Preparation method of assembly of carbon quantum dots (CQDS)

A technology of carbon quantum dots and assemblies, applied in chemical instruments and methods, photosensitive devices, luminescent materials, etc., can solve the problems of increased binding constant, low hydrogen bond force, low strength, etc., and achieve the effect of high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

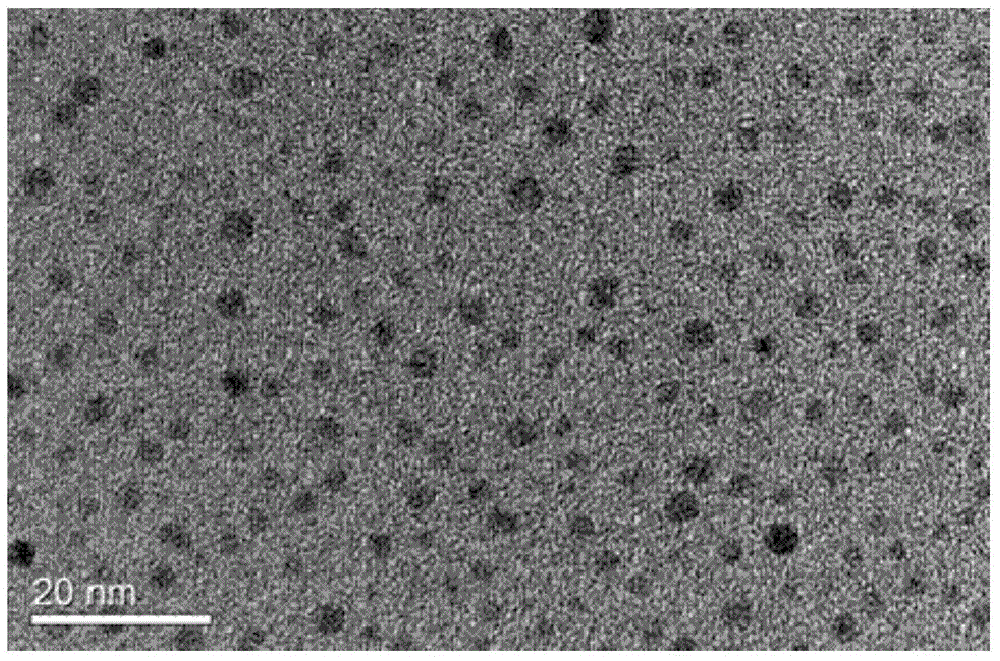

[0026] The preparation method of the CQDS assembly of embodiment comprises the following processes:

[0027] 1) Add 10-50μL of concentrated sulfuric acid as an ion catalyst to 5-20ml of 80% glycerol aqueous solution, ultrasonically treat the mixed solution for 3-5 minutes to make it evenly dispersed, and put it in a household microwave oven at high temperature. React for 5-10 minutes; after the reaction, cool the beaker to room temperature, add a small amount of deionized water for ultrasonication, and centrifuge to obtain a black-yellow solution; finally, dialyze and freeze-dry the solution to obtain CQDS solid powder;

[0028] 2) Weigh the quality of the above-mentioned solid powder, and weigh NaBH by 1-5 times the mass equivalent 4 ; Dissolve CQDS powder in NaBH 4 Put the solution into a polytetrafluoroethylene hydrothermal reaction kettle, cover and seal it, put the reaction kettle into a muffle furnace and raise the temperature to 160-220°C to react for 12-24h. After the...

Embodiment 1

[0032] Add 10 μL of concentrated sulfuric acid as an ion catalyst to 5 ml of a glycerol solution with a volume fraction of 80%, disperse it evenly by ultrasonication for 3 minutes, put it into a household microwave reactor and react for 5 minutes, wait to cool to room temperature, add 20 ml of deionized water for ultrasonication, The mixture was centrifuged at 5000r / min for 5min, and the bottom precipitate was removed to obtain a supernatant.

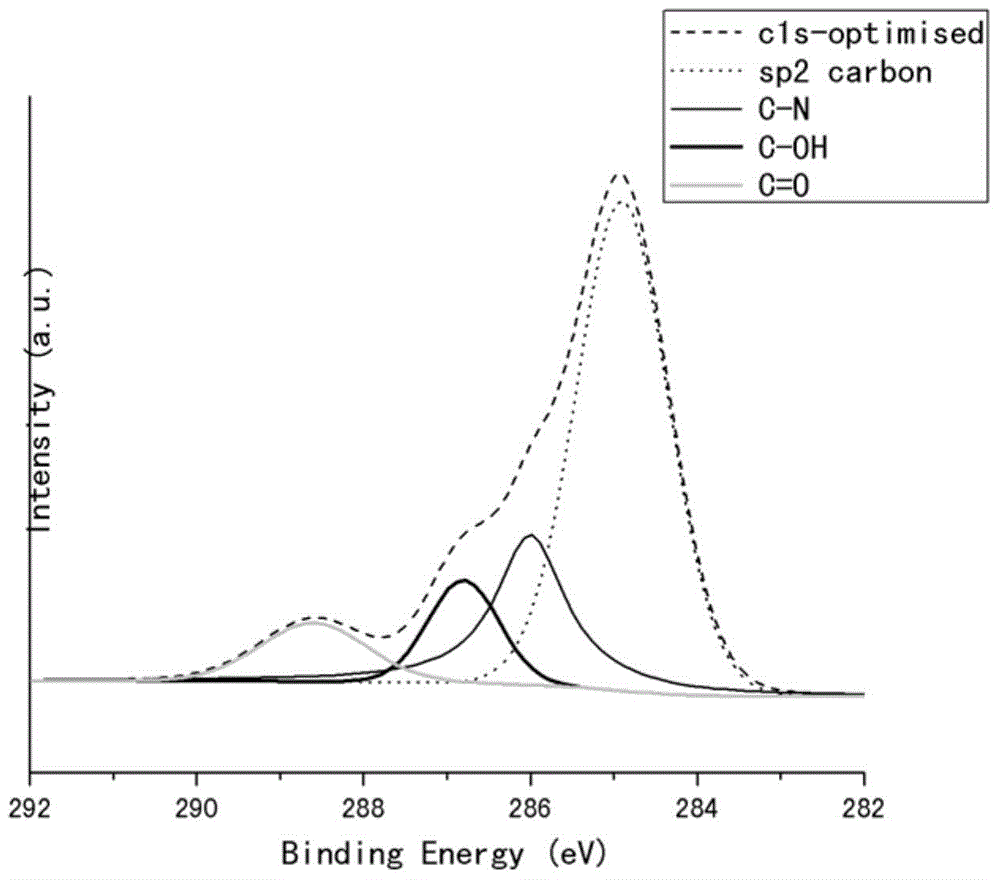

[0033] After concentrating the supernatant and lyophilizing, weigh 100 mg of powdered CQDS, and weigh 100 mg of NaBH 4 Solid; 2 solids were dissolved in water and placed in a 20ml polytetrafluoroethylene hydrothermal kettle, sealed and placed in a muffle furnace and heated to 160°C for 12 hours of reaction. After the end, the solution was dialyzed to neutrality and freeze-dried to obtain Reduced CQDS;

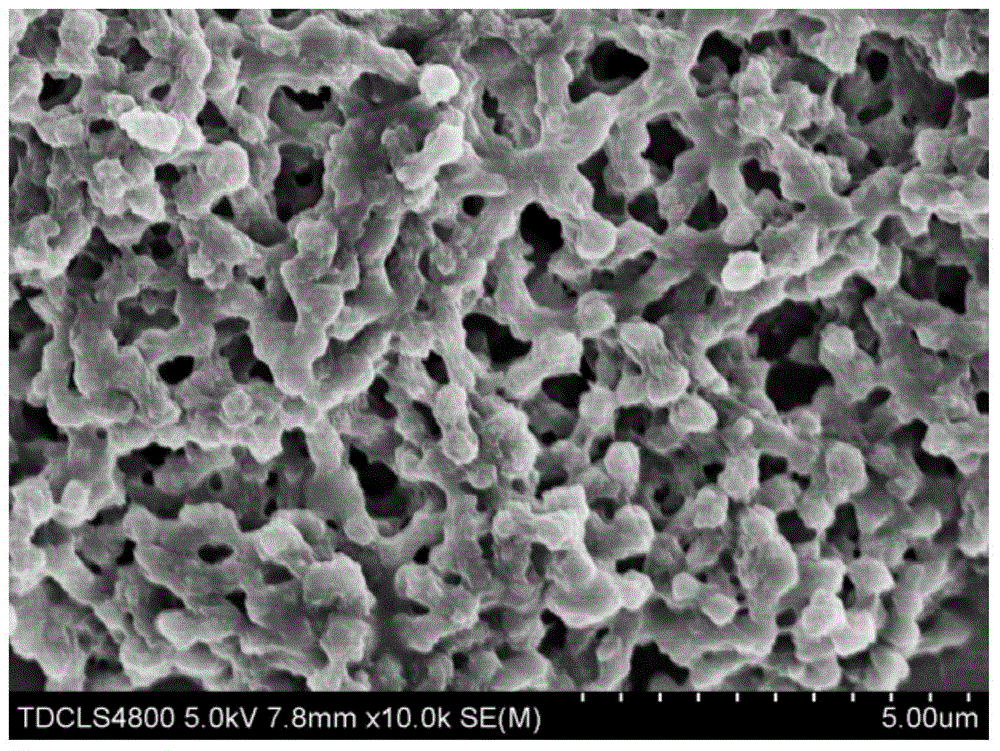

[0034] in N 2 Under protection, weigh 250mg of the small molecule compound UPy containing -NCO and 50mg of reduced lyophilized CQDS, ...

Embodiment 2

[0040] Add 50 μL of concentrated sulfuric acid as an ion catalyst to 15 ml of glucose solution with a volume fraction of 80%, disperse it evenly by ultrasonication for 4 minutes, put it into a household microwave reactor and react for 7 minutes, wait to cool to room temperature, add 20 ml of deionized water and ultrasonicate, and mix The solution was centrifuged at 5000r / min for 5min, and the bottom precipitate was removed to obtain the supernatant.

[0041] After concentrating the supernatant and lyophilizing, weigh 100 mg of powdered CQDS, and weigh 300 mg of NaBH 4 Solid; 2 solids were dissolved in water and placed in a 20ml polytetrafluoroethylene hydrothermal kettle, sealed and placed in a muffle furnace and heated to 190°C for 18 hours of reaction. After the end, the solution was dialyzed to neutrality and freeze-dried to obtain Reduced CQDS;

[0042] in N 2 Under protection, weigh 400 mg of the small molecule compound UPy containing -NCO and 50 mg of reduced-lyophiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com