High-efficiency moisture-proof ozonolysis catalyst and preparation method thereof

An ozone decomposition and catalyst technology, which is applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Moisture, ensure catalytic activity and moisture resistance, improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

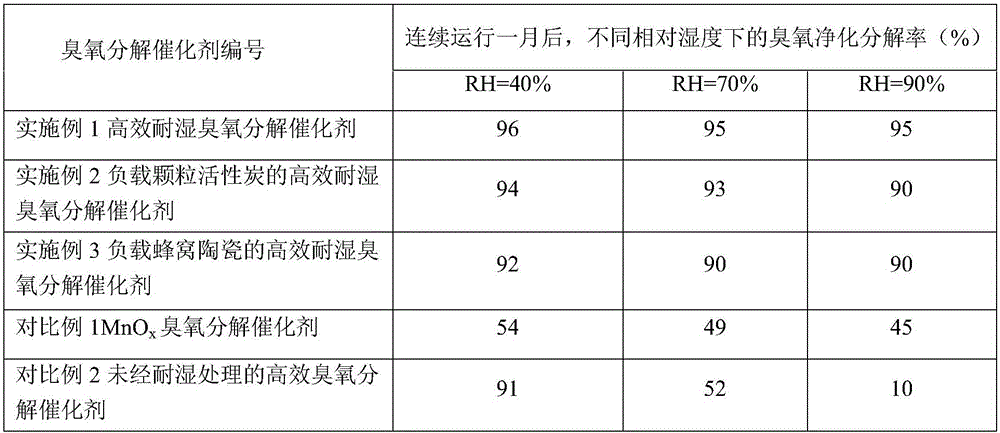

Examples

preparation example Construction

[0034] However, the preparation process of existing ozone decomposition catalysts is complicated, the cost is high, and the decomposition efficiency is relatively low, especially sensitive to ambient humidity, and its decomposition efficiency is greatly affected by ambient humidity, thereby limiting the wide application of ozone decomposition catalysts. It is also a technical problem that researchers urgently want to solve in the research process. In view of the above-mentioned problems existing in existing ozonolysis catalysts, the inventor finally obtained the technical solution of the present invention through a large number of long-term experimental researches. A kind of preparation method of high-efficiency moisture resistance ozonolysis catalyst of the present invention comprises the following steps:

[0035] (1) The molar ratio of manganese nitrate tetrahydrate, copper nitrate trihydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate is (30~80):(10~50):(5~20...

Embodiment 1

[0044] This embodiment provides a high-efficiency moisture-resistant ozonolysis catalyst, which is prepared through the following steps:

[0045] Dissolve manganese nitrate tetrahydrate, copper nitrate trihydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate in deionized water, and stir evenly to obtain a nitrate solution, wherein the concentrations of manganese nitrate, copper nitrate, nickel nitrate and cobalt nitrate are respectively 0.5 mol L -1 , 0.25mol·L -1 , 0.15mol·L -1 and 0.1mol L -1 . Dissolve citric acid and cetyltrimethylammonium hydroxide in deionized water sequentially to obtain a microscopic morphology adjustment solution, in which the concentration of citric acid is 2mol L -1 , the concentration of cetyltrimethylammonium hydroxide is 0.05mol L -1 . Slowly mix equal volumes of the above nitrate solution and micromorphology adjustment solution and then stir at a constant temperature of 55°C; add ammonia water dropwise to adjust the pH of the ...

Embodiment 2

[0047] This embodiment provides a high-efficiency moisture-resistant ozonolysis catalyst loaded with granular activated carbon, which is prepared by the following steps:

[0048] Dissolve manganese nitrate tetrahydrate, copper nitrate trihydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate in deionized water, and stir evenly to obtain a nitrate solution, wherein the concentrations of manganese nitrate, copper nitrate, nickel nitrate and cobalt nitrate are respectively 0.5 mol L -1 , 0.25mol·L -1 , 0.15mol·L -1 and 0.1mol L -1 . Dissolve citric acid and cetyltrimethylammonium hydroxide in deionized water sequentially to obtain a microscopic morphology adjustment solution, in which the concentration of citric acid is 2mol L -1 , the concentration of cetyltrimethylammonium hydroxide is 0.05mol L -1 . Slowly mix the above nitrate solution and the microscopic morphology adjustment solution in equal volumes and then stir at a constant temperature of 55°C; add amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com