Fireproofing and insect-proofing modifying liquid for collection tools of files and cultural relics and application of modifying liquid

A technology of modifying liquid and cultural relics, which is applied in the field of physical and chemical modification of wood, which can solve the problems of pollution of cultural relics body and working environment, poor permeability, human injury, etc., and achieve the effect of insect resistance, loss resistance and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Soak the wood to be treated in water, and use an ultrasonic wave with a power of 800W for 60 minutes every 4 hours. After the moisture content of the wood reaches more than 66%, take out the wood.

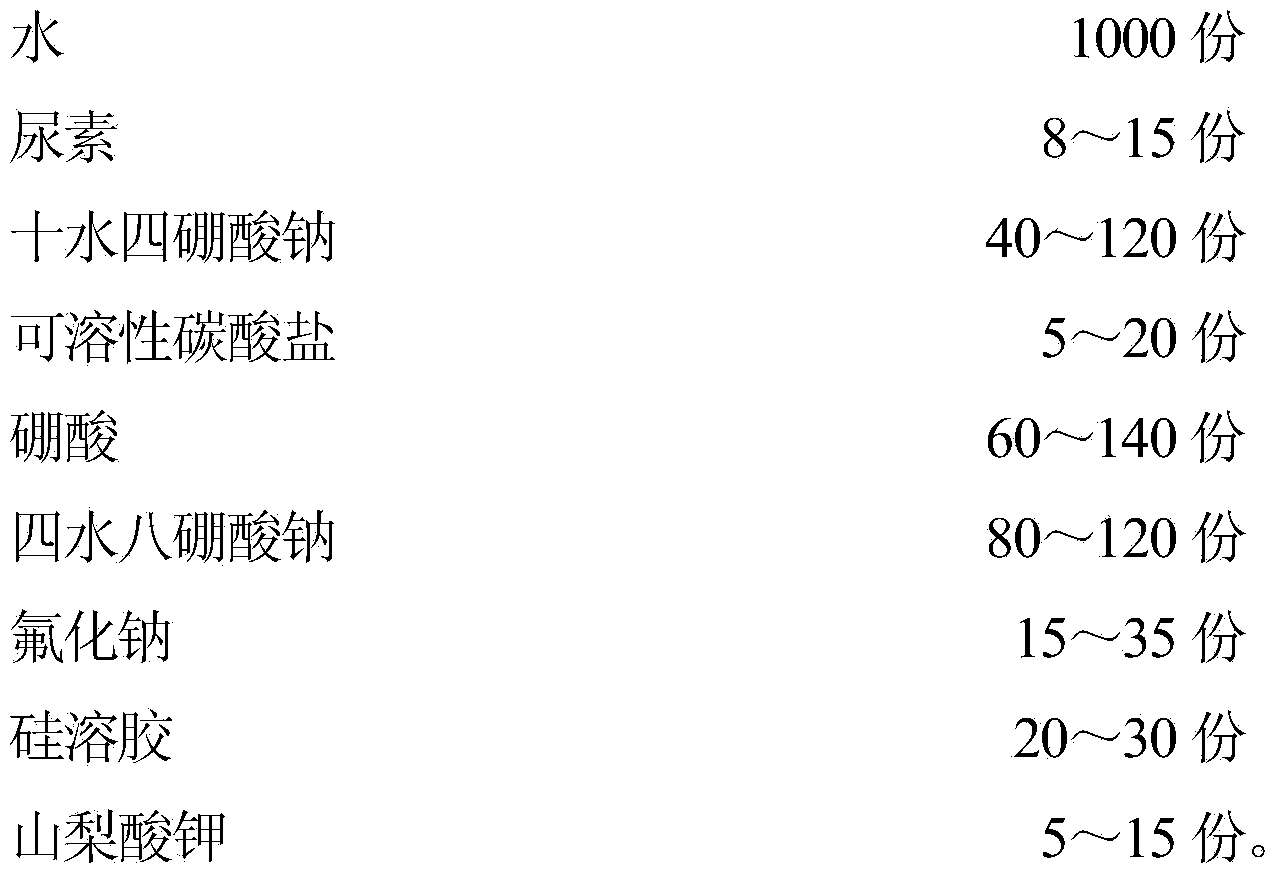

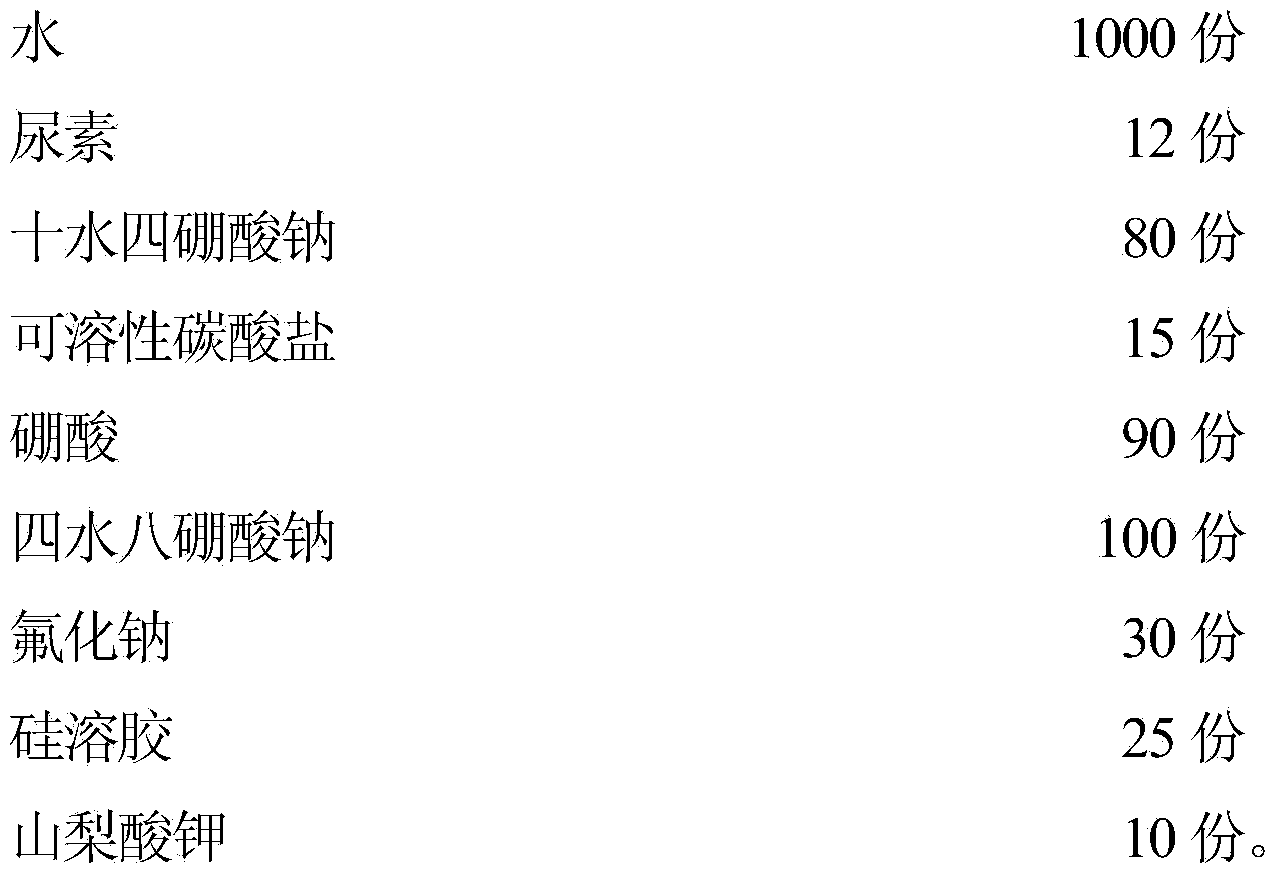

[0020] 2. Add 80g of sodium tetraborate decahydrate, 15g of sodium carbonate, 90g of boric acid, and 100g of sodium octaborate tetrahydrate into 1000g of water, heat and stir at 60-70°C until completely dissolved, then add 25g of silica sol, 12g of urea, and 30g of sodium fluoride , 10g potassium sorbate, keep stirring at constant temperature until the solution is clear and transparent, and prepare solution A; soak wood with a moisture content of more than 66% in solution A, heat to 60°C, and use an ultrasonic wave with a power of 800W every 4 hours 60 minutes, for a total soak time of 48 hours, remove the wood.

[0021] 3. Soak the wood treated by soaking in solution A in step 2 in an aqueous alum solution with a mass fraction of 20%, soak for 40 minutes, take out the wo...

Embodiment 2

[0023] In Example 1, 40g of sodium tetraborate decahydrate, 5g of sodium carbonate, 60g of boric acid, and 80g of sodium octaborate tetrahydrate were added to 1000g of water, heated and stirred at 60-70°C until completely dissolved, then 20g of silica sol, 8g of urea, 15g sodium fluoride, 5g potassium sorbate, keep stirring at constant temperature until the solution is clear and transparent, and prepare solution A. Other steps are identical with embodiment 1.

Embodiment 3

[0025] In Example 1, 120g of sodium tetraborate decahydrate, 20g of sodium carbonate, 140g of boric acid, and 120g of sodium octaborate tetrahydrate were added to 1000g of water, heated and stirred at 60-70°C until completely dissolved, then 30g of silica sol, 15g of urea, 35g of sodium fluoride and 15g of potassium sorbate were stirred at constant temperature until the solution was clear and transparent, and then solution A was prepared. Other steps are identical with embodiment 1.

[0026] In order to prove the beneficial effects of the present invention, the inventor has carried out a large amount of laboratory research tests, and various test conditions are as follows:

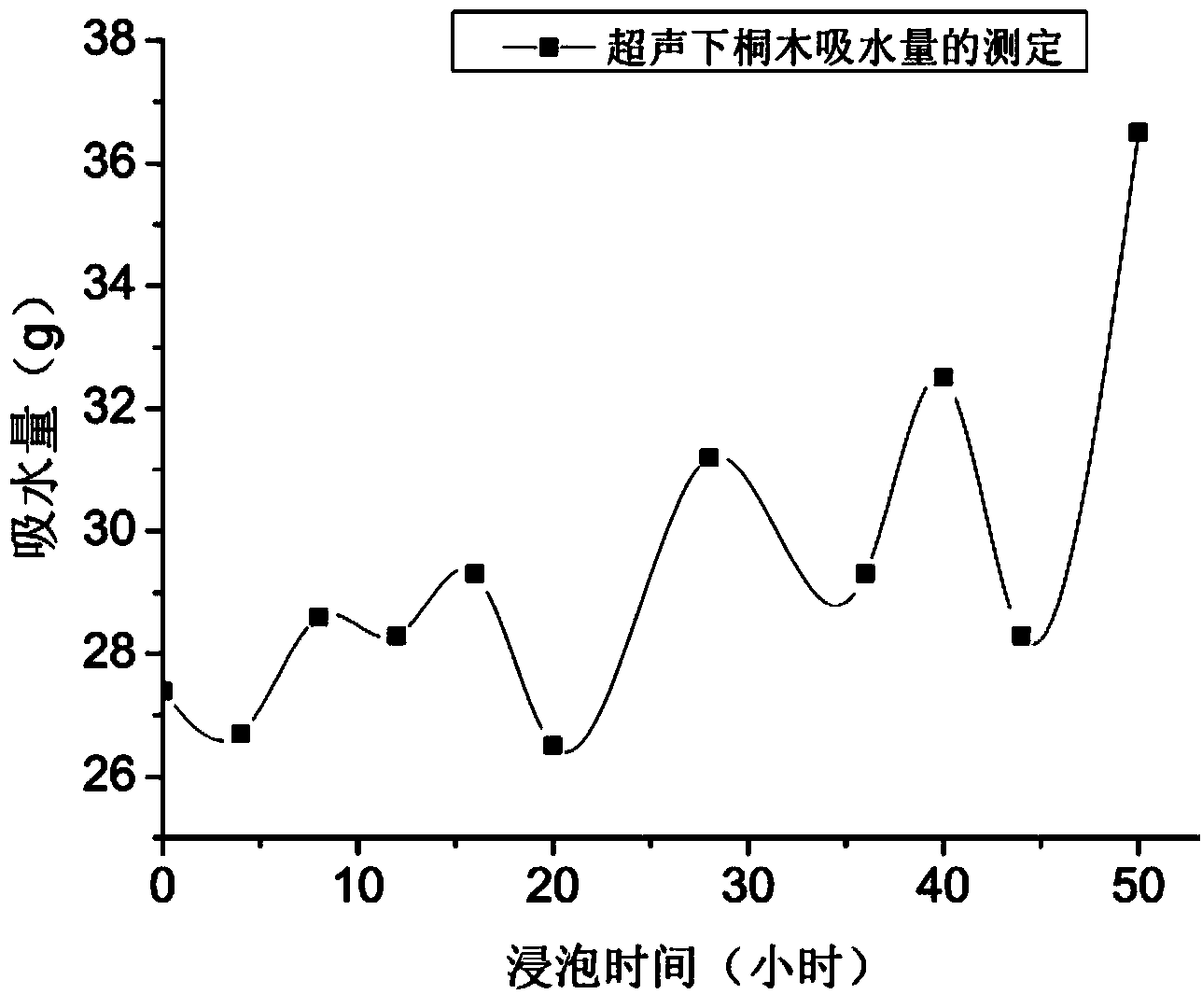

[0027] 1. Effect of ultrasonic treatment on water absorption of wood

[0028] According to the method of Example 1, paulownia wood with a size of 34cm×1.9cm×1.0cm was treated, and the mass of paulownia wood was weighed before and after each ultrasonic treatment, and the influence of ultrasonic treatment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com