Graphene thin film, graphene super capacitor and preparation method of graphene thin film and graphene super capacitor

A graphene film and supercapacitor technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of long time, high energy consumption, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

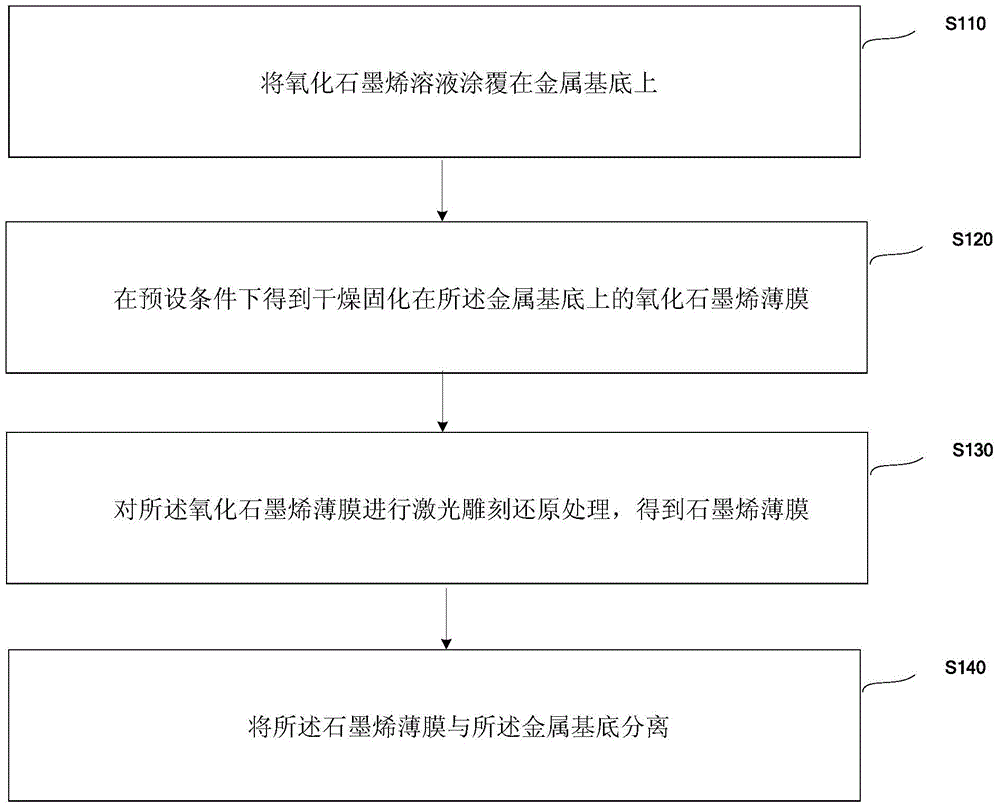

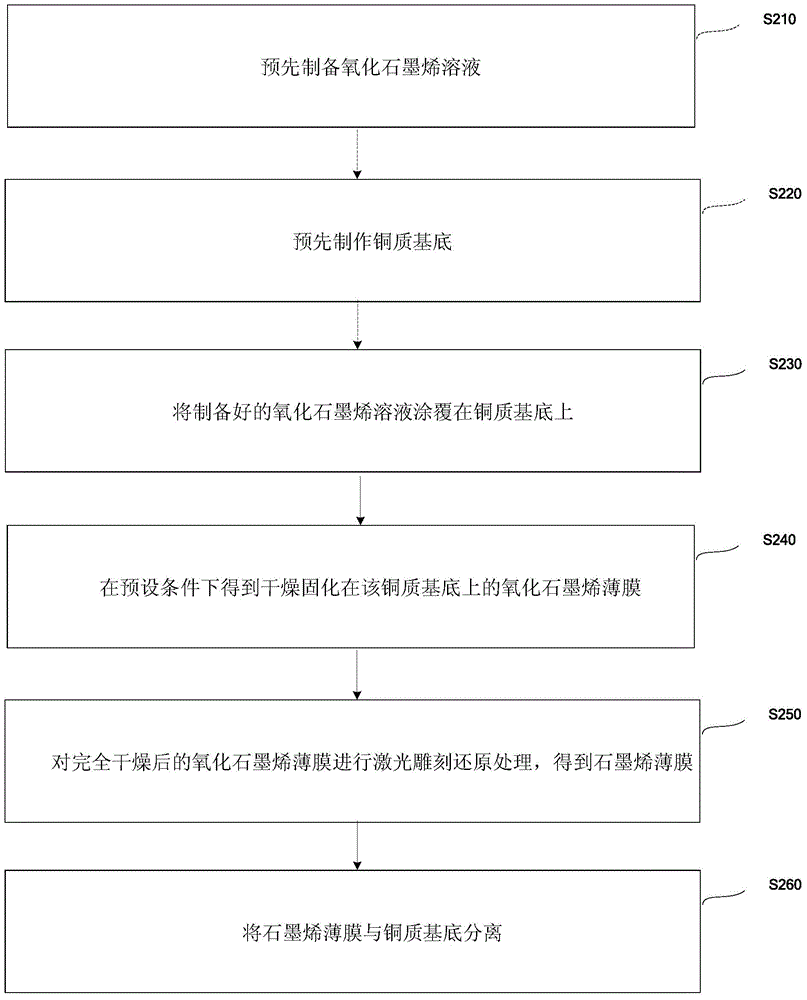

[0024] The invention provides a method for preparing a graphene film, such as figure 1 As shown, the method includes the following steps:

[0025] Step S110: coating the graphene oxide solution on the metal substrate.

[0026] Step S120: obtaining a graphene oxide film dried and solidified on the metal substrate under preset conditions. Optionally, the preset condition may include: drying the graphene oxide solution on the metal substrate to form a graphene oxide film, and passing the metal substrate to the graphite oxide film during the drying process. Alkene solution was pre-reduced.

[0027] Step S130: performing laser engraving and reduction treatment on the graphene oxide film to obtain a graphene film.

[0028] Step S140: separating the graphene film from the metal substrate.

[0029] In the preparation method of the graphene thin film provided by the present invention, the graphene oxide solution is coated on the metal substrate, dried and solidified, and then subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com