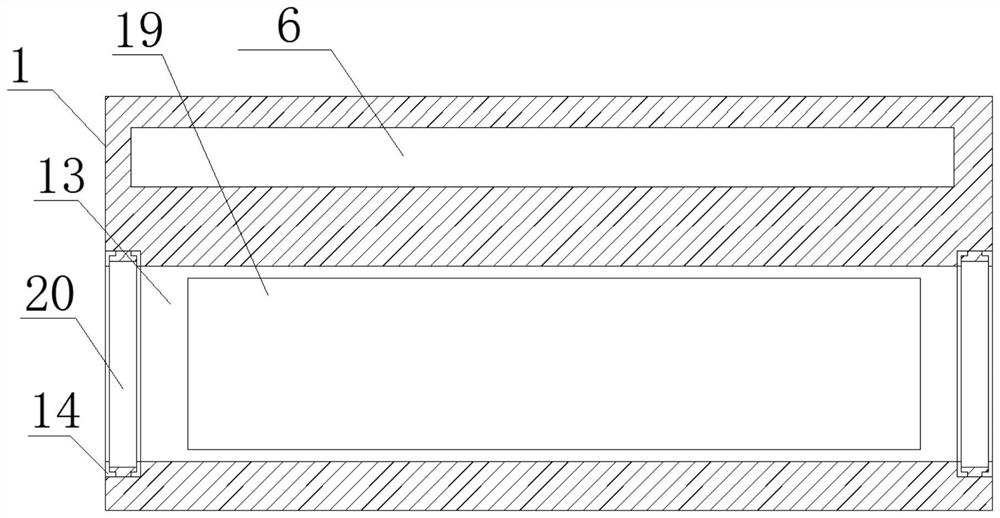

Method for automatically testing ripple noise of power supply

InactiveCN110632403AAccurate measurementRealize coordinate movementNoise figure or signal-to-noise ratio measurementPower supply testingSmall amplitudeComputer module

The invention belongs to the field of ripple noise, and particularly relates to a method for automatically testing the ripple noise of a power supply. In an existing mode of measuring the ripple noiseof a power supply, an oscilloscope probe is used to manually touch the two ends of an output pin of a single-board power supply module, the ripple noise of the power supply cannot be accurately measured due to instability, labor and time are consumed, and the efficiency is low. In order to solve the problem, a scheme as follows is proposed: the method comprises the following steps: S1, an oscilloscope is calibrated, and the original waveform of the oscilloscope is correctly debugged out before testing; and S2, the oscilloscope is set, a single-ended passive probe is adopted as an oscilloscopeprobe, and a probe with an attenuation ratio of 1: 1 is adopted for signals with very small amplitude. The scheme is simple in layout, low in manufacturing cost and beneficial to expanding production.

Owner:深圳市菲菱科思通信技术股份有限公司

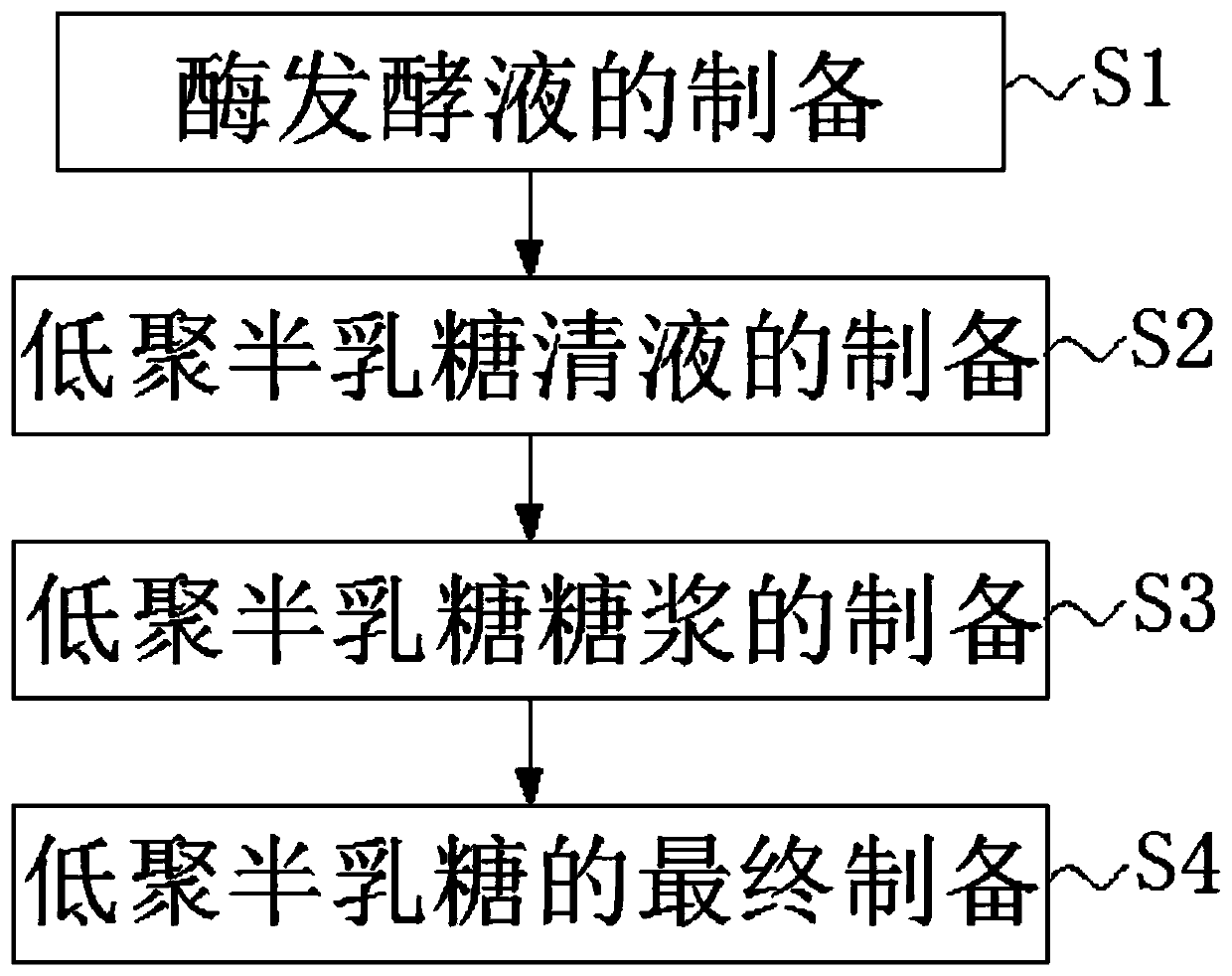

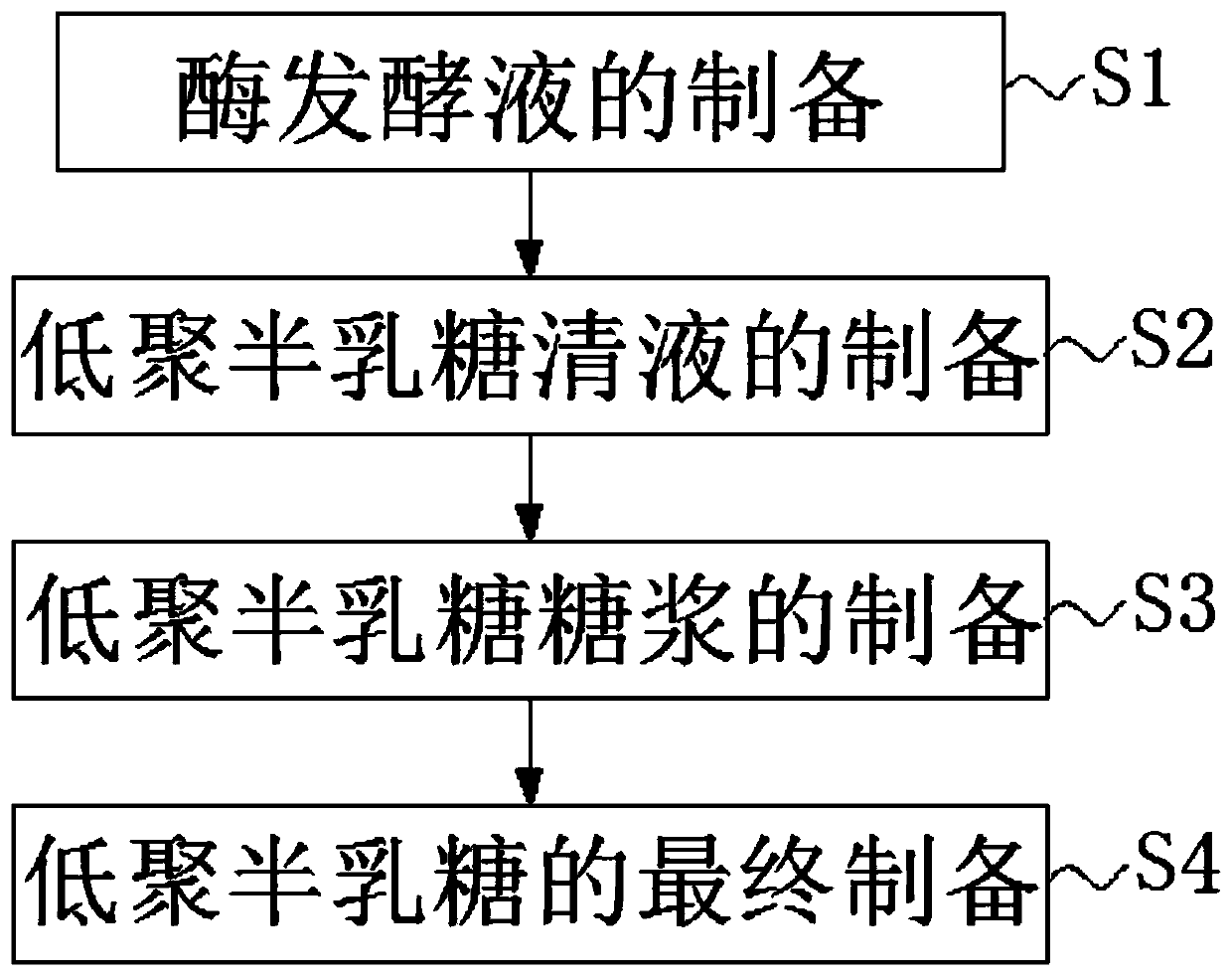

Production method for high-content galactooligosaccharide

InactiveCN111118085AImprove conversion rateShort reaction timeSugar derivativesMicroorganism based processesBiotechnologyUltrafiltration

The invention discloses a production method for high-content galactooligosaccharide. The production method comprises the following steps: S1, preparation of an enzyme fermentation liquor: with a lactose solution with a concentration of 300-400 g / L as a raw material, adding beta-galactosidase into the lactose solution, wherein 10-30 U of the beta-galactosidase is added into each gram of a lactose raw material, putting an obtained mixed solution into a high-speed stirrer, carrying out uniform stirring at 25-35 DEG C, wherein a pH value is 6-7, then carrying out culturing for 30-40 h, and when the mass percentage of glucose accounts for 10-15% of the total amount of sugar through an enzyme reaction, stopping reaction work so as to finally obtain an enzyme fermentation liquor for subsequent usage. The invention relates to the technical field of production of the galactooligosaccharide. The production method for high-content galactooligosaccharide has the following advantages: beer yeast isadded in the preparation process of the galactooligosaccharide, so the conversion rate of the galactooligosaccharide can be increased, and short reaction time and high synthesis rate are achieved; byusing of an ultrafiltration membrane and a nanofiltration membrane, the purity of the galactooligosaccharide can be greatly improved; meanwhile, the production cost is reduced to a certain extent, and the actual production requirements are met.

Owner:安徽民祯生物工程有限公司

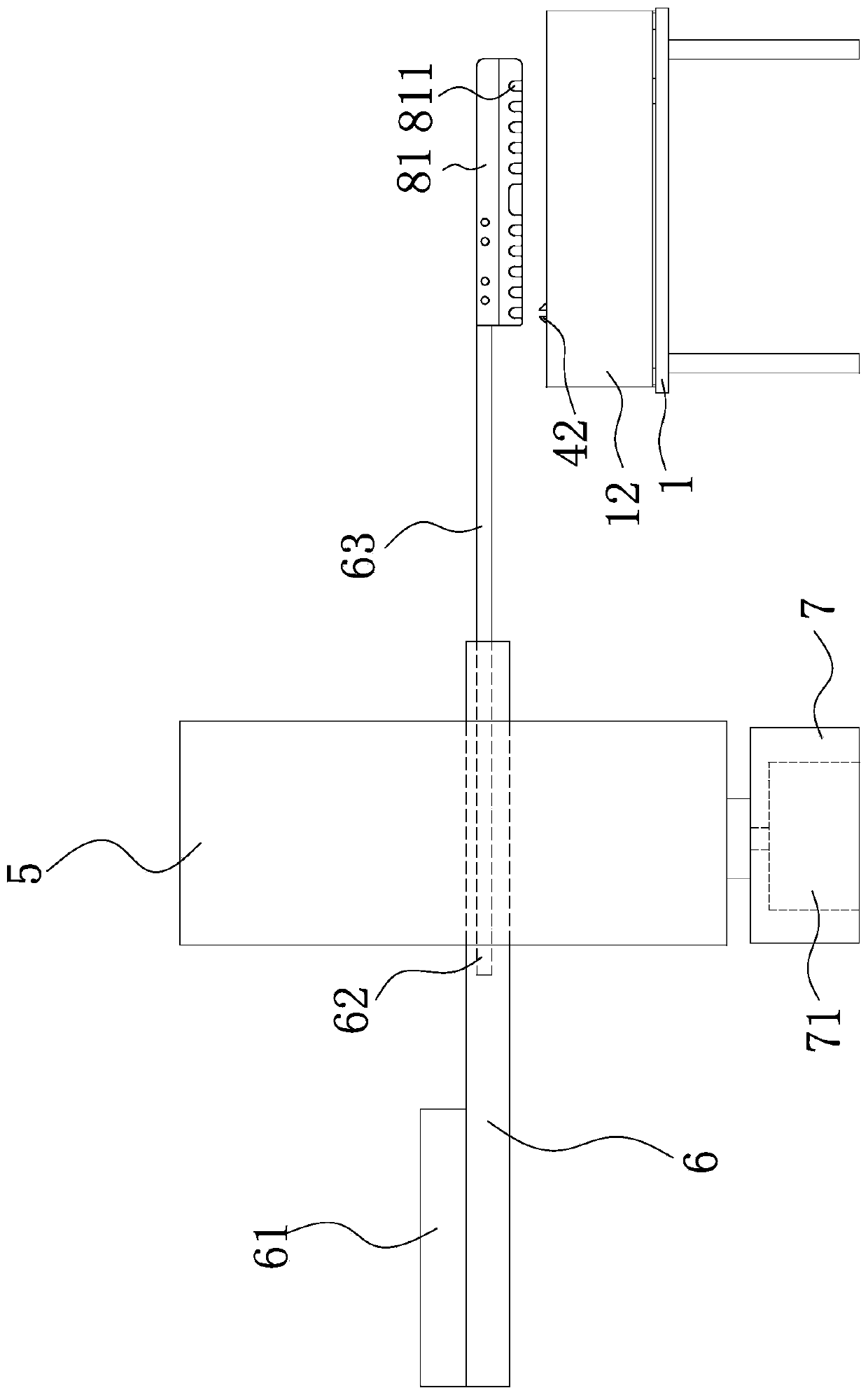

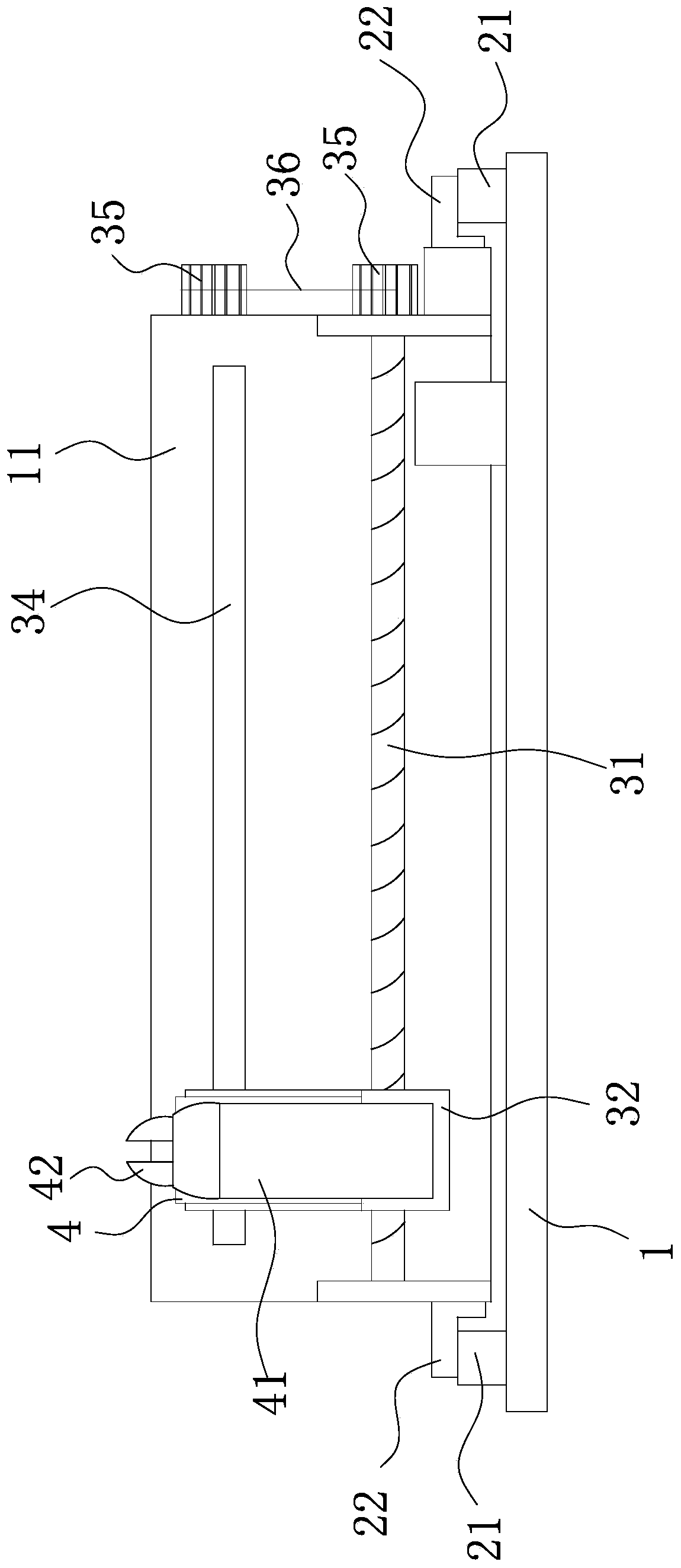

Automatic shearing device for injection molding pull rope and process thereof

InactiveCN110524816ARealize automated production and processingIncrease productivityInjection molding machineSupport plane

The invention relates to an automatic shearing device for an injection molding pull rope and a process thereof. The device comprises a shearing mechanism and a conveying mechanism, the shearing mechanism comprises a base, a first driving mechanism arranged on the base, a supporting frame capable of sliding front and back on the base, a second driving mechanism arranged on the supporting frame, a third driving mechanism arranged on the supporting frame in a left-right sliding mode, and an air shearing mechanism connected to the third driving mechanism; shear blades capable of being automatically opened and closed are arranged on the air shearing mechanism; the conveying mechanism comprises a frame body, a horizontal frame arranged on the frame body, a sliding frame capable of sliding on thehorizontal frame, a telescopic mechanism arranged on the horizontal frame and a clamping mechanism arranged at one end of the sliding frame. The invention relates to the field of injection molding pull rope production and processing equipment, the injection molding pull rope is automatically cut through the shearing mechanism and the conveying mechanism, the production efficiency is improved, thequality of the produced injection molding pull rope is good, and the technical problems of low efficiency and incomplete cutting of the injection molding pull rope caused by manual cutting of the injection molding pull rope are solved.

Owner:冉茂科

Composite coagulant for advanced treatment of biochemical tail water, as well as preparation method and application thereof

InactiveCN102633337ADense flocEasy to reuseWater/sewage treatment by flocculation/precipitationAlkaline hydrolysisHydrolysis

The invention relates to a composite coagulant for advanced treatment of biochemical tail water, as well as a preparation method and application thereof. The inorganic polymer composite coagulant containing boron, silicon, aluminum and iron, which is prepared by adopting an iron source, a boron source and a silicon-aluminum source as raw materials, is applied to coagulation purification processing coagulant of all kinds of waste water, and is particularly applied to advanced treatment of the biochemical tail water. The iron source, the boron source and the silicon-aluminum source are adopted as the raw materials; the inorganic polymer composite coagulant is prepared through alkaline hydrolysis, acid leaching oxidation, hydrolysis and polymerization under heating; and the prepared composite coagulant contains 20 percent-35 percent of silicon, 15 percent-25 percent of aluminum, 6 percent-11 percent of iron, and 3 percent-6 percent of boron. The coagulant has easy-to-get raw materials and concise process, and is economic and applicable. The obtained inorganic polymer composite coagulant has good capacities of absorption and bridging, charge neutrality, bonding aggregation and decoloration, and less dosage, and is widely applied to waste water treatment field, in particular to advanced treatment of the biochemical tail water; and the flocs are big and are fast in sedimentation velocity.

Owner:CHINA PETROLEUM & CHEM CORP +1

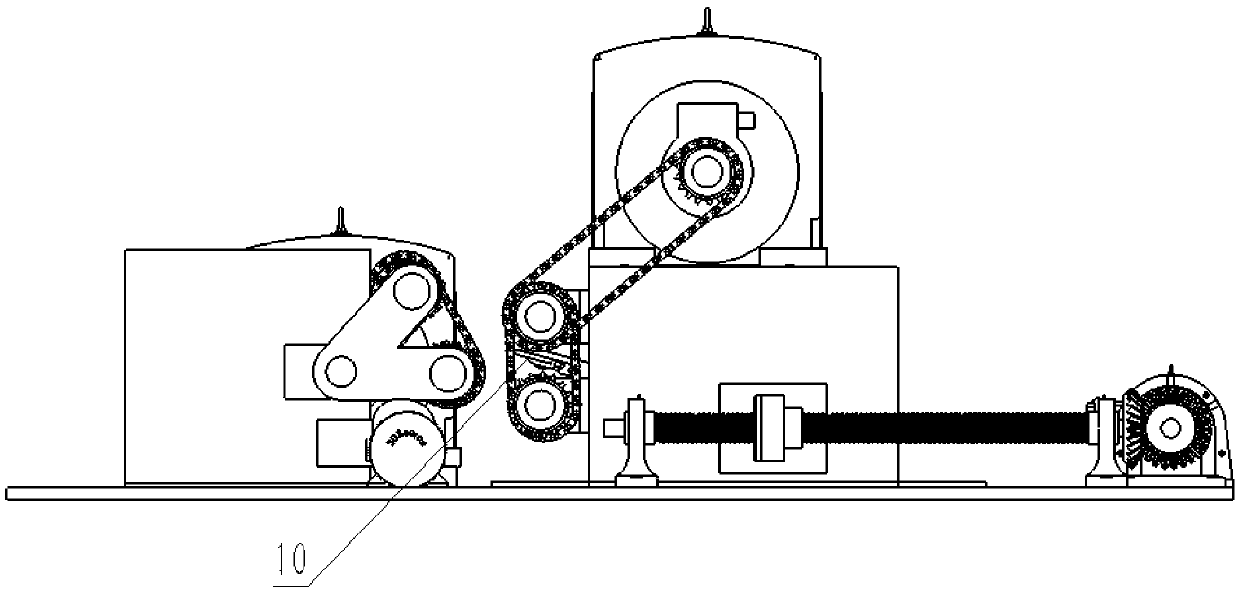

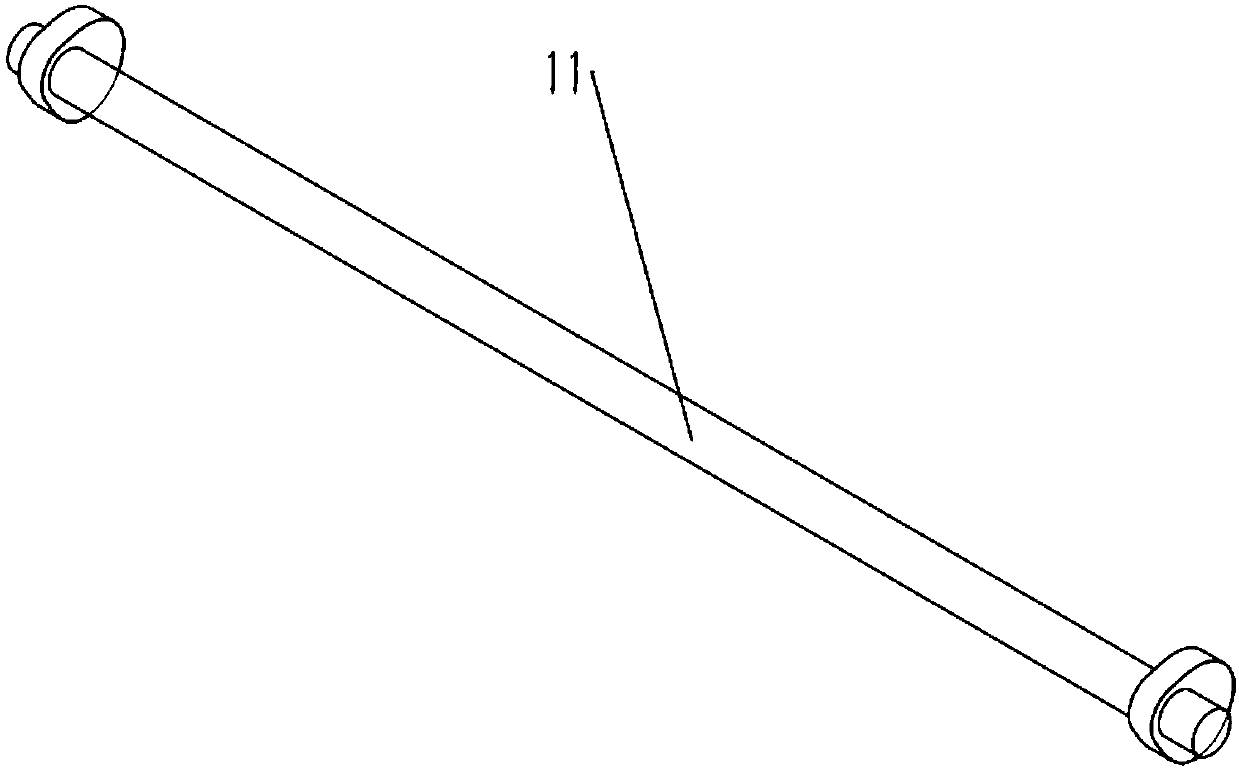

Small-diameter log four-roller automatic material supporting and rotary cutting mechanism for thick veneer machining

PendingCN111409165ACompact structureRealize the function of automatic supportVeneer manufactureCamManufacturing engineering

The invention relates to the technical field of wood machining rotary cutting equipment, in particular to a small-diameter log four-roller automatic material supporting and rotary cutting mechanism for thick veneer machining. The small-diameter log four-roller automatic material supporting and rotary cutting mechanism for thick veneer machining is characterized in that the small-diameter log four-roller automatic material supporting and rotary cutting mechanism for thick veneer machining increases the friction force of rollers on a small-diameter log through the four rollers when a rotary cutting machine is used for rotary cutting of a thick veneer. According to the four-roller automatic material supporting and rotary cutting mechanism for small-diameter log and thick veneer machining, thethick veneer is obtained through rotary cutting of a rotary cutter, and the effect of automatic material supporting before rotary cutting of the small-diameter log can be achieved through a set of extrusion roller wheels, a V-shaped frame, an upper pressing roller and a cam mechanism, so that the structure is more compact, and the requirement of actual production is more advantageously met.

Owner:NORTHEAST FORESTRY UNIVERSITY

Improved film blowing, printing and rolling all-in-one machine

InactiveCN105034569AUniform textureQuality improvementRotary pressesWebs handlingEngineeringPrinting press

The invention provides an improved film blowing, printing and rolling all-in-one machine. The improved film blowing, printing and rolling all-in-one machine comprises a film blowing device, a printing device and a rolling device. A film blowing film die head with an inner layer, a middle layer and an outer layer is adopted for a film blowing mechanism and can be used for blowing three layers of stacked plastic films. An adjustable scraper in the printing device can be used for adjusting the angle and the distance between the scraper and a printing roller through the coordination of three sets of adjusting assemblies. Due to elastic devices and meshed rails in the rolling device, a rolling shaft can be limited to be kept stable, and the rolling tightness degree is controlled. Compared with the prior art, the film blowing printing machine be used for blowing thick and high-strength plastic films with good hindering effects; due to the adjustable scraper, the machine can adapt to printing work of various specifications of thin films; and rolled plastic film disc rolled through the rolling shaft can be more compact under the limit of the elastic devices and the rails.

Owner:ANQING XINGFENG IND & TRADE

Lamination device

PendingCN107069058AShorten the timeFit closelyPrimary cell manufactureFinal product manufactureEngineeringMechanical engineering

A lamination device is used for a lamination process of a battery pole plate. The lamination device comprises a swinging lamination table, wherein the swinging lamination table can swing within a preset range and is provided with a first position and a second position, the swinging lamination table is provided with a lamination workbench, and an inclination angle is formed between the lamination workbench and a horizontal plane when the lamination device is used for lamination at the first position and the second position. With the adoption of the lamination device, the response speed of each action of a lamination machine can be improved, the lamination efficiency is improved, so that the production demand is met.

Owner:DONGGUAN CHAOHONG AUTOMATION EQUIP CO LTD

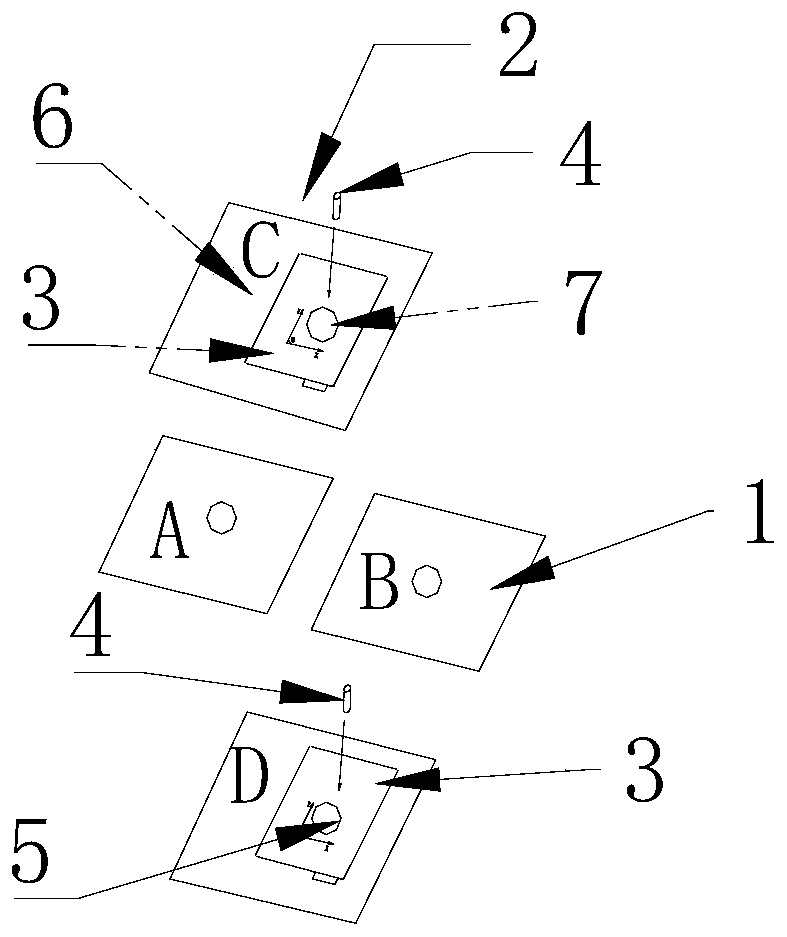

CCD positioning device and control method thereof

InactiveCN110083118AIncrease movement speedImprove correction efficiencyProgramme control in sequence/logic controllersMotor driveControl system

The invention belongs to the technical field of lithium battery pole piece equipment, and particularly relates to a CCD positioning device and a control method thereof. The CCD positioning device comprises a laminating mechanism, a first manipulator mechanism, a second manipulator mechanism and a deviation correcting mechanism, wherein a pole piece supply device comprises a first pole piece supplydevice and a second pole piece supply device; the lamination mechanism comprises a lamination motor and a lamination table, and the lamination motor drives the lamination table to move at the position A and the position B; the first manipulator mechanism comprises a first motor, a first rotating motor and a first manipulator, and the first rotating motor drives the first manipulator to rotate; the second manipulator mechanism comprises a second motor, a second rotating motor and a second manipulator, and the second rotating motor drives the second manipulator to rotate; and the deviation correcting mechanism comprises a CCD image sensor and a PLC control system. According to the invention, the deviation correcting efficiency is greatly improved, the moving speed of a manipulator sucker isgreatly improved, and the laminating efficiency is improved, so that the production requirement is facilitated.

Owner:温在东

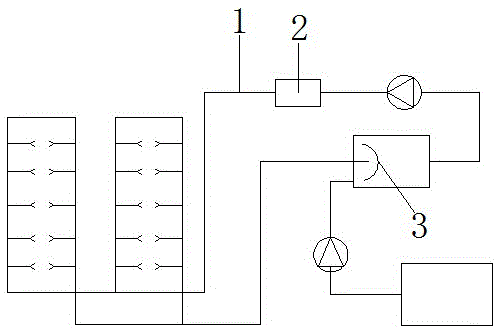

Coating circulating system cleaning technology

Owner:CHANGAN MAZDA AUTOMOBILE

Preparation method of metallic silicon reducing agent

The invention relates to the field of metal silicon production processing, and especially relates to a preparation method of a metallic silicon reducing agent. The method comprises the steps of ultralow ash coal preparation, pulping, batch mixing, carbonization and coke quenching. The purpose of the invention is to provide the preparation method of the metallic silicon reducing agent. The metallic silicon reducing agent prepared through adopting the preparation method has the advantages of low content of impurities, high activity in a high temperature state, high reducing efficiency, good quality and output of silicon produced after reduction, and realization of simple operation and convenient standardized production.

Owner:SHAODONG JIYUAN NEW MATERIAL CO LTD

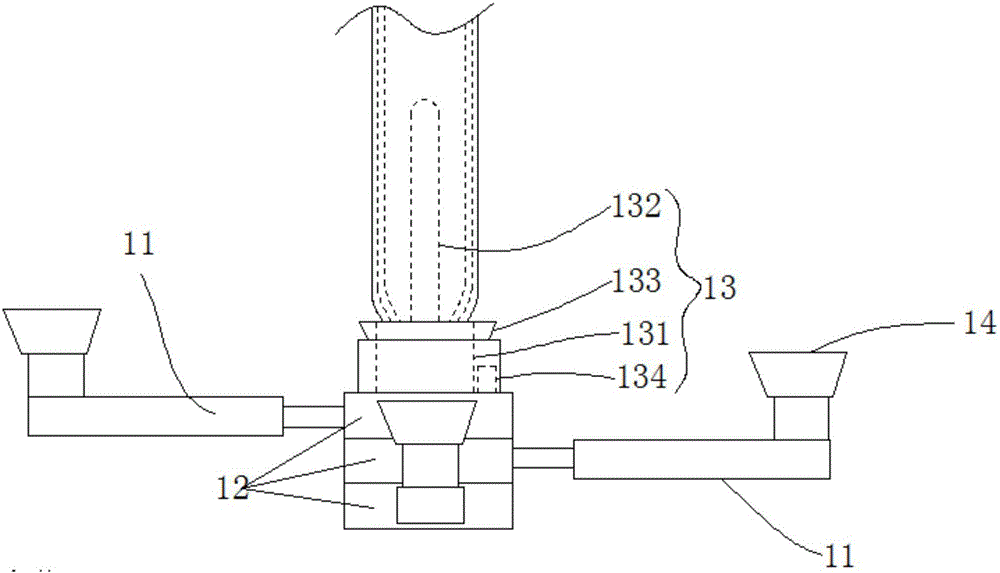

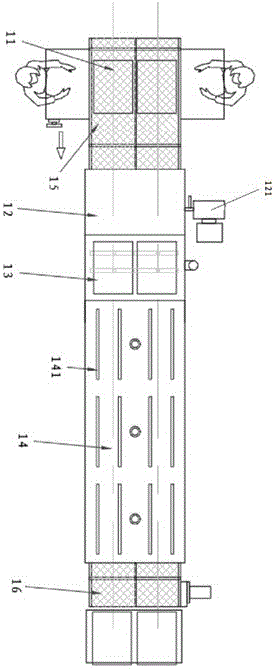

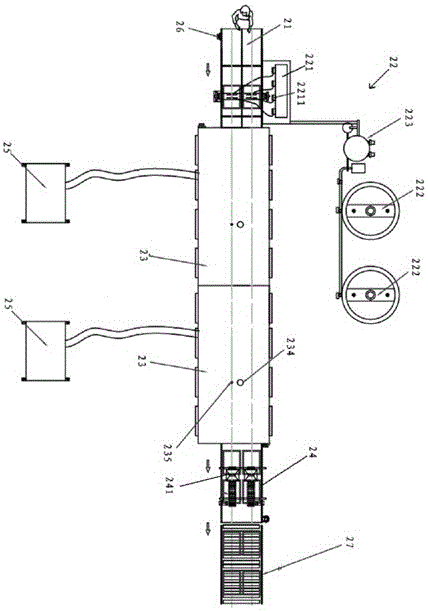

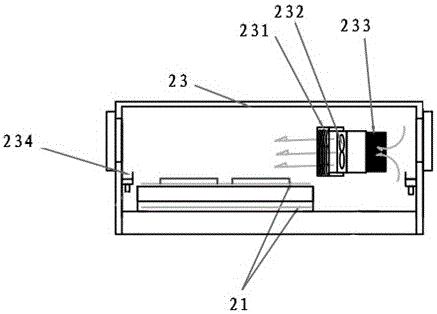

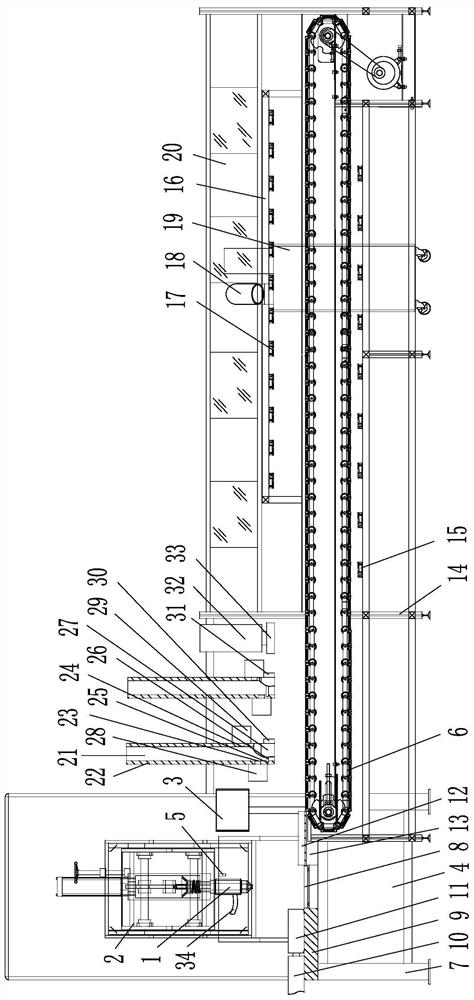

Production line for culturing plant stem cells on large scale

ActiveCN106047704AProduction needs to be goodBioreactor/fermenter combinationsBiological substance pretreatmentsProduction lineTechnological system

The invention discloses a production line for culturing plant stem cells on a large scale. The production line comprises a tray washing and drying line and a medium filling, freezing and inoculating line; the tray washing and drying line comprises a first conveying belt, a washing bin, a water blowing bin and a drying bin, and the first conveying belt sequentially penetrates through the washing bin, the water blowing bin and the drying bin; the medium filling, freezing and inoculating line comprises a second conveying belt, an automatic filling device, a freezing bin and an inoculating machine, the automatic filling device, the freezing bin and the inoculating machine are sequentially arranged in the conveying direction of the second conveying belt, an efficient filter, a draught fan and a condenser are sequentially arranged in the freezing bin, the inoculating machine is provided with a hopper, and the hopper is arranged above the second conveying belt. According to the production line, the thought of conventional liquid suspension culture is avoided during factory-like culture of the plant stem cells, and a simpler and more efficient solid culture technical system is developed.

Owner:厦门鹭港兆康生物科技有限公司

A kind of preparation, separation and purification method of latent curing agent microcapsules with temperature-responsive controlled release characteristics

ActiveCN104772085BExtended storage timeImprove applicabilityMicroballoon preparationMicrocapsule preparationTemperature responseThermoplastic

Relating to synthesis and optimization of latent curing agents, the invention provides a preparation and separation and purification method for a specific curing agent controlled release system with temperature responsiveness. According to the invention, a specific method is employed to prepare the specific curing agent so as to obtain a microcapsule with specific purpose. Through optimization of the preparation process, the use of polyvinyl alcohol and other stabilizers can be avoided, thus being conducive to separation and purification and drying at the later period. Also, the used reagents are all low toxic or non-toxic, and have very low environmental pollution. Single and pure thermoplastic plastic like polystyrene is selected as the coating material, which can melt at certain temperature and the release the curing agent so as to carry out curing reaction. Through selection of the solvent, rotation speed and feed ratio, microcapsules with different particle size distribution and curing agent content can be obtained. After centrifugation, a discontinuous timing ultrasonic method is carried out in absolute ethanol to prepare the curing agent microcapsule with very little impurity content and very good dispersibility, and agglomeration phenomenon does not appear.

Owner:北京中杰瑞康科技有限公司

Drying equipment for combed cotton yarn production

InactiveCN113267025AImprove drying efficiencyFast dryingDrying gas arrangementsDrying machines with progressive movementsYarnCombing

The invention discloses drying equipment for combed cotton yarn production, and relates to the technical field of combed cotton production. Aiming at solving the problems of single measure and low efficiency of heating wire drying after combed cotton cleaning in the prior art, the following scheme is provided: the drying equipment for combed cotton yarn production comprises an equipment box; a driving mechanism is arranged in the equipment box; the two sides of the top of the driving mechanism are fixedly connected with material guiding mechanisms; the top of the equipment box is fixedly connected with a heating box; two horizontally-arranged electric heating plates are arranged in the heating box; the electric heating plates are located between the two material guiding mechanisms; and the two sides of the driving mechanism are provided with blowing drying mechanisms rotationally connected to the inner wall of the equipment box. According to the drying equipment for combed cotton yarn production, hot air can be used for blowing and drying conveniently, the two faces of the cotton yarn make direct and temporary contact with the electric heating plates, and the cotton yarn drying speed is further increased; and therefore, enterprise production requirements are met.

Owner:安徽瑞翁科技有限公司

Novel power head structure

InactiveCN108662086AExtend your lifeShorten the lengthGearboxesGear lubrication/coolingGear driveDrive shaft

Owner:广东顺德煜腾机械设备有限公司

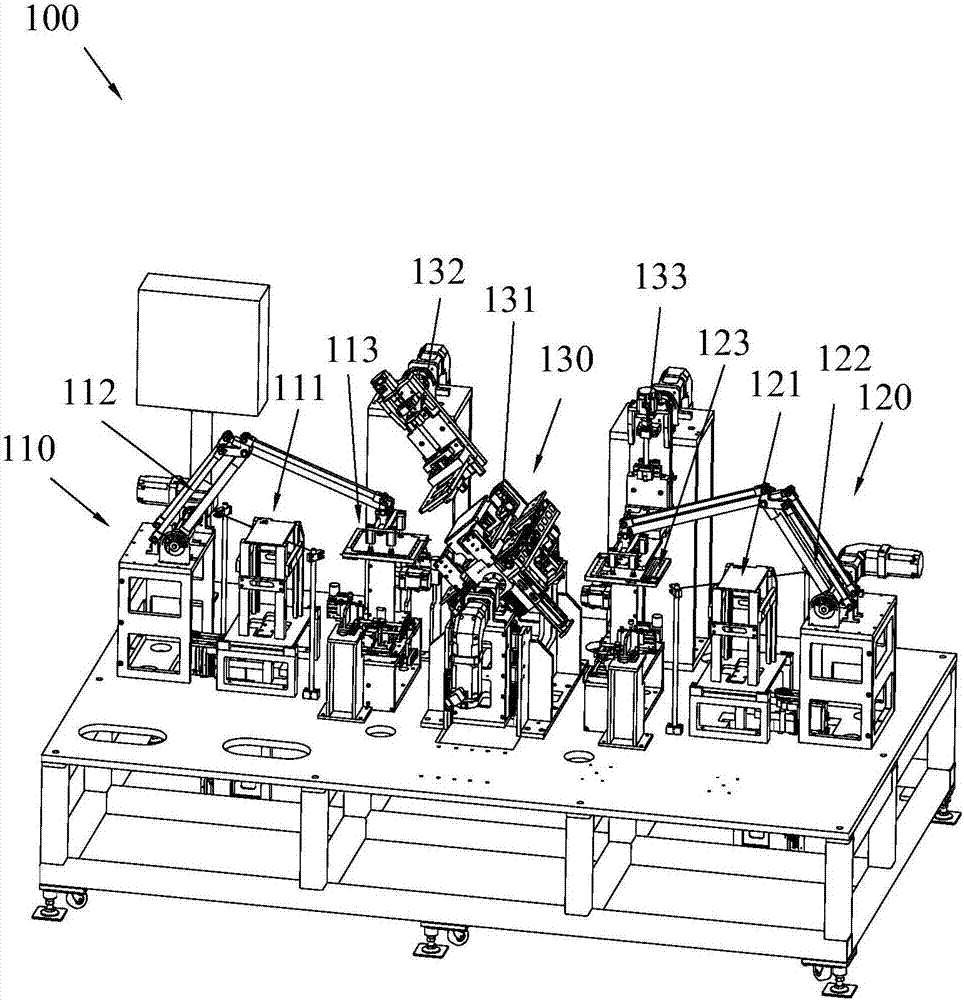

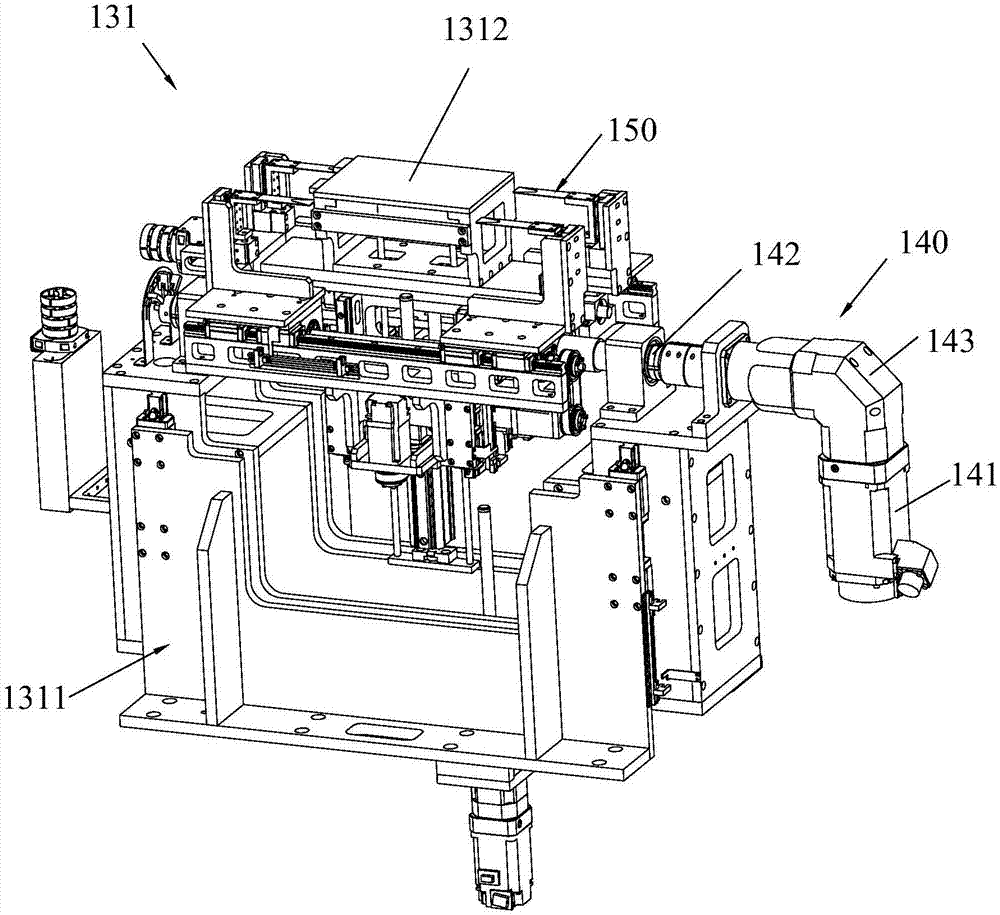

LED drive power filling vinyl assembly device and vinyl filling assembly method

ActiveCN109654095BExtended cooldownShort cooling time and high efficiencySpraying apparatusPretreated surfacesAdhesiveEngineering

The invention relates to an assembling device and an assembling method for filling a black adhesive to a Light-emitting diode (LED) drive power supply. The assembling device for filling the black adhesive to the LED drive power supply comprises a black adhesive filling machine with an adhesive discharging head, a controller with a display screen, an adhesive filling and metering device arranged under the discharging head, a conveying device arranged at the back end of the adhesive filling and metering device, a power supply main body feeding device, a power supply case cover feeding device, acover pressing device, a rapid cooling device arranged on the back side of the cover pressing device, and a power supply case feeding detection sensor located above the adhesive filling and metering device, wherein the power supply main body feeding device, the power supply case cover feeding device and the cover pressing device are sequentially arranged above the conveying device. According to the assembling device for filling the black adhesive to the LED drive power supply, the black adhesive filling amount is accurate, the assembled LED drive power supply is short in cooling time and highin efficiency, and the flow line production can be favorably arranged.

Owner:ZHEJIANG KAIYAO LIGHTING

Spherical mesoporous carbon nitride photocatalyst with multistage nano structure

ActiveCN103623856BImprove stabilityEasy to separateMaterial nanotechnologyPhysical/chemical process catalystsMicro nanoNano structuring

Owner:FUZHOU UNIV

Method for comprehensively generating biomass charcoal and pyroligneous by biomass pyrolysis

The invention provides a method for comprehensively generating biomass charcoal and pyroligneous by biomass pyrolysis, wherein the method includes steps of step one, smashing biomass raw materials to be grains; step two, placing granular biomass raw materials in a shaping machine to shape, and acquiring the shaping biomass; step three, putting the shaping biomass in a reactor at 70 DEG C and sealing the biomass at constant temperature for 30 min; step four, vacuumizing the reactor for 30-60 min; step five, filling nitrogen or inert gas in the reactor, and removing oxygen in the reactor; step six, heating up the reactor to 600 DEG C at the heating rate of 5-10 DEG C in an inertia atmosphere, and acquiring the biomass charcoal; step seven, not collecting gas generated from the reactor when the temperature of the reactor is 70-200 DEG C in heating process; when the reactor temperature is 200-450 DEG C, collecting gas generated in the reactor; when the reactor temperature is 450-600 DEG C, not collecting gas generated from the reactor; step eight, condensing the collected gas and acquiring the pyroligneous.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Efficient punching equipment for PE leakage pipe

PendingCN113715093AEasy to fixProduction needs to be goodMetal working apparatusPunchingStructural engineering

The invention discloses efficient punching equipment for a PE leakage pipe, and relates to the field of PE leakage pipes. The efficient punching equipment comprises a main supporting plate, supporting vertical rods are vertically and downwards welded to the bottom surface of the main supporting plate, a control panel is obliquely welded to one side edge of the main supporting plate, a display screen is embedded in the top surface of the control panel, and a setting plate is embedded in the top surface of the control panel; and a sliding transverse groove is horizontally formed in the top face of the main supporting plate, a movable vertical plate is vertically arranged on the top face of the main supporting plate, an extending top plate is horizontally welded to one side edge of the movable vertical plate, sleeving rods are symmetrically welded to the two side edges of the extending top plate, and extending rods are horizontally inserted into the ends, away from the extending top plate, of the sleeving rods. According to the efficient punching equipment, the design is integrated, the structure is simple, operation is convenient, fixing arrangement is more stable and saves more labor by adopting an electric clamping mode, and meanwhile, multi-direction intelligent drilling treatment can be achieved, so that the drilling efficiency is greatly improved.

Owner:钟通

A kind of preparation method of metal silicon reducing agent

The invention relates to the field of metal silicon production processing, and especially relates to a preparation method of a metallic silicon reducing agent. The method comprises the steps of ultralow ash coal preparation, pulping, batch mixing, carbonization and coke quenching. The purpose of the invention is to provide the preparation method of the metallic silicon reducing agent. The metallic silicon reducing agent prepared through adopting the preparation method has the advantages of low content of impurities, high activity in a high temperature state, high reducing efficiency, good quality and output of silicon produced after reduction, and realization of simple operation and convenient standardized production.

Owner:SHAODONG JIYUAN NEW MATERIAL CO LTD

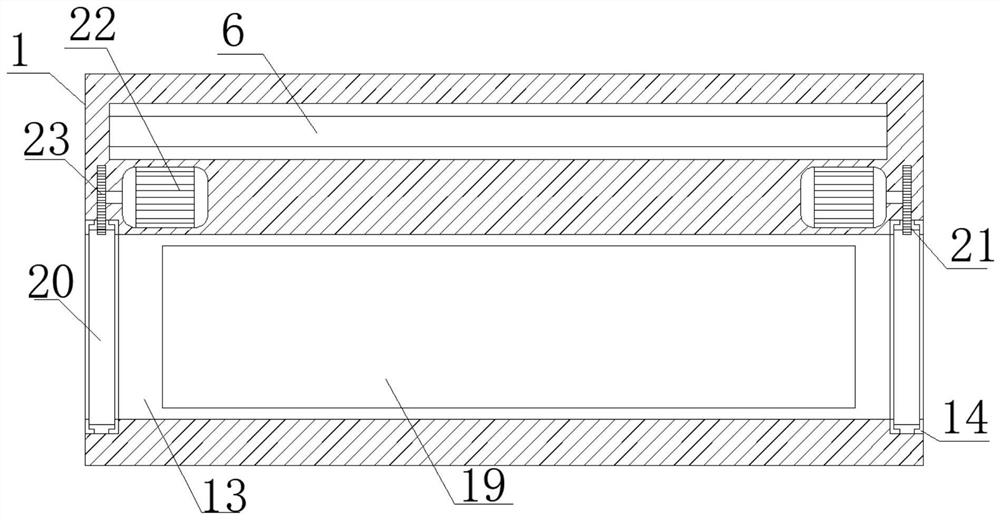

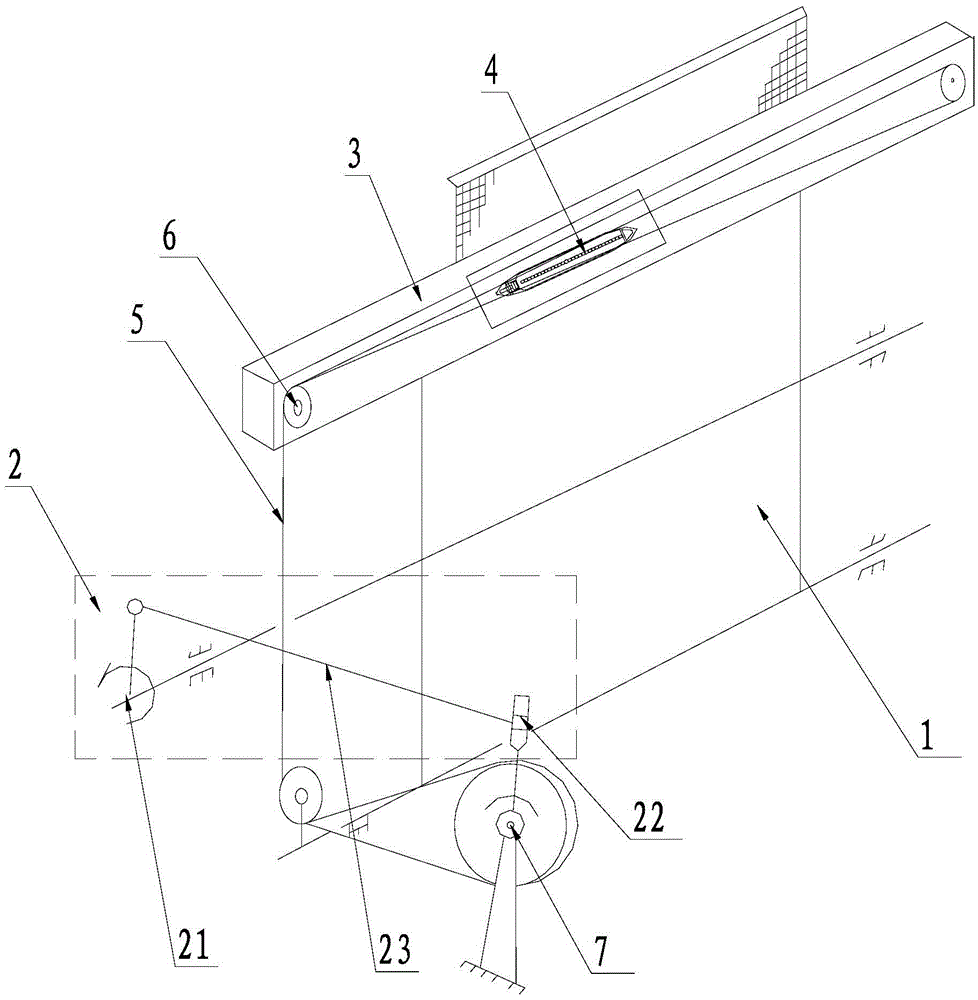

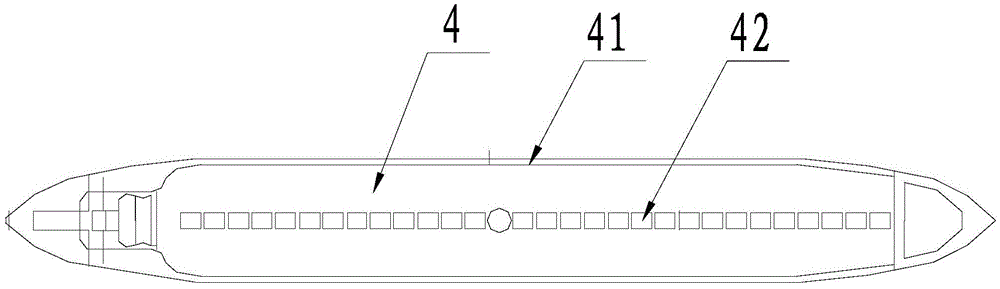

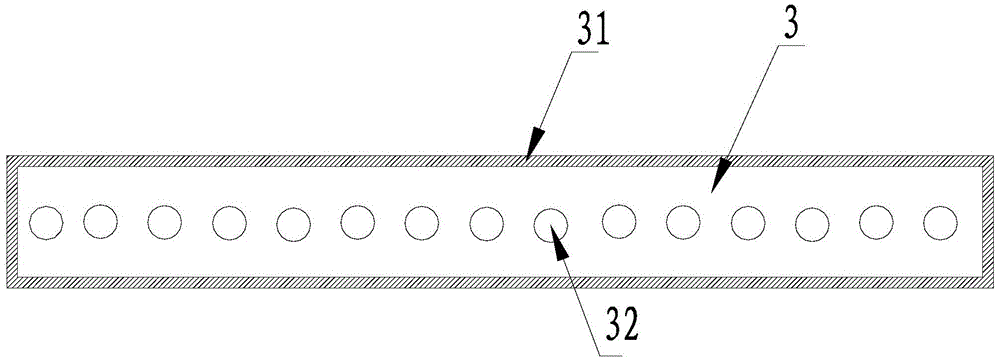

Maglev weft insertion automatic loom

The invention provides a magnetic levitation weft insertion automatic weaving loom to solve the problems that a traditional automatic weaving loom is complex in shuttle changing mechanism, prone to failures, long in process flow, high in amount of consumed labor, high in quantity of materials consumed by a machine and high in noise. The magnetic levitation weft insertion automatic weaving loom comprises a machine frame, a crank and rocker mechanism located on one side of the machine frame, a guide rail located on the machine frame, and a weft insertion shuttle located on the guide rail. The guide rail is fixed to the upper end of the machine frame. The weft insertion shuttle is connected with the crank and rocker mechanism through a weft insertion steel wire rope. The guide rail comprises a large portal frame and a guide rail magnetic sheet located on the large portal frame. The weft insertion shuttle comprises a shuttle guiding piece and a shuttle guiding magnetic sheet located at the bottom of the shuttle guiding piece. The opposite faces of the shuttle guiding magnetic sheet and the guide rail magnetic sheet have the same polarity. A steering pulley is arranged at the upper end of the machine frame. A speed increasing gear is arranged between the crank and rocker mechanism and the machine frame. The crank and rocker mechanism comprises a rocker, a crank and a connecting rod which is connected with the rocker and the crank, wherein the crank is fixed to the machine frame.

Owner:高密市三佳纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com