Method for preparing photoelectrocatalysis electrode material capable of efficiently degrading organic pollutants

An organic pollutant, photoelectric catalysis technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of weak bonding force of conductive substrates, shedding, use restrictions, etc., and achieve easy mass production and industrialization. The effect of production, light weight and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Anodizing and annealing conditions for preparing product 1:

[0024] ① Anodizing: Use clean titanium sponge as anode and graphite as cathode, the ratio of the area of titanium sponge to graphite is 1:10; The volume ratio of ethylene glycol and water is 50:1) as the anodic oxidation solution for anodic oxidation treatment, the anodic oxidation voltage is 40 volts, the temperature is 20 ° C, and the time is 1 hour;

[0025] ②Annealing: Put the anodized titanium sponge sheet in step ① into a muffle furnace at room temperature and raise the temperature to 500°C, anneal for 2.5 hours, take it out after natural cooling, and characterize its morphology, thickness and photoelectric catalytic performance.

[0026] Characterization results:

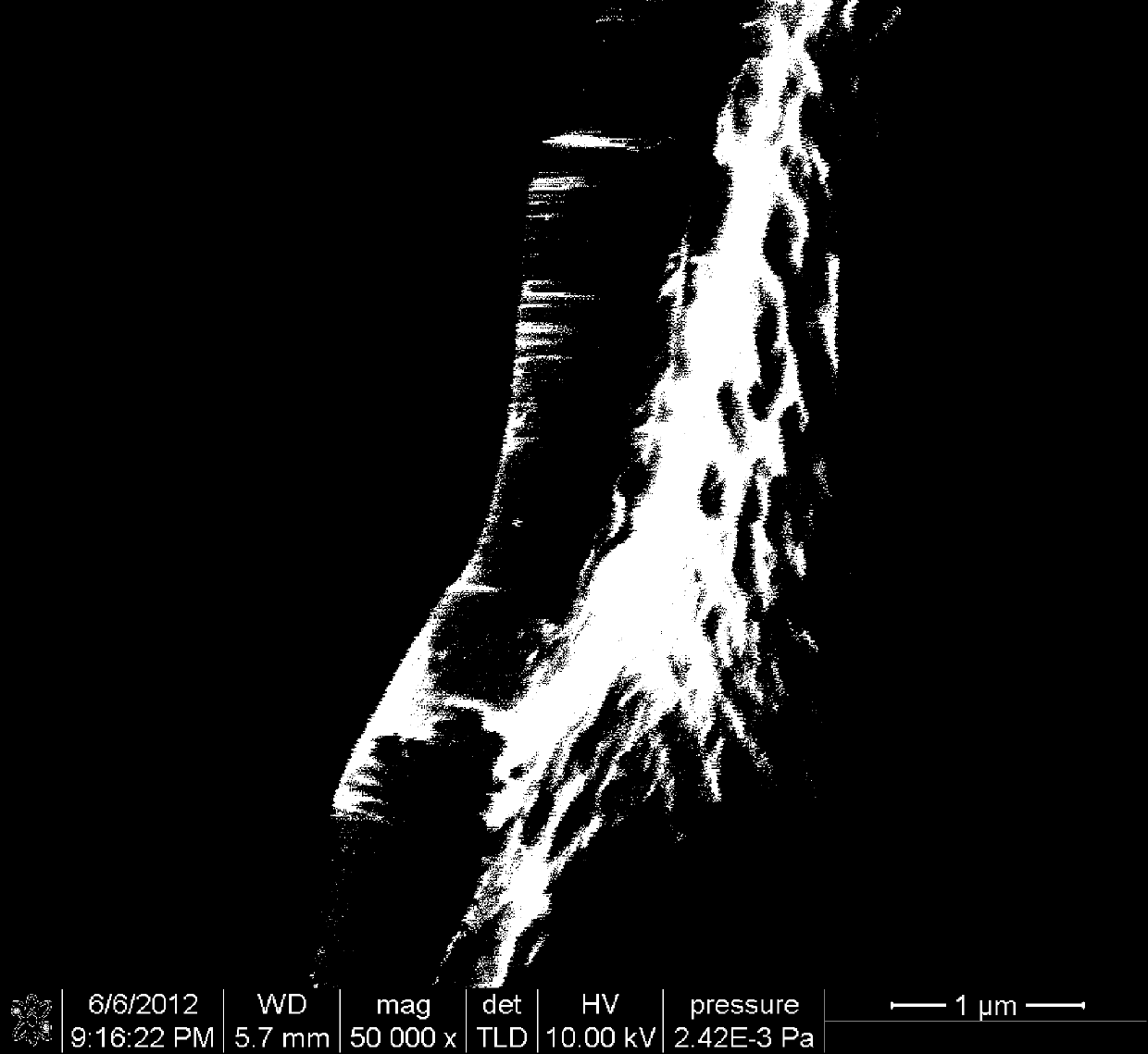

[0027] a. Characterization results of morphology, thickness, and crystal form: product 1 is anatase TiO with a thickness of about 1.2 microns based on titanium sponge 2 Nanoporous film, which is composed of highly ordered TiO with a ...

Embodiment 2

[0030] Anodizing and annealing conditions for preparing product 2:

[0031] ① Anodizing: use clean titanium sponge as anode and graphite as cathode, the area ratio of titanium sponge and graphite is 1:5; The volume ratio of ethylene glycol and water is 50:1) as the anodic oxidation solution for anodic oxidation treatment, the anodic oxidation voltage is 50 volts, the temperature is 30 ° C, and the time is 0.5 hours;

[0032] ②Annealing: Put the anodized titanium sponge sheet in step ① into a muffle furnace at room temperature and raise the temperature to 450°C, anneal for 3 hours, take it out after natural cooling, and characterize the morphology, thickness and photocatalytic performance.

[0033] Characterization results:

[0034] a. Characterization results of morphology, thickness, and crystal form: product 2 is anatase TiO with a thickness of about 0.6 microns based on titanium sponge 2 Nanoporous film, which is composed of highly ordered TiO with a pore size of abou...

Embodiment 3

[0037] Anodizing and annealing conditions for preparing product 3:

[0038] ① Anodizing: take clean titanium sponge as anode, graphite as cathode, the area ratio of titanium sponge to graphite is 1:8; The volume ratio of ethylene glycol and water is 50:1) as the anodic oxidation solution for anodic oxidation treatment, the anodic oxidation voltage is 60 volts, the temperature is 30 ° C, and the time is 2 hours;

[0039] ②Annealing: Put the anodized titanium sponge sheet in step ① into a muffle furnace at room temperature and raise the temperature to 550°C, anneal for 2 hours, take it out after natural cooling, and characterize its morphology, thickness, and photoelectrocatalytic performance.

[0040] Characterization results:

[0041] a. Characterization results of morphology, thickness, and crystal form: product 3 is anatase TiO with a thickness of about 2.2 microns based on titanium sponge 2 Nanoporous film, which is composed of highly ordered TiO with a pore size of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com