Chemical copper precipitation wastewater copper removing treatment process and chemical copper precipitation wastewater copper removing treatment system

A chemical copper precipitation and treatment system technology, applied in metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment, multi-stage water treatment, etc., can solve the problems of large amount of chemical input, poor stability, poor load impact resistance, etc., to achieve Reduce labor intensity, avoid poor stability, and reduce the effect of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

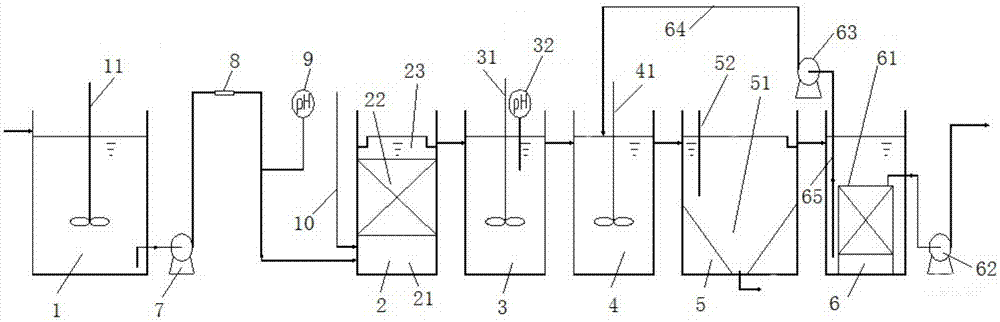

[0034] Such as figure 1 As shown, a copper removal treatment system for chemical copper precipitation wastewater includes a regulating tank 1, a micro-electrolysis reaction tank 2, a pH adjusting tank 3, a flocculation tank 4, a buffer tank 5 and an MCR tank 6.

[0035] Among them, the regulating pool 1 is used to receive the electroless copper precipitation wastewater discharged from the production line, and fully adjust the water quality and quantity. In order to prevent the precipitation of pollutants in the wastewater, a third mechanical mixing device 11 is also provided inside the regulating tank 1 . A lift pump 7 is also installed at the outlet of the regulating tank 1, and the lift pump 7 is connected to the micro-electrolysis reaction tank 2 through a pipeline.

[0036] The pipeline between the lift pump 7 and the micro-electrolysis reaction tank 2 is provided with a pipeline mixer 8 for adding sulfuric acid to adjust the pH value of the waste water. control.

[003...

Embodiment 2

[0043] A method for copper removal treatment of chemical precipitation copper wastewater, using the chemical copper precipitation wastewater treatment system for copper removal as described in embodiment 1, which includes the following steps:

[0044] In step (1), the electroless copper precipitation wastewater discharged from the production line is transported to the regulating tank, so as to fully adjust the water quality and quantity, and prevent the precipitation of pollutants in the wastewater.

[0045] In step (2), sulfuric acid is added to the waste water to adjust the pH of the waste water to 3-4.

[0046] In step (3), the wastewater treated in step (2) is transported to the micro-electrolysis reaction tank, and discharged after being treated with aeration and micro-electrolysis filler. The hydraulic retention time of the micro-electrolysis reaction pool is 1-2 hours, and the reaction time between the micro-electrolysis filler and wastewater is controlled at 30-60 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com