3D assembling tool clamp for escalator

A technology for assembling tooling and escalators, used in manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of manual manual adjustment, time-consuming, complex structure, etc., and achieves reduced alignment accuracy requirements, convenient and fast operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

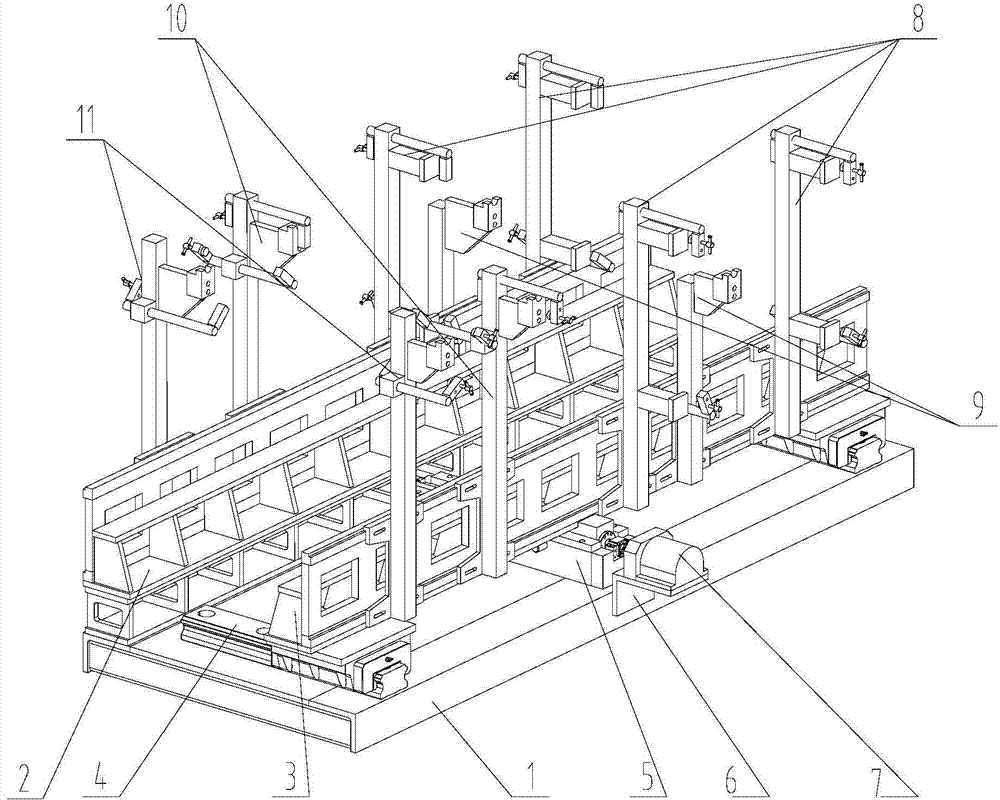

[0022] The present invention will be further elaborated below by taking the escalator 3D assembly fixture suitable for the lower curve of the guide rail as an example.

[0023] Such as figure 1 As shown, the present invention is a 3D assembly fixture for an escalator, including a working platform 1, a reference beam 2 parallel to each other supported on the working platform 1, and a laterally movable beam 3 and the like. The fixed reference beam 2 remains stationary as a reference.

[0024] The transversely movable beam 3 is supported on the working platform 1 through the screw drive guide rail 5, and the screw drive guide rail 5 is connected with the motor 7 and drives the laterally movable beam 3 to move laterally. In this embodiment, the middle part of the transversely movable beam 3 is supported on the working platform 1 through the screw drive guide rail 5 , and the two ends are supported on the working platform 1 through the linear guide rail 4 . preferred, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com