Integral treatment method for drying and incinerating sludge

A treatment method, sludge drying technology, applied in the direction of combustion method, dehydration/drying/thickened sludge treatment, incinerator, etc., can solve the problems of large energy consumption of sludge, high initial investment of equipment, high operating cost, etc. Achieve low operating costs, reduce pollution, and reduce midway dumping and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

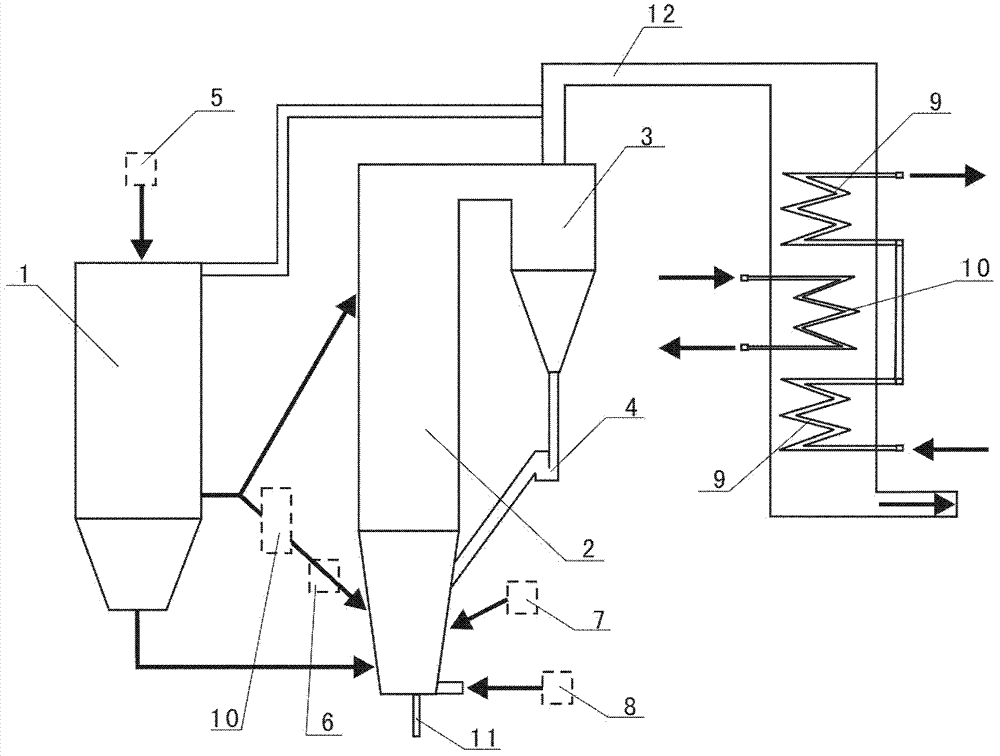

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] As shown in the drawings, the equipment used in the present invention includes a spray dryer 1, a fluidized bed incinerator 2, a separator 3, a feeder 4, a flue 12, an air preheater 10 and a waste heat boiler 9.

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] First, the original sludge is treated with a dehydrator, and the water content of the treated sludge 5 is 70-90%. This process adopts the traditional method of drying sludge.

[0032] Then, the sludge 5 with a moisture content of 70 to 90% is injected into the spray dryer 1 for high-pressure atomization or centrifugal atomization. The final sludge is mixed to evaporate most of the water in the atomized sludge instantly to obtain dry sludge with a moisture content of 5-25%; the dry sludge enters from the sludge outlet at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com