Drying equipment for combed cotton yarn production

A technology for drying equipment and cotton yarn, applied in progressive dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of single heating wire drying measures and low efficiency, achieve novel design, improve drying efficiency, and facilitate blow dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

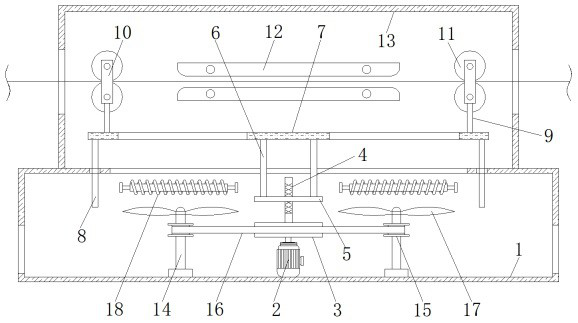

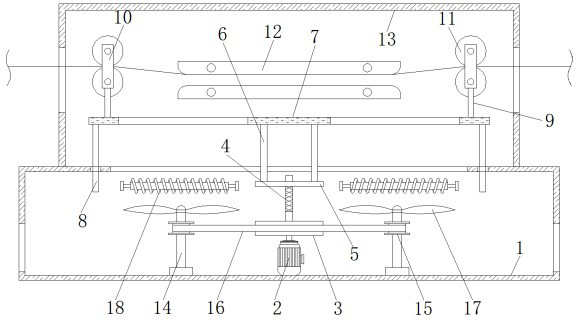

[0027] refer to Figure 1-4 A kind of drying equipment for combed cotton yarn production, including equipment box 1, the inside of equipment box 1 is provided with driving mechanism, the top both sides of the driving mechanism are fixedly connected with material guide mechanism, the top of equipment box 1 is fixedly connected with heating box 13 , the inside of the heating box 13 is provided with two electric heating plates 12 arranged horizontally, and the electric heating plates 12 are located between the two material guide mechanisms, and the both sides of the driving mechanism are provided with a blowing drying mechanism that is rotatably connected with the inner wall of the equipment box 1.

[0028] In the present invention, the drive mechanism includes a drive motor 2 fixedly connected to the bottom inner wall of the equipment box 1, the output shaft of the drive motor 2 is fixedly connected with a drive disc 3, and the top of the drive disc 3 is fixedly connected with a ...

Embodiment 2

[0031] refer to figure 2 , image 3 , Figure 4-6 : a combed cotton yarn production drying equipment, in the present embodiment, the guide mechanism includes two support rods 9 fixedly connected with the top of the movable plate 7, the top of the support rod 9 is fixedly connected with a splint 10, two splints 10 There are two guide rollers 11 rotatingly connected between them, and the cotton yarn passes between the two guide rollers 11; the drive motor 2 on the drive mechanism also drives the drive disc 3 and the reciprocating screw mandrel 4 to rotate, and the rotation of the reciprocating screw mandrel 4 will drive The connecting plate 5 moves up and down, and the connecting plate 5 drives the movable plate 7 to move up and down through the fixed rod 6, and the movable plate 7 drives the material guide mechanism to move up and down, and the material guide mechanism will drive the cotton yarn to move up and down, so that the upper and lower sides of the cotton yarn will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com