A kind of preparation, separation and purification method of latent curing agent microcapsules with temperature-responsive controlled release characteristics

A temperature-responsive, controlled-release technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of reduced operating time, high cost of material preparation, complex reaction equipment, etc., to avoid the use of stabilizers, particle size distribution, etc. The effect of uniformity and simple method and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

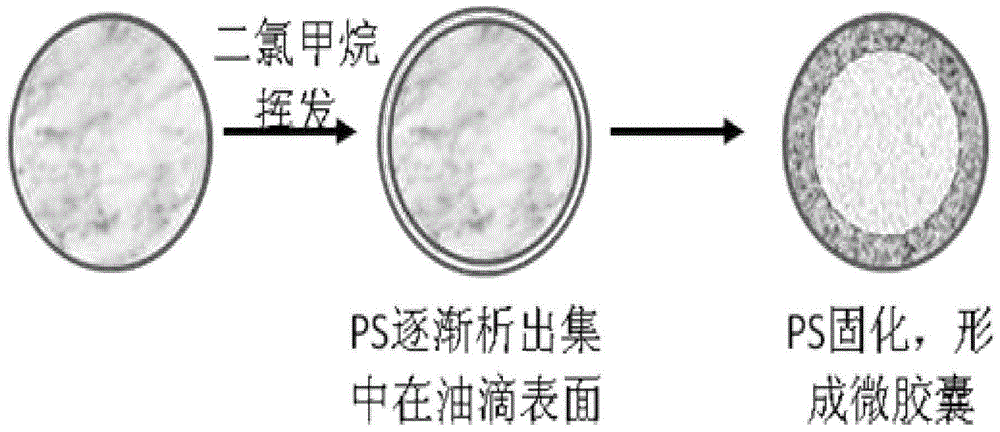

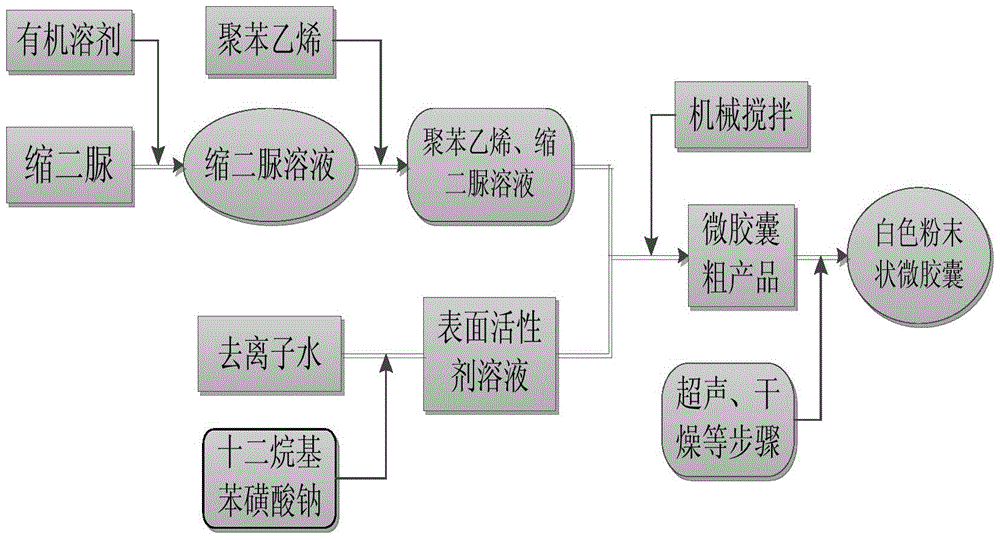

Method used

Image

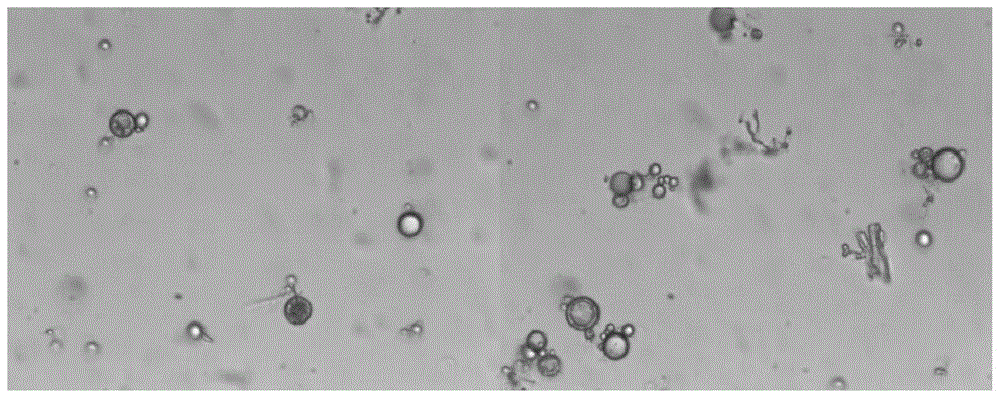

Examples

example 1

[0051] Step 1. Measure 30ml of dichloromethane into the beaker, add 1.5g of curing agent biuret into the beaker, and dissolve it completely under the condition of magnetic stirring;

[0052] Step 2. Weigh 1.5g of industrial-grade polystyrene particles, add them to the solution obtained in step 1, and heat to 30°C under magnetic stirring until the polystyrene particles are completely dissolved;

[0053]Step 3. Weigh 3g of sodium dodecylbenzenesulfonate and dissolve it in 300ml of deionized water, place the solution in a 1000ml beaker, and perform mechanical stirring with the speed controlled at around 400r / min;

[0054] Step 4. Add the solution obtained in Step 2 dropwise into the sodium dodecylbenzenesulfonate aqueous solution, and adjust the rotating speed to 600r / min for 5 hours;

[0055] Step 5. After 5 hours, stop the mechanical stirring, pour the solution in the beaker together with the white flocculent substances that appear into the centrifuge tube, centrifuge at a spee...

example 2

[0059] Step 1. Measure 30ml of chloroform into a beaker, add 1.5g of curing agent biuret into the beaker, and dissolve it completely under the condition of magnetic stirring;

[0060] Step 2. Weigh 1.5 g of industrial-grade polystyrene particles, add them to the solution obtained in step 1, seal the beaker with plastic wrap, and heat to 35° C. under magnetic stirring until the polystyrene particles are completely dissolved;

[0061] Step 3. Weigh 4g of sodium dodecylbenzenesulfonate and dissolve it in 400ml of deionized water, place the solution in a 1000ml beaker, perform mechanical stirring, and control the speed at around 400r / min;

[0062] Step 4. Add the solution obtained in Step 2 dropwise into the sodium dodecylbenzenesulfonate aqueous solution, and adjust the rotating speed to 600r / min for 5 hours;

[0063] Step 5. After 5 hours, stop the mechanical stirring, pour the solution in the beaker together with the white flocculent substances that appear into the centrifuge t...

example 3

[0067] Step 1. Measure 50ml of dichloromethane into a beaker, add 3g of curing agent biuret into the beaker, and dissolve it completely under the condition of magnetic stirring;

[0068] Step 2. Weigh 1.5g of industrial-grade polystyrene particles, add them to the solution obtained in step 1, and heat to 30°C under magnetic stirring until the polystyrene particles are completely dissolved;

[0069] Step 3. Weigh 4g of sodium dodecylbenzenesulfonate and dissolve it in 400ml of deionized water, place the solution in a 1000ml beaker, perform mechanical stirring, and control the speed at around 400r / min;

[0070] Step 4. Add the solution obtained in Step 2 dropwise into the sodium dodecylbenzenesulfonate aqueous solution, and adjust the rotating speed to 600r / min for 5 hours;

[0071] Step 5. Stop the mechanical stirring after 5 hours, pour the solution in the beaker together with the white flocculent substances that appear into the centrifuge tube, centrifuge at a speed of 6000r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com