Magnetic element based on spin hall effect, microwave oscillator and manufacturing method thereof

A spin Hall effect, microwave oscillator technology, applied in the fields of magnetic field controlled resistors, the manufacture/processing of electromagnetic devices, material selection, etc., can solve the problem of thermal noise affecting the quality of output microwave signals, high preparation conditions current density and other issues, to achieve the effect of easy mass preparation, simple preparation process and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

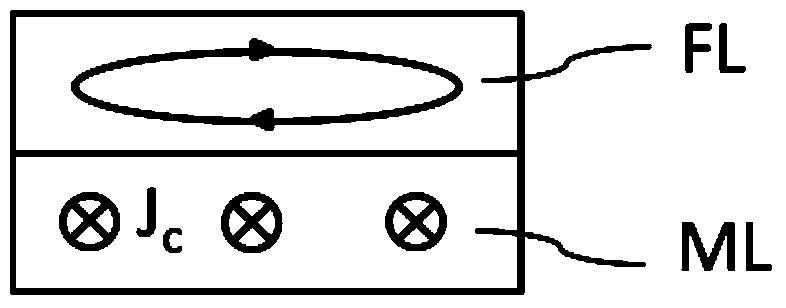

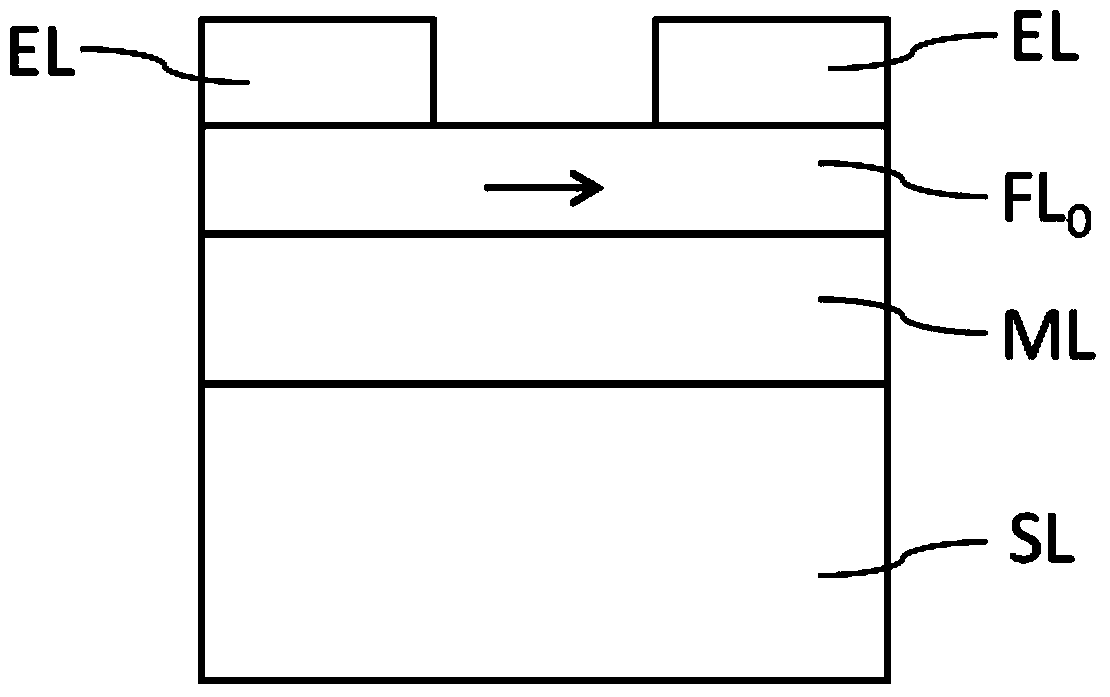

[0057] Embodiment 1 This embodiment relates to a two-terminal microwave oscillator based on the spin Hall effect, which includes: a substrate layer 1; a non-magnetic layer 121 located on the substrate; a magnetic layer 131 located on the non-magnetic layer ; and a metal electrode 141 located on the magnetic layer. Based on this structure, the spin current generated by the spin Hall effect and the anisotropic magnetoresistance effect to generate the oscillating signal are utilized.

[0058] refer to image 3 As shown, in a typical embodiment, the involved device includes a single crystal silicon substrate (Si / SiO 2 ), non-magnetic metal layer (Pt), magnetic film layer (Py) and metal electrode (Au).

[0059] The manufacturing process of the two-terminal device includes:

[0060] First, on Si / SiO 2 A nonmagnetic metal layer 121 (Pt, 2nm) and a magnetic film layer 131 (Py, 1nm) are deposited on the substrate by magnetron sputtering. Then, the pattern structure of the non-magn...

Embodiment 2

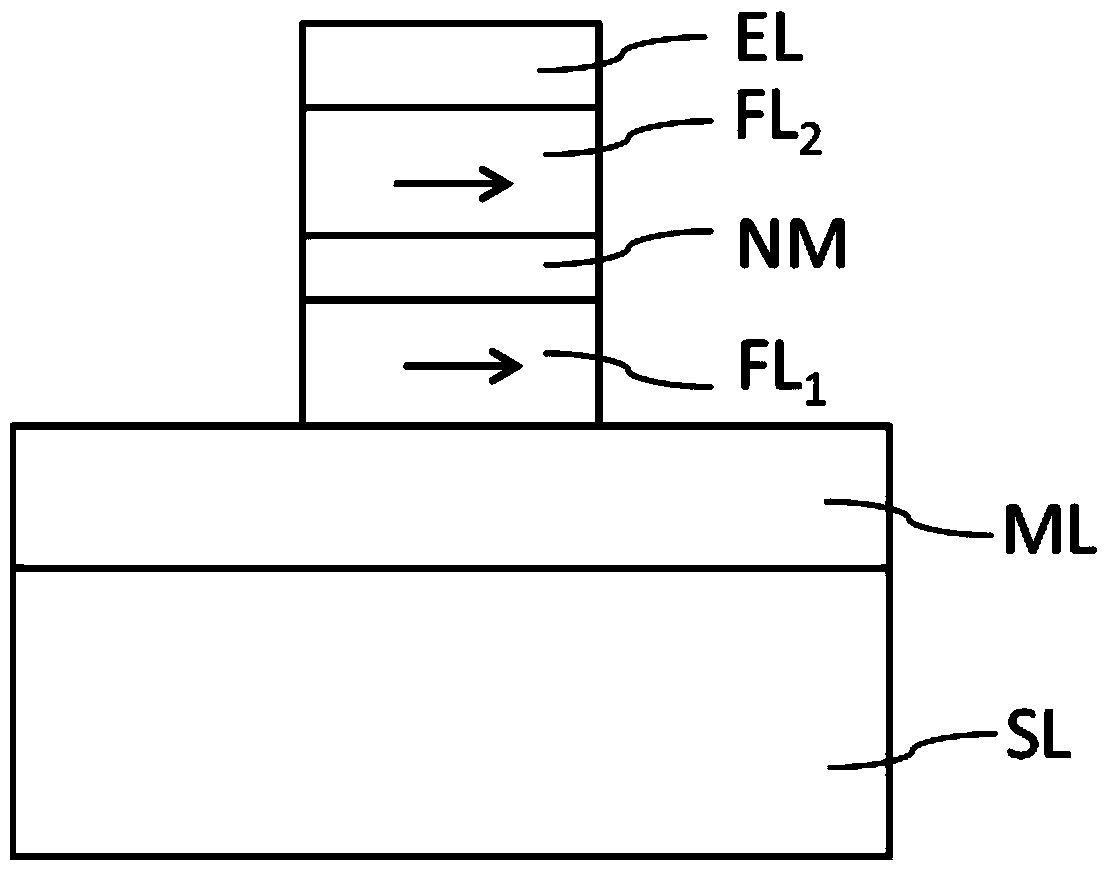

[0063] Embodiment 2 This embodiment also relates to a two-terminal microwave oscillator based on the spin Hall effect, which is composed of different materials from Embodiment 1, and the corresponding manufacturing process is also different.

[0064] More specifically, the two-terminal device structure of this embodiment includes: a substrate layer 2; a non-magnetic layer 221 located on the substrate; a magnetic layer 231 located on the non-magnetic layer; and a metal electrode located on the magnetic layer 241. Based on this structure, the spin current generated by the spin Hall effect and the anisotropic magnetoresistance effect to generate the oscillating signal are utilized.

[0065] In a more specific typical embodiment, the device involved includes a single crystal silicon substrate (Si / SiO 2 ), non-magnetic metal layer (Pb), magnetic film layer (YIG) and metal electrode (Cu).

[0066] The manufacturing process of the two-terminal device includes:

[0067] First, take...

Embodiment 3

[0069] Embodiment 3 This embodiment also relates to a two-terminal microwave oscillator based on the spin Hall effect, which is different from Embodiments 1 and 2 in terms of composition and materials, and the corresponding manufacturing process is also different.

[0070] More specifically, the two-terminal device structure of this embodiment includes: a substrate layer 3; a non-magnetic layer 321 located on the substrate; a dilute magnetic semiconductor layer 331 located on the non-magnetic layer; and a metal electrode 341 . Based on this structure, the spin current generated by the spin Hall effect and the anisotropic magnetoresistance effect to generate the oscillating signal are utilized.

[0071] In a more specific typical embodiment, the related device includes a sapphire substrate, a non-magnetic metal layer (W), a magnetic film layer (GaMnAs) and a metal electrode (Au) distributed sequentially along a set direction.

[0072] The manufacturing process of the two-termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com