Improved film blowing, printing and rolling all-in-one machine

An all-in-one machine and rewinding shaft technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of uneven film texture, difficulty in adjusting the angle and position of the scraper, and difficulty in controlling the winding tightness, etc., to achieve uniform texture, The gap adjustment is convenient and quick, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

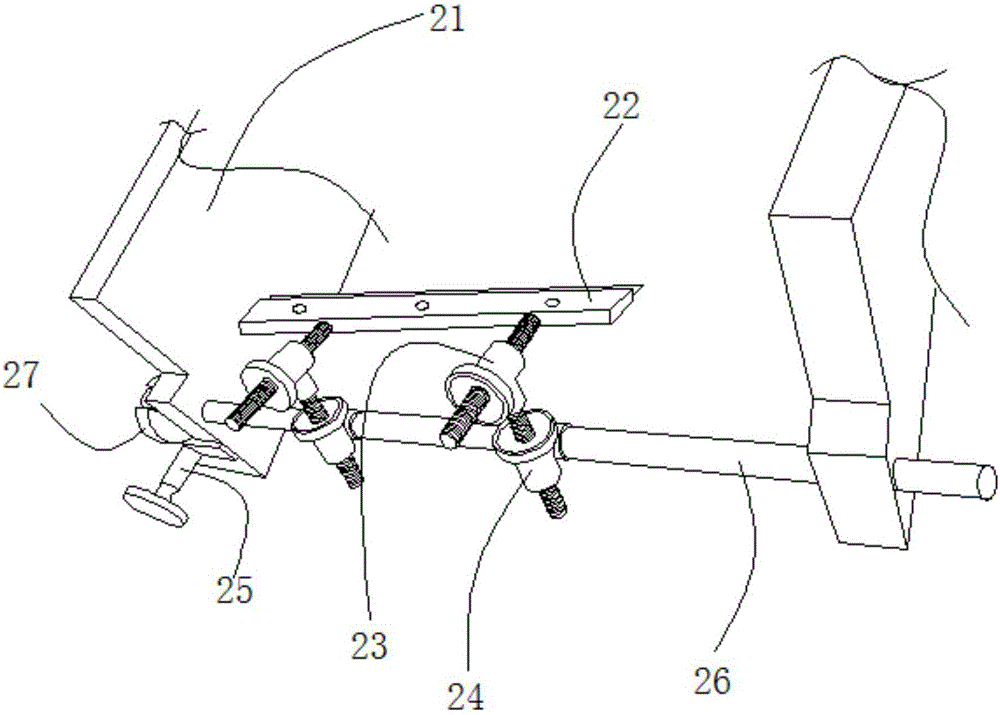

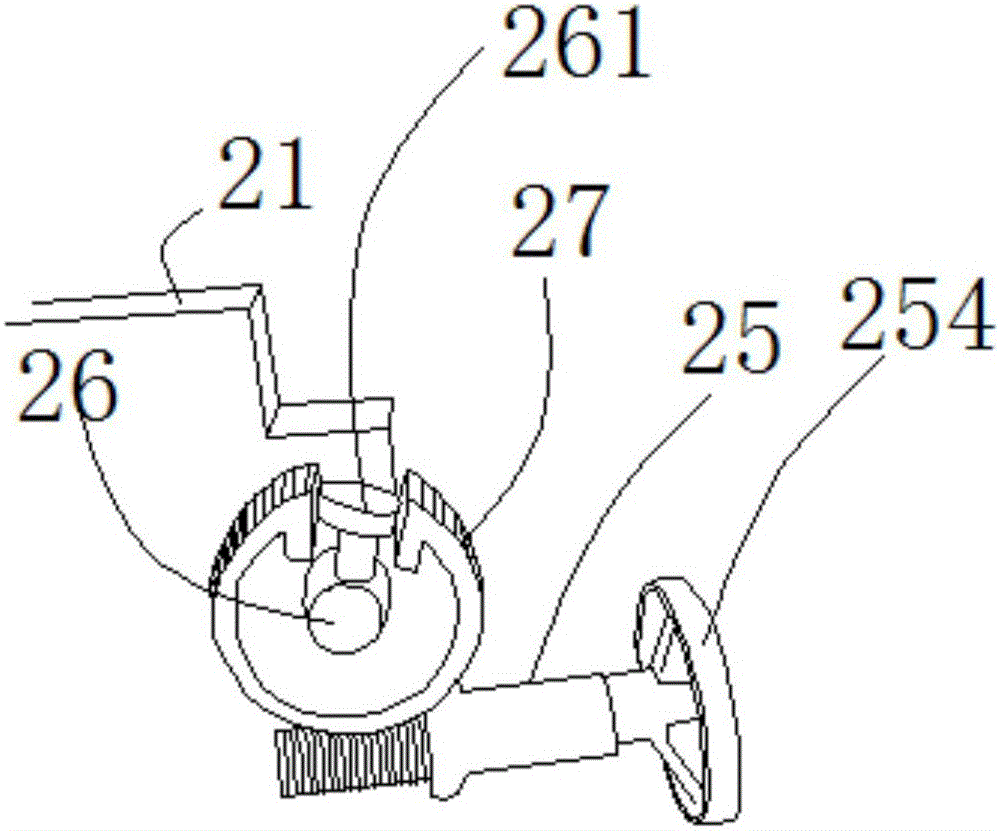

[0030] An improved film blowing, printing and winding integrated machine includes a film blowing device 1 , a printing device 2 and a winding device 3 .

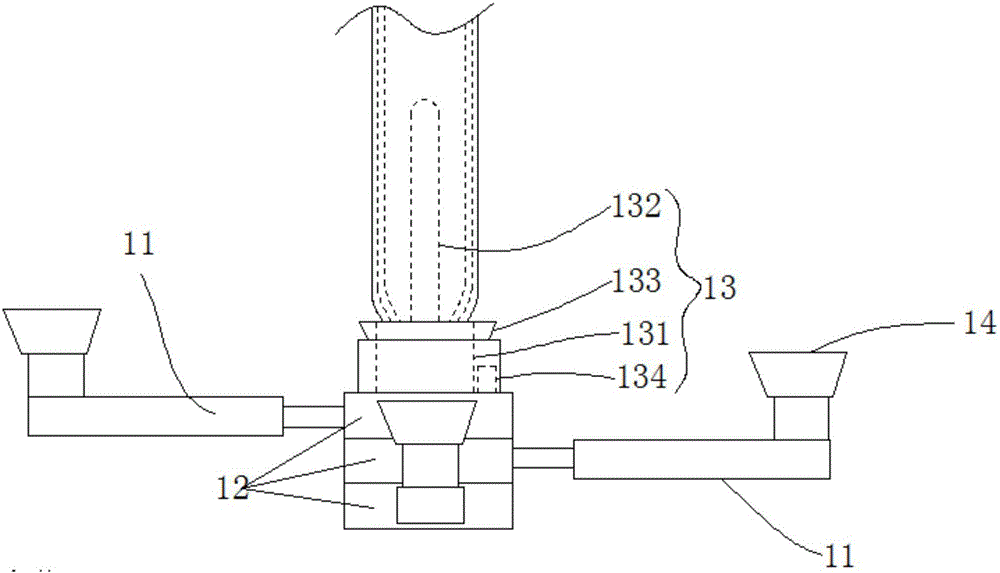

[0031] Among them, the blown film device, such as figure 1 As shown, it includes an extruding feeding shaft mechanism 11 , a sealing and rotating connection mechanism 12 , a film blowing mechanism 13 , and a hopper 14 . There are three sets of extruding feeding shaft mechanism 11, sealing rotating connection mechanism 12 and hopper 14 respectively. The film blowing mechanism 13 includes a film blowing die head 131 , a fixed core rod 132 , an air ring 133 , and a driving mechanism 134 . The blown film die head 131 is divided into an inner die head, a middle die head and an outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com