Synthesis method of novel visible-light photocatalyst indium sulfide

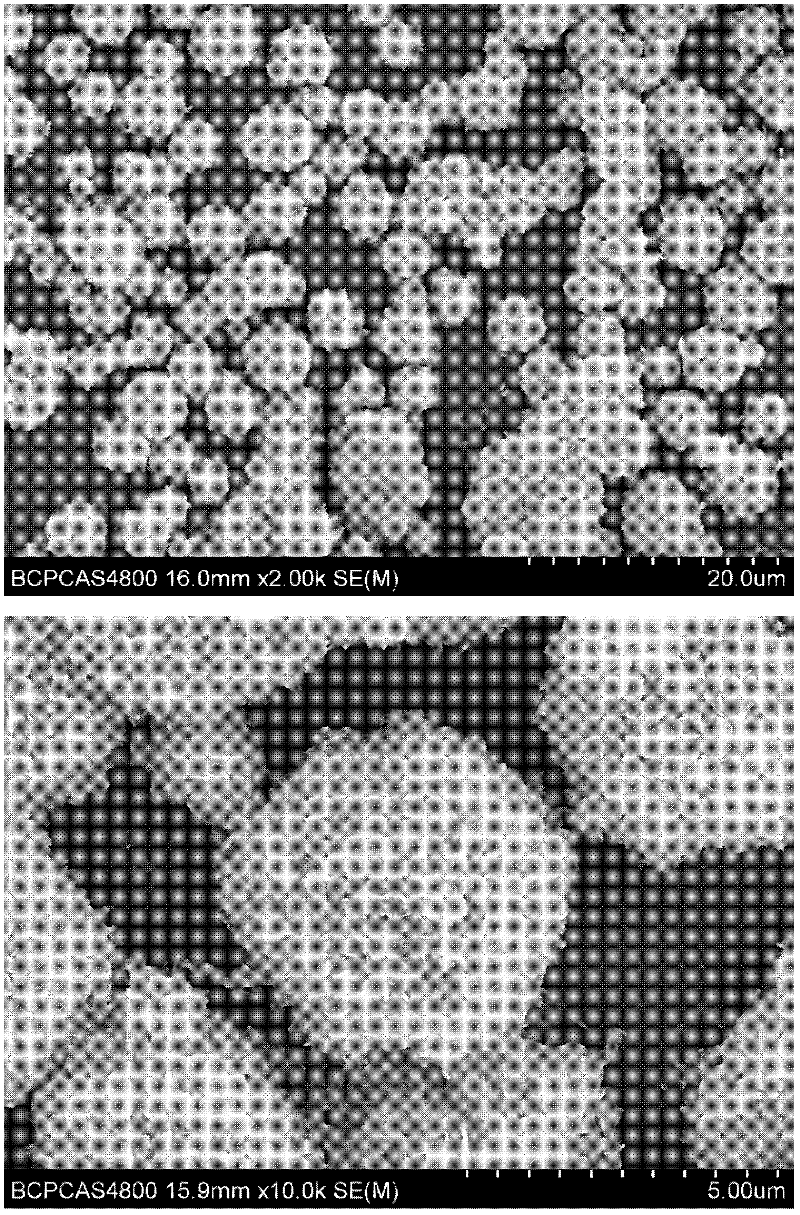

A technology of photocatalyst and synthesis method, applied in chemical instruments and methods, physical/chemical process catalyst, chemical/physical process, etc., can solve the problems of unstable visible light photocatalyst, photocorrosion of sulfide anode, low activity, etc. Good degradation effect, uniform size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (a) Weigh an appropriate amount of indium chloride tetrahydrate (InCl 3 4H 2 O) Dissolve in deionized water, add acetic acid to adjust its pH value to 1, then add thioacetamide (CH 2 CSNH 2 ) solution, the concentration of indium ions is 0.025mol / L, wherein the ratio of the amount of In and S substances is 1:4;

[0019] (b) Put the mixed solution obtained in step (a) into an oven to heat to make it react, adjust the temperature to 80° C., conduct a hydrothermal reaction for 6 hours, and cool at room temperature;

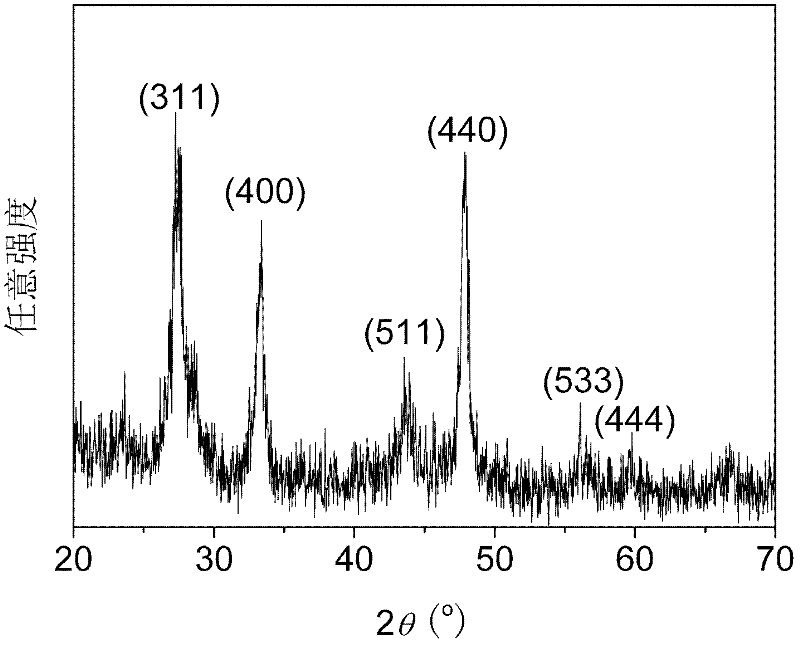

[0020] (c) suction filtration under reduced pressure, washing, and drying to obtain orange-red indium sulfide powder, the powder X-ray diffraction pattern of the product is shown in figure 1 .

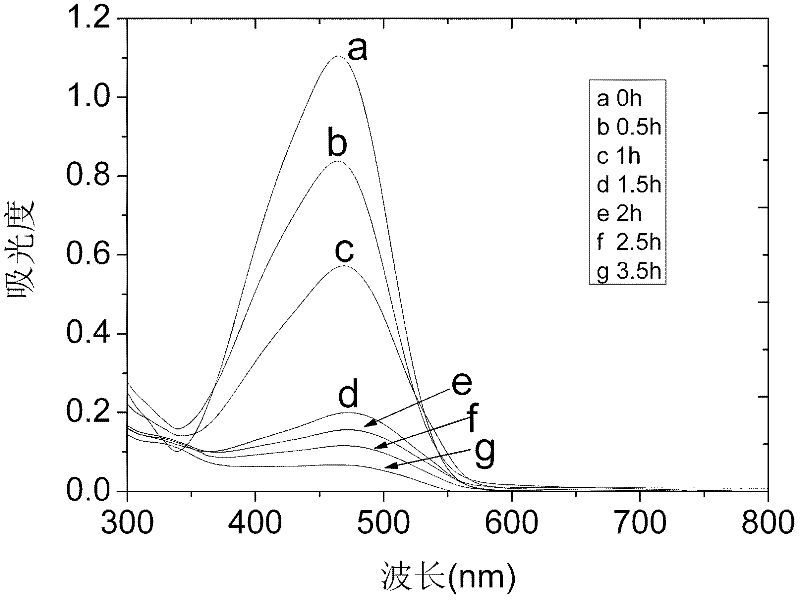

[0021] (d) Weigh 0.10 g of indium sulfide and place it in 1×10 -5 mol / L (absorbance is about 1.0) methyl orange solution, the visible light photocatalytic degradation test was carried out.

Embodiment 2

[0023] (a) Weigh an appropriate amount of indium chloride tetrahydrate (InCl 3 4H 2 O) Dissolve in deionized water, add acetic acid to adjust its pH value to 2, then add thioacetamide (CH 2 CSNH 2 ) solution, the concentration of indium ions is 0.025mol / L, wherein the ratio of the amount of In and S substances is 1:4;

[0024] (b) Put the mixed solution obtained in step (a) into an oven to heat it to react, adjust the temperature to 80° C., conduct a hydrothermal reaction for 4 hours, and cool at room temperature;

[0025] (c) Suction filtration under reduced pressure, washing and drying to obtain orange-red indium sulfide powder.

[0026] (d) Weigh 0.10 g of indium sulfide and place it in 1×10 -5 mol / L (absorbance is about 1.0) methyl orange solution, the visible light photocatalytic degradation test was carried out.

Embodiment 3

[0028] (a) Weigh an appropriate amount of indium chloride tetrahydrate (InCl 3 4H 2 O) Dissolve in deionized water, add acetic acid to adjust its pH value to 3, then add thioacetamide (CH 2 CSNH 2 ) solution, the concentration of indium ions is 0.025mol / L, wherein the ratio of the amount of In and S substances is 1:6;

[0029] (b) Put the mixed solution obtained in step 1 into an oven to heat to make it react, adjust the temperature to 80°C, conduct hydrothermal reaction for 8 hours, and cool at room temperature;

[0030] (c) Suction filtration under reduced pressure, washing and drying to obtain orange-red indium sulfide powder.

[0031] (d) Weigh 0.10 g of indium sulfide and place it in 1×10 -5 mol / L (absorbance is about 1.0) methyl orange solution, the visible light photocatalytic degradation test was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com