Method and equipment for monitoring gas in combustion system

A gas and burner technology, which is used in the field of gas monitoring and equipment in combustion systems, and can solve problems such as difficulty in obtaining practical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

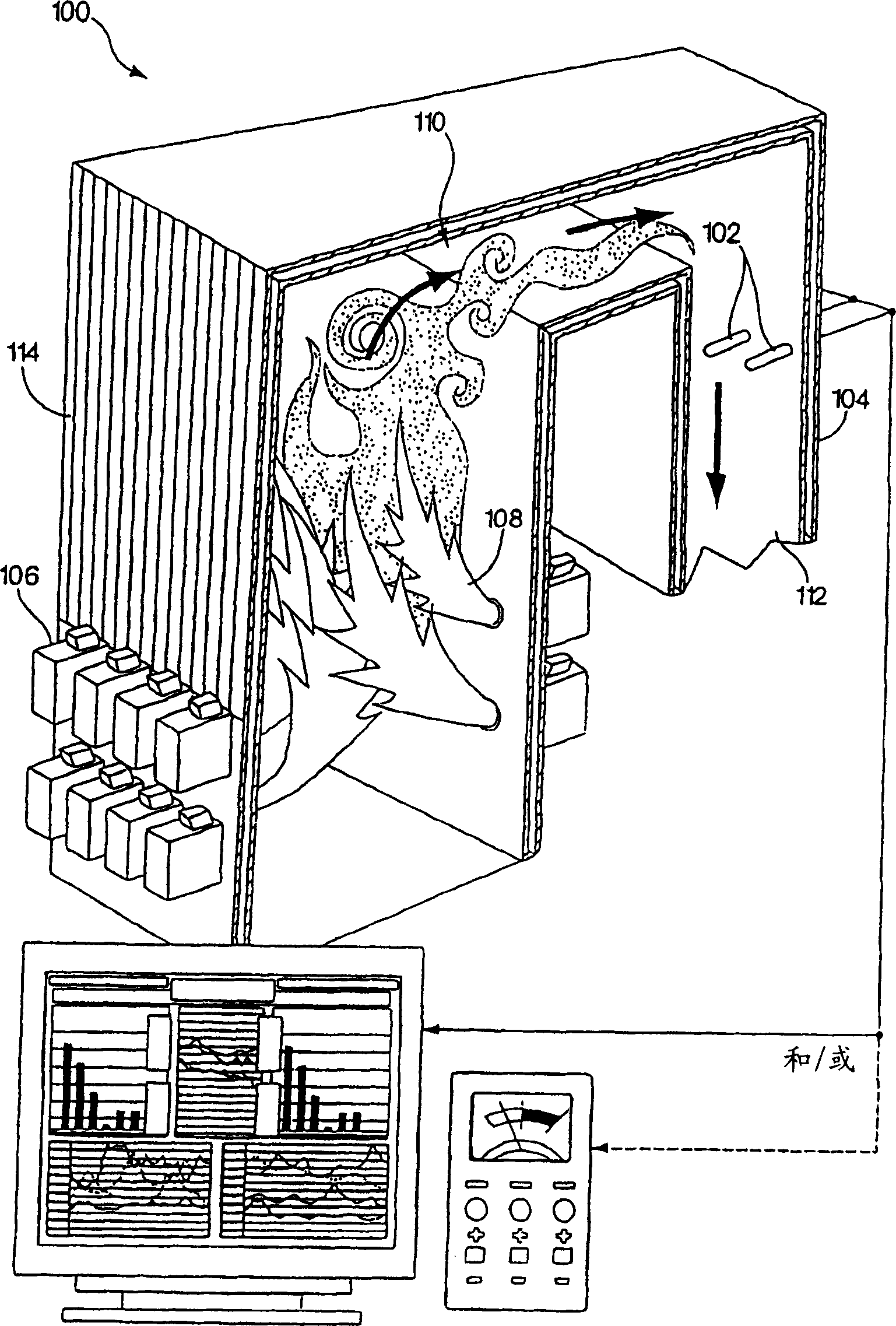

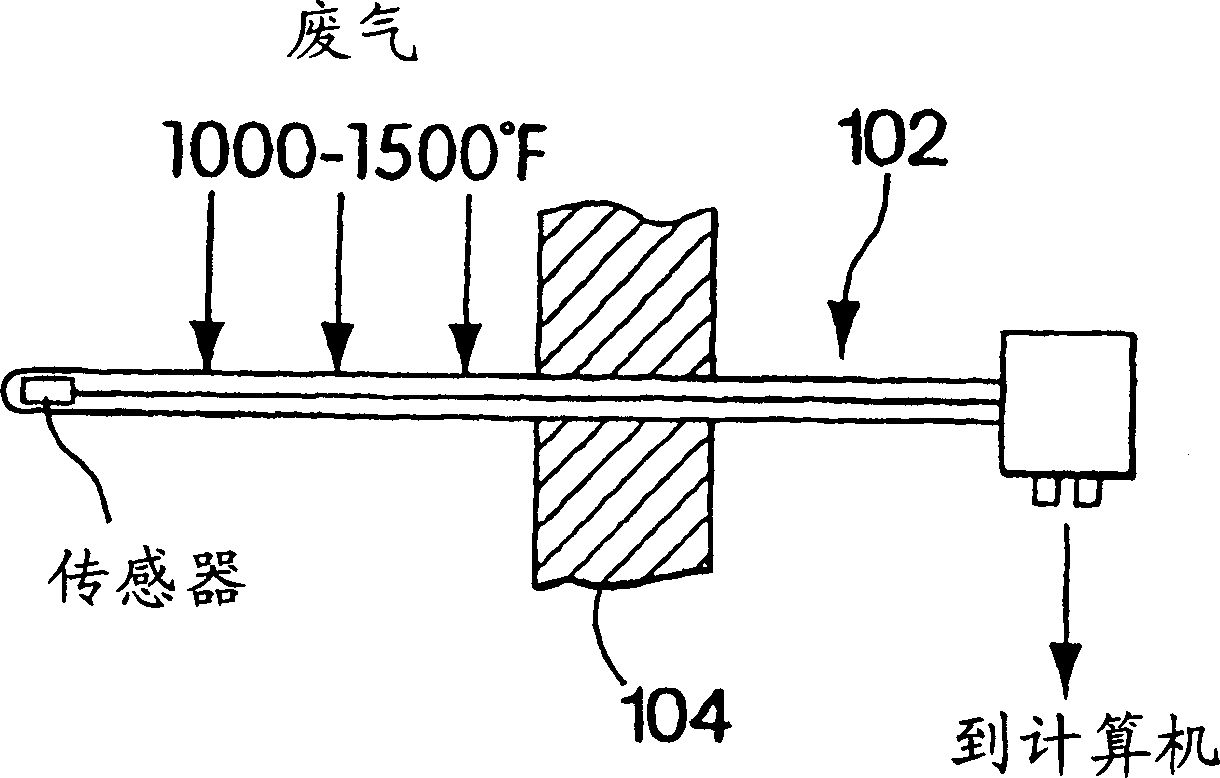

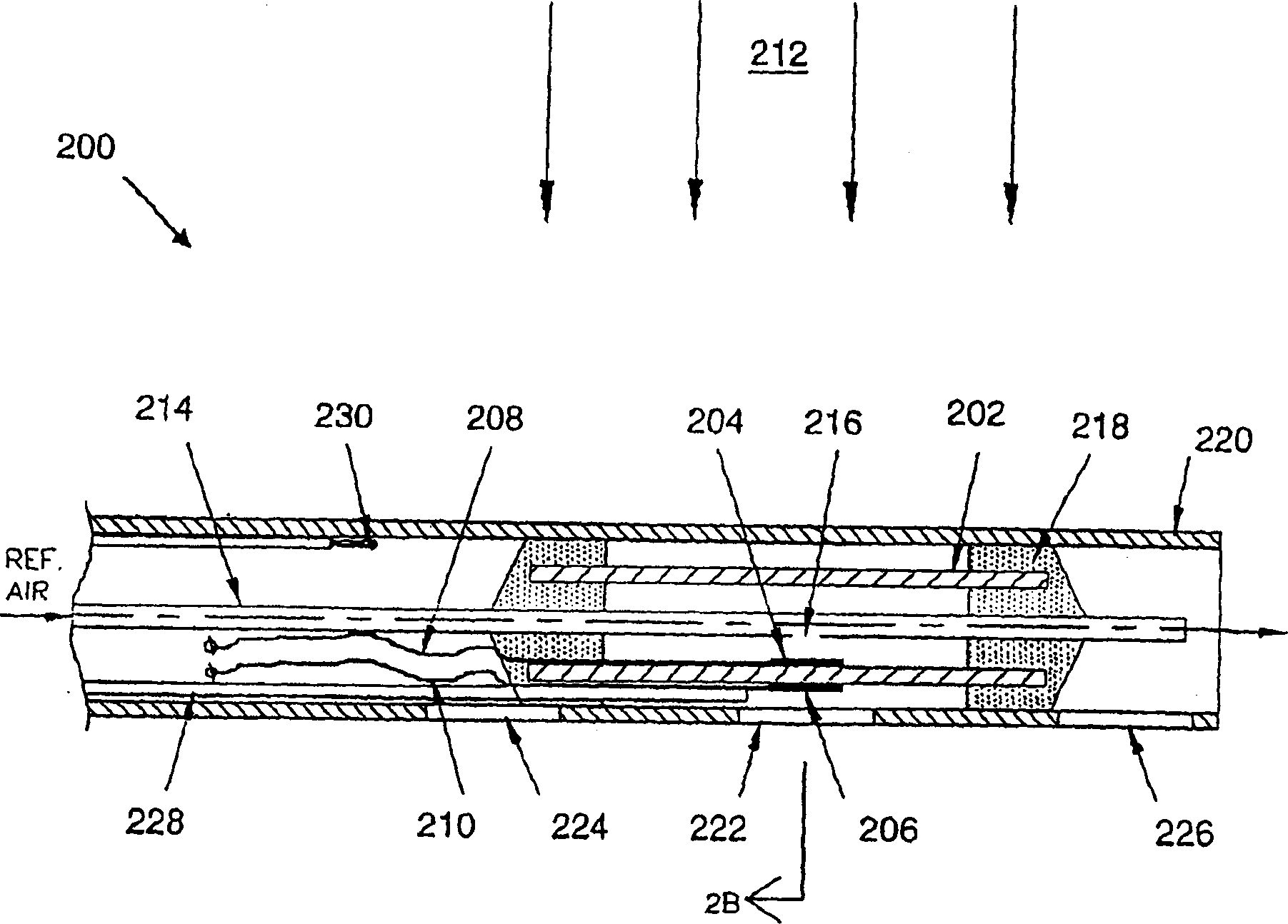

[0034] The invention can be used in several combustion applications, including electric boilers and fossil burners. In one form, the present invention monitors and / or measures oxygen, NO x and various flammable gases. These sensors can be combined to provide distribution and mapping of combustion variables as an effective tool for combustion optimization.

[0035] To achieve the goal of stable and efficient operation of any combustion plant, continuous, on-line monitoring of various combustion variables and their distribution in the different combustion zones is useful. When this type of monitoring is effectively implemented, individual burners and post-flame combustion controls can be adjusted to achieve the optimum relationship between fuel and airflow, optimum distribution of individual airflows and reburning fuel flow, and optimization of other boiler adjustments, Thereby greatly improving the efficiency of the burner.

[0036] It is known to use on-site oxygen sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com