Preparation method of hollow CoMn2O4-RGO flexible super capacitor material

A technology of flexible materials and electrical materials, applied in the field of supercapacitors, can solve the problems of unfavorable electrolyte transmission, easy dense accumulation, electrochemical performance attenuation, etc., and achieve the effect of improving electrochemical performance and facilitating penetration and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Hollow CoMn 2 o 4 - Preparation of RGO flexible material

[0023] 0.125 mmol of Co(NO 3 ) 2 ·6H 2 O and 0.25 mmol Mn(NO 3 ) 2 4H 2 O was dissolved in 40 ml of isopropanol, 8 ml of glycerol was added to the above solution and stirred for 30 minutes; subsequently, the resulting mixture was transferred to a 100 ml stainless steel autoclave, and reacted at 180°C for 6 hours. The obtained precipitate (Co—Mn precursor) was collected by centrifugation, washed 6 times with absolute ethanol, and dried at 60° C. for 12 hours. Finally, the obtained Co-Mn precursor was calcined in a muffle furnace at 400 °C for 2 hours, and the heating rate was 1 °C / min, and finally CoMn was obtained. 2 o 4 Hollow ball material. Graphene oxide (GO) was prepared by the Hummer method. The prepared CoMn 2 o 4 and GO powder were prepared into solutions with a concentration of 0.5 mg / ml and 0.2 mg / ml respectively, and a certain amount (CoMn 2 o 4 and GO at a mass ratio of 1:2, 1...

Embodiment 2

[0024] Example 2 Hollow CoMn 2 o 4 -Characterization analysis of RGO flexible materials

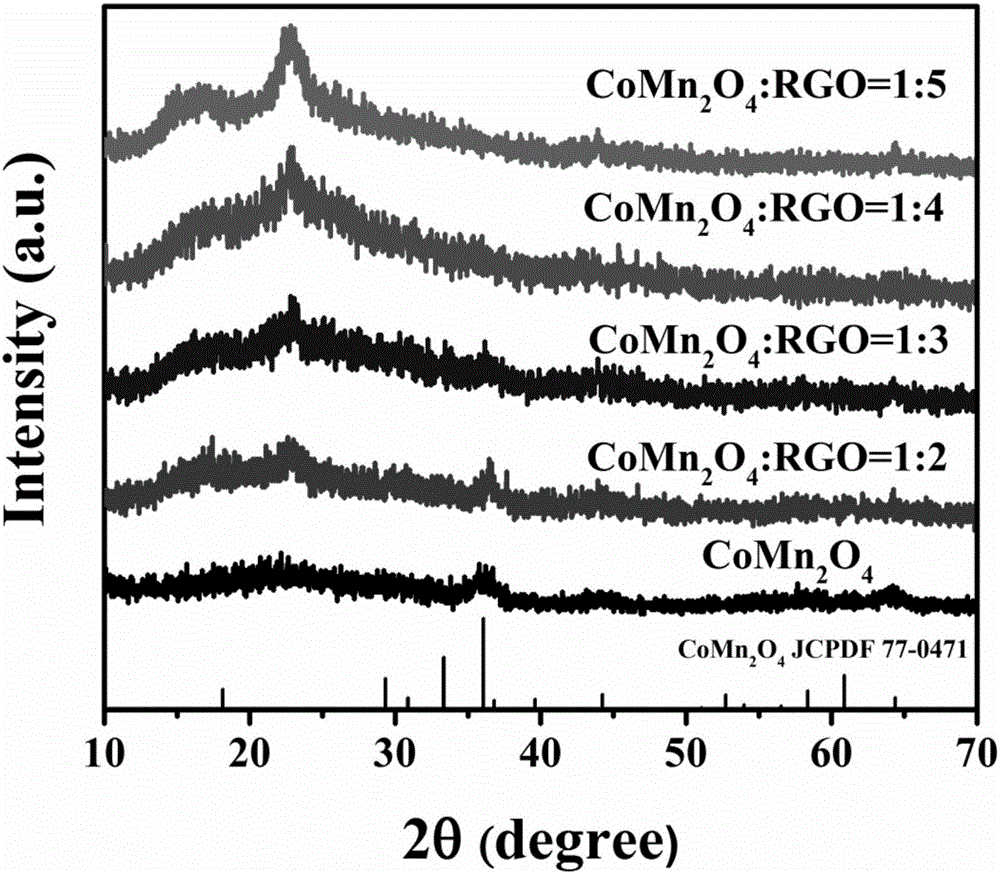

[0025] Such as figure 1 As can be seen from the figure, CoMn 2 o 4 and the characteristic peaks of RGO appear in CoMn 2 o 4 -RGO composites, and with the increase of the amount of RGO, the characteristic peaks of RGO are gradually enhanced.

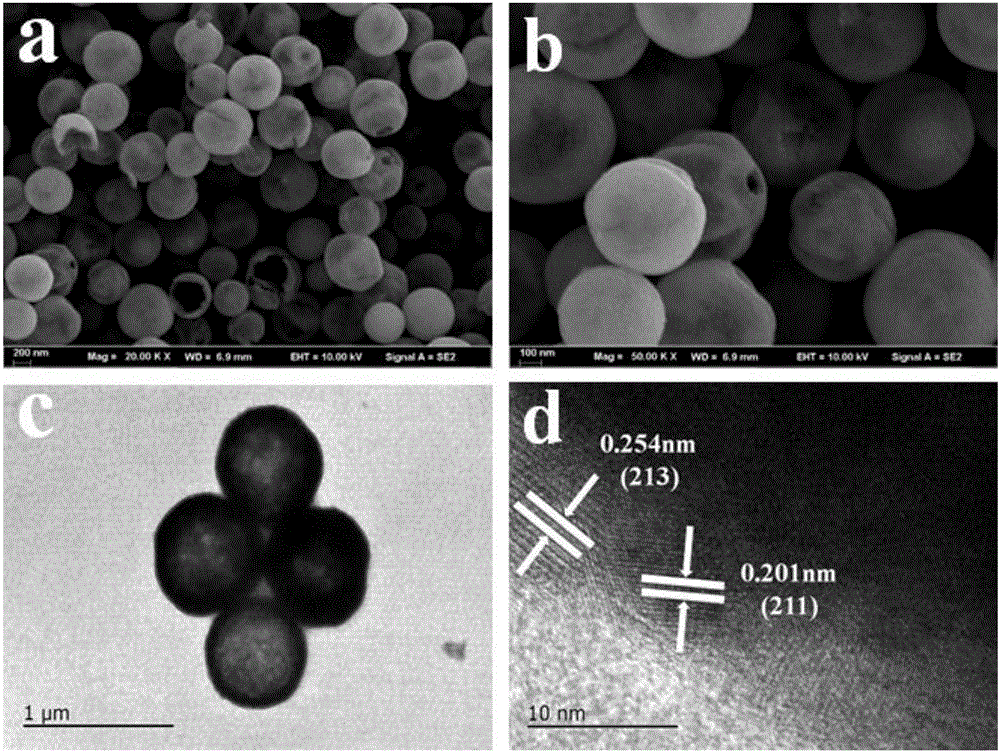

[0026] figure 2 It can be observed that CoMn 2 o 4 It exhibits a spherical structure between 400-500nm, and the sphere is a hollow structure.

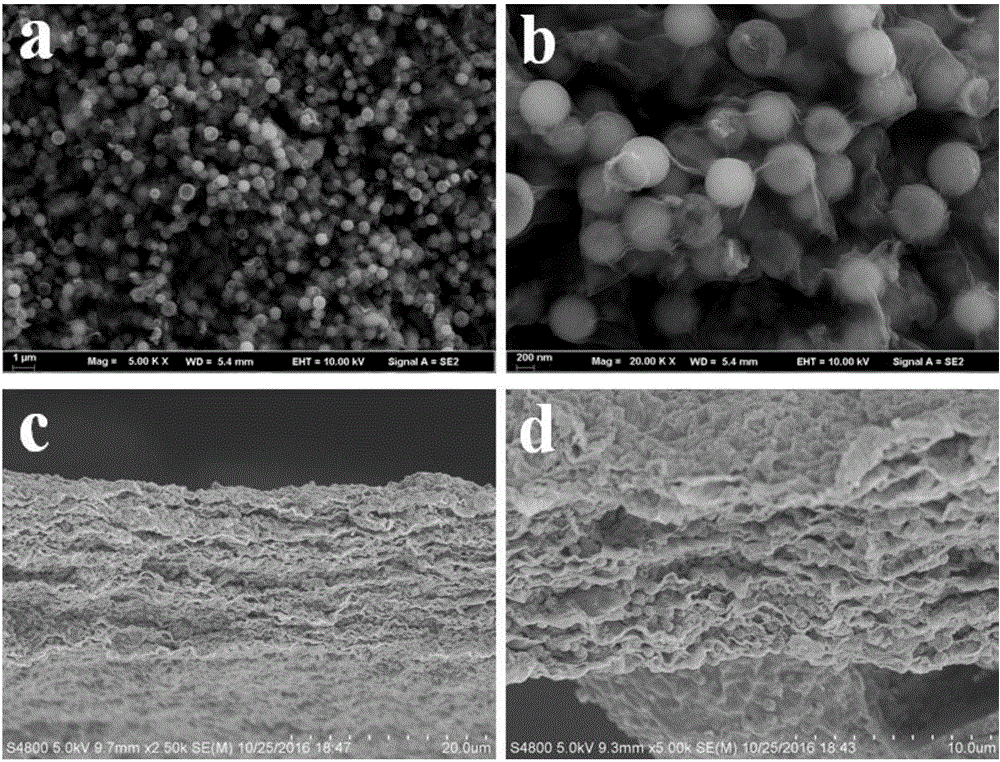

[0027] image 3 a-b show CoMn2 o 4 mixed with RGO and coated together, image 3 c–d show a sandwich-like structure, illustrating the hollow-shell structure of CoMn 2 o 4 The ball successfully propped up the layered structure of the RGO sheet.

[0028] Figure 4 It can be seen from the XPS figure that there are Mn, Co, O, and C elements.

[0029] Figure 5 It can be observed that the mass ratio of CoMn 2 o 4 : In the case of RGO=1:4, hollow core-shell CoMn 2 o 4 -RGO flexible material ha...

Embodiment 3

[0031] Example 3 Hollow CoMn 2 o 4 -Electrochemical experiment of RGO flexible material

[0032] (1) The prepared CoMn 2 o 4 - The RGO film was cut into a square with an area of one square centimeter, and it was sandwiched between two nickel foams of the same size as the working electrode.

[0033] (2) The prepared working electrode, silver / silver chloride electrode, and platinum sheet electrode were electrochemically tested in 6 mol / liter KOH electrolyte.

[0034] (3) The prepared hollow core-shell CoMn 2 o 4 -RGO flexible material at 1Ag -1 The specific capacity at the current density reaches 992.9F g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com