Abrasion-scratch resistant AS modified plastic

A modified plastic technology, applied in the field of anti-wear and scratch AS modified plastics, can solve the problems of high cost, unsuitable for industrial application, etc., and achieve the effect of improving toughness and anti-scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

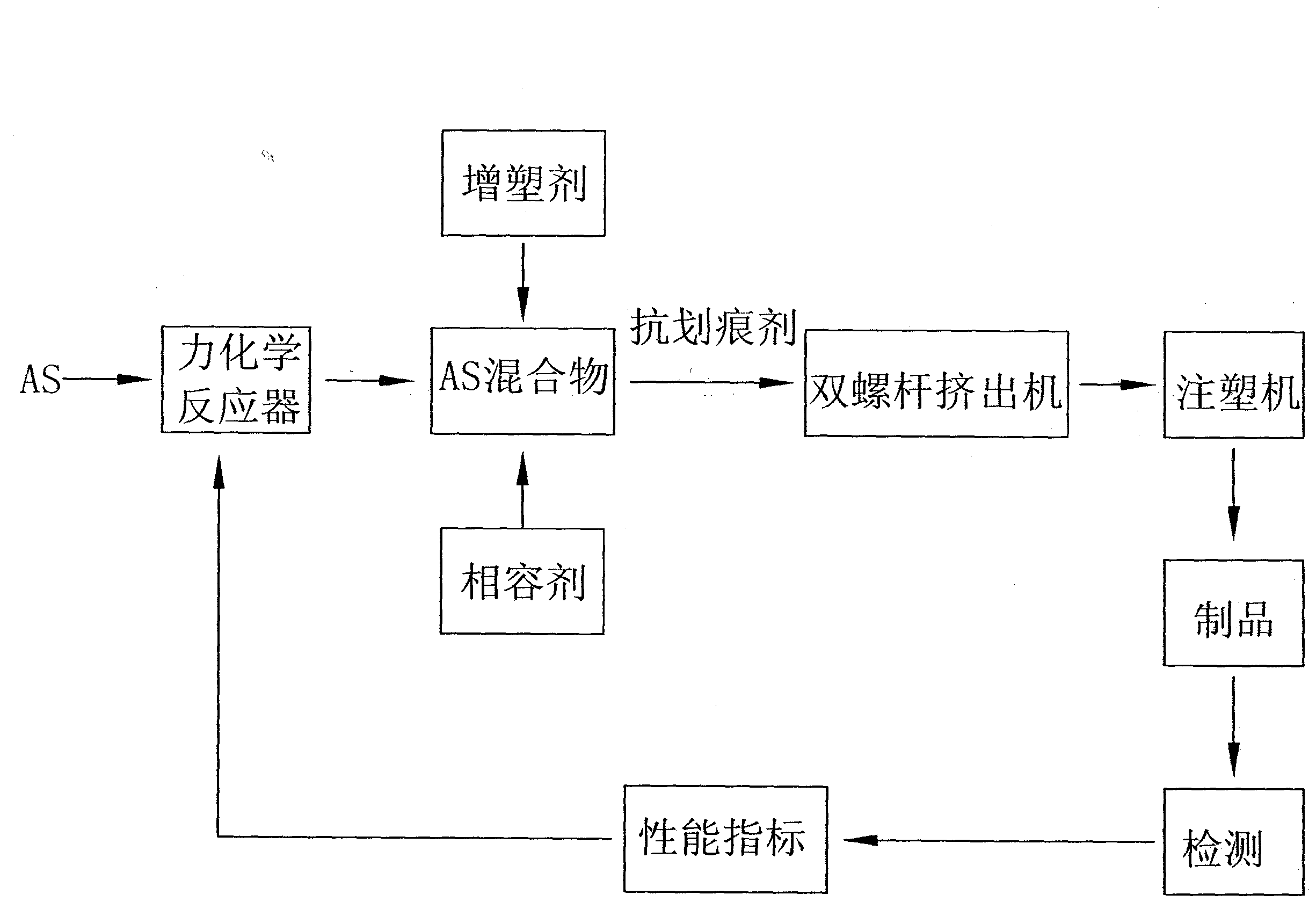

[0023] The following is the preparation method of the present invention

[0024] 1. Preparation of AS rubber powder by mechanochemical reactor

[0025] AS is usually a granular material, and the modified additive of AS, such as rubber powder or CPE powder, in order to improve the dispersion and compatibility of AS and rubber powder or CPE powder, the granular AS is prepared into AS by grinding mechanochemical method. Powder.

[0026] 2. Preparation of AS modified material

[0027] Select a toughening agent that has a certain compatibility with AS, melt and blend different compatibilizers, toughening agents and AS powder with a twin-screw extruder to prepare AS modified materials, use the toughening agent to toughen, and use the corresponding The compatibilizer is compatibilized, so that the toughener and the compatibilizer are synergistically strengthened.

[0028] Prepare AS modified material by melt blending and granulating AS, modifier and processing aid with twin-screw ...

Embodiment 1

[0037] Grind 5kg of AS pellets into powder, add 2kg of ABS, 1kg of maleic anhydride graft, and 0.5kg of anti-scratch agent-treated nano-calcium carbonate into a high-speed mixer for 15 minutes, and discharge; extrude with a twin-screw The machine extrudes and granulates at 200°C, and injects it into a fuel tank with an injection molding machine.

Embodiment 2

[0039] Grind 10kgAS pellets into powder, add 2kgPOE, 1kg maleic anhydride graft, 10kgCPE, 0.5kg anti-scratch agent-treated nano-calcium carbonate, add high-speed mixer for 15min, and discharge; use twin-screw The extruder extruded and granulated at 200°C, and was injection-molded into electric fan blades with an injection molding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com