Method for preparing rGO-In2O3 nanoparticle composite

A technology of nano-microspheres and composite materials, applied in gallium/indium/thallium compounds, nano-carbon, nanotechnology, etc., can solve the problems of low carrier mobility, low utilization rate, and small comparative area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

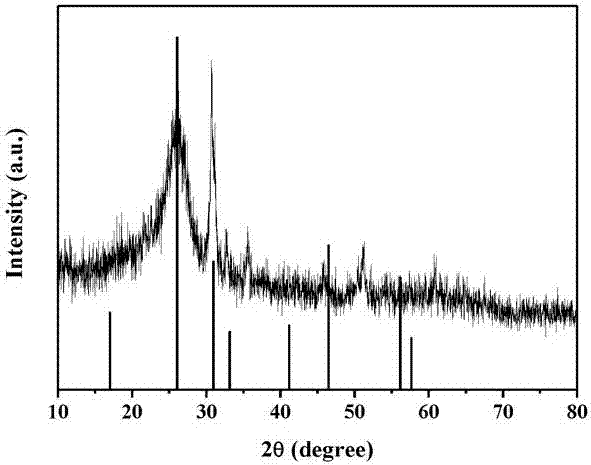

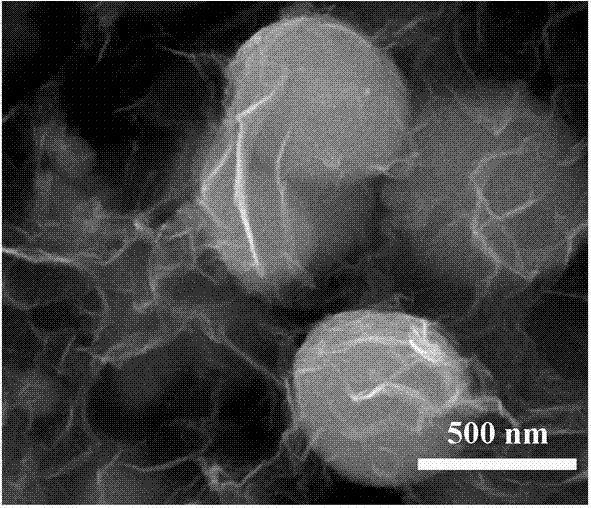

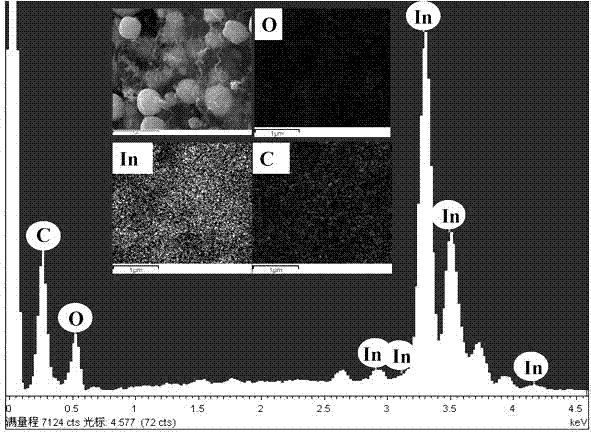

Image

Examples

Embodiment 1

[0015] (1) Weigh a certain amount of indium trichloride tetrahydrate and dodecylamine, and dissolve them in 35 mL of absolute ethanol, wherein the concentration of indium trichloride tetrahydrate is 0.025 mol / L, and the concentration of dodecylamine is 0.025 mol / L, and the molar ratio of indium trichloride tetrahydrate and dodecylamine is controlled to be 1:1;

[0016] (2) Weigh a certain mass of In obtained in step (1) 2 o 3 , ultrasonically dispersed in 50 ml ethanol solution, and then added a certain amount of aminopropyltriethoxysilane (APTES), stirred at 60 °C for 4 h, the precipitate was washed several times with ethanol centrifugation, at 60 °C drying. which controls In 2 o 3 The mass volume ratio is: 1 mg / mL, and control In 2 o 3 : The molar ratio of APTES is 100:1;

[0017] (3) Weigh a certain amount of graphene oxide GO, and ultrasonically disperse it in 80 mL deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.0625 mg / mL. ...

Embodiment 2

[0019] (1) Weigh a certain amount of indium trichloride tetrahydrate and dodecylamine, and dissolve them in 35 mL of absolute ethanol, wherein the concentration of indium trichloride tetrahydrate is 0.0285 mol / L, and the concentration of dodecylamine is 0.0285 mol / L, and the molar ratio of indium trichloride tetrahydrate and dodecylamine is controlled to be 1:1;

[0020] (2) Weigh a certain mass of In obtained in step (1) 2 o 3 , ultrasonically dispersed in 50 ml ethanol solution, and then added a certain amount of aminopropyltriethoxysilane (APTES), stirred at 60 °C for 4 h, the precipitate was washed several times with ethanol centrifugation, at 60 °C drying. which controls In 2 o 3 The mass volume ratio is: 1 mg / mL, and control In 2 o 3 : The molar ratio of APTES is 84:1;

[0021] (3) Weigh a certain amount of graphene oxide GO, and ultrasonically disperse it in 80 mL deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.125 mg / mL. ...

Embodiment 3

[0023] (1) Weigh a certain amount of indium trichloride tetrahydrate and dodecylamine, and dissolve them in 35 mL of absolute ethanol, wherein the concentration of indium trichloride tetrahydrate is 0.025 mol / L, and the concentration of dodecylamine is 0.05 mol / L, and the molar ratio of indium trichloride tetrahydrate and dodecylamine is controlled to be 1:2;

[0024] (2) Weigh a certain mass of In obtained in step (1) 2 o 3, ultrasonically dispersed in 50 ml ethanol solution, and then added a certain amount of aminopropyltriethoxysilane (APTES), stirred at 60 °C for 4 h, the precipitate was washed several times with ethanol centrifugation, at 60 °C drying. which controls In 2 o 3 The mass volume ratio is: 1 mg / mL, and control In 2 o 3 : The molar ratio of APTES is 70:1;

[0025] (3) Weigh a certain amount of graphene oxide GO, and ultrasonically disperse it in 80 mL deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.125 mg / mL. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com