Spherical mesoporous carbon nitride photocatalyst with multistage nano structure

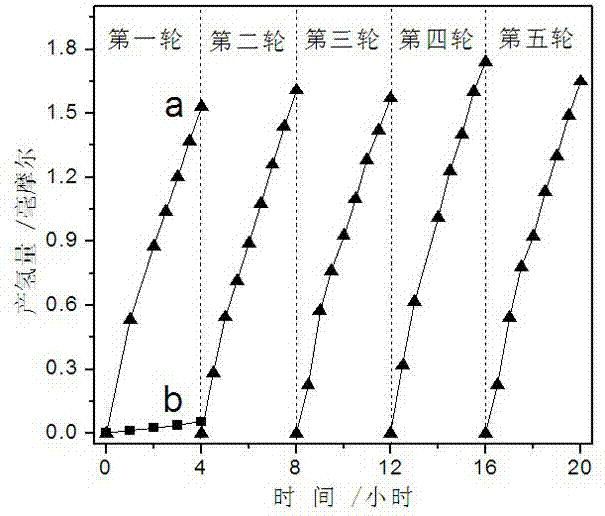

A technology of mesoporous carbon nitride light and mesoporous carbon nitride, which is applied in the field of spherical mesoporous carbon nitride photocatalysts and its preparation, can solve the problem of inability to effectively promote the mass transfer and diffusion of reaction substrates in nanopores and unfavorable photocatalysis Efficient reaction, hindering the chemical reaction on the inner surface, etc., to achieve the effect of easy recycling, high practical value, and improved hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

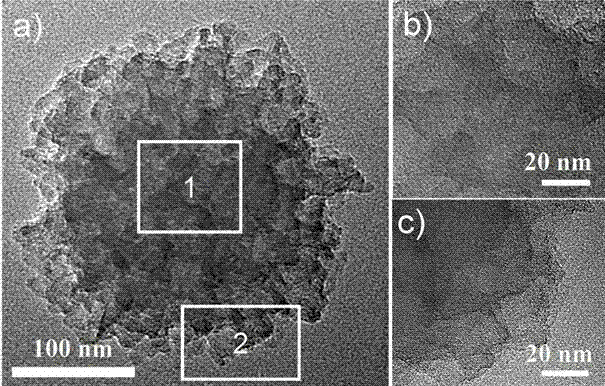

Embodiment 1

[0017] Dissolve 2.5g tetraethyl silicate (TEOS) and 3.0mL pentanol in 30mL cyclohexane to form solution A; dissolve 1.0g cetylpyridinium bromide (CPB) and 0.8g urea in 30mL water Dubbed solution B. The two solutions of A and B were mixed and stirred, and transferred into a microwave reactor, and heated by microwave at 413K for 4h. After the reaction, it was centrifuged and washed with water and acetone, dried in the air, and calcined in a muffle furnace at 923K for 4 hours to obtain the KCC-1 silica template. Dissolve the template agent in 1.0 mol / L HCl, close and stir at 353K for 24 hours, and carry out acid treatment on the template agent. Centrifuge, dry and grind. In a round-bottomed flask with a suction filter, add KCC-1 and cyanamide in step (2) with a mass ratio of 1:9, and treat with "ultrasonic + heating (328K)" for 6 hours under vacuum (4 HF 2 The silicon dioxide template is removed by aqueous solution etching, washed with water, and dried to prepare spherical mes...

Embodiment 2

[0019] Dissolve 3.0g tetraethyl silicate (TEOS) and 2.0mL pentanol in 30mL cyclohexane to form solution A; dissolve 2.0g cetylpyridinium bromide (CPB) and 1.0g urea in 30mL water Dubbed solution B. The two solutions of A and B were mixed and stirred, and transferred into a microwave reactor, and heated by microwave at 393K for 6h. After the reaction, it was centrifuged and washed with water and acetone, dried in the air, and calcined in a muffle furnace at 873K for 8 hours to obtain the KCC-1 silica template. Dissolve the template agent in 2.0 mol / L HCl, close and stir at 353K for 12 hours, and carry out acid treatment on the template agent. Centrifuge, dry and grind. In a round-bottomed flask with a suction filter, add KCC-1 and cyanamide in step (2) with a mass ratio of 1:5, and treat with "ultrasonic + heating (333K)" for 6 hours under vacuum (4 HF 2 The silicon dioxide template is removed by aqueous solution etching, washed with water, and dried to prepare spherical mes...

Embodiment 3

[0021] Dissolve 2.5g tetraethyl silicate (TEOS) and 1.5mL amyl alcohol into 30mL cyclohexane to form solution A; dissolve 1.0g cetylpyridinium bromide (CPB) and 0.6g urea into 30mL water Dubbed solution B. The two solutions of A and B were mixed and stirred, and transferred into a microwave reactor, and heated by microwave at 393K for 2h. After the reaction, it was centrifuged and washed with water and acetone, dried in the air, and calcined in a muffle furnace at 823K for 6 hours to obtain the KCC-1 silica template. Dissolve the template agent in 1.0 mol / L HCl, close and stir at 353K for 24 hours, and carry out acid treatment on the template agent. Centrifuge, dry and grind. In a round-bottomed flask with a suction filter, add KCC-1 and cyanamide in step (2) with a mass ratio of 1:8, and treat with "ultrasonic + heating (328K)" for 4 hours under vacuum (4 HF 2The silicon dioxide template is removed by aqueous solution etching, washed with water, and dried to prepare spheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com