Production method for high-content galactooligosaccharide

The technology of a galacto-oligosaccharide and a production method is applied in the production field of high-content galacto-oligosaccharide, and can solve the problems of low purity of galacto-oligosaccharide, decreased lactose content, low synthesis efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

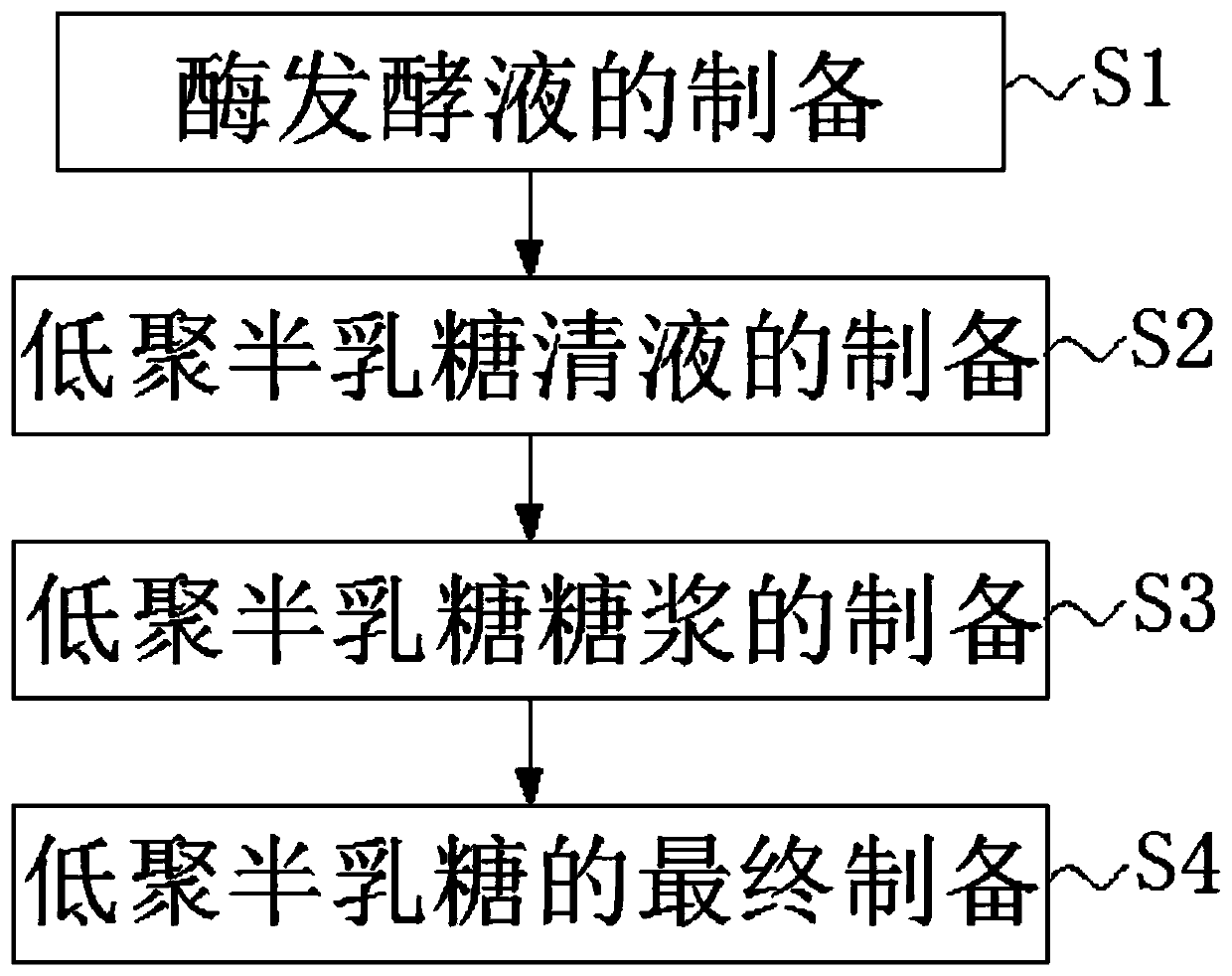

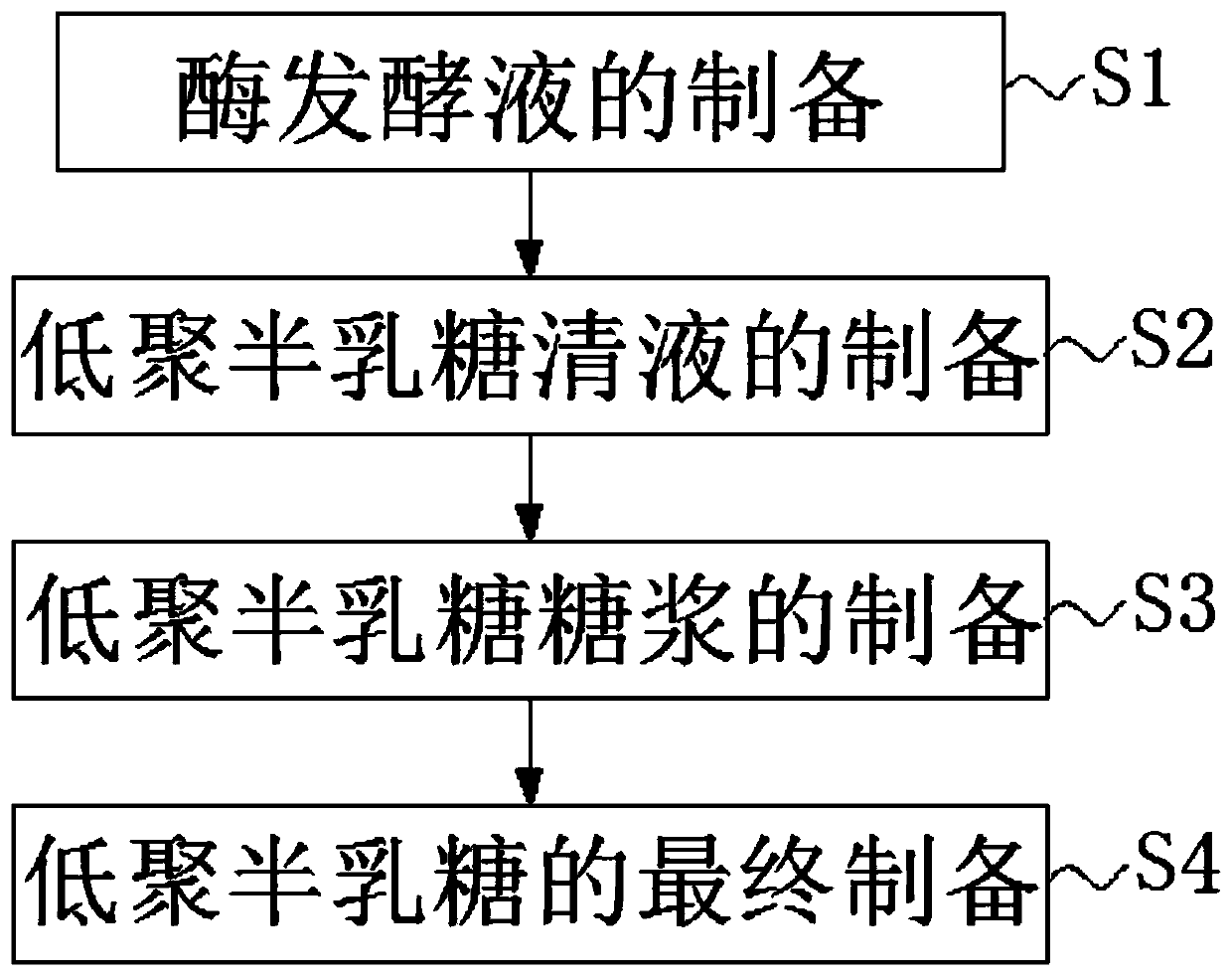

[0020] S1. Preparation of enzyme fermentation broth: use 300g / L lactose solution as raw material, add β-galactosidase in the lactose solution, add 10U of β-galactosidase per gram of lactose raw material, put it in a high-speed mixer, Stir evenly at a temperature of 25° C., with a pH value of 6. After cultivating for 30 hours, when the enzyme reacts until the mass percentage of glucose in the total sugar is 10%, the reaction work is terminated, and finally the enzyme fermentation broth is obtained, waiting for use;

[0021] S2. Preparation of galactooligosaccharide serum: put the enzyme fermentation broth obtained in S1 into a high-speed mixer, and then add a galactosidase solution with a concentration of 200g / L. After stirring and reacting for 15 hours, the obtained solution was centrifuged to remove the internal bacteria, and finally the galacto-oligosaccharide serum was obtained, which was left to stand for later use;

[0022] S3. Preparation of galacto-oligosaccharide syrup...

Embodiment 2

[0025] S1. Preparation of enzyme fermentation broth: use 350g / L lactose solution as raw material, add β-galactosidase in the lactose solution, add 20U of β-galactosidase per gram of lactose raw material, put it in a high-speed mixer, Stir evenly at a temperature of 30° C., with a pH value of 6.5. After culturing for 35 hours, when the enzyme reacts until the mass percentage of glucose in the total sugar is 12%, the reaction work is terminated, and finally the enzyme fermentation broth is obtained, waiting for use;

[0026] S2. Preparation of galacto-oligosaccharide serum: put the enzyme fermentation liquid obtained in S1 into a high-speed mixer, and then add a galactosidase solution with a concentration of 400g / L. After stirring and reacting for 18 hours, the obtained solution was centrifuged to remove the internal bacteria, and finally the galacto-oligosaccharide serum was obtained, which was left to stand for later use;

[0027] S3. Preparation of galacto-oligosaccharide syr...

Embodiment 3

[0030] S1. Preparation of enzyme fermentation broth: use 400g / L lactose solution as raw material, add β-galactosidase in the lactose solution, add 30U of β-galactosidase per gram of lactose raw material, put it in a high-speed mixer, Stir evenly at a temperature of 35° C., with a pH value of 7. After 40 hours of cultivation, when the enzyme reacts until the mass percentage of glucose in the total sugar is 15%, the reaction work is terminated, and finally the enzyme fermentation broth is obtained, waiting for use;

[0031] S2. Preparation of galactooligosaccharide serum: put the enzyme fermentation broth obtained in S1 into a high-speed mixer, and then add a galactosidase solution with a concentration of 500g / L. After stirring and reacting for 20 hours, the obtained solution was centrifuged to remove the internal bacteria, and finally the galacto-oligosaccharide serum was obtained, which was left to stand for later use;

[0032] S3. Preparation of galacto-oligosaccharide syrup:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com