LED drive power filling vinyl assembly device and vinyl filling assembly method

A technology for LED driving and assembling devices, which is applied in the direction of spraying devices, devices for coating liquid on the surface, connecting components, etc., which can solve the problems of short cooling time, low efficiency, and disadvantages of LED driving power supply, and facilitate the organization of assembly line production , Improve cooling speed, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

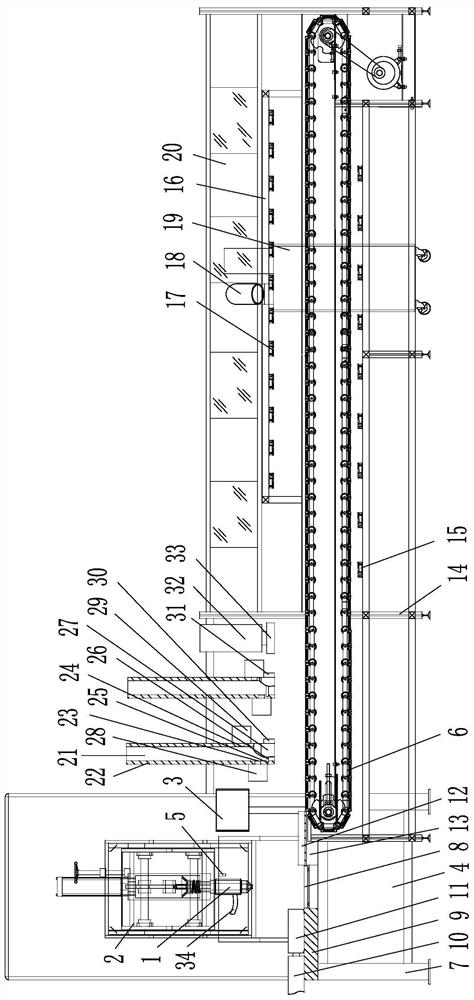

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 Shown: an assembly device for filling black glue with an LED drive power supply, including: a black glue filling machine 2 with a glue head 1, a controller 4 with a display screen 3, and a glue filling machine under the glue head 1 The metering device is the conveying device set at the back end of the glue filling metering device, the power supply main body positioning device, the power supply shell cover positioning device and the capping device are arranged in turn above the conveying device, and the rapid cooling device is set on the rear side of the capping device, The power supply casing in-position detection sensor 5 is located above the glue filling metering device and is screwed to the black glue glue filling machine 2 .

[0019] The conveying device is a stepping stainless steel chain conveyor 6 .

[0020] The glue filling meterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com