Graphene oxide/metal organic framework composite material and preparation method and application thereof

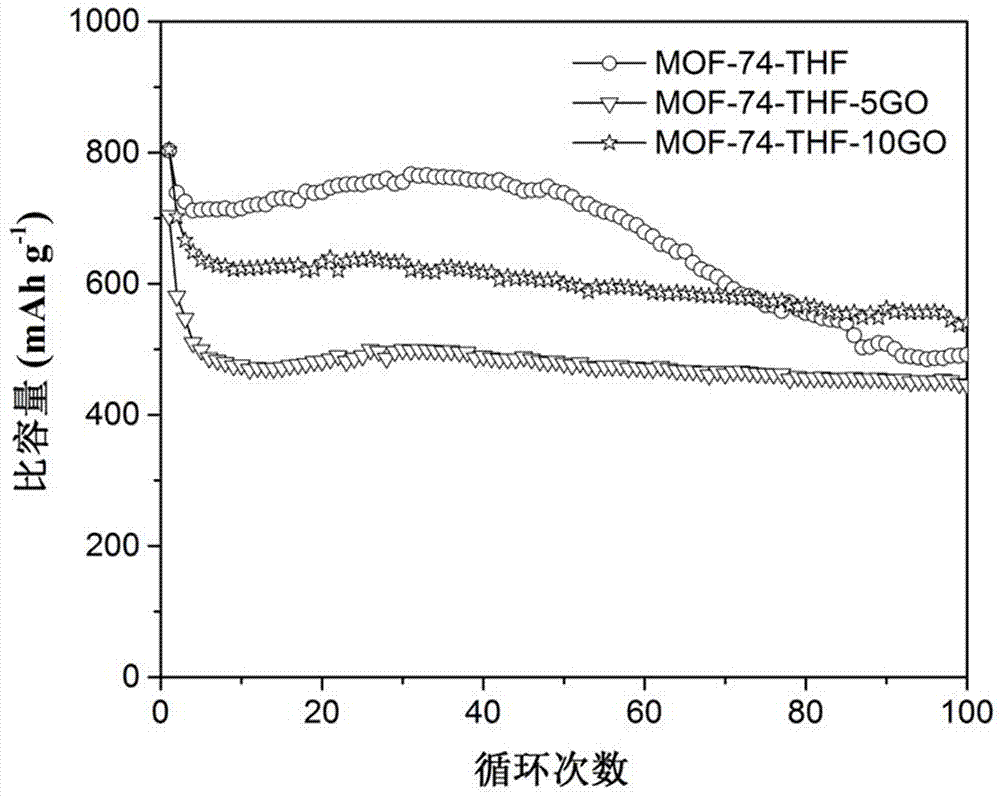

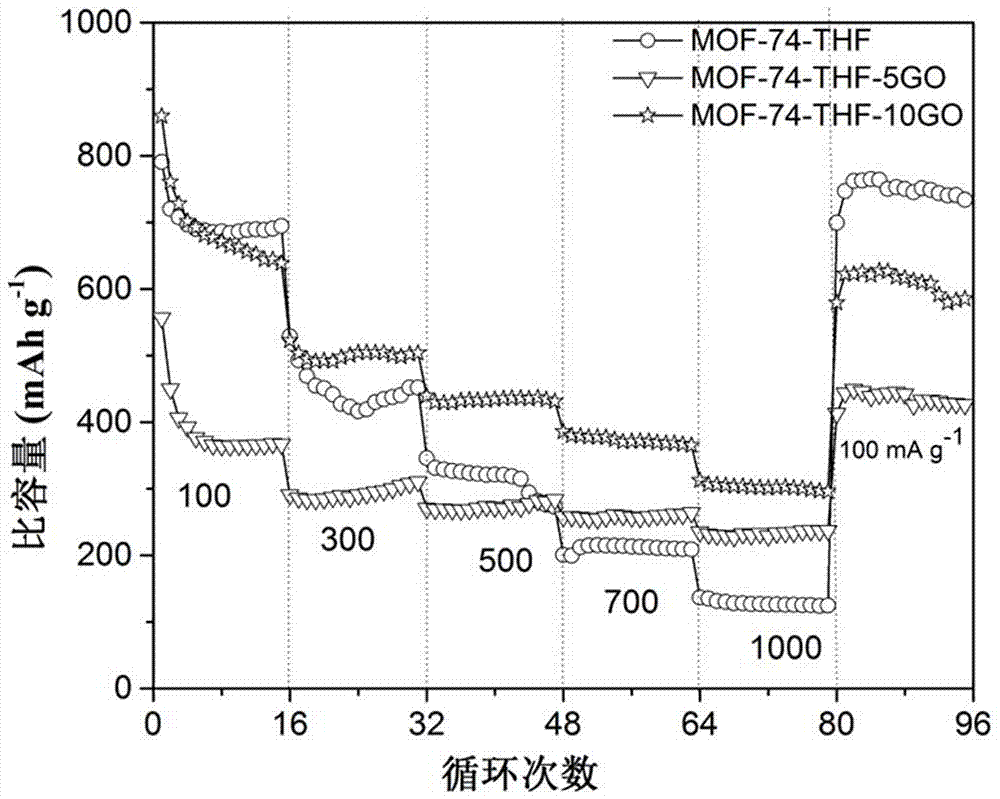

A metal-organic framework and composite material technology, which is applied in the field of graphene oxide/metal-organic framework composite material and its preparation, can solve the problems of low specific capacity and unreachable capacity, improve electrochemical performance, and improve charge-discharge cycle life. , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

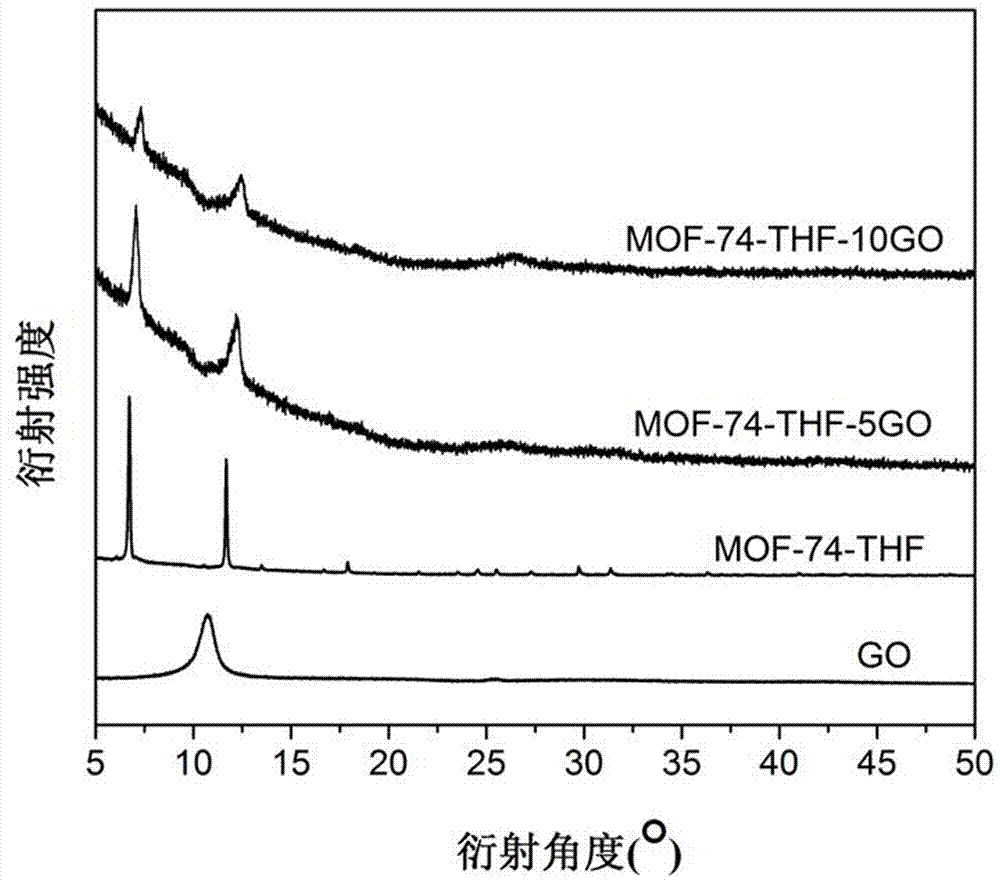

[0032] The preparation method of the graphene oxide / metal organic framework composite material MOF-74-THF-5GO containing 5% graphene oxide, the specific operation steps are as follows:

[0033] In step (1), weigh 12.454 mg of graphene oxide and add it to a mixed solution of tetrahydrofuran and deionized water (1:1 volume ratio, 20 mL in total), and oscillate ultrasonically for 30 min to form a uniformly dispersed graphene oxide solution;

[0034] Step (2), weigh 0.24908 g (0.001 mol) of cobalt acetate tetrahydrate and 0.19813 g (0.001 mol) of 2,5-dihydroxyterephthalic acid into 10 mL of deionized water, and ultrasonically vibrate to form a mixture liquid;

[0035] Step (3), mix 10 mL of the mixed solution obtained in step (3) with 20 mL of the graphene oxide solution obtained in step (2), and ultrasonically oscillate for 10 min. After mixing evenly, put it into the reaction kettle. The quality of graphene is 5% of the quality of cobalt acetate tetrahydrate;

[0036] Step (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com