Calibration tool for gas sensors and calibration method

A gas sensor and sensor group technology, applied in the field of calibration tooling and calibration of gas sensors, can solve problems such as low accuracy, cross-interference, poor consistency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] to SO 2 The gas sensor is the gas sensor to be calibrated

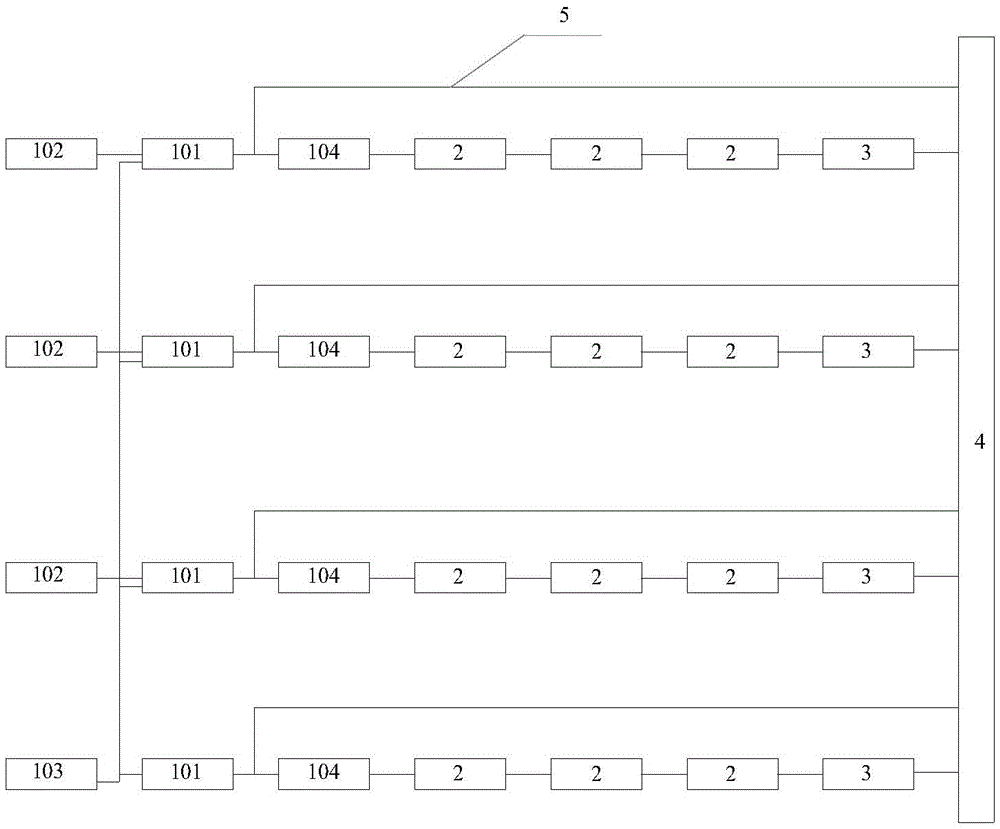

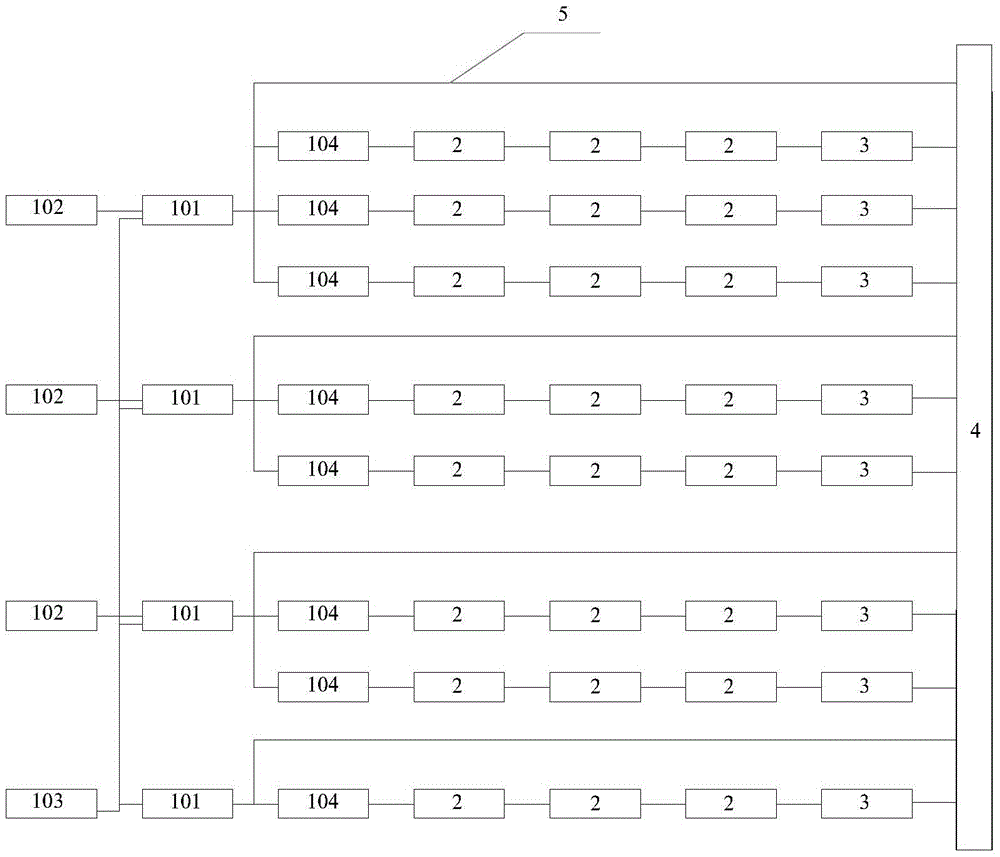

[0036] Single Point Calibration: by SO 2 Cylinder gas 102 provides a fixed high concentration of SO 2 Standard gas, zero gas generator 103 generates diluent gas, and the two-way gas is mixed in the dynamic calibrator 101 to generate SO with a certain mixing ratio 2 Calibration gas (span gas), according to the SO to be calibrated 2 The number of gas sensors, after the flow rate is adjusted by the rotameter, enters the calibrating gas chamber in series, and the SO gas to be calibrated 2 Gas sensor contact, SO collected by data acquisition device 2 The output signal of the gas sensor, the final SO 2 Calibration gas into SO 2 In gas analyzers, detect SO 2 actual concentration. During work, the power supply system supplies the SO to be calibrated through the circuit board 2 The gas sensor provides 5V voltage, and uses ~1 to collect each SO to be calibrated 2 The output signal of the gas sensor.

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com