Small-diameter log four-roller automatic material supporting and rotary cutting mechanism for thick veneer machining

A technology for small-diameter wood and veneer, which is used in wood processing appliances, manufacturing tools, and veneer manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

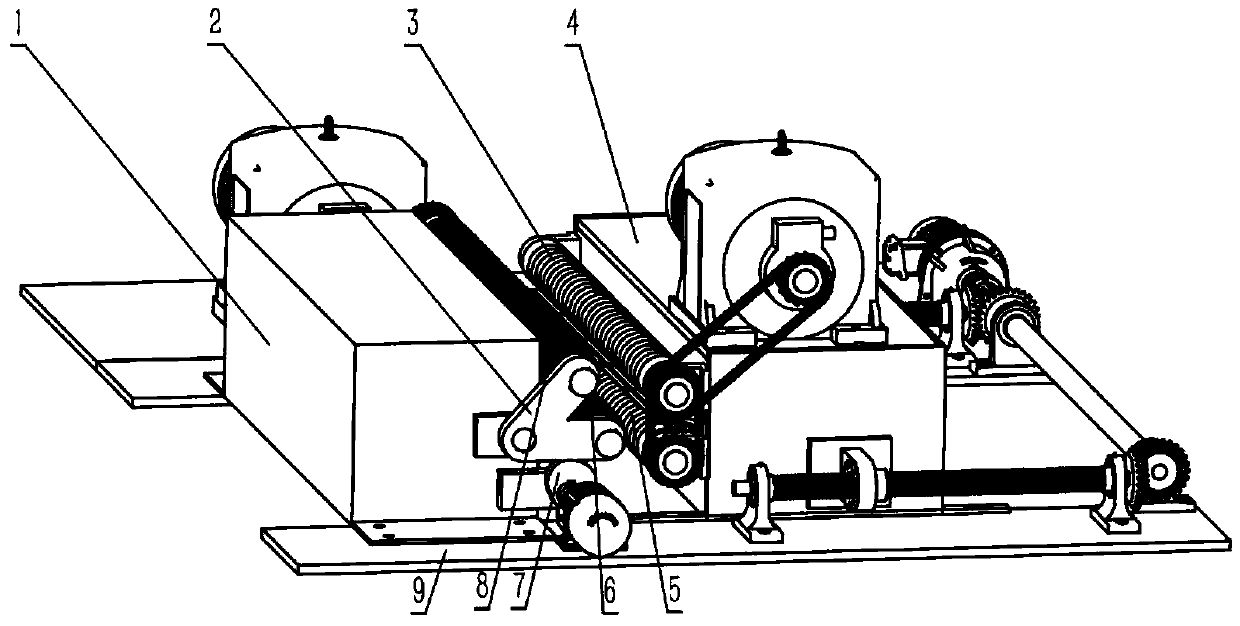

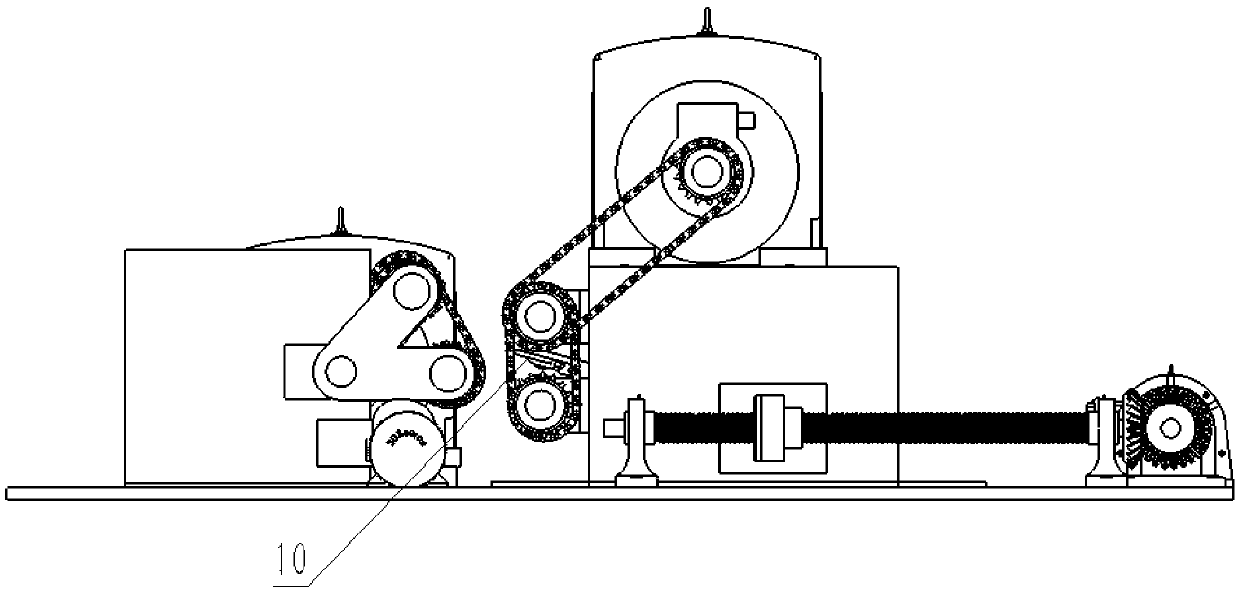

[0015] The four-roller automatic supporting rotary cutting mechanism for small-diameter thick veneer processing consists of a front fixed frame 1, a V-shaped frame 2, an upper pinch roll 3, a knife bed 4, a lower pinch roll 5, a lower squeeze roll 6, and a cam 7. , Upper extrusion roller 8, frame connecting plate 9, rotary cutter 10, cam transmission shaft 11 constitute.

[0016] The following is an introduction to the components and functions of each part of the device:

[0017] The front fixed frame 1 is connected to the frame connecting plate 9 by bolts, the knife bed 4 is connected to the frame connecting plate 9 through a ball screw pair, driven by a motor, and the knife bed 4 is connected to the frame through the transmission of the ball screw pair The plate 9 moves horizontally, and the front fixed frame 1 is fixed with a V-shaped frame 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com