Brown lactobacillus beverage and preparation method thereof

A lactic acid bacteria beverage, brown technology, applied in the field of beverages, can solve the problems of increasing product calories and increasing product costs, and achieve the effect of reducing calories and strengthening market demand prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

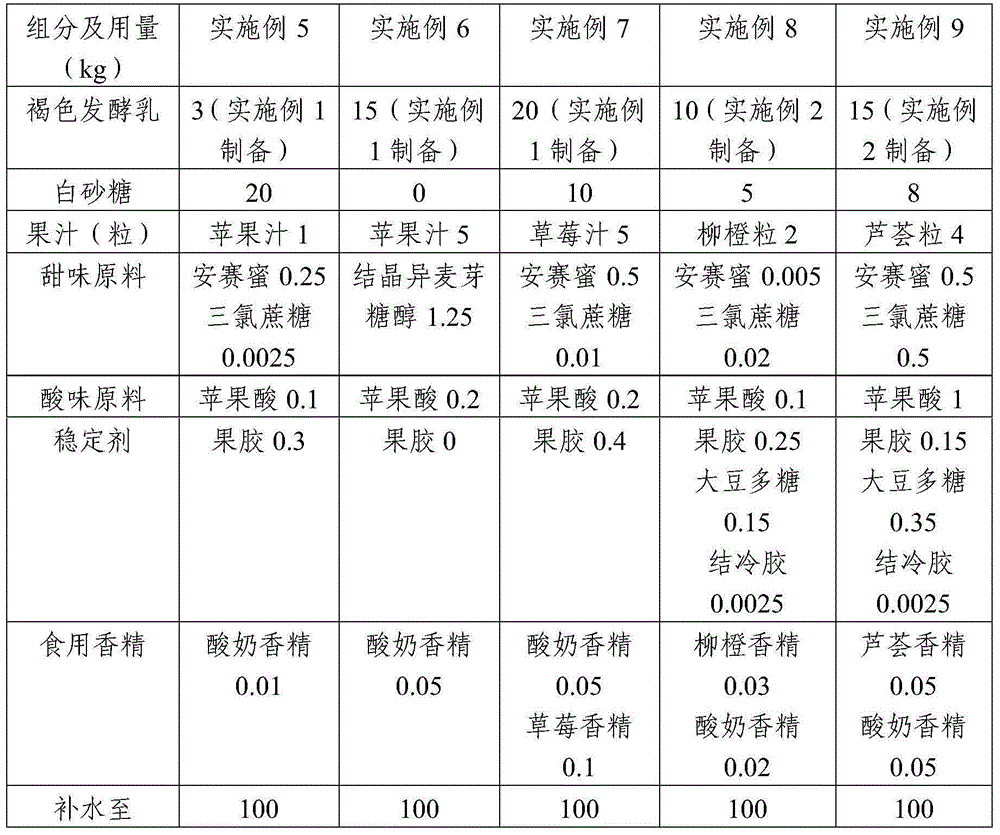

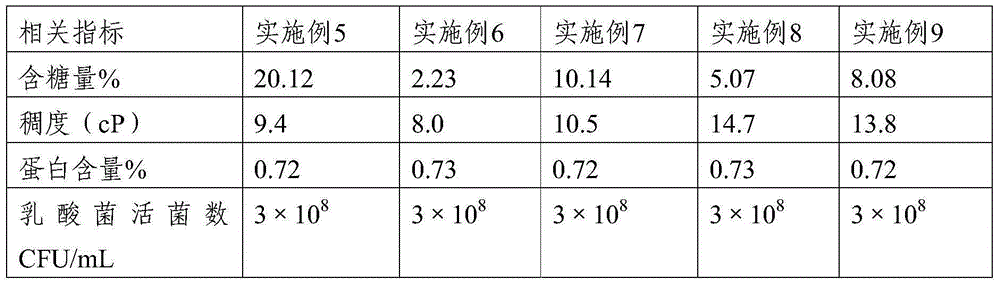

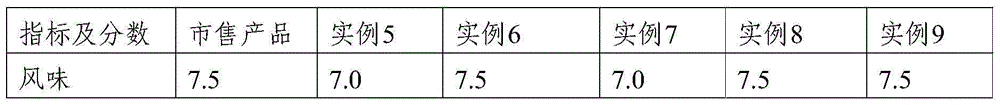

Examples

Embodiment 1

[0037] This embodiment provides a kind of brown fermented milk, and this brown fermented milk is prepared by the following steps:

[0038] (1) Skim reduction and lactose hydrolysis: Add 86kg of pure water to the mixing tank, heat up to 40°C, then add 16kg of skim milk powder and 0.1kg of hydrolase into the tank, stir evenly, and let it stand for 2 hours to obtain reconstituted milk ;

[0039] (2) Browning of reconstituted skim milk: heating the reconstituted milk obtained in step (1) to 80° C., keeping it for 3 hours, and then cooling down to 40° C. to obtain brown reconstituted skim milk;

[0040] (3) Fermentation of defatted reconstituted milk: put 20dcu / 100kg of strains into the defatted fermented milk obtained in step (2), heat-preserve and ferment for 120 hours, and terminate the fermentation to obtain brown fermented milk.

[0041] Wherein, the skimmed milk powder is New Zealand medium-temperature skimmed milk powder, the hydrolase is lactose hydrolase, and the strain i...

Embodiment 2

[0043] This embodiment provides a kind of brown fermented milk, and this brown fermented milk is prepared by the following steps:

[0044] (1) Skimming recovery and lactose hydrolysis: Add 86kg of pure water to the mixing tank, heat up to 50°C, then add 16kg of skimmed milk powder and 0.1kg of hydrolase into the tank, stir evenly, and let stand for 0.5 hours to obtain reconstituted milk ;

[0045] (2) Browning of reconstituted skim milk: heating the reconstituted milk obtained in step (1) to 100° C., keeping it for 0.5 hours, and then cooling down to 30° C. to obtain brown reconstituted skim milk;

[0046] (3) Fermentation of skimmed reconstituted milk: put 30dcu / 100kg strains into the skimmed fermented milk obtained in step (2), heat-preserve and ferment for 40 hours, stop fermentation, and obtain brown fermented milk.

[0047] Wherein, the skimmed milk powder is Australian medium-temperature skimmed milk powder, the hydrolase is lactose hydrolase, and the strains are Lactob...

Embodiment 3

[0049] Compared with Example 1, the only difference is that in this example, the raw materials for preparing brown fermented milk are: 80kg of purified water, 10kg of skim milk powder and 0.05kg of hydrolase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com