A kind of production method of comprehensively utilizing oleaginous microalgae

A production method and technology of microalgae, applied in the field of bioengineering, can solve the problems of low production efficiency and achieve the effect of simple operation and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

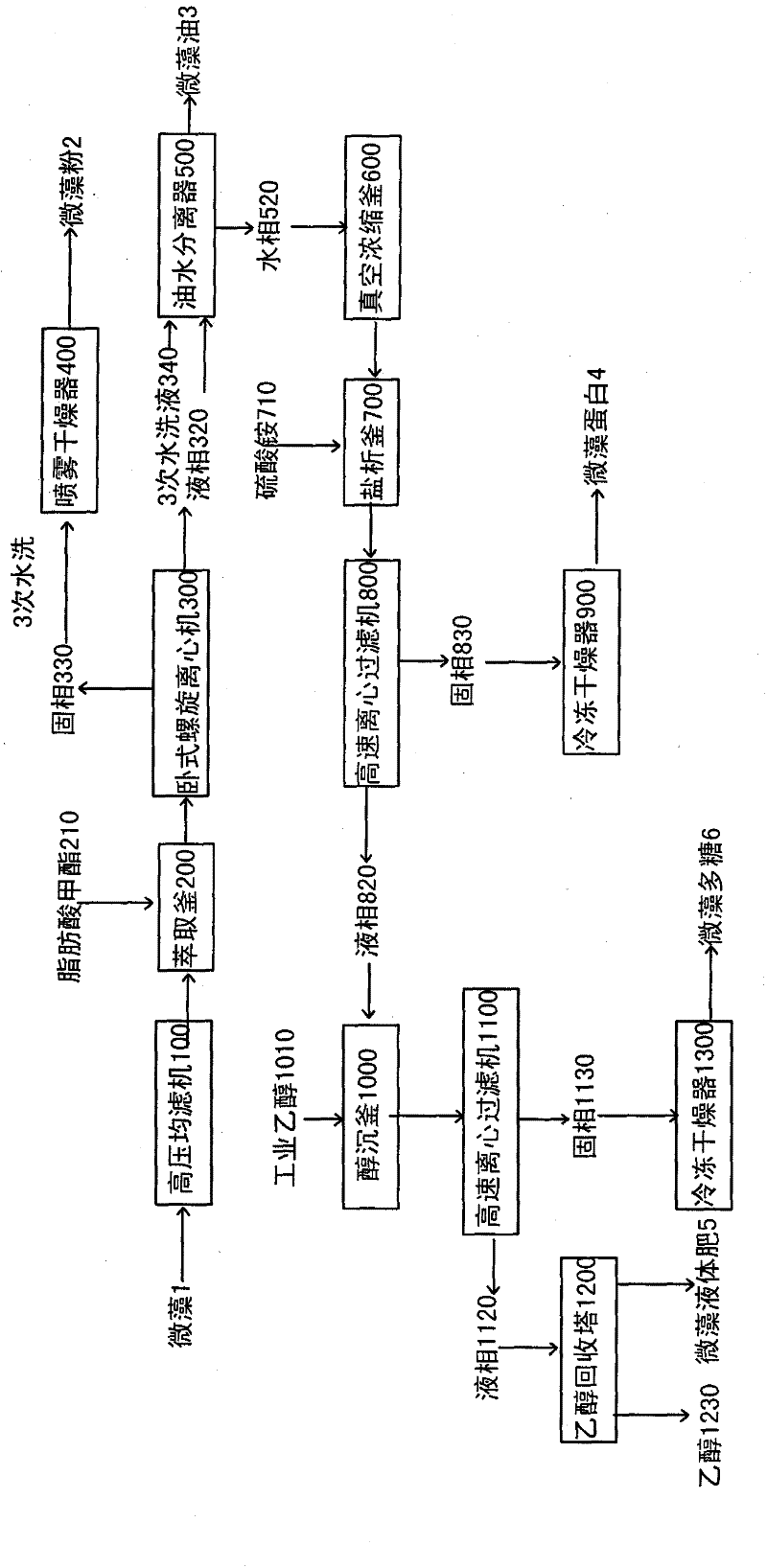

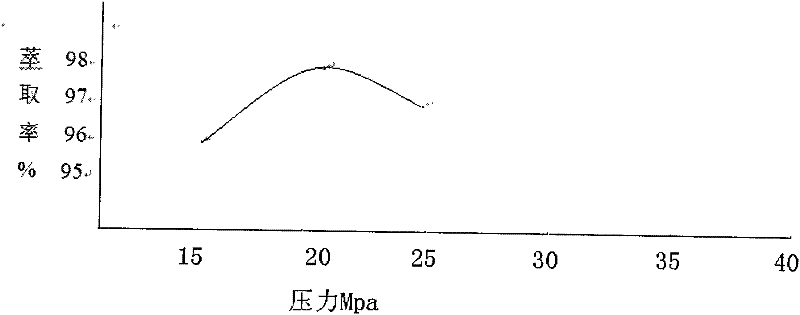

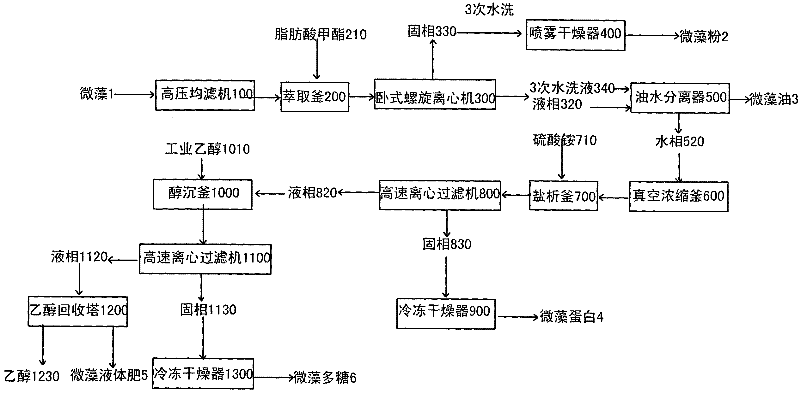

[0064] like figure 1 As shown, get 1000KG harvested microalgae 1 (Pavlova viridis), with a moisture content of 90%, and use a high-pressure homogenizer 100 to homogenize once at room temperature (20° C.) with a homogenizing pressure of 20 MPa. Reach more than 95% microalgae wall breaking rate. The method has high wall breaking rate, simple production equipment, large-scale production, low production cost and short cycle.

[0065] The material after microalgae 1 breaks into 2m 3 The extraction kettle 200, and add 300KG extractant (fatty acid methanol 210), extract the microalgae oil under stirring. Parameters such as the amount of extractant, temperature, and time have a significant impact on the yield of microalgae oil. In the extraction operation, the extraction temperature was 70° C., and the extraction time was 4 hours. The ratio of material to extractant is set to 1:0.2-0.5.

[0066] Since the residue after breaking the wall of microalgae is only a few microns, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com